Table of Contents

Advertisement

Quick Links

R R

S

tation aster -

Reversing Train Controller, V2 version

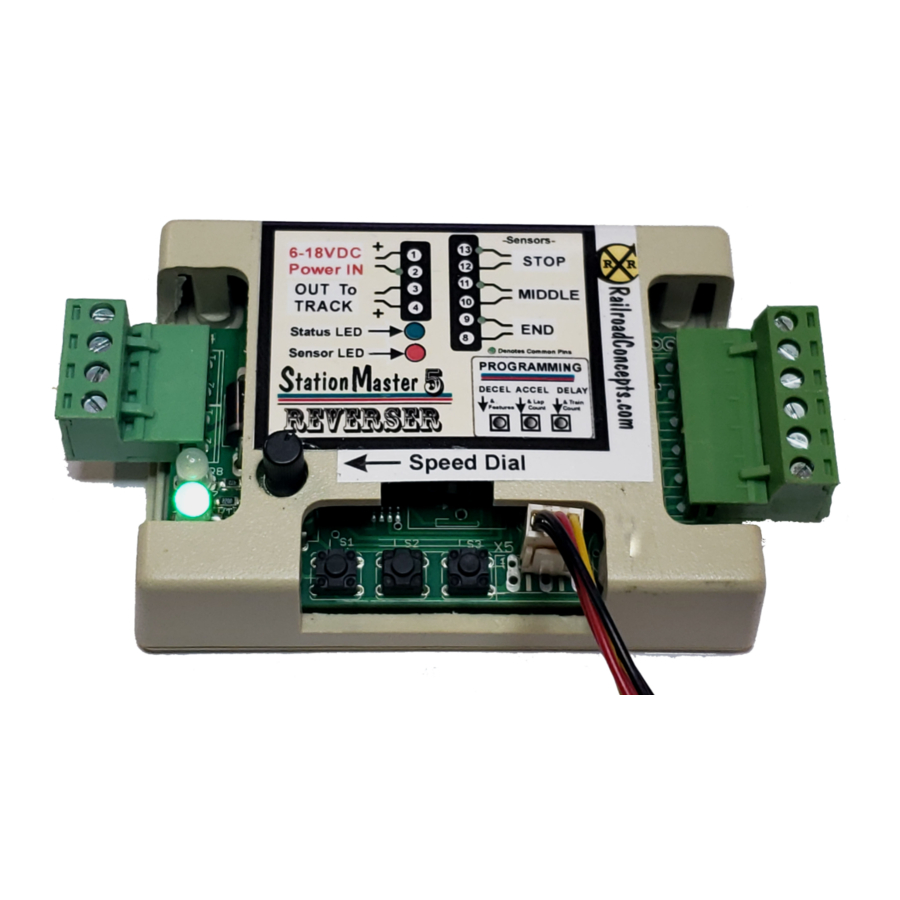

This manual contains detailed hookup and programming instructions for the

StationMaster - Reversing train controller.

The Reversing StationMaster is similar to a standard StationMaster however

it contains software to perform automatic back-and-forth operation with or without

sensors.

Before we Start

transformer) to any other terminals except the designated inputs.

Your StationMaster will be damaged if power is put on any of the sensor terminals.

ONLY ATTACH WIRES WHILE THE POWER IS OFF.

IN 8-20VDC

Out to Track

Status LED

Sensor LED

Top Speed Adjust and

Programming Dial

RR Concepts

M

Please do not attach power wires (from your power pack or

-

Programming

Pushbuttons

5

Sensor Inputs

July, 2019

STOP sensor

In-between stop

sensor

End

sensor

YardMaster data cable

plug.

1

Advertisement

Table of Contents

Summary of Contents for RR-Concepts StationMaster-5

- Page 1 July, 2019 RR Concepts tation aster - Reversing Train Controller, V2 version This manual contains detailed hookup and programming instructions for the StationMaster - Reversing train controller. The Reversing StationMaster is similar to a standard StationMaster however it contains software to perform automatic back-and-forth operation with or without sensors.

- Page 2 RR-Concepts.com Reversing Operations - No Sensors, acceleration, deceleration. The default hookup uses diodes at the ends which will stop the train when it crosses the boundary. If desirable, LGB 10151 units can be use in place of diodes. PROGRAMMING: Best performance is achieved with the factory default settings. (See factory default programming instructions) If desired the acceleration rate and time delays can be changed.

- Page 3 RR-Concepts.com Reversing Operations - No Sensors Continued... OPERATIONS: Basically watch the train, and set the location where the deceleration should start The Reverser has a 2 step speed profile. Speed #1 is the top speed of the train set by the transformer.

- Page 4 RR-Concepts.com Reversing Operations - No Sensors Continued... Notes Most important- Always allow the trains to enter the stops on the ends before setting the TIME TO DECELERATE value (button #3). We need to record the time to start the deceleration for the full length of track.

- Page 5 RR-Concepts.com Reversing Operations using Sensors When sensors are used the StationMaster will reverse before every acceleration and ignore the next DECEL sensor it encounters after a reversal. Using sensors provides a more consistent day-to-day operation regardless of changing speeds changing trains, etc.

- Page 6 RR-Concepts.com StationMaster Basic Hookup Description The StationMaster is designed to be installed between the train transformer, and the track. Attach 1 & 2 to your transformer's DC output (Sometimes labeled as TRACK). Set your transformer’s throttle position to the desired top speed of the train. If the StationMaster does not "light up", then reverse the direction on the transformer...

-

Page 7: Sensor Descriptions

RR-Concepts.com Sensor Descriptions StationMaster In-between station stop Sensor - Only when programmed to use sensors Terminals 10 and 11 will perform an in-between station stop. When this sensor detects a magnet the StationMaster/Reverser will use a fixed deceleration and acceleration rate for a station stop.. -

Page 8: Speed Dial

RR-Concepts.com Speed Dial Speed Adjust StationMaster Programming Mode Full counter-clockwise will enter Programming Mode. When not full counter-clockwise, this dial does the following: When programed to use sensors: The top "cruising" speed of the train can be adjusted by turning the "top speed" dial. -

Page 9: Led Indicators

RR-Concepts.com LED indicators StationMaster STATUS LED SENSOR LED STATUS LED Green flashing: train is ACCELERATING. SENSOR LED Green NOT flashing: Train is AT TOP CRUISING SPEED. Orange NOT flashing, StationMaster will ignore next DECEL sensor 1. Quick Red flashing: Train is DECELERATING. -

Page 10: Deceleration Rate

RRConcepts.com Programming: Deceleration Rate Fully counter clockwise 1. Make sure all three sensor inputs are open. 2. If the top speed dial is not already at zero, then turn the top speed dial to zero. (fully counter-clockwise.) The sensor LED will turn ORANGE. 3. -

Page 11: Acceleration Rate

RRConcepts.com Programming: Acceleration Rate Fully counter clockwise 1. Make sure all three sensor inputs are open. (Red LED is off) 2. If the top speed dial is not already at zero, then turn the top speed dial to zero. (fully counter-clockwise.) The sensor LED will turn ORANGE. 3. -

Page 12: Pause Time

RRConcepts.com Programming: Fully Pause Time counter clockwise 1. Make sure all three sensor inputs are open. (red Led is off) 2. If the top speed dial is not already at zero, then turn the top speed dial to zero. (fully counter-clockwise.) The sensor LED will turn ORANGE. 3. -

Page 13: Operating Modes

RRConcepts.com Please go to RRconcepts.com to view an informational video on how to program Programming: operating modes. Orange Operating Modes HOW TO PROGRAM: (Perform a factory reset to clear everything if needed) 1. Enter Secondary Programming mode: (Skip this step if already in secondary programming mode) * Turn the Top Speed dial fully counter-clockwise to enter programming mode The sensor LED will turn ORANGE (Skip this step if already in programming mode). - Page 14 RRConcepts.com Programming: Green Train Count The train count is needed for 2 reasons: 1. Manage different creeping speeds for up to 5 trains. (sensor mode only) 2. Send proper signals to attached YardMasters to correctly fire turnouts. For example, a 3 track siding using 2 YardMasters wired in parallel would have a train count of 3, since 3 trains will be controlled.

-

Page 15: Factory Reset

RRConcepts.com Programming: Factory Reset Fully counter clockwise To set the StationMaster back to factory defaults perform the following: 1: Enter programming mode by turning the top speed dial fully counter-clockwise 2. Press and hold both button #1 AND button #3 at the same time. 3 Turn the top speed dial fully clockwise to exit programming mode. - Page 16 RRConcepts.com “Creep-Stop” Deceleration for Incredible Realism - Sensor mode only - A unique and extremely realistic feature of the StationMaster is “Creep-Stop” Deceleration. By using both a DECEL sensor and a STOP sensor the StationMaster will provide a very realistic station stop. Programming your StationMaster to use “Creep-Stop”...

- Page 17 RRConcepts.com StationMaster “Deadman Timer” A unique feature of the StationMaster is the DeadmanTimer. If a train is sensed on the track and no sensor has been detected for 10 minutes, the StationMaster will SHUT DOWN and flash both the GREEN LEDs. This prevents the condition where a train is hung up on an obstruction and spinning it’s wheels, most probably grinding a divot in the rails and wearing out wheels and gears.

- Page 18 RR-Concepts.com Electrical Details For reference only The locations of the common grounds could be useful for some wiring harnesses. + Voltage INPUT Common Ground StationMaster Common Ground Sensor Input Common Ground Output Voltage to Track Sensor Input Output Voltage to Track...

-

Page 19: Troubleshooting

Troubleshooting Problem: The StationMaster goes into shutdown mode when it should not. Background: When exiting programming mode the StationMaster turns on internal relays to short circuit the track for a brief amount of time. During this time the power entering the current sensor is measured. This is then stored as the “shutdown” current. - Page 20 RR-Concepts.com Sensor Placements on Track The suggested sensor placement on track is shown below with the train magnet installed in the center of the train. Best sensing is done with the magnet passing over the tip of the sensor. Sensor Placement for identifying a train.

Need help?

Do you have a question about the StationMaster-5 and is the answer not in the manual?

Questions and answers