Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ParTech ASLD 2200 Monitor

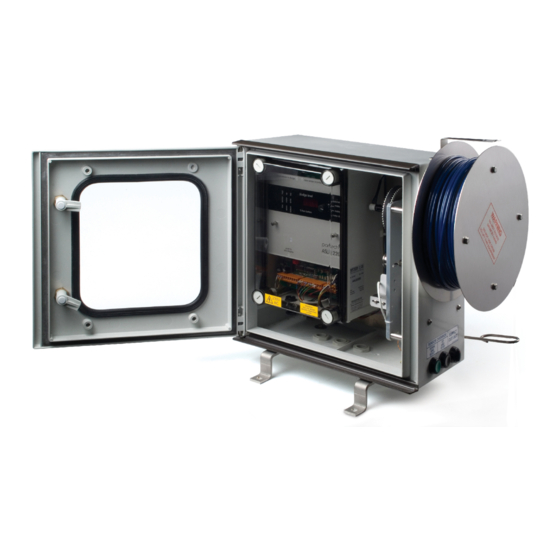

- Page 1 INSTRUCTION MANUAL ASLD 2200 Monitor Sludge Blanket Level Monitor Partech (Electronics) Ltd Charlestown, St Austell Cornwall, PL25 3NN, UK Phone: +44 (0) 1726 879800 Fax: +44 (0) 1726 879801 email: sales@partech.co.uk website: www.partech.co.uk...

-

Page 2: Table Of Contents

ASLD 2200 Monitor Instruction Manual Tel +44 (0)1726 879800 Contents Introduction...........................3 Principle of Operation........................4 Sensor Selection..........................5 Controls and Settings........................6 Installation.............................8 Configuration..........................10 Calibration...........................12 Scraper Clearance........................13 Outputs............................14 Maintenance..........................15 Fault Finding..........................16 Spare Parts..........................18 Technical Specification.......................19 Technical Support........................20 Declaration of Conformity......................21 Issue: Document Reference:... -

Page 3: Introduction

20 mA to the water surface. Sensors The ASLD 2200 Monitor can be used with the Soli-Tech 20 sensor, minor modifications will allow use with the older IR sensor series. The function of the ASLD 2200 is identical for Soli-Tech 20 and IR Sensors. References to IR sensors are retained to allow this manual to be compatible with older units. -

Page 4: Principle Of Operation

Principle of Operation The ASLD 2200 uses a Suspended Solids sensor to detect the density of the sludge; the instrument moves the sensor to a point that is just above the interface. The motor is then used to keep the sensor in that position when the interface moves. The user is provided with information about the sensor reading by the panel of LED’s on the circuit board. -

Page 5: Sensor Selection

The ASLD 2200 is supplied with a Soli-Tech 20 sensor; the correct sensor should have been selected before purchase. If you are in any doubt about the sensor that has been supplied please contact Partech. Sensor replacement in the field is easy to carry out; the table below indicates the normal application of the each of the four sensor ranges. -

Page 6: Controls And Settings

Controls and Settings The principle control during operation is the rotary switch; this allows the user to select the following operations automatic motor up motor stop motor down In ‘automatic’ mode the instrument will continually monitor the suspended solids density and will move the sensor up and down to track the sludge blanket interface. - Page 7 Up and Down Buttons The ASLD 2200 has 2 sets of Up and Down buttons; one set is on the outside of the enclosure the other set is on the main circuit board. Both sets have the same function. These buttons are normally used to aid cleaning of the sensor by bringing the sensor to the surface.

-

Page 8: Installation

It is normal for the 4-20 mA output signal to be transmitted via slip rings to the site control system, where this is not possible Partech are happy to offer a radio telemetry system for transmission directly to the desired point. - Page 9 Electrical Connections Number Function Colour of Internal Wiring Remote Up Switch White/Black Remote Down Switch Orange/Black Remote Switch Common Yellow/Black 4-20 mA Hi (+) 4-20 mA Lo (-) Regulated 12 VDC Output 0 VDC Limit Relay, 0% and/or 100% Limit Relay, 0% and/or 100% 0 VDC Sensor Lo Blue...

-

Page 10: Configuration

The ASLD 2200 requires very little configuration, the user must check the following details before use. If you find that the incorrect sensor or encoder disc has been purchased contact Partech to arrange a replacement. Sensor Selection The Soli-Tech 20 sensor is available in four ranges; which are shown below along with typical applications. - Page 11 Links The circuit board has four sets of links that need to be set in the correct position for the application. Link C Link A Link D Link B Link Group A When a jumper is placed across this link the limit relay will activate when the bottom limit LED is on –...

-

Page 12: Calibration

Calibration Calibration is carried out in 2 stages; firstly set the zero point, then the 100% value. As the sensor is going to be lowered to the bottom of the tank it is important that attention is paid to any hazards such as moving scrapers below the surface of the tank. Set Zero Set the rotary switch to ‘motor stop’... -

Page 13: Scraper Clearance

It is recommended that the installer consult Partech before starting installation to ensure that the correct measures are taken to prevent damage to either instrument or to the scraper mechanism. -

Page 14: Outputs

Outputs Analogue Output The ASLD 2200 has one analogue output that is directly proportional to the 0 to 100% digital display. Under normal circumstances this relates to 4 mA with the sensor at the bottom of the tank and 20 mA with the sensor at the water surface. There is no need to make any field adjustments during commissioning. -

Page 15: Maintenance

Maintenance General Precautions • Do not lift the unit by the drum • Check that the unit is bolted firmly to the support bracket Warning: Isolate the mains supply before commencing any maintenance to the electronics enclosure; the external switch does not isolate the electronics Routine Maintenance The sensor will require routine cleaning;... -

Page 16: Fault Finding

Fault Finding Listed below are some of the common problems found on the ASLD 2200, the list is not comprehensive and if you are in any doubt please contact your local distributor or Partech. Symptom Digital display changes but does not relate correctly to the sensor position... - Page 17 It is likely that the sensor is fouled, if the problem persists after sensor cleaning then the sensor is likely to have failed. Corrective Action Clean the sensor, if the problem persists contact Partech. Symptom The motor does not respond to changes in the sludge blanket level, but the sensor is working correctly.

-

Page 18: Spare Parts

Spare Parts The parts listed below are available for the ASLD 2200; it is advisable to contact your local distributor or Partech’s technical support team before purchasing these parts to ensure that the correct items are purchased. Sensor Part No... -

Page 19: Technical Specification

Technical Specification General Supply Voltage .......115/230 VAC, 50/60 Hz, +10/-15% (Voltage Selector) Power Consumption.......25 VA Supply Fuse........1A Anti Surge 20 mm (Fitted to fuse holder) ............5 A Anti Surge 20mm (Fitted to circuit board) Operating Temperature....0 to 50°C Storage Temperature......-20 to 70°C Display ...........3 Digit LED Sensing Speed.........1 metre per minute Manual Operation Speed....5 metres per minute... -

Page 20: Technical Support

Monitor type, and serial number. Sensor type, and serial number. Application details. Description of fault. Returning Instruments for Repair If equipment needs to be returned to Partech for repair or service the following address should be used: SERVICE DEPT. PARTECH (ELECTRONICS) LTD CHARLESTOWN... -

Page 21: Declaration Of Conformity

Declaration of Conformity DECLARATION OF CONFORMITY According to EN 45014 We, Partech (Electronics) Limited, Charlestown, St Austell, Cornwall, United Kingdom, declare under our sole responsibility that the product: Product Name: ASLD 2200 Monitor Model Number(s): 167430 to which this declaration relates is in conformity with the standards noted below:...

Need help?

Do you have a question about the ASLD 2200 Monitor and is the answer not in the manual?

Questions and answers