Advertisement

Quick Links

Micromatic, LLC

525 Berne St

Berne, IN 46711

1-260-589-2136 x3211 or 800-333-5752

customerservice@micromaticllc.com

Repair of Rotac

OVERHAUL INSTRUCTIONS

Read the entire contents of these instructions before installing the actuator and before making any

connections to the actuator. These instructions must be followed in all respects to avoid damage to

the actuator and associated components and/or injury to personnel.

Rotac® TEARDOWN, INSPECTION AND ASSEMBLY

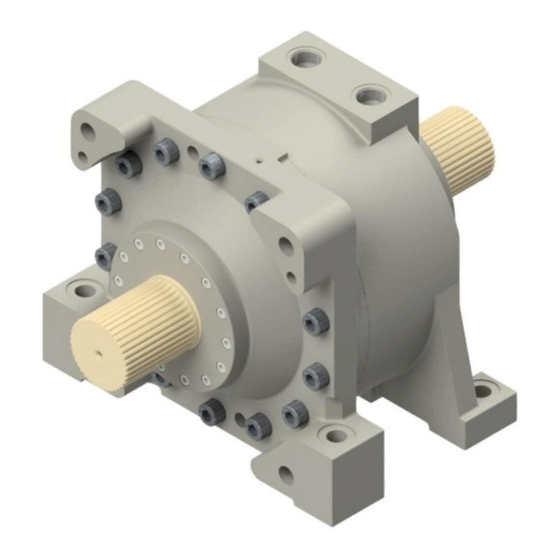

Repair Manual – 26R-2 thru 26R-124

®

26R Model

Page 1 of 14

11NOV2019

Actuators

micromaticllc.com

MODEL: 26R

Advertisement

Summary of Contents for MICROMATIC Rotac 26R

- Page 1 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com Repair of Rotac Actuators ® 26R Model OVERHAUL INSTRUCTIONS Read the entire contents of these instructions before installing the actuator and before making any connections to the actuator. These instructions must be followed in all respects to avoid damage to the actuator and associated components and/or injury to personnel.

- Page 2 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com PURPOSE: To instruct designated personnel in the teardown, inspection, seal replacement and the reassembly of Rotac® Rotary Actuators. Minor repairs will be examined; however, repairs without proper engineering information and machine capabilities may be costly.

- Page 3 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com C. Metal particles – Metal chips can be found from valve spools, Rotac internal parts and ® other metal components in the system. The appearance of symptoms A, B or C above, will require total flushing and cleaning of the entire hydraulic system.

- Page 4 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com 2. Cracks may be found across the dowel holes, bolt holes or ports. This requires replacement. 3. Bearing area – units will have two separate bearings, a thrust bearing (3) and roller bearings (4).

- Page 5 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com Page 5 of 14 Repair Manual – 26R-2 thru 26R-124 11NOV2019 MODEL: 26R...

- Page 6 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com A. Lubricate all seals and internal parts with grease that is compatible with the driving fluid used. DE-ES lubriplate by Fiske Brothers is used at the factory. Petroleum jelly also works fine in most hydraulic systems.

- Page 7 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com 9. Apply medium strength thread locker and torque the retainer bolts (25) to the proper torque. (See TABLE 2) IMPORTANT – Recheck the thrust bearing shoulder height. (See FIGURE 5) 11.

- Page 8 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com FIGURE 5A – MEASUREMENT ‘A’ FOR BEARING SHIMS FIGURE 5B – MEASUREMENT ‘B’ FOR BEARING SHIMS Page 8 of 14 Repair Manual – 26R-2 thru 26R-124...

- Page 9 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com C. Install shoulder seals a. Place ½ of the metal shims into the bottom of the shoulder seal groove b. Place shoulder seal cushion (16), Wedge (15) and Cap (14) into the groove on top of the shims.

- Page 10 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com D. Place the rubber shoe seal cushion (8) in its groove around shoe (6). E. Place dowel pins (24) into the shoe (6) if necessary. F. Cut the shoe seal cap (9) and place it over the shoe seal cushion (8). Match the radius on the shoe seal cap (8) with the radius of the shoe (6).

- Page 11 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com G. Place shaft vane seal cushion (10) into its groove around vane on the shaft (5). Place vane seal cap (11) on top of vane seal cushion (10).

- Page 12 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com Q. Apply medium strength thread lock to head bolts and pull down evenly by alternating the tightening of bolts and secure with the head bolts. R. Torque to the value shown on chart on TABLE 2.

- Page 13 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com TABLE 3 – BREAKAWAY & LEAKAGE CHART 26R Rotac Models ® INTERNAL BY-PASS LEAKAGE: Leakage checks to be made at a gauge pressure as listed. Air pressure to be maintained at pressure listed for one (1) full minute before check is started.

- Page 14 Micromatic, LLC micromaticllc.com 525 Berne St Berne, IN 46711 1-260-589-2136 x3211 or 800-333-5752 customerservice@micromaticllc.com FIGURE 4 – PARTS LIST DRAWING Item Description Housing Item Description Head Seal, Shoulder Cap Bearing Thrust Seal, Shoulder Wedge Bearing Roller Seal, Shoulder Cushion Shaft...

Need help?

Do you have a question about the Rotac 26R and is the answer not in the manual?

Questions and answers