Table of Contents

Advertisement

Available languages

Available languages

Quick Links

1101 Myers Parkway

Ashland, OH 44805

Phone: 1-419-289-1144

Fax: 1-419-289-6658

Web Site: http://www.myerspump.com

Grinder Pumps

INSTALLATION, OPERATION, & PARTS MANUAL

SAFETY INFORMATION

Carefully read and follow all safety instructions in this

manual or on pump.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury!

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns bout hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

1. Read these rules and instructions carefully. Failure to

follow them could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing. You must com-

ply with their rules.

3. Vent sewage or septic tank according to local codes.

4. Disconnect electrical power and keep hands away from

pump inlet opening when working on or handling pump

for any reason. Do not use automatic reset controls with

this pump. Accidental rotation of the cutter with hands in

the cutter area can cause severe injury.

5. Always keep pump properly serviced and maintained.

6. Use pump for designed task – that is, pumping domestic

sewage and waste water containing solids. Do not pump

metal particles, rocks, or other hard objects.

7. Do not pump corrosive or flammable liquids with this

pump.

© 2005

Models MRGD300MC2,

MRGD300MC3, MRDG500MC2,

MRDG500MC3 and MRGD750MC3

DESCRIPTION

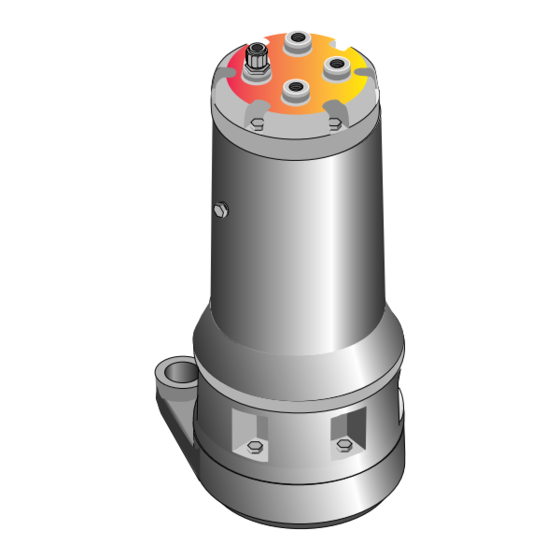

These submersible wastewater pumps are designed for

sewage, effluent and wastewater removal or transfer, sump

drainage, dewatering, flood control and for circulation.

Pumps include internal circuitry that detects seal leakage

and overheating of windings. Other options available include

lift-out system components, control panels, switches and

alarms. Not for use with salt water or brine.

SPECIFICATIONS

Power Supply Required: . . . . . . . . . . . .230/1Ø - 230/460/3Ø

Motor Duty: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Intermittent

Maximum Liquid Temperature: . . . .1 Phase - 40° C (104° F)

Discharge Adapter: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2"

Power Cable: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Type STO

Volute, Impeller and Pump Body: . . . . . . .Class 30 Cast Iron

O-Rings and Elastomer Part of Shaft Seal: . . . . . . . .Buna-N

Shaft Seal Faces: . . . . . . . . . . . . .Carbon and Ceramic with

Fasteners in contact with liquid

being pumped: . . . . . . . . . . . . . . . . . . . . . . . .Stainless Steel

Grinder Assembly: . . . . . . . . . . . . . . .17-4ph Stainless Steel

3 Phase - 60° C (140° F)

Stainless Steel Trim

MY500 (Rev. 4/18/05)

Advertisement

Table of Contents

Summary of Contents for MYERS MRGD300MC2

- Page 1 Models MRGD300MC2, MRGD300MC3, MRDG500MC2, MRDG500MC3 and MRGD750MC3 1101 Myers Parkway Ashland, OH 44805 Phone: 1-419-289-1144 Fax: 1-419-289-6658 Web Site: http://www.myerspump.com Grinder Pumps INSTALLATION, OPERATION, & PARTS MANUAL SAFETY INFORMATION DESCRIPTION Carefully read and follow all safety instructions in this These submersible wastewater pumps are designed for manual or on pump.

-

Page 2: Motor Specifications

MOTOR SPECIFICATIONS PIPING DIMENSIONAL GUIDE Motor Minimum Model Voltage/ Max. Load Circuit Vert. Disch. Number Phase Amps Req.(Amp) Pipe Length MRGD300MC2 208-230/1 28.0 MRGD300MC3 208-230/460/3 15.5-14.0/7.0 20/10 Locking Rail Length MRGD500MC2 208-230/1 34.0 MRGD500MC3 208-230/460/3 20.0-18.0/9.0 30/20 MRGD750MC3 208-230/460/3 24.3-22.0/11.0... - Page 3 PIPING DIMENSIONAL GUIDE FOR GUIDE-RAIL 7-15/16'' (202mm) LIFT-OUT SYSTEM Locking Rail 23-1/2" (597mm) Guide Rails Connection Height of Stationary Flange 10-9/16" (268mm) 13-1/4" (337mm) Figure 3A: Pump Dimensions. 1931 0895 Figure 2: Duplex Dimensions. Lift-Out Opening Basin Cover Base Flange 2"...

- Page 4 GUIDE RAIL LIFT-OUT ASSEMBLY STEPS 1938 0895 1937 0895 1939 0895 1934 0895 1935 0895 Figure 4: Assembly sequence for Guide Rail Lift-out System. Follow the numbered steps to assemble and install your Lift-Out system. 1933 0895 Make sure that you use the correct sequence for your pump or the piping assembly will not mount on the pump or on the guide rails.

-

Page 5: Installation

A full range of controls and switches is listed in our floor. catalog. If a Myers control panel is not used, install a control panel 2. Thread the 2-1/2" (64 mm) dia. pipe section (Step 2) into with circuit breaker or fused disconnect as required by local the base flange and tighten it. -

Page 6: Operation

1. After the basin cover is removed and the necessary dis- charge piping disconnected, lift the pump from the basin. Single phase units Power that are not installed Cable 230 VOLTS 460 VOLTS with Myers control Black & panels require a White & capacitor/overload & package. Purchase... - Page 7 2. Place the pump in a suitable area where it can be Reassembly: cleaned thoroughly. NOTICE: Use all new O-Rings and seals during 3. Remove all scale and deposits from the pump. re-assembly. 4. Submerge the complete pump in a disinfectant 1.

- Page 8 1945 0895...

-

Page 9: Repair Parts List

Repair Parts List Part No. Part Description Qty. MRGD300MC2 MRGD300MC3 MRGD500MC2 MRGD500MC3 MRGD750MC3 3/8-16x1-1/4” Hex Hd Cap Screw, SS S23568 S23568 S23568 S23568 S23568 3/8” Lockwasher, SS S23036 S23036 S23036 S23036 S23036 Terminal Cover Assemby W52017L W54002L W52098L W52017L W52017L... - Page 10 Guide Rail Lift-out System Repair Parts 1946 0895 Part Description Qty. MW52440L Eyebolt † Discharge Pipe Bracket † 2" Ball Check Valve † 2x6 Nipple, Galvanized Guide Rail Bracket † 2" Union, Galvanized 2x2-1/2 Nipple, Galvanized Base Flange † Base Pipe †...

-

Page 11: Warranty Period

MYERS LIMITED WARRANTY During the time periods and subject to the conditions hereinafter set forth, F.E. Myers will repair or replace to the original user or consumer any portion of your new MYERS product which proves defective due to defective materials or workmanship of MYERS. -

Page 13: Spécifications

Modèles MRGD300MC2, MRGD300MC3, MRDG500MC2, MRDG500MC3 and MRGD750MC3 1101 Myers Parkway Ashland, OH 44805 Téléphone: 1-419-289-1144 Télécopieur: 1-419-289-6658 Site Web: http://www.myerspump.com Pompes broyeuses NOTICE D’INSTALLATION, DE FONCTIONNEMENT ET DES PIÈCES DÉTACHÉES SÉCURITÉ DESCRIPTION Lire et suivre attentivement toutes les consignes de sécurité... -

Page 14: Spécifications Du Moteur

(mètres) illustrée Numéros 110(34) ci-dessous - 20(6) 50(15) 80(24) des modèles en pi (m) Capacité en gallons/minute (L/min) MRGD300MC2 104(394) 76(288) 15(57) – 84(25,6) MRGD300MC3 104(394) 76(288) 15(57) – 84(25,6) MRGD500MC2 116(439) 108(409) 80(303) 18(68) 116(35) - Page 15 GUIDE DES DIMENSIONS DES TUYAUX DU SYSTÈME 7 15/16 po 7-15/16'' (202mm) (202 mm) DE LEVAGE À GLISSIÈRES DE GUIDAGE 23-1/2" 23 1/2 po Glissière Locking (597mm) (597 mm) de blocage Rail Glissières Guide de guidage Rails Hauteur du Connection raccord de Height of la bride fixe...

- Page 16 OPÉRATIONS DE MONTAGE DU RAIL-GUIDE DE LEVAGE 1938 0895 1937 0895 1939 0895 1934 0895 1935 0895 Figure 4 : Ordre de montage des systèmes de levage à glissières de guidage. Suivre dans l’ordre les opérations numérotées pour monter et démonter le système de levage. 1933 0895 S’assurer de suivre le bon ordre de montage en fonction de la pompe, sinon il sera impossible de brancher la tuyauterie sur la...

- Page 17 Figures 4 et 5) Si un panneau de commande Myers n’est pas utilisé, installer un panneau de commande doté d’un disjoncteur ou d’un sectionneur Visser la bride de base sur le fond du bassin (se reporter à...

-

Page 18: Entretien

(16-14) T4,T5,T6 T4 & T7 Myers n’est pas instal- Pas utilisé Not Used T5 & T8 Black Noir lé. Se reporter au Myers Pas utilisé Not Used Thermal Sensor T6 & T9 Sonde thermique White Blanc pour acheter cet Rouge ensemble. - Page 19 Mettre la pompe sur une surface adéquate, là où elle pourra Remontage : être complètement nettoyée. NOTA : N’utiliser que des joints toriques et d’étanchéité neufs lors Enlever tout le tartre et tous les dépôts de la pompe. du remontage. Avant de démonter la pompe, l’immerger complètement dans Pousser la tête d’un joint en céramique neuf en place dans la une solution désinfectante (chlorox ou chlore) pendant au...

- Page 20 1945 0895...

-

Page 21: Liste Des Pièces De Rechange

Liste des pièces de rechange Nos de pièce des séries Réf. Désignation des pièces Qté MRGD300MC2 MRGD300MC3 MRGD500MC2 MRGD500MC3 MRGD750MC3 Vis à chapeau à tête hexagonale en acier inoxydable de 3/8-16 x 1/4 de po S23568 S23568 S23568 S23568 S23568... - Page 22 Pièces de rechange du système de levage à glissières de guidage 1946 0895 Réf. Désignation des pièces Qté MW52440L Boulon à oeil † Support du tuyau de refoulement † Clapet de non retour à bille de 2 pouces † Mamelon galvanisé de 2 x 6 Support des glissières de guidage †...

- Page 23 Pendant les périodes et sous réserve des conditions stipulées dans les présentes. F.E MYERS réparera ou remplacera, pour l’utilisateur ou le consommateur initial, toute partie d’un produit neuf MYERS qui s’avérerait défectueux suite à un défaut de matériau ou de fabrication MYERS. Pour tout service au titre de la garantie, s’adresser à...

-

Page 25: Información Sobre La Seguridad

Modelos MRGD300MC2, MRGD300MC3, MRDG500MC2, MRDG500MC3 and MRGD750MC3 1101 Myers Parkway Ashland, OH 44805 Teléfono: 1-419-289-1144 Fax: 1-419-289-6658 Dirección web: http://www.myerspump.com Bombas moledoras MANUAL DE INSTALACIÓN, OPERACIÓN Y PIEZAS INFORMACIÓN SOBRE LA DESCRIPCIÓN SEGURIDAD Estas bombas sumergibles para aguas residuales han sido dis- eñadas para la remoción o transferencia de aguas cloacales, servi-... -

Page 26: Especificaciones Del Motor

(m) indicada Número abajo 20(6) 50(15) 80(24) 110(34) de modelo en pies (m) Capacidad en galones/minuto (L/m) MRGD300MC2 104(394) 76(288) 15(57) – 84(25,6) MRGD300MC3 104(394) 76(288) 15(57) – 84(25,6) MRGD500MC2 116(439) 108(409) 80(303) 18(68) 116(35) MRGD500MC3 116(439) 108(409) 80(303) - Page 27 GUÍA DE DIMENSIONES DE LOS TUBOS PARA EL 7-15/16" 7-15/16'' (202mm) (202 mm) SISTEMA DE EXTRACCIÓN CON RIEL GUÍA 23-1/2" 23-1/2" Riel de Locking (597mm) (597 mm) enganche Rail Rieles Guide guía Rails Altura de Connection conexión Height of de la brida Stationary Flange fija...

- Page 28 PASOS PARA EL ENSAMBLAJE DEL SISTEMA DE EXTRACCIÓN CON RIEL GUÍA 1938 0895 1937 0895 1939 0895 1934 0895 1935 0895 Figura 4: Secuencia de ensamblaje para el Sistema de Extracción con Riel Guía. Siga los pasos numerados para armar e instalar su sistema de Extracción.

-

Page 29: Instalación

(Consultar los Pasos para el Ensamblaje en la página 4) interruptores. Si no se usa un tablero de control Myers, instale un tablero de con- (Consultar las Figuras 4 y 5 antes de ensamblar). trol con un disyuntor o con un fusible de desconexión conforme a Coloque la brida de base (Consultar el Paso 1, Page 4) sobre las normas locales. -

Page 30: Operación

& monofásicas que no Blanco White & Rojo estén instaladas con & tableros de control Ground Tierra Myers requieren un cable de Control paquete de capacitor / Cable control (16-4) (16-14) T4,T5,T6 dispositivo de sobre- T4 & T7 No se usa Not Used T5 &... - Page 31 Coloque la bomba en un área adecuada en donde se pueda Re-ensamblaje: limpiar a fondo. AVISO: Use todos los nuevos aros tóricos y sellos durante el re- Elimine toda la cal y los depósitos de la bomba. ensamblaje. Sumerja toda la bomba en una solución desinfectante (Clorox o Presione un nuevo cabezal de sello de cerámica en posición cloro) durante un mínimo de una hora antes de desarmarla.

- Page 32 1945 0895...

-

Page 33: Lista De Piezas De Repuesto

Lista de piezas de repuesto Clave Pieza No. Descripción de la pieza Cant. MRGD300MC2 MRGD300MC3 MRGD500MC2 MRGD500MC3 MRGD750MC3 Tornillo de casquete con cabeza hexagonal - 3/8-16x1-1/4", acero inoxidable S23568 S23568 S23568 S23568 S23568 Contratuerca de 3/8", acero inoxidable S23036 S23036... - Page 34 Piezas de repuesto del sistema de extracción con riel guía 1946 0895 Clave No.. Descripción de la pieza Cant. MW52440L Perno de argolla † Ménsula de la tubería de descarga † Válvula de bola de retención de 2" † Niple galvanizado de 2x6 Ménsula del riel guía †...

-

Page 35: Período De Garantía

MYERS que se compruebe defectuoso debido a materiales o a mano de obra de Myers defectuosos. Comuníquese con su Representante Autorizado de MYERS más cercano para obtener servicio bajo garantía. En todo momento, MYERS tendrá y poseerá el derecho y la opción exclusivos de determinar si se reparará o se reemplazará...

Need help?

Do you have a question about the MRGD300MC2 and is the answer not in the manual?

Questions and answers