Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Parker HB632

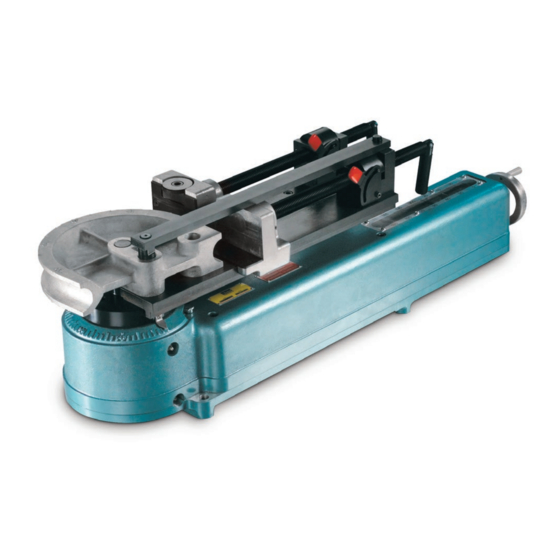

- Page 1 Hydraulic Tube Bender Model HB632 Bulletin 4391-B26...

-

Page 2: Table Of Contents

Offer of Sale The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed by the provisions stated in the “Offer of Sale”. -

Page 3: Introduction

Table 2 – Tube Benders Maximum Capacity Guide * See page 3 for pipe bending capabilities Specifications: 8) The HB632 is capable of bending 1/2" O.D. and 1) Min. tube size 3/8" 2) Max. tube size 2" under fully annealed steel and stainless steel tubing 3) Min. -

Page 4: Bender Parts And Accessories

It keeps the mandrel and rod in align- ment when mandrel bending. The stop screws can be adjusted for correct length and positioning of the mandrel in the tubing. Part No. 631141 – HB632 Mandrels, Mandrel Rods and Rod Stop Description Part No. Assembly... -

Page 5: Radius Blocks

— — 0.840 974326 2-5/8 ***Note: Size 38mm close bend radius blocks requires removal of the clamp 1.050 974327 3-1/4 arm before installation. 974328 1.315 1-1/4 1.660 974329 1-1/2 1.900 974330 Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd... -

Page 6: Side Blocks

3/8, 1/2, 3/4 0.675, 0.840, 1.050 974332 3/8, 1/2, 3/4 0.675, 0.840, 1.050 974336 1.315 974338 1.315 974340 1-1/4 1.660 974341 1-1/4 1.660 1-1/2 1.900 974342 1-1/2 1.900 974343 Clamp Block Slide Block Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd... -

Page 7: Medium To Heavy Wall Tube Bending

Connect the hose assembly (part no. bender table and bolt securely in place. The 910004) to the pump (3/8" NPT end) and Parker bender table has pre-drilled holes for then connect hose to the bender. Be careful bender attachment. not to twist the hose when tightening. Use a pipe sealant on the pipe threads. - Page 8 The clamp block and the bender. slide block should not be touching. For 180° bends, position the mark similar to 90° bends. On long lengths of tubing, support is recommended to prevent sag. Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd...

- Page 9 Your tubing is bent, without flattening or cracking. Releasing system pressure by opening the valve will relieve tension in the bender and the clamp arm will return to its original position. Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd...

-

Page 10: Thin Wall Tube Bending With Mandrel Equipment

O.D. and rod during the bending process.) Since mandrel equipment must be accurately aligned The Parker bender table has pre-drilled holes for the and rigidly held, we recommend the use of the bender bender and rod stop assembly attachment. These table. - Page 11 Step 4: Insert the Tube First lubricate the mandrel with light lubricat- ing oil. Then, slip the tube over the mandrel. Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd...

- Page 12 Then release the system pressure by opening the valve. The clamp arm will return to the starting position. Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd...

-

Page 13: Parts Schematic

502-G Oil Hole Cover, 5/16" diameter Radial Pointer 631136 13179 #6-32 x 1/4" Round Head Screw 13359 1/8" NPTF Grease Fitting *Contact the Tube Fittings Division for repair. Phone: (614) 279-7070. Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd... - Page 14 Dowel Pin, 1/4" dia. x 3/4" long 631103 Vise Adjusting Screw Vise Adjusting Screw Handle 522196 5/32 X 7/8 ROLL PIN Roll Pin, 5/32" dia. x 7/8" long (Table continued on the following page) Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd...

- Page 15 18, 19, 26-28, Clamp Arm Bracket Sub-Assembly 660223 30-33, 43, 44, 47 18, 19, Slide Arm Bracket Sub-Assembly 13388 26-33, 47 *Contact the Tube Fittings Division for repair. Phone: (614) 279-7070. Parker Hannifin Corporation Tube Fittings Division Columbus, OH www.parker.com/tfd...

-

Page 16: Maintenance

(see Parts List). For repair of internal working condition. parts, the bender must be returned to Parker Hannifin Tube Fittings Division. Please contact the Division (614- Visually check all hydraulic connections regularly for 279-7070) before sending the bender back for repair.

Need help?

Do you have a question about the HB632 and is the answer not in the manual?

Questions and answers