DAB E.Box Plus Instruction For Installation And Maintenance

Hide thumbs

Also See for E.Box Plus:

- Quick manual (2 pages) ,

- Instruction for installation and maintenance (552 pages)

Subscribe to Our Youtube Channel

Summary of Contents for DAB E.Box Plus

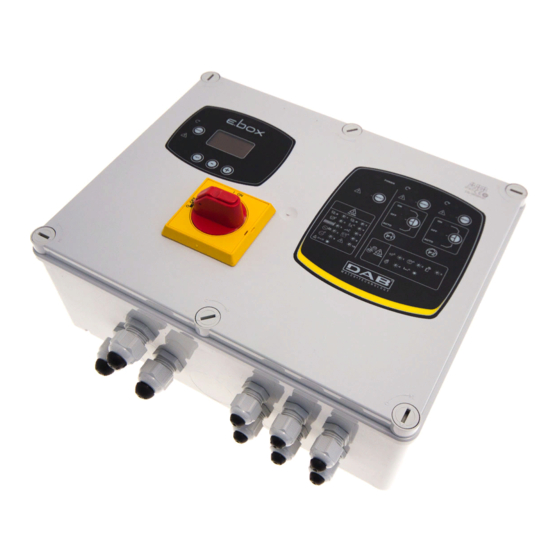

- Page 1 INSTRUCTIONS FOR INSTALLATION AND MAINTENANCE (GB) E.Box Plus E.Box Plus D E.Box Basic E.Box Basic D...

- Page 2 Pag. ENGLISH...

- Page 3 ENGLISH INDEX KEY .................................. 67 WARNINGS ..............................67 RESPONSIBILITY ............................67 GENERAL ..............................68 Technical characteristics ........................ 68 Protections ............................68 INSTALLATION ............................69 Electrical connections........................69 ...

- Page 4 ENGLISH Connection of additional protections: overflow, water lack, motor thermal protection ..92 Connection of the alarm outputs ....................94 Connection of floats or level probes ..................... 94 Depth sensor connection ....................... 94 ...

- Page 5 ENGLISH with pressure sensor) ..........................111 HC: Pump P2 starting level (only in drainage or filling with depth sensor) ..........111 HB: Pump P1 starting level (only in drainage or filling with depth sensor) ..........111 HA: Pumps stopping level (only in drainage or filling with depth sensor) ..........

-

Page 6: Table Of Contents

Table 21: NI alarms ............................121 INDEX OF FIGURES Figure 1: E.box Basic Board ..........................70 Figure 2: E.Box Plus Board ..........................71 Figure 3: Electrical connection of pumps ......................72 Figure 4: Connection of pump external capacitors ..................73 ... - Page 7 ENGLISH Figure 27: Setting the filling dip switches ......................89 Figure 28: Enabling P1 and P2........................89 Figure 29: Regulating the rated current SP and DP ..................90 Figure 30: Filling with a depth sensor ......................91 ...

- Page 8 ENGLISH The following symbols have been used in the discussion: Situation of general danger. Failure to respect the instructions that follow may cause harm to persons and property. Situation of electric shock hazard. Failure to respect the instructions that follow may cause a situation of grave risk for personal safety.

-

Page 9: Table 1: Technical Data

Choose the sensors with a grade of protection suitable for the place in which they will be positioned. 1.1 Technical characteristics E.box Plus E.box Basic E.box Plus D E.box Basic D Power supply 3 x 400V 1 x 230V... - Page 10 ENGLISH 2 INSTALLATION Strictly respect the electric supply values indicated on the electrical data plate. Although it has a grade of protection IP55, it is not advisable to use it in an atmosphere charged with oxidising or corrosive gases. ...

-

Page 11: Figure 1: E.box Basic Board

ENGLISH 2.1.2 Boards and connections Figure 1: E.box Basic Board... -

Page 12: Figure 2: E.box Plus Board

ENGLISH Figure 2: E.Box Plus Board Function Supply line isolating switch (On the front panel of the e.box not shown in the figure) L1 – L2 – L3 Three-phase power supply line connection L – N Single-phase power supply line connection... -

Page 13: Figure 3: Electrical Connection Of Pumps

Pump P1 protection fuse (Plus version only) The supply voltage of the E.BOX PLUS panel must be the same as that of the pumps used. For example, if the panel is fed with a supply voltage of 3~400V the pumps must be at 3~400V. -

Page 14: Figure 4: Connection Of Pump External Capacitors

ENGLISH The capacitors must be connected as shown in Figure 4. Take care because in the E.Box Plus they share the same terminal as the pump. Figure 4: Connection of pump external capacitors 2.3 Power supply electrical connection Before starting work, disconnect the power from the supply line. Use cables with a suitable size for the currents involved, considering that the in-line current is the total of the currents on the pumps. -

Page 15: Figure 6: Display Label, Present Only On Plus Models

ENGLISH 3 FRONT PANEL Figure 6: Display label, present only on plus models Figure 7: Front label Section concerning the panel White led indicating that the panel is fed Red alarm led of the panel with the alarm reset button next to it. The number of blinks of the led indicates the type of error, as shown in the table below. - Page 16 ENGLISH 4 PANEL INTERNAL REGULATING BOARD Before starting regulation, switch off the mains power. To access the internal panel, slacken the screws, turn the cover of the electric panel downwards and operate the commands. Ref. Function Warning lights for activating the digital inputs (N-A-B-C-R) Trimmer for regulating the system (Imax –...

- Page 17 ENGLISH 4.2 Dip-switch for selecting functions (DS_A – DS_B) STANDARD expansion MAXI expansion vessels, minimum vessels, over 100 litres per pump. litres per pump. Effective only Effective only pressure boosting and pressure boosting kiwa and kiwa Automatic exchange Automatic exchange between pump P1 and between pump P1 P2 every 24 hours.

-

Page 18: Figure 8: Inputs And Outputs

ENGLISH 5 PRESSURE BOOSTING FUNCTION The E.box panel can be used for making a system to increase water pressure. As control inputs, either pressure switches on a pressure sensor can be used. To operate, the panel requires an expansion vessel. 5.1 Expansion vessel In pressure boosting it is necessary to use an expansion vessel of at least 19 litres per pump. -

Page 19: Figure 9: Thermal Protection Inputs Kk

ENGLISH Figure 9: Thermal protection inputs KK 5.4 Connection of the alarm outputs If alarms occur, this is indicated by the E.box in three ways: With the leds on the front panel, which give a number of blinks depending on the error. ... -

Page 20: Figure 11: Terminals For Connecting The Pressure Switches

ENGLISH Figure 11: Terminals for connecting the pressure switches 5.8 Setting with the display, wizard The E.box D can be configured with a simple wizard. The device asks the user for all the parameters necessary for its configuration. If necessary, it can be loaded by pressing the “set” + “+” keys when switching on. To navigate in the wizard, use the following keys: ... -

Page 21: Figure 12: Configuration With A Pressure Sensor

ENGLISH 5.9 Setting with a pressure sensor Figure 12: Configuration with a pressure sensor... -

Page 22: Figure 13: Configuration With Pressure Switches

ENGLISH 5.10 Configuration with pressure switches Figure 13: Configuration with pressure switches 5.11 Setting the E.box with dip switches If the E.box is provided with a display, it is recommended to use the display for configuration. Otherwise it is possible to use the dip switches inside the panel and set them as shown in Figure 14 Dip switches for pressure boosting. -

Page 23: Figure 15: Enabling P1 And P2

ENGLISH 5.12 Activation of the set To activate the set it is necessary to enable the pumps. During the first configuration, for safety’s sake, the pumps are disabled and are OFF. To change to automatic mode, just briefly press the buttons on the pumps P1 and P2. -

Page 24: Table 2: Pressure Boosting Operation With Pressure Switches

ENGLISH 5.14 System operation Pressure switches: The operating logic is the following: Pressure boosting operation with pressure switches Start Stop Pressure switch Pressure switch B = OPEN CLOSED Pressure switch Pressure switch C = OPEN CLOSED Table 2: Pressure boosting operation with pressure switches ... -

Page 25: Figure 19: Diagram Of Filling System Inputs

ENGLISH 6 FILLING FUNCTION The E.box panel can be used for making filling systems. As control inputs, any of the following may be used: floats, level probes or a depth sensor. The general diagram is as follows: Open contact Closed contact Level probes Depth Floats... -

Page 26: Figure 20: Inputs And Protections

ENGLISH If the display is present, in all cases the type of alarm is indicated. When the alarm conditions no longer exist, the E.box resumes normal operation. Maximum level alarm: the signal for this alarm may come from a float, from a level probe, or from the depth sensor (only for E.Box with display). -

Page 27: Figure 22: Inputs

ENGLISH 6.4 Connection of the alarm outputs If alarms occur, this is indicated by the E.box in three ways: With the leds on the front panel, which give a number of blinks depending on the error. With the outputs Q1, Q2, Q3 which short circuit as specified in Table 17. The operating logic of the alarms is as follows: Q1 closes following malfunctions of pump 1, Q2 of pump 2 and Q3 for general errors. -

Page 28: Figure 24: Configuration Of Filling With Floats Or Level Probes

ENGLISH 6.7 Setting with the display, wizard The E.Box D can be configured with a simple wizard. The device asks the user for all the parameters necessary for its configuration. If necessary, it can be loaded by pressing the “set” + “+” keys when switching on. To navigate in the wizard, use the following keys: ... -

Page 29: Figure 26: A System Status With Depth Sensor Only, B Depth Sensor And Floats, C Depth Sensor And Level Probes

ENGLISH 6.9 Configuration with a depth sensor Figure 26: A System status with depth sensor only, B depth sensor and floats, C depth sensor and level probes... -

Page 30: Figure 27: Setting The Filling Dip Switches

ENGLISH 6.10 Setting the E.box with dip switches If the E.box is provided with a display, it is recommended to use the display for configuration. Otherwise it is possible to use the dip switches inside the panel and set them as shown in Figure 27. Figure 27: Setting the filling dip switches The following modifications may be made during configuration: ... -

Page 31: Table 5: Filling Operation With 2 Floats

ENGLISH Figure 29: Regulating the rated current SP and DP 6.13 System operation: Operation with 2 floats or level probes The operating logic is the following: Float or level probe connected to input B starts pump P1 and stops both pumps. ... -

Page 32: Table 7: Operation With Depth Sensor, Without Display

ENGLISH The following table sums up the behaviour described: Operation with depth sensor, without display STARTING STOPPING Tank level <= DP Tank level = SP Pump P1 = started for at least 4 seconds and Tank level = SP tank <= DP Table 7: Operation with depth sensor, without display Maximum Alarm P1 + P2 = OFF... -

Page 33: Figure 31: Draining System Diagram

ENGLISH 7 DRAINING FUNCTION The E.box panel can be used as a control and protection panel for draining systems. As control inputs, any of the following may be used: floats, level probes or a depth sensor. The general diagram is as follows: Closed contact Open contact Depth sensor... -

Page 34: Figure 32: Position Of Inputs And Alarms

ENGLISH If the display is present, in all cases the type of alarm is indicated. When the alarm conditions no longer exist, the E.box resumes normal operation. Maximum level alarm: the signal for this alarm may come from a float, from a level probe, or from the depth sensor (only for E.Box with display). -

Page 35: Figure 34: Inputs

ENGLISH 7.4 Connection of the alarm outputs If alarms occur, this is indicated by the E.box in three ways: With the leds on the front panel, which give a number of blinks depending on the error. With the outputs Q1, Q2, Q3 which short circuit as specified in Table 17. The operating logic of the alarms is as follows: Q1 closes following malfunctions of pump 1, Q2 of pump 2 and Q3 for general errors. -

Page 36: Figure 36: Configuration Of Drainage Floats Or Level Probes

ENGLISH 7.7 Setting with the display, wizard The E.Box D can be configured with a simple wizard. The device asks the user for all the parameters necessary for its configuration. If necessary, it can be loaded by pressing the “set” + “+” keys when switching on. To navigate in the wizard, use the following keys: ... -

Page 37: Figure 38: Configuration With Only A Depth Sensor

ENGLISH 7.9 Configuration with a depth sensor Figure 38: Configuration with only a depth sensor... -

Page 38: Figure 39: System Status In Configurations: A With Only Depth Sensor, B: Depth Sensor And Floats, C Depth Sensor And Level Probes

ENGLISH In point 7 it is possible to choose the type of signal that will generate the maximum and minimum level alarms. Floats, level probes or the data provided by the depth sensor may be used. If the depth sensor is used, the maximum ML and the minimum LL level alarm thresholds must be set in accordance with Figure 43. -

Page 39: Table 8: Filling Operation With 2 Floats

ENGLISH The following modifications may be made during configuration: If you want the pumps to be exchanged every 24 hours and not at each restart, set DS_A2 at ON. If you do not want protection against too rapid restarts, set DS_A3 at OFF. ... -

Page 40: Table 10: Drainage With Depth Sensor, Without Display

ENGLISH Note: the function with 3 floats is used in installations with deep narrow tanks that do not allow an ample travel of the floats! Note: in the E.box version with display, the correct number of floats or level probes used is displayed automatically. -

Page 41: Figure 44: Inputs

ENGLISH 8 KIWA PRESSURE BOOSTING FUNCTION The E.box panel can be used for making a system to increase water pressure that respects the KIWA standard. This mode is available only if the language chosen is French, Dutch or English. As control inputs, either pressure switches on a pressure sensor can be used. -

Page 42: Figure 45: Thermal Protection Inputs Kk

ENGLISH Figure 45: Thermal protection inputs KK 8.4 Connection of the alarm outputs If alarms occur, this is indicated by the E.box in three ways: With the leds on the front panel, which give a number of blinks depending on the error. ... -

Page 43: Figure 47: Pressure Switch Terminal Board

ENGLISH Figure 47: Pressure switch terminal board 8.9 Connecting the low-pressure pressure switch To comply with the KIWA standard it is necessary to connect a low-pressure pressure switch on the pump intake, set at such a pressure that it intervenes in the event of water lack. The pressure switch must be connected to contact N of the E.Box and the contact must open if the pressure falls below the minimum value. -

Page 44: Figure 48: Kiwa Pressure Boosting With Pressure Sensor

ENGLISH 8.11 Setting with a pressure sensor: Figure 48: KIWA pressure boosting with pressure sensor 8.12 Configuration with pressure switches: Figure 49: Kiwa configuration with pressure switches... -

Page 45: Figure 50: System Status In Kiwa Mode

ENGLISH 8.13 System status in Kiwa mode Figure 50: System status in KIWA mode 8.14 Setting the E.box with dip switches If the E.box is provided with a display, it is recommended to use the display for configuration. Otherwise it is possible to use the dip switches inside the panel and set them as shown in Figure 51. -

Page 46: Table 11: Pressure Boosting Operation With Pressure Switches

ENGLISH The following modifications may be made during configuration: If the expansion vessel is larger than 100 litres, set DS_A1 at OFF. If you want the pumps to be exchanged every 24 hours and not at each restart, set DS_A2 at ON. ... -

Page 47: Table 12: Pressure Boosting Operation Standard Vessel < 100 Litres

ENGLISH Pressure boosting operation standard vessel < 100 litres Pumps Start Stop System pressure <= SP System pressure => SP+RP System pressure <= SP – RP System pressure => SP+RP Table 12: Pressure boosting operation standard vessel < 100 litres Operation with additional expansion vessel >... -

Page 48: Figure 56: Label And Keys

ENGLISH 9 THE KEYPAD AND THE DISPLAY Main display of the E.Box. Figure 56: Label and keys If it refers to a pump, the RESET Eliminate alarms key eliminates the errors of that pump. If it is general, it eliminates the panel errors. It allows you to choose the operating mode of the pumps P1 and P2. -

Page 49: Table 14: Key Functions

ENGLISH The number of blinks of the leds next to the alarm symbol represents the type of error. There is a legend on the label. Figure 57: Label, keys and display E.box display label. The functions of the keys are summed up in Table 14. The MODE key allows you to move on to the next items in the same menu. -

Page 50: Table 15: Access To The Menus

ENGLISH MENU NAME DIRECT ACCESS KEYS HOLD-DOWN TIME On releasing the User button Monitor 2 Sec Setpoint 2 Sec Installer 5 Sec Technical assistance 5 Sec 2 sec after switching Reset factory values on appliance Reset 2 Sec Table 15: Access to the menus Main User Monitor... -

Page 51: Table 16: Menu Structure

ENGLISH Legend Identifying colours Notes on the parameters Only in pressure boosting with active pressure sensor Only if a pressure or depth sensor is used Only in kiwa mode Only in filling or drainage with a depth sensor Read-only parameters. Table 16: Menu structure Access by name with a drop-down menu The selection of the various menus is accessed by name. -

Page 52: Figure 59: Errors In The Memory

ENGLISH 9.4.2 MONITOR MENU From the main menu, by holding down simultaneously for 2 sec the keys “SET” and “-“, or using the selection menu and pressing “+” or “-“, you can access the MONITOR MENU. In this menu, by pressing the MODE key, the following values are displayed in sequence. FF: Fault log display Chronological display of the faults that have occurred during system operation. - Page 53 ENGLISH HA: Pumps stopping level (only in drainage or filling with depth sensor) Stopping level of pumps P1 and P2. 9.4.4 INSTALLER MENU From the main menu, hold down simultaneously the “MODE” and “SET” keys until “INSTALLER MENU” appears on the display (or use the selection menu pressing “+”...

- Page 54 ENGLISH 9.4.5 TECHNICAL ASSISTANCE MENU From the main menu, hold down simultaneously the “MODE” and “SET” and “-“ keys until “TECHNICAL ASSISTANCE MENU” appears on the display (or use the selection menu pressing “+” or “-“). The menu allows you to view and modify various configuration parameters: the MODE key allows you to scroll through the menu pages, the + and –...

- Page 55 ENGLISH = 0 and lastly, before leaving, he sets the PW so as to be sure that the machine is already protected without any further action). If the password is lost there are 2 possibilities for editing the parameters of the E.Box: ...

-

Page 56: Table 17: General Table Of Alarms: Signals And Contacts

ENGLISH Led signal Alarm property Remote signal on front board Name of alarm/malfunction Alarm relay/remote control switch Pump disconnected Dry operation alarm Alarm too frequent starts Current overload alarm Alarm coming from R Alarm coming from N X (***) Pressure/depth sensor alarm Floats incoherence... -

Page 57: Table 18: Digital Inputs R And N Protection /Alarm

ENGLISH Indicates the number of blinks made by the warning led Led lit with fixed light The alarm may occur up to a maximum of 6 times in 24 hours, after which it becomes blocking. If malfunctions/alarms occur on both pumps at the same time, the REMOTE ALARM (relays Q1, Q2, Q3) is activated and the GENERAL ALARM (red) is lit with a fixed light. - Page 58 ENGLISH - Dry running protection/alarm When the pressure falls to a value of less than 0.5 bar for about 10 seconds, the alarm is activated with stopping of the pump and lighting of the led. The dry running protection/alarm is activated in pressure boosting mode when an analog pressure sensor is connected.

- Page 59 - Voltage selector error This error may occur on the E.Box plus, in the case of a fault of the E.Box Plus or breakage of the fuse FU2. In the case of an alarm, check the fuse FU2 and ensure the panel is supplied with an adequate voltage, as specified in Table 1 –...

-

Page 60: Table 19: E.box Errors Shown On The Display

ENGLISH Relay/remote control switch Pump disconnected Dry operation Too frequent starts Current overload Pressure switch for maximum pressure Maximum level float Minimum level float Minimum level probe Maximum level probe Pressure switch for minimum pressure X(**) Maximum level float Minimum level float Minimum level probe Maximum level probe Maximum level... -

Page 61: Table 20: Ri Alarms

ENGLISH This protection can be activated by setting the parameter TB at a value other than zero. The protection intervenes: When the pressure falls to a value lower than the parameter MP (default 0.45bar) for a time equal to the parameter TB, the alarm is activated with stopping of the pump and lighting of the led. -

Page 62: Table 21: Ni Alarms

ENGLISH Message Meaning and description This error appears in pressure boosting and indicates that the maximum Pressure switch for minimum pressure switch is activated or that the contact N has not been jumpered. The E.Box stops. In KIWA pressure boosting the error is not self-resetting pressure and manual intervention is necessary. -

Page 63: Pk: Key Error

- VS: Voltage selector error This error may occur on the E.Box plus, in the case of a fault of the E.Box Plus or breakage of the fuse FU2. In the case of an alarm, check the fuse FU2 and ensure the panel is supplied with an adequate voltage, as specified in Table 1 –... - Page 64 Tel.: +32 2 4668353 Tel.: +31 416 387280 Fax: +32 2 4669218 Fax: +31 416 387299 PUMPS AMERICA, INC. DAB PUMPS DIVISION DWT South Africa 3226 Benchmark Drive Podium at Menlyn, 3rd Floor, Unit 3001b, Ladson, SC 29456 USA 43 Ingersol Road, C/O Lois and Atterbury, info.usa@dwtgroup.com...

Need help?

Do you have a question about the E.Box Plus and is the answer not in the manual?

Questions and answers