YOKOGAWA FN510 User Manual

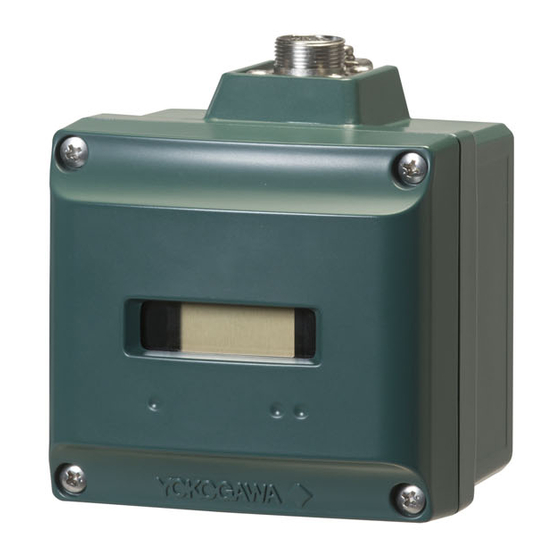

Field wireless multi-function module

Hide thumbs

Also See for FN510:

- User manual (67 pages) ,

- User manual (20 pages) ,

- User manual (77 pages)

Summary of Contents for YOKOGAWA FN510

- Page 1 User’s Manual FN510 Field Wireless Multi-Function Module IM 01W03E01-01EN IM 01W03E01-01EN 5th Edition...

-

Page 2: Table Of Contents

Installation ....................4-1 Precautions ......................4-1 Mounting ......................4-1 4.2.1 Installation of FN110 ................4-1 4.2.2 Mounting of FN510 ................4-2 Wiring ......................5-1 Notes on Wiring ....................5-1 Cable Selection ....................5-1 Installation and Connection of FN110 ............5-2 5.3.1 Installation of FN110 ................ - Page 3 Replacing the Battery Pack ................8-1 Replacing the Batteries ..................8-3 Handling Batteries .................... 8-3 Switching LCD Display ..................8-4 Replacing the FN110 ..................8-5 Replacing the FN510 ..................8-5 Replacing the Connected Device ..............8-5 8.10 Troubleshooting ....................8-5 8.10.1 Basic Troubleshooting Flow ...............

- Page 4 Toc-3 Parameter Summary ................9-1 10. General Specifications ................10-1 Revision Information IM 01W03E01-01EN...

-

Page 5: Introduction

Wireless Multi-Function Module (hereafter simply limited to those for the standard type under referred to as FN510). the specified model number break-down and do not cover custom-made products. When FN510 was precisely calibrated at the factory products whose suffix code or optional codes before shipment. To ensure both safety and contain code “Z” and an exclusive document is efficiency, please read this manual carefully before attached, please read it along with this manual. you operate this product. • Please note that changes in the specifications, FN510 works by utilizing the FN110 Field Wireless construction, or component parts of this Communication Module (hereafter simply referred product may not immediately be reflected in to as FN110). Please attach FN110 before use. this manual at the time of change, provided Table1.1 summarizes the related document list of that postponement of revisions will not cause this manual. difficulty to the user from a functional or performance standpoint. Table 1.1 Related Document List • Yokogawa assumes no responsibilities for this... -

Page 6: Safe Use Of This Product

• Repair or modification to this instrument by instructions when handling this product. If these customer will cause malfunction of explosion instructions are not heeded, the protection provided protect function and hazardous situation. If you by this product may be impaired. In this case, need to repair or modification, please contact Yokogawa cannot guarantee that this product can the nearest Yokogawa office. be safely operated. Please pay special attention to the following points: (e) Modification • Yokogawa will not be liable for malfunctions or (a) Installation damage resulting from any modification made • This product may only be installed by an to this product by the customer. engineer or technician who has an expert (f) Authorized Representative in the EEA knowledge of this product. Operators are not allowed to carry out installation unless they • The Authorized Representative for this product meet this condition. in the EEA is: Yokogawa Europe B.V. • With high process temperatures, care must... -

Page 7: Trademark And Notice

- Improper and/or inadequate maintenance by the purchaser. - Malfunction or damage due to a failure to handle, use, or store this product in accordance with the design specifications. - Use of the product in question in a location not conforming to the standards specified by Yokogawa, or due to improper maintenance of the installation location. - Failure or damage due to modification or repair by any party except Yokogawa or an approved representative of Yokogawa. - Malfunction or damage from improper relocation of the product in question after delivery. - Reason of force majeure such as fires, earthquakes, storms/floods, thunder/ lightening, or other natural disasters, or disturbances, riots, warfare, or radioactive contamination. Trademark and Notice Trademarks In this document, trademarks or registered trademarks are not marked with “™” or “®”. Product... -

Page 8: Control Of Pollution Caused By The Product

(Cr(VI)) (PBB) (PBB) (PBDE) (PBDE) 壳体(金属) 壳体(金属) × × ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ FN510 FN510 壳体(塑料) 壳体(塑料) ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ 基板组件 基板组件 × × ○ ○... -

Page 9: Notes On Handling

U-bolt F0202.ai Spring washer Figure 2.2 Nameplate Bracket fastening nut MODEL : Specified model code. F0201.ai SUFFIX : Specified suffix code. Figure 2.1 FN510 Mounting Hardware STYLE : Style code. S/N : Serial number. Table 2.1 FN510 Mounting Hardware DATE : Date of manufacture. Item SUPPLY : Supply voltage. FN510 mounting bracket TOKYO 180-8750 JAPAN: The manufacturer name FN510 fastening bolt and the address* Bracket fastening bolt “... -

Page 10: Storage

NOTE • The following temperature and humidity range is recommended. Ordinary The installation location of this product must temperature and humidity (25°C, 65%) are meet the following conditions: preferable. • Install this product to be perpendicular to the Temperature: -40 to 85°C ground. Humidity : 0 to 100% RH • When using a remote antenna cable, (no condensation) regardless of the installing direction of the 2. If at all possible, store the FN510 in factory- FN510, install the FN110 to be perpendicular shipped condition, that is, in the original to the ground. shipping container. • Install the FN110 at least 1.5 m above the 3. Preferably remove the batteries for storage. For ground or floor. maximum battery life, the storage temperature should not exceed 30°C. NOTE When storing FN510 with a battery pack, it is recommended to put the FN510 in Deep Sleep mode to conserve the batteries. For details on how to switch to Deep Sleep mode, refer to subsection 7.3.9 “Switching to the Deep Sleep... -

Page 11: Use Of A Transceiver

• When replacing the battery pack, be sure An explosion protected products is certified for to minimize the risk of explosion from installation in a hazardous area containing specific electrostatic discharge. Avoid any actions gas types. See subsection 2.6 “Installation of an that cause the generation of electrostatic Explosion Protected Instrument”. charge, such as rubbing surface of the battery pack and product with a dry cloth. Use of a Transceiver IMPORTANT CAUTION Although FN510 has been designed to resist • This instrument has been tested and certified high frequency electrical noise, if a radio as being intrinsically safe. Please note that transceiver is used near the FN510 or its severe restrictions apply to this instrument’s external wiring, the FN510 may be affected by construction, installation, external wiring, high frequency noise pickup. To test this, start maintenance and repair. A failure to abide by out from a distance of several meters and slowly these restrictions could make the instrument approach the FN510 with the transceiver while a hazard to operate. -

Page 12: Fm Approval (United States)

<2. Notes on Handling> 2.6.1 FM Approval (United States) Note 7. WARNING • A modification of the equipment would (1) Technical Data no longer comply with the construction described in the certificate documentation. Caution for FM Approval (US) Intrinsically safe type. • Only personnel authorized by Yokogawa Electric Corporation can repair the Note 1. M odel FN510 Field Wireless Multi-Function equipment Module with optional code /FS17 for • USE ONLY YOKOGAWA BATTERY PACK potentially explosive atmospheres: F9090FC or F9090GC • Applicable Standards: • THE BATTERY PACK CAN BE REPLACED FM 3600, FM 3610, FM 3810, IN A HAZARDOUS LOCATION. - Page 13 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 2020-09-11 Page Revision Date DIDO IM 01W03E01-01EN...

- Page 14 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision AI (1) Hazardous (Classified) Hazardous (Classified) Location Hazardous (Classified) Location Class I, Division 1, Location Class I, Division 1,...

- Page 15 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision AI (2) IM 01W03E01-01EN...

- Page 16 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision PULSE IM 01W03E01-01EN...

- Page 17 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision Notes: As allowable connection values of an Intrinsically Safe Apparatus (2) or (3) and (4), the following conditions of (a) or (b) must be satisfied.

-

Page 18: Fm Approval (Canada)

<2. Notes on Handling> 2.6.2 FM Approval (Canada) Note 6. Specific conditions of use • Precaution shall be taken to minimize the risk (1) Technical Data from electrostatic discharges on the non- metallic parts of the equipment. Caution for FM Approval (Canada) Intrinsically safe • The connector (FN110 terminal) on the type. enclosure contains aluminum and is considered a potential risk of ignition caused Note 1. M odel FN510 Field Wireless Multi-Function by impact or friction. When the equipment Module with optional code /CS17 for is mounted in Zone 0, it shall be installed in potentially explosive atmospheres: such a way that, even in the event of rare • Applicable Standards: incidents, an ignition source due to impact CAN/CSA-C22.2 No.0 and/or friction sparks is excluded. C22.2 No. 60079-0:19 • Rigid type conduit shall not be used as the CAN/CSA-C22.2 No. 60079-11:14... - Page 19 2-11 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 2020-09-11 Page Revision Date DIDO IM 01W03E01-01EN...

- Page 20 2-12 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision AI (1) Hazardous (Classified) Hazardous (Classified) Location Hazardous (Classified) Location Class I, Division 1, Location Class I, Division 1,...

- Page 21 2-13 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision AI (2) IM 01W03E01-01EN...

- Page 22 2-14 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision PULSE IM 01W03E01-01EN...

- Page 23 2-15 <2. Notes on Handling> Yokogawa Electric Corporation FN510, FN310 (Modbus) Model Control drawing of FN510 (FN510-xx-AxxA, US / Canada) Title IFM045-A81 Page Revision Notes: As allowable connection values of an Intrinsically Safe Apparatus (2) or (3) and (4), the following conditions of (a) or (b) must be satisfied.

-

Page 24: Atex Certification

2-16 <2. Notes on Handling> 2.6.3 ATEX Certification WARNING / AVERTISSEMENT (1) Technical Data • DANGER POTENTIEL DE CHARGES Caution for ATEX Intrinsically safe type. ÉLECTROSTATIQUES - QUAND LE MATÉRIEL EST Note 1. M odel FN510 Field Wireless Multi-Function UTILISÉ DANS DES ENDROITS Module with optional code /KS27 for DANGEREUX, ÉVITER TOUTE potentially ACTION QUI GENERENT CHARGES explosive atmospheres: ELECTROSTATIQUES, COMME • Certificate number: FM15ATEX0071X FROTTANT AVEC UN CHIFFON SEC • Applicable Standards: • QUAND LE MATÉRIEL EST UTILISÉ DANS EN IEC 60079-0, EN 60079-11, LA ZONE 0, IL DOIT ÊTRE INSTALLÉE... - Page 25 IS Apparatus (4) Ui, Ii, Pi, Ci, Li Co ≥ Ci + Ccable or Simple Apparatus Lo ≥ Li + Lcable connected to the terminal 3, 4 Terminal Intrinsically Safe FN510 Associated Apparatus (2) Sensor Apparatus (1) Field Wireless (**) IS Apparatus (Load)

- Page 26 2-18 <2. Notes on Handling> Note 4. B attery Pack (2) Operation • Use only YOKOGAWA battery pack F9090FC or F9090GC. WARNING WARNING Take care not to generate mechanical sparking when access to the instrument and peripheral • Be sure to use the specified battery pack devices in a hazardous location. and batteries. For details, refer to section 8.5 POTENTIAL ELECTROSTATIC CHARGING “Handling Batteries.” HAZARD • With an intrinsically safe Products, the In hazardous areas, avoid any actions which battery pack is replaceable in a hazardous generate electrostatic charges, such as rubbing area. During the replacement work, make the equipment with a dry cloth. sure that dust and water droplets do not To prevent electrostatic discharge caused by enter inside the Products. For details on how...

-

Page 27: Iecex Certification

2-19 <2. Notes on Handling> (3) Maintenance and repair 2.6.4 IECEx Certification (1) Technical Data WARNING Caution for IECEx Intrinsically safe type. The instrument modification or parts replacement by other than an authorized Representative of Note 1. M odel FN510 Field Wireless Multi-Function Yokogawa Electric Corporation is prohibited and Module with optional code /SS27 for will void the certification. potentially explosive atmospheres: • A modification of the equipment would • Certificate number: IECEx FMG 15.0042X no longer comply with the construction • Applicable Standards: described in the certificate documentation. - Page 28 IS Apparatus (4) Ui, Ii, Pi, Ci, Li Co ≥ Ci + Ccable or Simple Apparatus Lo ≥ Li + Lcable connected to the terminal 3, 4 Terminal Intrinsically Safe FN510 Associated Apparatus (2) Sensor Apparatus (1) Field Wireless (**) IS Apparatus (Load)

- Page 29 2-21 <2. Notes on Handling> Note 4. B attery Pack (2) Operation • Use only YOKOGAWA battery pack F9090FC or F9090GC. WARNING WARNING Take care not to generate mechanical sparking when access to the instrument and peripheral • Be sure to use the specified battery pack devices in a hazardous location. and batteries. For details, refer to section 8.5 POTENTIAL ELECTROSTATIC CHARGING “Handling Batteries.” HAZARD • With an intrinsically safe products, the battery In hazardous areas, avoid any actions which pack is replaceable in a hazardous area. During generate electrostatic charges, such as rubbing the replacement work, make sure that dust and the equipment with a dry cloth. water droplets do not enter inside the products. To prevent electrostatic discharge caused by For details on how to replace the battery pack, static charge built up on the operator, ground the refer to section 8.3 “Replacing the Battery Pack.” operator through conductive shoes and floors and by wearing antistatic work clothes to prevent Note 5. S pecific conditions of use charge build-up.

-

Page 30: Emc Conformity Standards

(1) Pollution Degree 2 Yokogawa Electric Corporation is prohibited and “Pollution degree” describes the degree to which will void the certification. a solid, liquid, or gas which deteriorates dielectric • A modification of the equipment would strength or surface resistivity is adhering. “2” no longer comply with the construction applies to normal indoor atmosphere. Normally, described in the certificate documentation. only non-conductive pollution occurs. Occasionally, • Only personnel authorized by Yokogawa however, temporary conductivity caused by Electric Corporation can repair the condensation must be expected. equipment • USE ONLY YOKOGAWA BATTERY PACK (2) Installation Category I F9090FC or F9090GC “Overvoltage category (Installation category)” • THE BATTERY PACK CAN BE REPLACED describes a number which defines a transient IN A HAZARDOUS LOCATION. THE overvoltage condition. It implies the regulation for... -

Page 31: Component Names

Frame Ground * Signal Ground Power Supply Integral indicator Transmit/Receive Data positive Transmit/Receive Magnet switch 1 Data negative * W ired to the grounding terminal inside the FN510 housing. ** C onnector type of FN510: Magnet switch 2 JR13WRI-5S (connector mating with type of JR13WPI-5P) F0301.ai Battery terminal Grounding terminal Slide switch... -

Page 32: Installation

The FN110 terminal is covered with a cap during The installation procedure is as follows. shipping. Keep the cap attached until connecting 1. Check the direction of the pin, connect FN110 the FN110 or remote antenna cable to protect to FN510. the inside connection part. The unscrewed 2. Tighten the lock nut to torque of 1.2 N•m. cap should be stored in order to replace it Removal is the reverse procedure of the installation. immediately after the FN110 or remote antenna cable is removed. If there is a possibility that get wet with water, order FN510 with optional specification for a protection cap. Lock nut Installation Work • When performing on-site pipe fitting work that involves welding, use case to prevent the welding current to damage the FN510. • Do not use the FN510 as a foothold. NOTE • Before using FN510, install FN110. For detail on how to install FN110, refer to subsection 4.2.1 “Installation of FN110”. F0401.ai • To connect FN510 to the field wireless... -

Page 33: Mounting Of Fn510

“Installation and Connection of FN110”. • Remove the battery pack before installing FN110. Refer to subsection 8.3 “Replacing the Battery Pack” for the battery pack removing. • When installing FN110, fix the FN110 by tightening the lock nut. Screwing by holding the FN110 housing may cause failure such as cable disconnection. The same manner should be taken when removing the FN110. 4.2.2 Mounting of FN510 Bracket fastening bolt FN510 fastening bolt FN510 mounting bracket U-bolt nut Spring washer Bracket fastening nut 2-inch pipe U-bolt F0402.ai Figure 4.2 Vertical Pipe Mounting... - Page 34 Spring washer Bracket fastening nut 2-inch pipe U-bolt F0403.ai Figure 4.3 Horizontal Pipe Mounting To install FN510 on a 50A (2-inch) pipe, follow the procedure below. 1) Assemble the FN510 mounting bracket. 2) Install FN510 to the mounting bracket using provided bolt (4) with a torque 1.4 N•m. 3) Install FN510 mounting bracket to the 2-inch pipe by U-bolt. IM 01W03E01-01EN...

-

Page 35: Wiring

<5. Wiring> Wiring Notes on Wiring Cable Selection For wiring the sensor and the FN510, use a IMPORTANT shielded multi-core cable of AWG22 to 14. • Apply a waterproofing sealant to the threads Applicable Cables of the connection port. (It is recommended Cables for industrial equipment such as; that you use non-hardening sealant made of • Control cables: JIS C 3401 silicon resin for waterproofing.) Use the following grounding cable. • Lay wiring as far away as possible from electrical noise sources such as large Applicable Cables transformers, motors and power supplies. Insulated cables for industrial equipment such as; • Remove the wiring connection dust-caps • 600V polyvinyl chloride insulated wires (IV); JIS... -

Page 36: Installation And Connection Of Fn110

3) Protect the connection as necessary. For cable to protect the inside connection part. The details of the protection, refer to subsection unscrewed cap should be stored in order to 4.2.1 “Installation of FN110”. replace it immediately after the FN110 or remote 4) Fix the FN110 to the mounting bracket. antenna cable is removed. If there is a possibility that get wet with water, order FN510 with FN110 holder bolt optional specification for a protection cap. FN110 FN110 mounting bracket 5.3.1 Installation of FN110 FN110 holder Location of FN110 Mount the FN110 at the proper location according to the wireless environment described in subsection Remote 2.4 “Selecting the Installation Location”. The... -

Page 37: Installation Of Fn110

5.3.2 Connection of FN110 Cable To install FN110 with remote antenna cable, follow the procedure below. Strip the insulated cover of the cable end. Remove the battery pack from FN510 before 5.4.1 Connecting Input Terminal and connecting the remote antenna cable. Grounding Terminal 1. Connect the FN110 and the FN510 with the dedicated remote antenna cable. Tighten the Vertical Connection connector of the remote antenna cable with a After stripping the insulated cover, keep a length torque of 1 to 1.2 N•m. The minimum bending of about 50mm for input signal cables, and about radius should be more than 100 mm. 65mm for grounding cable. 2. Protect the connectors of the FN110 and remote antenna cable as necessary. For details... - Page 38 <5. Wiring> Wiring to Input Terminals:1 (with sleeve) IMPORTANT The sleeve can prevent cable leads from untwist when you connect the cable. Select a sleeve to When using a cable gland, apply a water match the cable size. If the length of cable leads proofing sealant to the threads of the cable does not match the length of sleeve (l ), strip the gland. (It is recommended that you use non- cable to the correct length. Strip the cable for a hardening sealant made of silicon resin for length so that the core wire slightly extends from the waterproofing.) metal tube of the sleeve. If this causes the length of the metal tube of the sleeve to be slightly shorter Input Terminal than the stripping length, this is no problem. The wiring cables and applicable sleeves are listed Input terminal is a spring terminal. When using a in the table below. Use the same manufacturer for solid conductor cable or with sleeve, connect the sleeves and tools. cable to the input terminal. When using a standard Example of tool: Phoenix Contact’s CRIMPFOX6 conductor, push down the top of a cable inlet and For details on sleeves and crimp tools, contact to insert the cable. To unplug the cable, push down the Phoenix Contact Inc.

- Page 39 – devices. 4-20mA External Analog Power – Device Source F0510.ai NOTE Strip the insulated cover of the input cable inside the FN510 so as not to interfere with the battery pack. DIDO Load Dry contact + – Wiring to Ground Terminal External Power Protect the cable of the ground terminal by using Source F0511.ai heat-shrink tubing, etc. Use a ring tongue terminal for M4 terminals with an insulation sleeve.

-

Page 40: Grounding

<5. Wiring> Grounding Input Cable Wiring The input cable shield should be connected to Class D grounding with the grounding resistance grounding terminal inside of the housing. of 100Ω or less is necessary. To connect the • The input cable shield should not be connected grounding cable to FN510 directly, use the ground to grounding terminal inside of the connected terminal on the top of the housing. sensor. Do not share the ground wiring with other devices. • Connection to the ground terminal of the connected device housing, refer to the User's Ground Wiring Manual. Connect the grounding cable to ground terminal on IMPORTANT the top of the housing. Grounding terminal Proper grounding is necessary to maintain the function and performance of this product. When the grounding is inadequate, the equipment may be damaged. Refer to TI 01W01A58-01EN for details of grounding method and precautions. -

Page 41: Operation

(2) Power On and Connecting to the Field display of the integral indicator or the device Wireless Network configuration tool, refer to subsection 8.10.3 “Errors and Countermeasures” for the corrective Insert batteries into the battery case, and install action. to the FN510. For details of installation of battery, refer to subsection 8.3 “Replacing the Battery Pack” and subsection 8.4 “Replacing the Batteries”. Verify and Change the FN510 Setting and Provisioning is to set the security and network Values information. For details of provisioning, refer to The followings are the required settings of the section 6.3 “Connecting to the Field Wireless... -

Page 42: Connecting To The Field Wireless Network

Preparation Work Prior to Connecting to a Provisioning work performs provisioning for each Field Wireless Network field wireless device using FieldMate and an infrared adapter. FN510 does not need to be connected with a When using the Yokogawa recommended near physical wire. Instead of physical wiring, to set infrared adapter for the provisioning device, the security and field network information is required. distance between the front panel of this product This procedure is called a provisioning. and the infrared surface of the near infrared FN510 supports provisioning via infrared adapter should be within 30 cm. For details on the communication using a provisioning device and Yokogawa recommended infrared adapter, refer to can be securely connected to a network. If the subsection 8.2 “Recommended Products List”. provisioning information is not set, the FN510 Perform the following provisioning tasks. cannot be connected to the field wireless network. • Setting provisioning information NOTE • Creating a provisioning information file (1) Setting provisioning information Before provisioning, connect the FN110. For... - Page 43 (Disconnect) (Connect) F0607.ai (Connect) Figure 6.7 Display showing Join State Confirm connecting status: Join (c) Operation (d) NOTE (Publish) F0603.ai If the FN510 searches the field wireless network * B y using a magnet switch or field device configuration tool, transitions to the Deep sleep state from any state. for long time low ambient temperature condition, Figure 6.3 Wireless Status Transition sometimes error “AL.20 LOWBAT” is displayed on the integral indicator. It occurs because of (a) Deep Sleep battery characteristics even when using new batteries. After joining to the field wireless network, this error will be cleared within one hour if battery has no failure.

-

Page 44: Display Contents Of The Integral Indicator

Process Value Shutting Down The process value obtained from the sensor is When shut down the FN510, remove the battery displayed. For detail information about the display pack or set the FN510 to deep sleep mode by the settings, refer to section 7 “Setting Parameters”. device configuration tool or magnet switch. When sensor data is more than five orders of magnitude, scroll automatically after 2 seconds. NOTE • Refer to subsection 8.3 “Replacing the Battery Pack” for the battery pack removing. • When storing the FN510 with a battery pack inserted, it is recommended to put the FN510 into deep sleep mode to conserve battery power. For details on how to switch to F0608.ai deep sleep mode, refer to subsection 7.3.9 Figure 6.8 Example of Data Scrolling “Switching to the Deep Sleep Mode”. When publish is not configured, following is displayed. F0609.ai Figure 6.9 Display when Publish is not Configured... -

Page 45: Setting Parameters

<7. Setting Parameters> Setting Parameters Preparing Software FN510 can remotely handle sensor type changes, Tag No. setup, monitoring of self-diagnostic results, according to communication with the field wireless 7.2.1 Softwares for the Field Wireless configuration tool or the device configuration tool. Configuration Tool and the Device Configuration Tool Preparation for Parameter Before using the device configuration tool, confirm Setting that CF/DD and DeviceDTM for this product are installed in the device configuration tool. This product can be set parameters via infrared port Refer to the following website for the latest or field wireless network. information on CF/DD and DeviceDTM. When setting parameters via field wireless network, <http://www.field-wireless.com/> connect this product to the field wireless network. -

Page 46: Parameter Usage And Selection

<7. Setting Parameters> Setting Parameters 7.3.1 Parameter Usage and Selection Before setting a parameter, please see the following table for a summary of how and when each parameter is used. IMPORTANT After setting and sending data with the field wireless configuration tool or the device configuration tool, wait 30 seconds before turning off the FN510. If it is turned off too soon, the setting will not be stored in the FN510. Table 7.1 Parameter Usage and Selection Item Description Tag No. Sets the Tag No. for Device Tag (software tag). The Tag No. can be set sixteen characters (alphanumeric characters, including – ). Output mode Allows outputting process value and self-diagnostic information via field wireless network. -

Page 47: Function Block And Menu Tree

<7. Setting Parameters> 7.3.2 Function Block and Menu Tree (1) Function Block The function of FN310 is shown below. Some functions may not be available depending on the device configuration tool used. When the device configuration tool of our recommendation is used, the software attached to the Field Wireless Integrated Gateway or Field Wireless Management Station is necessary for setting the dotted line part. Refer to subsection 8.2 “Recommended Products List” for the field wireless configuration tool of our recommendation. Menu (Online) (UAPMO) (Configuration) • UAPMO • UAPMO • Configuration • UAP Option • UDO • UDO • Diagnostics • Hardware Write Protect •... - Page 48 <7. Setting Parameters> Menu (Online) (Continued) (TRANSDUCER) (Block Info) • Tag Description • Block Info • Configuration/Calibration (Configuration/Calibration) • Others • Model • Serial Number • Wireless Status • Display Selection • LCD Intermittent Time • LCD Exp Mode • Measurement Rate •...

- Page 49 <7. Setting Parameters> (2) Menu Tree The menu tree of our recommended device configuration tool is shown below. Refer to subsection 8.2 “Recommended products list” for the device configuration tool of our recommendation. (Device Configuration) (UAPMO) (Configuration/Setup) Online Menu • Device Configuration • UAPMO • Configuration/Setup • UAP Option • Diagnostics • TRANSDUCER • Hardware Write Protect • Process Variable • AI1 • Static Revision •...

- Page 50 <7. Setting Parameters> Online Menu Device Configuration (Continued) (Continued) (Block Info) (BI1/BI2) • Configuration/Setup • Tag Description (Block Mode) • Mode.Target • Mode.Actual • Mode.Permitted • Mode.Normal (Configuration) (Block Mode) • Block Mode • Mode.Target • Concentrator OID • Mode.Actual •...

-

Page 51: Parameters For Wireless Communication

<7. Setting Parameters> 7.3.3 Parameters for Wireless NOTE Communication When the FN510 detects AL.01, AL.02 and (1) Network Information AL.03 error, the LCD display does not dim CO block: Configuration regardless of the status in LCD mode. See Table The network-related information can be checked. 8.4 for details. DIS block: Configuration Information related to the communication handled 7.3.4 Tag and Device Information by DO can be checked. You can specify the Device Tag when ordering (2) Update Time the corresponding FN110 Field Wireless CO block: Data publication period Communication Module. DIS block: Data publication period Device Tag and device information can be checked For AI, DI Pulse Count, and DI, set the update time as follows. -

Page 52: Parameters For Each Sensor Type

<7. Setting Parameters> 7.3.7 Parameters for each Sensor Type IMPORTANT Setting parameters are different by the Sensor Type. • When restart FN510 by removing the battery pack, output value follows the specified DI Pulse Count Options parameter in the BO1 block. • When switching to the deep sleep mode or AI1 block: Reset Pulse Count silence mode, FN510 holds the output value When this parameter is set to Reset, DI Pulse set from field wireless gateway just before Count value will be reset if the Sensor Type is set to or specified Options parameter in the BO1 DI Pulse Count. The count range is 0 to 999999. -

Page 53: Switching To The Silence Mode

<7. Setting Parameters> 7.3.10 Switching to the Silence Mode Magnet Switch Operation Procedures for switching to the deep sleep mode This is a function to pause the FN510 when it using a magnet switch are as follows. cannot join the field wireless network after a 1. Touch the magnet switch 1 for 5 seconds by a specified time has elapsed. This function is effective magnet (LCD displays “SLEEP” flashing). in conserving battery power when, for example, 2. Touch the magnet switch 1 for an additional 5 the installation of the Field Wireless Integrated seconds by a magnet (LCD displays “SLEEP”). Gateway is delayed compared to that of field 3. Touch the magnet switch 2 within next 5 wireless devices. When the FN510 fails to search seconds by a magnet. the network for about 120 minutes, it switches to silence mode automatically. Thereafter, a cycle Write Parameter... -

Page 54: Self-Diagnostics

7-10 <7. Setting Parameters> Self-Diagnostics NOTE 7.4.1 Identify Problems by Using the Be careful when changing the alert category and Device Configuration Tool turning detection on and off as described above. Be sure to set UAP Option Enable diagnostic The device configuration tool allows checking the status configuration to disable again to prevent self-diagnostic results and settings of the FN510. setting errors. First, check Diagnostic Status of the self-diagnostic results. 7.4.2 Alert Report Procedure to Call Up the Self-Diagnostic Parameter FN510 generates alert information related to Diagnostic Status and automatically sends to a field UAPMO block: Diagnostic Status wireless gateway. To use this function, the following Any of the four categories (Function check, alert setting is necessary. When “Out of Service” for Maintenance required, Failure, and Out of Diagnostic Status alert is required, choose “FALSE”... -

Page 55: Checking With Integral Indicator

7-11 <7. Setting Parameters> 7.4.3 Checking with Integral Indicator NOTE If an error is detected by running self-diagnostics, an error number is displayed on the integral indicator. If there is more than one error, the error number changes at 2 seconds interval. See table 8.4 regarding the alarm codes. F0706.ai Figure 7.2 Error Check with Integral Indicator Table 7.4 Diagnostic Status NAMUR NE107 Bits Contents Categorization* Bit31(MSB) F:Failure status Bit30 C:Function check status Bit29 O:Out of specification status Bit28 M:Maintenance required status Bit27 Faults in electronics... - Page 56 Table 7.5 Diagnostic Results Summary NAMUR Diagnostic Status Alert NE107 Diagnostic Status Detail Description Contents Type Category* Faults in electronics ADAPTER FAIL FN510 failure ANTENNA FAIL FN110 failure INTERNAL BUS FAIL Communication failure between FN110 and FN510 Faults in sensor or SENSOR FAIL Communication failure between FN510 actuator element and connected devices mA_FAIL mA value is in the following range, which is not within the specification.

-

Page 57: Maintenance

Recommended Products List dry cloth. If static electricity cannot be suppressed, Yokogawa-recommended Instrument check that the surrounding atmosphere does Provisioning Device Tool • FieldMate (R2.03 or later) not contain explosive gas or steam before • P rovisioning Device Tool replacing the Battery Pack. • I nfrared Adapter certified by Yokogawa • Be sure to use a battery pack that is Supplier: ACTiSYS Product name: IrDA InfraRed USB Adaptor indicated as “Rev.1” or higher for explosion Product number: IR224UN-LN96 (9600bps) protected instruments. Field Wireless Configuration Tool • F ield Wireless Integrated Gateway attached Software Field Wireless Configurator Field Wireless Management Tool •... - Page 58 <8. Maintenance> Removing Remounting 1. Loosen the four screws on the front panel. 1. Insert the new battery pack. The orientation of 2. Pull the lever in the direction of the arrow in the battery pack, “PART NO.” display is the front Figure 8.1. and connector cable is left side. 3. Pull out the battery connector from the front 2. Plug the battery connector into the terminal panel back. on the front panel back. Connect facing down 4. Pull the battery pack. the white surface of the connector. Push the connector until it touches the back of the front panel then slide it to the left. 3. Push the lever in the direction of the arrow in Figure 8.2. 4. Close the front panel and tighten the four screws to a torque of 0.7 N • m.

-

Page 59: Replacing The Batteries

<8. Maintenance> Replacing the Batteries Handling Batteries The batteries in the battery pack can be replaced. This battery pack uses two primary lithium- Batteries are not installed when shipped from the thionyl chloride batteries. Each battery contains factory. Assemble the battery pack as follows. approximately 5 grams of lithium, for a total of 10 grams in each pack. Under normal conditions, WARNING the battery materials are self-contained and are not reactive as long as the batteries and the pack Be sure to replace the batteries or open and close integrity are maintained. Care should be taken to the battery pack in a non-hazardous area. Doing prevent thermal, electrical or mechanical damage. so in a hazardous area could cause an explosion. Protect the electrode of the battery pack to avoid rapid electrical discharge. Discharged a battery may lead to fluid leakage and excessive heat. Batteries CAUTION should be stored in a clean and dry area. For maximum battery life, storage temperature should When replacing the batteries, be sure to replace not exceed 30°C. the two batteries at the same time and do not use an old and a new battery together. WARNING ... -

Page 60: Switching Lcd Display

<8. Maintenance> Switching LCD Display Batteries Part number: F9915NR The process value and the wireless communication Alternatively, following batteries may be purchased status are displayed on the LCD by touching a and used. magnet to the magnet switch1. The contents of the • Tadiran TL-5930/S or SL-2780/S display changes as follows every two seconds. • VITZROCELL SB-D02 If the Sensor Type in TRANSDUCER block is set to DIDO; Transportation of products containing lithium 1. Wireless Communication Status. See Table 8.2. batteries 2. Object Name (BI1) Batteries used for this product contain lithium. 3. Process Value Binary of BI1 block Primary lithium batteries are regulated in 4. Object Name (BI2) transportation by the U.S. Department of 5. Process Value Binary of BI2 block Transportation, and are also covered by the 6. Object Name (BO1) International Air Transport Association (IATA), the... -

Page 61: Replacing The Fn110

Performing provisioning work is necessary when FN510 is equipped with a self-diagnostic function replacing the FN110. Update the configuration which will be useful in troubleshooting, and this information of the target device by using field product is equipped with an integral indicator wireless configuration tool. For details of and it will show an alarm code as a result of self- provisioning, refer to subsection 6.3 “Connecting to diagnosis. the Field Wireless Network”. See subsection 8.10.3 “Errors and Countermeasures” for the list of alarms. Replacing the FN510 : Areas where self-diagnostic This subsection describes the procedure for offers support replacing the FN510. Replace the FN510 as follows. Abnormalities appear in 1. Back up the configuration of the FN510. measurement Measurement 2. Remove the battery pack. system problem 3. Remove the FN110 and the connected device, Is process variable and install them to the new FN510. -

Page 62: Example Of Troubleshooting Flow

<8. Maintenance> 8.10.2 Example of Troubleshooting Flow The following shows an example of the flow for troubleshooting. Refer to this example and Table 8.3. Locate the problem and take the corresponding countermeasure. The following phenomena indicate that this instrument may be out of operation. [Example] • No output signal is delivered. • Process variable changes but the output signal remains unchanged. •... -

Page 63: Errors And Countermeasures

Output NE107 Cause conditions Action indicator Status Status Detail Operation category * (except restart) * AL.01 * 27 Faults in ADAPTER FAIL FN510 None Output value: Contact electronics failure Hold previous Yokogawa value service AL.02 * ANTENNA FAIL FN110failure Output status: personnel. BAD Device AL.03 *... - Page 64 FN510 Recovers Normal action Check the conditions TEMP HI temperature when the ambient out of device is above temperature temperature specification +85°C returns to of the FN510 +85°C below ADAPTER FN510 Recovers TEMP LO temperature when the is below temperature -40°C returns to -40°C or more ANTENNA...

- Page 65 Refer to Table W(P) Configuration Status when Enable diagnostic status configuration 9.2. in UAP Option is set to Enable. 0x08: F:Failure status 0x04: C:Function check status 0x02: O:Out of specification status 0x01: M:Maintenance required status Find Device When set a value other than 0, FN510 displays “Squ.” on the LCD. The value means the display duration. After displaying, this value returns to 0. Unit: second Range: 0 to 60 IM 01W03E01-01EN...

- Page 66 Energy Harvest Available to write note into this parameter. W(P) Type Power Supply Indicates the measured power supply voltage (V). Voltage Hardware Write Indicates the status of the hardware write protection Protect switch. 0: Off 1: On Antenna Indicates the temperature of the FN110. Temperature Adapter Indicates the temperature of the FN510. Temperature Temperature Selects the temperature unit to be indicated on °C W(P) Unit Antenna Temperature and Adapter Temperature. 1000: K 1001: °C (default) 1002: °F 1003: °R Other Faults The On/Off or priority for Other Faults Alert can be 1. Off W(P) Alert set.

- Page 67 <9. Parameter Summary> Object Attribute Handling Label Description Default value Power Low Alert The On/Off or priority for Power Low Alert can be 1. Off W(P) UAPMO set. 2. 15 block 1. On/Off setting (continued) 0: On, 255: Off (default) 2. Alert report priority: 0 to 15 (default: 15) Power Critical The On/Off or priority for Power Critical Low Alert 1. Off W(P) Low Alert can be set. 2.

- Page 68 3. Actual_Phase PUB_ITEM_ Maximum PUB_ITEM value. PUB_ITEM_ PUB_ITEM number. PUB_ITEM Indicates the PUB_ITEM information. The following shows the components. 1. ObjectID 2. AttributeID 3. AttributeIndex 4. Size Tag Description Memo field available to write anything. Transducer W(P) TRANSDUCER Model Indicates the model name of the FN510. block Serial Number Indicates the serial number of the FN510. Display Select PV Value displaying on the integral indicator. W(P) Selection Following value can be selected depending on the Sensor Type. SensorType Value DIDO 32:BI1(Default) 33:BI2 64:BO1 DI Pulse Count 0:AI1(Default) 4-20mA...

- Page 69 Bit0 Join status 0: Idle 1: Joined Measurement Indicates the publish period. Rate Unit: second Special Cmd Special function parameter. Normal mode 0: Normal mode (default) 1: Deep-sleep mode Sensor Type Select the type of sensor to be connected to the DIDO W(P) FN510. 40: DIDO (default) 41: DI Pulse Count 44: 4-20 mA 45: Not Used REVISION Indicates the revision number such as COMM_ ENDPOINT, etc. block COMM Indicates the Endpoint information. The following ENDPOINT shows the components. 1. Network address of remote endpoint 2. Transport layer port at remote endpoint 3. Object ID at remote endpoint 4. Stale data limit 5. Data publication period...

- Page 70 <9. Parameter Summary> Object Attribute Handling Label Description Default value Process Value Output object of AI1(DI Pulse Count or 4-20 mA). 1. --- 1. Value: output value of the object. 2. --- block 2. S tatus: indicates the status of the object’s output value. Block Mode Select the block’s operation status. O/S and Auto 1. Auto W(P) can be selected. 2. Auto 1. Target: Specify object mode of the object. 3. O/S|Auto 2. Actual: Indicates current mode of the object. 4. Auto 3. P ermitted: Indicates the mode selected by Target of the object. 4. N ormal: Indicate normal status mode of the object.

- Page 71 <9. Parameter Summary> Object Attribute Handling Label Description Default value Process Value Output object of BI1 and BI2. 1. --- 1. Discrete Value: output value of the object. 2. --- block 0: Off(Open), 255: On(Close) 2. D iscrete Status: indicates the status of the object’s output value. block Block Mode Select the block’s operation status. O/S and Auto 1. Auto W(P) can be selected. 2. Auto 1. Target: Specify object mode of the object. 3. O/S|Auto 2. Actual: Indicates current mode of the object. 4. Auto 3. P ermitted: Indicates the mode selected by Target of the object.

- Page 72 <9. Parameter Summary> Object Attribute Handling Label Description Default value Options Option parameter for the object 1.Normal W(P) 1. Invert 2.Off Block 0: Normal(default), 3.Off (continued) 1: Invert(Inverts the output value) 2. Fault State supported 0: Off(default), 1: O n(Sets Fault Status Value to the input on detection of device failure or Stale Limit) 3. Use Fault State Value 0: Off(default), 1: O n(Sets Fault Status Value to the input at startup.)

- Page 73 <9. Parameter Summary> BI Object (BI1/BI2 block) BI algorithm Mode and PV_B.Status Operator Mode.Target handling PV_B Simulate Switch PV_B Publish Simulate Value Invert PV_B Transducer Auto Options.Invert F0902.ai Figure 9.2 Example schema of Binary Input Object BO Object (BO1 block) BO algorithm Operator Mode.Target...

- Page 74 9-10 <9. Parameter Summary> Table 9.2 Diagnostic Status Detail Diagnostic NAMUR Diagnostic Status Detail Description status NE107 assignment bit Category Diagnostic Status Detail.1 ADAPTER FAIL FN510 failure Bit27 ANTENNA FAIL FN110 failure Bit27 INTERNAL BUS FAIL Communication failure between FN110 and Bit27 FN510 SENSOR FAIL Disconnection or communication error, Bit26 between the connected device and FN510 BO_STALE_LIMIT_FAIL Detect Stale Limit...

- Page 75 Document Title Document No. YFGW410 Field Wireless Management Station GS 01W02D01-01EN YFGW610 Field Wireless Media Converter GS 01W02D02-01EN YFGW510 Field Wireless Access Point GS 01W02E01-01EN YFGW520 Field Wireless Access Point GS 01W02E02-01EN FN110 Field Wireless Communication Module GS 01W03B01-01EN FN310 Field Wireless Multi-Protocol Module GS 01W03D01-01EN FN510 Field Wireless Multi-Function Module GS 01W03E01-01EN LN01 Piezoelectric Accelerometer (for FN series) GS 01W03H01-01EN LN90 Interface Adapter GS 01W03L01-01EN YTMX580 Multi-Input Temperature Transmitter GS 04R01B01-01EN If you cannot find it on our website, please contact YOKOGAWA office. IM 01W03E01-01EN...

- Page 76 Rev-1 Revision Information Title : FN510 Field Wireless Multi-Function Module Manual No. : IM 01W03E01-01EN Edition Date Page Revised item Dec. 2014 ― New Publication May 2016 ― Add FM Approvals (United States and Canada) and IECEx Certification. July 2016 ― Add ATEX Certification and Canadian Safety Standards Apr. 2017 Add section 1.3 and 1.5 ― Change title of section 7.3.7 Update CE Conformity (RoHS) July 2021 ―...

Need help?

Do you have a question about the FN510 and is the answer not in the manual?

Questions and answers