Advertisement

Quick Links

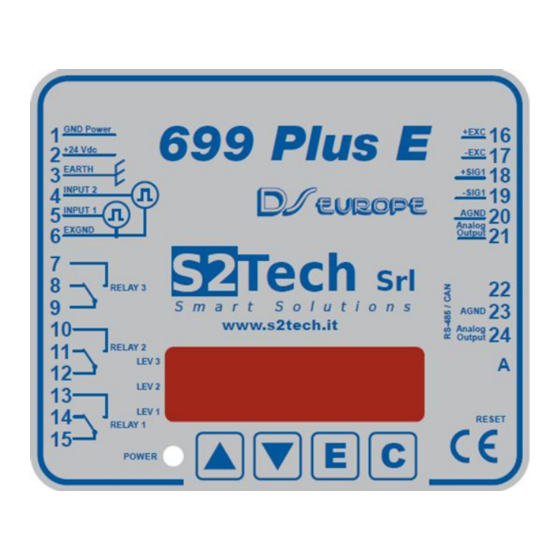

699Plus –

New Functions – FIRMWARE UPDATE

Troubleshooting functions

During system's calibration it can happen that the lift

installer has unsatisfying calibration due to errors in

performing the calibration procedure or due to the

way lift has been installed or for wrong installation of

the measurement system (wrong placement of the

sensor with poor sensitivity to load variations, etc).

The

above

conditions

can

be

detected

measurements with poor repeatability or larger than

expected measurement errors, or errors indicated on

699Plus display.

Messages can be:

a) indications to the installer, that something is

not as ideal for the correct working of the

measurement system, without blocking the lift

b) error messages indicating that performed calibration cannot grant a conversion of the internal

measurement into trustable weight indication, blocking the measurement system

c) error messages indicating a calibration where the internal AD converter is not working, for the

expected measuring range on its working area

A) Calibration concepts:

•

To calibrate 699, MANU procedure needs to acquire the coordinates of two points, to define the

conversion function between the measured signals (expressed in internal AD points) and the

reference load.

•

TARE: empty cabin.

•

HI: cabin loaded with a load as near as possible to the lift's maximum capacity.

•

After a calibration, at the reboot, calibration parameters are verified to check the correctness of

the conversion in the selected engineering units, signaling (with Error codes Er.XX) the

measurement conditions that may lead to non-consistent conversions.

•

If 699 Plus indicates an Er condition, Tare and HI parameters can be substituted with a new set of

coordinates with a new calibration.

Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material. This manual contains information protected by

copyright. No part of this manual may be photocopied, or reproduced in any form, or translated without prior written consent from S2Tech.

S2Tech srl

Via Imperia, 28 Milano – ITALY

Tel: +39 02 8910142 Fax: + 39 02 89124848

as

e-mail:

info@s2tech.it

www.s2tech.it

Some common calibration mistakes:

942 Strain Link is installed on the neutral axis of a bending beam, having not enough signal

variation (as percentage) corresponding to load changes

Structure is too stiff, or Strain link is not correctly fixed on the structure surface (screws not

tightened, paint / rust as interface on the mounting surface, elastic washers used instead of supplied

plain washers, etc.)

MRL Multirope sensor is installed on the counterweight rope side and measurement is not in

position to represent - with enough percentage change - the changes of the applied load

MRL Multirope sensor has been installed with screws not correctly touching the inside of the

deflection bar (see instruction manual)

Electrical connections are not properly done, since no percentage changes are shown when load

changes.

Car floor is installed on TSP sensors but touches other structures

Excessive friction between the guides and the sliding guide shoes is indicated by a suddenly

increase of the value when car starts to move, that then stabilize at lower values.

Problems of guide geometry can be associated to sudden changes in the displayed value, when car

is moving on the shaft

Etc

In the event of an excessive load, which saturates the input of the instrument, Er.28 will appear on the

display.

B) To understand the situation, the following error messages indicates:

ER.01

Negative measurement. ER01 indication is displayed alternatively to the measured weight

(polarity is indicated only with 3 digits values, i.e. -999) – verify zeroing with C key,

electrical connection and system calibration.

Available from firmware version 1.37

ER.22

High load sensitivity. Verify that calibrated [C] screws correspond to rope's diameter

and that no ropes overlap

HI(AD)-Tare(AD)/ HI(Kg)-TARE(Kg) > 500 bit/kg

Conversion slope not correct: Verify that HI value is entered with the right resolution (use

weight at least 80% FSCA).

ER.23

HI value is too low (in engineering units).

HI-Tare must be > 10

ER.24

Known load for calibration is too low. Increase load.

HI(AD)-Tare(AD) <100

ER.28

Overflow state detected for ADC (positive or negative) during normal measurement.

In case that AREL parameter (available on SERV menu, default = 0) is set to 1, this error

condition will activate relay the greatest percentage, blocking the lift.

ER.30

Pushbutton detected as continuously pressed at the end of the calibration procedure (reboot)

ER.FF

ER.FF can be shown after calibration and reboot of the unit, if the calculated ADC points

corresponding to the greatest LEV percentage (Lev1, Lev2 or Lev3) multiplied by FSCA

value is greater than the working limits for the ADC.

ER.FE or ER.FD can be shown after calibration and reboot of the unit, if the calculated

ADC points corresponding to HI / Tare is greater / lower than the working limit for the

ADC.

In case that AREL parameter (available on SERV menu, default = 0) is set to 1, this error

condition will activate relay the greatest percentage, blocking the lift.

Z:\Manuali\699Plus 2k17\699Plus Troubleshooting Functions Fw 1.41 UK 130421.docx

Versione : UK 1r1 dated 13/04/21

Page: 1/2

Advertisement

Summary of Contents for S2Tech 699Plus

- Page 1 Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

- Page 2 Notice: The information in this manual is subject to change without notice.S2Tech shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

Need help?

Do you have a question about the 699Plus and is the answer not in the manual?

Questions and answers