Table of Contents

Advertisement

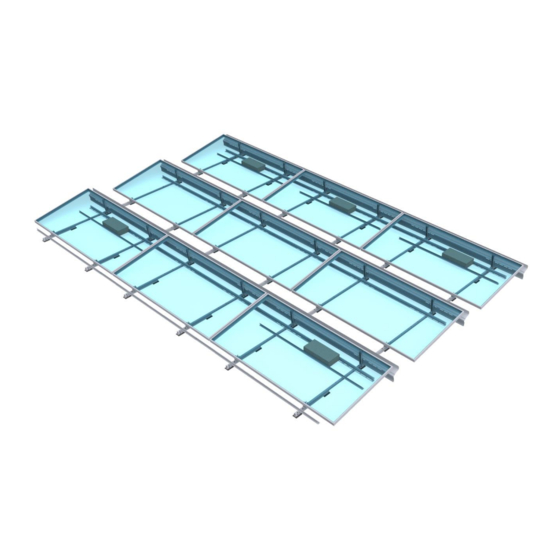

clawFR 10 Degree

Installation Manual

9910045 RevF

October

2020

System Fire Class Rating: Class A for low slope roofs with Type I & Type II Modules

Mechanical Load Rating: See

Table of Contents

O&M considerations

Accessories

Appendix A-G

ANSI/UL 2703

Appendix B: UL 2703 Grounding

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18-27

Advertisement

Table of Contents

Summary of Contents for PanelClaw clawFR 10 Degree

-

Page 1: Table Of Contents

Accessories Construction Aid Setup Build Assemblies Build North Array Row Build Remaining Rows Place Ballast Install Module Low Side clawFR 10 Degree Install Module High Side Continue Installing Modules Installation Manual Install Deflectors Cam & Lock Claw Inspection Electrical Grounding... -

Page 2: Introduction & Safety Overview

This section does not claim modules. to address or support all safety concerns that may arise during the installation of PanelClaw mounting systems or any other aspect of the work This installation manual explains how to build a PV array using clawFR 10 Degree. -

Page 3: Storage, Array Construction, And

Construction Set. from breathing and causes condensation. Storing parts in any other manner is at the customer’s own risk. PanelClaw is not liable for claims related to improper storage and any such claims are not covered by the Operations & Maintenance product warranty. -

Page 4: System Components

System Components Pair of grooves Base Module Connector Cam Claw* M6x16mm Bolt 2000673 (1 pair of grooves) 5000502 [02/03] 5000507 [01/02] 5000500 2000697 2000815 (1 groove) For Fully Attached or Partially Attached Designs Rail Wind Deflector Mechanical Hardware Kit for 2000695 2000887 [01/02/03/04] Attachment Strut... -

Page 5: Tools, Torque, Construction Aid

Optional Accessories See: 9910047 - Accessories Installation Manual Wire Router Shim Pad Wire Clip Base Pad Optimizer Attachment 5000225 [01/02] 5000228 5000226 2000678 5000509 Note: Use of non-UL listed accessories, including non-metallic components, does not affect the system ANSI/UL 2703 certification. Tools Construction Aids Drill with torque limiter or Torque Wrench... -

Page 6: Construction Aid Setup

1. Construction Aid Setup Tip: L, S, and Cam Spacer dimensions are found in the Racking Construction Set 1.1 Assemble the Spacer Stick and adjust to L & S dimensions. All dimensions are measured from the Base centerlines. Tip: To stiffen the Spacer Stick, place one Rail 2000695 on the assembly as shown, shift the Rail to find a location Rail 2000695 which allows for attachment with the specified bolts. -

Page 7: Build Assemblies

2. Build Assemblies Hole 1 Tilt Arm 2.1 Position components as required per assembly type and loosely assemble the Cam, Module Connector and Base. Hole 2 ALERT: Note location of orientation marker on Base “ ” Hole 3 Tip: Base length may vary depending on the row spacing option. Tip: Immediately tighten bolts to 6 ft-lb which are at the Tilt Arm Base Module Connector... -

Page 8: Build North Array Row

3. Build North Row ALERT: ensure system alignment, use the Spacer Stick to align Module Connectors before securing Rails Spacer Stick Tip: L, S, R and AEBE dimensions are found in the Racking See Racking Construction Set for Construction Set. AEBE dimension. -

Page 9: Build Remaining Rows

4. Build Remaining Rows Spacer Stick Tip: Raise Tilt Arms after bolting assemblies in preparation for Rail installation. Middle or South Assembly Choose correct 4.2 Install Rails throughout the array using the same hole Note steps described on the previous page. Alternating Orientation between “S”... -

Page 10: Place Ballast

5. Place Ballast Tip: Installing the north row ballast blocks helps keep the ALERT: Do not step racking structure from moving as the rest of the array is built. on ballast blocks Tip: The Racking Construction Set identifies where Ballast is to be installed. - Page 11 5. Place Ballast (Continued) 5.3 Ballast must be placed as shown. Ballast quantity affects the Ballast placement on the Rails and in some cases additional Rails are required as noted below. Rail 2 *ALERT: Modules longer than 2100 mm with 7 or 8 ballast blocks require two (2) Rails.

-

Page 12: Install Module Low Side

6. Install Module Low Side ALERT: Install Mechanical Attachments before installing modules. See: 9910047 - Accessories Installation Manual Tip: R dimension is found in the Racking Construction Set. Cam Seat Tip: Installing modules starting at the south array edge provides more working Cam Claw room and speeds installation. -

Page 13: Install Module High Side

7. Install Module High Side Tongue Tilt Arm Lock Claw Tip: Use two hands when engaging Lock Claw to ensure correct installation. Tip: See Appendix G for Lock Claw Support module while carefully Pull the Tilt Arm forward until the Lock Rotate module down and rest the module reset method. -

Page 14: Continue Installing Modules

7. Continue Installing Modules Use Cam Claw as spacer to set spacing between adjacent modules. ALERT: Check the R dimension every 5 module and adjust spacing between adjacent modules as needed. Tip: R dimension is found in the Racking Construction Set. 9910045 RevF October 2020... -

Page 15: Install Deflectors

8. Install Deflectors* ALERT: When forecasted wind gusts exceed 25% of the wind speed listed in the site criteria table of the Racking Construction Set, Deflectors must be installed on all mounted modules to avoid possible system damage. Tip: Adjacent Deflectors will overlap Center Deflector on module (adjacent deflector not shown). -

Page 16: Cam & Lock Claw Inspection

If it is not clear the module low side connection is good, contact PanelClaw for assistance. ALERT: Verify correct installation by lifting up on the module near the Cam and making sure no movement occurs. -

Page 17: Electrical Grounding

The clawFR grounding method conforms to ANSI/UL 2703 and is For modules that have been evaluated for use with clawFR 10 Degree, certified by SolarPTL for use with approved photovoltaic please follow the instructions below in Appendix B: UL 2703 Grounding. - Page 18 The subsections below outline some of the obvious / major hazards that could exist during the installation or O&M of PanelClaw products and are divided to bring a level of clarity to such hazards. Some sections do not apply to all PanelClaw product lines and such exclusions are noted within each section.

- Page 19 All required tools to perform the installation of PanelClaw racking are outlined in the installation procedure. All tools should be inspected daily and before use by the operator. If any tool appears to be defective, stop the use of such equipment immediately, and ensure it is replaced before work continues.

- Page 20 Appendix B: UL 2703 Grounding The clawFR 10 Degree flat roof system may be used to ground and/or mount a PV module complying with ANSI/UL 1703 or ANSI/UL 61730 only when the specific module has been evaluated for grounding and/or mounting in compliance with the included instructions.

- Page 21 Tyco solid wire grounding assembly must be attached to one Rail within each group of strings. PanelClaw’s clawFR Rails have a hole to which this grounding device/lug can be attached. In an array that requires multiple bonding jumpers to satisfy the equipotential...

- Page 22 Appendix C: UL 2703 Fire Classification The system has a Fire Class A rating for low slope roofs with Type I modules when the following requirements are met: • System is installed over a fire resistant roof covering rated for the application (UL2703, 26.3B) •...

- Page 23 Appendix D: Electrical Grounding (Non 2703 PV Module) The clawFR 10 Degree flat roof system may be used to ground a PV module only when the specific module grounding instructions are followed. A separate bonding jumper must be used between the PV Module and the clawFR 10D system.

- Page 24 Tyco solid wire grounding assembly must be Typical Module Ground Connection Detail attached to one Rail within each group of strings. PanelClaw’s clawFR Rails have a hole to which this grounding device/lug can be attached. In an array that requires multiple bonding jumpers to...

- Page 25 PanelClaw does not provide the ballast blocks required to construct the system in accordance with PanelClaw’s Racking Construction Set drawings. However, PanelClaw maintains a list of potential block suppliers across the country and this list is available upon request. BALLAST BLOCKS FOR ANY BALLASTED ROOFTOP SYSTEM MUST BE MANUFACTURED TO RESIST FREEZE-THAW AS REQUIRED BY LOCAL CONDITIONS AND TO MAINTAIN THEIR WEIGHT OVER THE LIFE OF THE SYSTEM.

- Page 26 Appendix F: Rail Configurations Torque to 4 ft-lb In cases where a contiguous array has module omissions additional Rails must be installed as shown. Rails are installed across the edge to connect row Rails are installed across the edge to connect row Torque to 4 ft-lb Roof obstruction Module(s) omitted...

- Page 27 Appendix G: Lock Claw Reset Method In rare cases, Lock Claw performance can be degraded by damage from improper handling or excessive cycling. If the Lock Claw angle relative to the Tilt Arm is outside the specified range of 8 to 10 degrees, follow the steps below to reset the Lock Claw.

Need help?

Do you have a question about the clawFR 10 Degree and is the answer not in the manual?

Questions and answers