Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Buchi NIR-Online PA2

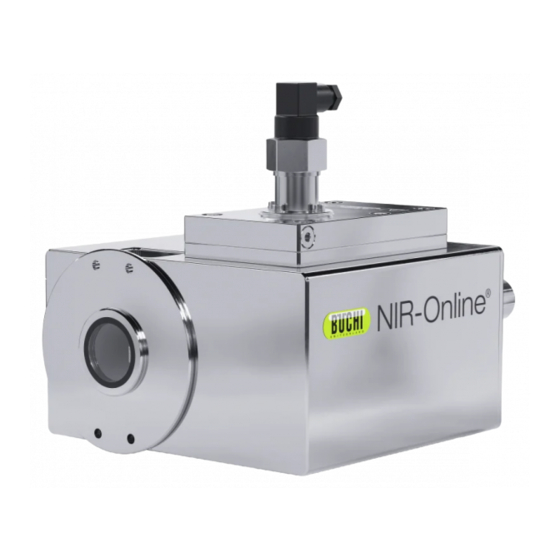

- Page 1 Process Analyser PA2 Operation Manual NIR-Online ®...

- Page 2 NIR-Online GmbH Altrottstrasse 31 D-69190 Walldorf E-mail: info.nir-online@buchi.com NIR-Online reserves the right to make changes to this manual as required on the basis of future insights, especially with respect to layout, illustrations and technical detail. This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties.

-

Page 3: Table Of Contents

NIR-Online GmbH Table of contents Contents About this document...................... 5 Warning notices in this document...................... 5 Symbols ............................... 5 1.2.1 Warning symbols ........................ 5 1.2.2 Mandatory directive symbols .................... 5 Mark-ups and symbols......................... 6 Safety............................ 7 Proper use ............................ 7 Use other than that intended ....................... 7 Location of safety notices and warning signs on the product .............. - Page 4 Table of contents NIR-Online GmbH Operation.......................... 28 Journal button ............................ 28 Entering reference data in the journal.................... 28 Cleaning and servicing ..................... 29 Regular maintenance work ........................ 29 Taking out of service and disposal.................. 30 Disposal ............................. 30 Returning the instrument ........................ 30 Appendix .......................... 31 Certificates............................

-

Page 5: About This Document

If you still have any questions after reading this instruction manual, please contact NIR-Online GmbH Customer Service. service.nir-online@buchi.com Warning notices in this document Warning notices warn you of dangers that can occur when handling the device. There are four danger levels, each identifiable by the signal word used. -

Page 6: Mark-Ups And Symbols

1 | About this document NIR-Online GmbH Mark-ups and symbols NOTE This symbol draws attention to useful and important information. R This character draws attention to a requirement that must be met before the in- structions below are carried out. This character indicates an instruction that must be carried out by the user. -

Page 7: Safety

NIR-Online GmbH Safety | 2 Safety Proper use The sensor is used to analyze substances and samples in production and in the labo- ratory. The sensor is intended exclusively for that purpose. The sensor can be used in laboratories and production facilities for the following oper- ations: —... -

Page 8: Safety Features

2 | Safety NIR-Online GmbH Fig. 1: Location of safety notices and warning signs on the product General warning General warning ONLY OPERATE INSTRUMENT DO NOT SEPARATE WHEN ENER- WHEN TEMPERATURE SWITCH GIZED DO NOT OPEN IN A HAZ- IS IN USE ARDOUS AREA Safety features 2.4.1... -

Page 9: Staff Qualification

— Safety-related incidents that occur while operating the instrument are to be re- ported to the manufacturer. service.nir-online@buchi.com NIR-Online service technicians Service technicians authorized by NIR-Online have attended special training courses and are authorized by NIR-Online GmbH to carry out special servicing and repair measures. - Page 10 2 | Safety NIR-Online GmbH NIR-Online GmbH accepts no liability whatsoever for damage arising as a result of unauthorized modifications. 10/36 Operation Manual Process Analyser PA2...

-

Page 11: Product Description

NIR-Online GmbH Product description | 3 Product description Description of function The sensor is an optical instrument for nondestructive determination of substances and concentrations in a sample. A sample absorbs and reflects light across the entire wavelength spectrum according to its color and chemical composition. The signal reflected by the sample is recorded and analyzed by a spectrometer. -

Page 12: Rear View

3 | Product description NIR-Online GmbH 3.2.2 Rear view Fig. 3: Rear view Coolant connection Coolant connection Thermostat Beacon (make-switch) Button Type plate Video connection Ground connection (Equipotential bonding) Device cable connection Type plate The type plate identifies the instrument. The type plate is attached to the rear panel. See Chapter 3.2.2 "Rear view", page 12 12/36 Operation Manual Process Analyser PA2... -

Page 13: Atex Rating

NIR-Online GmbH Product description | 3 Fig. 4: Type plate Company name and address Revision number Product name Serial number Production date IP class ATEX rating Power consumption (nominal) Power consumption 10 Ambient temperature (maximum) 11 Current draw 12 ATEX certification number (maximum) 13 Certification center number 14 Certificates... -

Page 14: Scope Of Delivery

3 | Product description NIR-Online GmbH Letter Option Camera setting X-ROT (15 mm) Camera setting (20 mm (X-Cell+X-Cool)) System temperature 0 - 80 °C Humidity sensor 0-100% RH X-Quvette (Fiber lens (approx. 0 - 2 cm)) Bluetooth® (without ATEX certification) Camera setting special flange ZB-0103 External button = X-Beam... -

Page 15: Technical Data

NIR-Online GmbH Product description | 3 Technical data 3.6.1 Sensor Specifications Dimensions (W x D x H) 236 x 278 x 252 mm Weight 14 kg Max. working pressure 30 bar at flange Coolant inlet temperature +10 °C to +30 °C Coolant flow rate 10 L/h Coolant pressure max. -

Page 16: Materials

3 | Product description NIR-Online GmbH 3.6.4 Materials Component Materials of construction Casing Stainless steel (1.430,1 high-gloss pol- ished) Heat sink Nickel and zinc-coated aluminum Seals FFKM (standard) 3.6.5 Computer system requirements The system requirements for the computer are as follows: Operating systems Windows 7 (32-bit or 64-bit) SP1 Windows 10... - Page 17 NIR-Online GmbH Product description | 3 Name Description Used for User When used SX-Center User interface Selection of Users Daily workflow measurement method Viewing mea- surement re- sults Entry of refer- ence data SX-Backup Data backup Automatic NIR adminis- During installa- planner backup of trator...

-

Page 18: Transport And Storage

4 | Transport and storage NIR-Online GmbH Transport and storage Transport NOTICE Risk of breakage due to incorrect transportation Make sure that all parts of the device are safely packed in such a way as to pre- vent breakage, ideally in the original box. Avoid sharp movements during transit. -

Page 19: Installation

NIR-Online GmbH Installation | 5 Installation Installation site (production) Make sure that the installation site meets the following requirements: — Minimum space requirements: 250 mm x 300 mm x 270 mm (W x D x H). — At least 300 mm clearance on all sides. The clearance ensures air circulation and prevents the instrument from overheating. -

Page 20: Installation Point In Piping System (Example)

5 | Installation NIR-Online GmbH Installation point in piping system (example) < 1 m Fig. 5: Configuration Flow restrictor Bypass Analyser Sample removal point Flow restrictor 20/36 Operation Manual Process Analyser PA2... -

Page 21: Installation (Example)

NIR-Online GmbH Installation | 5 Installation (example) Production Server/Control room Control center Zone 21 Product flow Process control system Zone 20 Video/Frame grabber card Optional Video interfaces: filter -Profibus -4-20 mA Sensor cables USB converter -TCP/IP (power supply, -OPC Video cable RS 422) -Modbus Remote access via Ethernet... -

Page 22: Sensor Installation

5 | Installation NIR-Online GmbH Fig. 6: Dimensions of flange Sensor installation DANGER Use of an unsuitable flange in potentially explosive atmospheres. The use of an unsuitable flange may cause an explosion. In potentially explosive atmospheres use a double flange. The following installation positions are possible: 22/36 Operation Manual Process Analyser PA2... -

Page 23: Connecting The Sensor

NIR-Online GmbH Installation | 5 Fig. 7: Fixing sensor with screws Tools required: — Torque wrench, size Torx T30 Tightening torque: 8.4 Nm +-1 Precondition: R Installation point has been established. See Chapter 5.5 "Establishing installation point", page 21. R The fixing points or bolts conform to M6 A2-70 15 mm Fix the sensor to the installation point using the bolts. - Page 24 5 | Installation NIR-Online GmbH Slide the cable guard over the con- nector. Plug the connector into the sensor. Secure the connector. Tightening torque: 2.5 Nm ± 0.5 Fix the cable guard to the sensor. Tightening torque: 2 Nm ± 0.5 Fix the ground cable to the sensor.

-

Page 25: Connecting The Video Cable (Optional Accessory)

NIR-Online GmbH Installation | 5 Connecting the video cable (optional accessory) — Socket, 7 mm Slide the cable guard over the video cable connector. Plug the connector into the sensor. Tightening torque: 2.5 Nm ± 0.5 Fix the cable guard to the sensor. Operation Manual Process Analyser PA2 25/36... -

Page 26: Connecting The Thermostat

5 | Installation NIR-Online GmbH Connecting the thermostat Screw the thermostat onto the bracket. 5.10 Connecting the coolant NOTE The coolant supply is within the specified parameters. See Chapter 3.6 "Technical data", page 15 Connect the coolant supply to the condenser. 5.11 Establishing the electrical connection to the installation box WARNING Death or serious burns by electric current. - Page 27 NIR-Online GmbH Installation | 5 The power supply must fulfil the following conditions: 1. Provide the specified mains voltage and frequency. 2. Be designed for the load imposed by the instruments connected. 3. Be equipped with suitable fuses and electrical safety devices. 4.

-

Page 28: Operation

6 | Operation NIR-Online GmbH Operation The product is operated via the SX-Suite software on a computer. See software oper- ating instructions. Journal button Pressing the button generates a journal entry. Entering reference data in the journal To perform a calibration and continuously check the calibration, reference data is re- quired. -

Page 29: Cleaning And Servicing

NIR-Online GmbH Cleaning and servicing | 7 Cleaning and servicing NOTE Users may only carry out the servicing and cleaning operations described in this sec- tion. Any servicing and repair work which involves opening up the casing may only be car- ried out by NIR-Online service technicians. -

Page 30: Taking Out Of Service And Disposal

When disposing, observe the disposal regulations of the materials used. Materials used see Chapter 3.6 "Technical data", page 15 Returning the instrument Before returning the instrument, contact the NIR-Online GmbH Service Department. service.nir-online@buchi.com 30/36 Operation Manual Process Analyser PA2... -

Page 31: Appendix

NIR-Online GmbH Appendix | 9 Appendix Certificates 9.1.1 CE certificate Operation Manual Process Analyser PA2 31/36... - Page 32 9 | Appendix NIR-Online GmbH 32/36 Operation Manual Process Analyser PA2...

-

Page 33: Spare Parts And Accessories

NIR-Online GmbH Appendix | 9 Spare parts and accessories NOTE Any modifications of spare parts or assemblies are only allowed with the prior written permission of NIR-Online GmbH. 9.2.1 Accessories Order no. USB-RS422 interface 11060741 Analog interface (DataLabIO) 11060742 PC video card ( Frame-grabber) 11060746 PCI express, High Profile PC video card ( Frame-grabber) - Page 34 9 | Appendix NIR-Online GmbH Device cables NOTE Loss of performance due to use of unsuitable device cables Max. cable length between installation box and sensor 10 m. Pin assignment on device connector viewed from rear of instrument: Fig. 8: Pin assignment PIN 1- blue, ground PIN 2- red, 12.7 VDC PIN 3- green, RxD-...

- Page 36 T +971 4 313 2860 T +52 55 9001 5386 F +66 2 862 08 54 F +971 4 313 2861 latinoamerica@buchi.com bacc@buchi.com middleeast@buchi.com www.buchi.com/es-es www.buchi.com/th-th www.buchi.com We are represented by more than 100 distribution partners worldwide. Find your local representative at: www.buchi.com...

Need help?

Do you have a question about the NIR-Online PA2 and is the answer not in the manual?

Questions and answers