Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ATI Technologies 9150-CDB-8-11-ATC

- Page 1 ATI Compliant Deburring Blade (Models 9150-CDB-8-11-ATC, 9150-CDB-8-11-000) Product Manual Document #: 9610-50-1030 Engineered Products for Robotic Productivity Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com...

-

Page 2: Foreword

Manual, Compliant Deburring Blade Document #9610-50-1030-04 Foreword CAUTION: This manual describes the function, application, and safety considerations of this product. This manual must be read and understood before any attempt is made to install or operate this product. Failure to do so may result in personnel injury and/or damage to equipment. Information contained in this document is the property of ATI Industrial Automation, Inc (ATI) and shall not be reproduced in whole or in part without prior written approval of ATI. -

Page 3: Table Of Contents

Manual, Compliant Deburring Blade Document #9610-50-1030-04 Table of Contents Foreword ............................2 Glossary ............................5 Safety ............................6 1.1 Explanation of Notifications ......................6 General Safety Guidelines ......................6 Safety Precautions ........................7 Product Overview ........................8 ATC Collet System ........................9 Tool Stand ............................ - Page 4 Manual, Compliant Deburring Blade Document #9610-50-1030-04 Troubleshooting and Service Procedures ................21 Troubleshooting .......................... 21 Service Procedures ........................22 6.2.1 Replacement of Bit Holders in ATC Tool Stand ..............22 Serviceable Parts ........................23 8. Specifications ......................... 23 Drawings ..........................24 9630-50-CDB-8-11-ATC ........................

-

Page 5: Glossary

Manual, Compliant Deburring Blade Document #9610-50-1030-04 Glossary Definition Term Axially Compliant. Device for removing contamination from air supply lines. Typically refers to removal of Air Filter particulates. Auto Tool Changer Blade Cutting tool used to remove burrs from the work piece. Burr Any unwanted, raised protrusion on the work piece. -

Page 6: Safety

Manual, Compliant Deburring Blade Document #9610-50-1030-04 1. Safety The safety section describes general safety guidelines to be followed with this product, explanations of the notifications found in this manual, and safety precautions that apply to the product. More specific notifications are imbedded within the sections of the manual where they apply. -

Page 7: Safety Precautions

Manual, Compliant Deburring Blade Document #9610-50-1030-04 1.3 Safety Precautions WARNING: Never operate the CDB tool without wearing eye protection. Flying debris can cause injury. Always use eye protection while working in the neighborhood of the CDB tool. CAUTION: Do not use spare parts other than original ATI spare parts except for consumables. -

Page 8: Product Overview

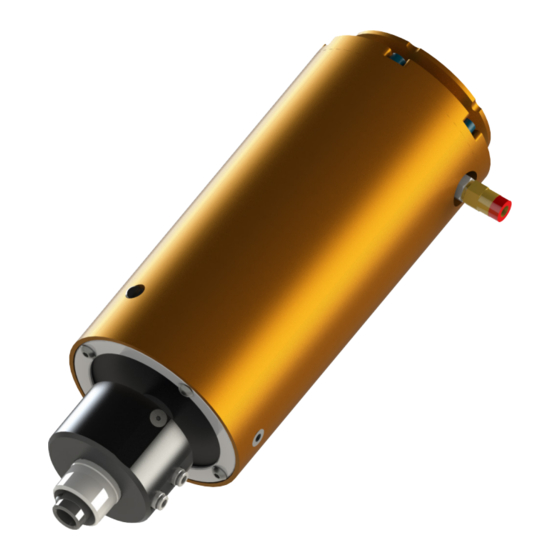

Manual, Compliant Deburring Blade Document #9610-50-1030-04 2. Product Overview The Compliant Deburring Blade (CDB) is especially suited for removal of parting lines and flash from parts. The CDB’s Auto Tool Changer (ATC) allows it to be used in a wide variety of applications without human interaction. The CDB’s pneumatically controlled, articulated compliance allows the blade to follow the part profile and compensate for surface irregularities while maintaining a constant force. -

Page 9: Atc Collet System

Manual, Compliant Deburring Blade Document #9610-50-1030-04 2.1 ATC Collet System The ATC’s pneumatically controlled collet system allows the tool holder to be locked and unlocked to the CDB without human interaction, once a program is in place. The ATC’s pneumatically controlled tool stand allows the tool holder to be locked and unlocked to the storage location As a result, faster tool changeovers are achievable. -

Page 10: Compliance Unit Performance

Manual, Compliant Deburring Blade Document #9610-50-1030-04 2.3.2 Compliance Unit Performance The graphs in Figure 2.3 Figure 2.4 illustrates the variation of compliance force with applied air pressure in the vertical orientation with the collet pointed toward the ground. Measurements may vary from one product to another and should only be treated as nominal. The actual force characteristics depend on mounting orientation and condition of the unit. -

Page 11: Installation Of The Compliance Device

Manual, Compliant Deburring Blade Document #9610-50-1030-04 3. Installation of the Compliance Device The CDB tool is delivered fully assembled. Optional equipment such as mounting plates and additional customer supplied tool holders are separate. 3.1 Transportation and Protection during Transportation The CDB tool is packaged in a case designed to secure and protect it during transportation. Always use the case when transporting the CDB tool in order to minimize the risk of damage. -

Page 12: Axial Mounting Installation

Manual, Compliant Deburring Blade Document #9610-50-1030-04 3.5 Axial Mounting Installation A blank interface plate is also available to allow axial mounting off the rear of the CDB housing. This plate may be modified by the system integrator or by the owner/user of the CDB. ATI can provide custom interface plates and adapters upon request. -

Page 13: Pneumatics

Manual, Compliant Deburring Blade Document #9610-50-1030-04 3.7 Pneumatics Connect the air lines as shown in Section 9.3—9630‑50‑CDB‑PNEUMATIC. WARNING: All pneumatic fittings and tubing must be capable of withstanding the repetitive motions of the application without failing. The routing of pneumatic lines must minimize the possibility of over stressing, pullout, or kinking the lines. -

Page 14: Operation

Manual, Compliant Deburring Blade Document #9610-50-1030-04 4. Operation For assistance in programming, starting up, and complete a robotic deburring cell containing a CDB tool refer to the following section. The system integrator should be familiar with the task of deburring and have extensive knowledge about automation applications that incorporate robots. -

Page 15: Normal Operation

Manual, Compliant Deburring Blade Document #9610-50-1030-04 4.2 Normal Operation The following sections describe the normal operating conditions for CDB. 4.2.1 Air Quality The air supply should be dry, filtered, and free of oil. A coalescing filter with elements rated for 5 micron or better is required. -

Page 16: Programming For Atc Tool Stand

Manual, Compliant Deburring Blade Document #9610-50-1030-04 4.3 Programming for ATC Tool Stand The tool stand component of the ATC system uses divots in the tool holder shaft for securing the tool to the tool stand. Due to this the tool holder has to extend further out of the ATC collet. The robot program must accommodate for this clearance between the tool stand and collet. -

Page 17: Installing The Customer Supplied Blade Holder In The Manual Collet

Manual, Compliant Deburring Blade Document #9610-50-1030-04 4.4 Installing the Customer Supplied Blade Holder in the Manual Collet The customer supplied blade holder can be adjusted and locked at various heights in the compliance device. 1. Securely grasp the blade holder. 2. -

Page 18: Removing The Customer Supplied Blade Holder In The Manual Collet

Manual, Compliant Deburring Blade Document #9610-50-1030-04 4.5 Removing the Customer Supplied Blade Holder in the Manual Collet The customer supplied blade holder can be adjusted and locked at various heights in the compliance device. 1. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.). 2. -

Page 19: Locking And Unlocking Single Axis Compliance

Manual, Compliant Deburring Blade Document #9610-50-1030-04 4.6 Locking and Unlocking Single Axis Compliance The compliance device can be manually locked and unlocked to be compliant in a single axis. Tools required: Flat headed screwdriver 1. Turn the single axis lockout screw as shown in Figure 4.5 for desired compliance. -

Page 20: Preventive Maintenance

Manual, Compliant Deburring Blade Document #9610-50-1030-04 5. Preventive Maintenance The CDB tool is designed to provide reliable service for long periods of operation. While simple in design, there are few user serviceable parts in the assembly. The user is encouraged to return the unit to ATI for service. Section 6—Troubleshooting and Service Procedures is provided to assist the user when they chose to service the unit in the field. -

Page 21: Troubleshooting And Service Procedures

Manual, Compliant Deburring Blade Document #9610-50-1030-04 6. Troubleshooting and Service Procedures 6.1 Troubleshooting The following section provides troubleshooting information to help diagnose conditions with the product and resolve these conditions. CAUTION: Thread locker applied to fasteners must not be used more than once. Fasteners might become loose and cause equipment damage. -

Page 22: Service Procedures

Manual, Compliant Deburring Blade Document #9610-50-1030-04 6.2 Service Procedures 6.2.1 Replacement of Bit Holders in ATC Tool Stand NOTICE: The customer must have familiarity with how to actuate each ATC station in order to manually replace each blade. If plant regulations require all pressurized air is released prior to operator’s entrance into a robot cell, the ATC station can be used in conjunction with a swivel table to rotate ATC stations out of the cell. -

Page 23: Serviceable Parts

Manual, Compliant Deburring Blade Document #9610-50-1030-04 7. Serviceable Parts for exploded drawings showing the user replaceable components of Refer to Section 9.1—9630‑50‑CDB‑8‑11‑ATC for exploded drawings showing the user replaceable the ATC tool. Refer to Section 9.2—9630‑50‑CDB‑8‑11‑000 components of the manual collet tool. All other repairs must be performed by ATI. Table 7.1—Tool Changer Collet (Sheet 3 of Section 9.1—9630‑50‑CDB‑8‑11‑ATC) -

Page 24: Drawings

Manual, Compliant Deburring Blade Document #9610-50-1030-04 9. Drawings 9.1 9630-50-CDB-8-11-ATC Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com... - Page 25 Manual, Compliant Deburring Blade Document #9610-50-1030-04 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com...

- Page 26 Manual, Compliant Deburring Blade Document #9610-50-1030-04 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com...

- Page 27 Manual, Compliant Deburring Blade Document #9610-50-1030-04 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com...

-

Page 28: 9630-50-Cdb-8-11-000

Manual, Compliant Deburring Blade Document #9610-50-1030-04 9.2 9630-50-CDB-8-11-000 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com... - Page 29 Manual, Compliant Deburring Blade Document #9610-50-1030-04 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com...

-

Page 30: 9630-50-Cdb-Pneumatic

Manual, Compliant Deburring Blade Document #9610-50-1030-04 9.3 9630-50-CDB-PNEUMATIC Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com... - Page 31 Manual, Compliant Deburring Blade Document #9610-50-1030-04 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com...

-

Page 32: Terms And Conditions

Manual, Compliant Deburring Blade Document #9610-50-1030-04 10. Terms and Conditions ATI warrants the compliant tool product will be free from defects in design, materials and workmanship for a period of one (1) year from the date of shipment and only when used in compliance with manufacturer’s specified normal operating conditions.

Need help?

Do you have a question about the 9150-CDB-8-11-ATC and is the answer not in the manual?

Questions and answers