Allen-Bradley PowerFlex 755T Frame 5 Installation Instructions Manual

Marine discharge kits

Hide thumbs

Also See for PowerFlex 755T Frame 5:

- User manual (193 pages) ,

- Installation instructions manual (192 pages) ,

- Product information, original instructions (48 pages)

Advertisement

Quick Links

Installation Instructions

Original Instructions

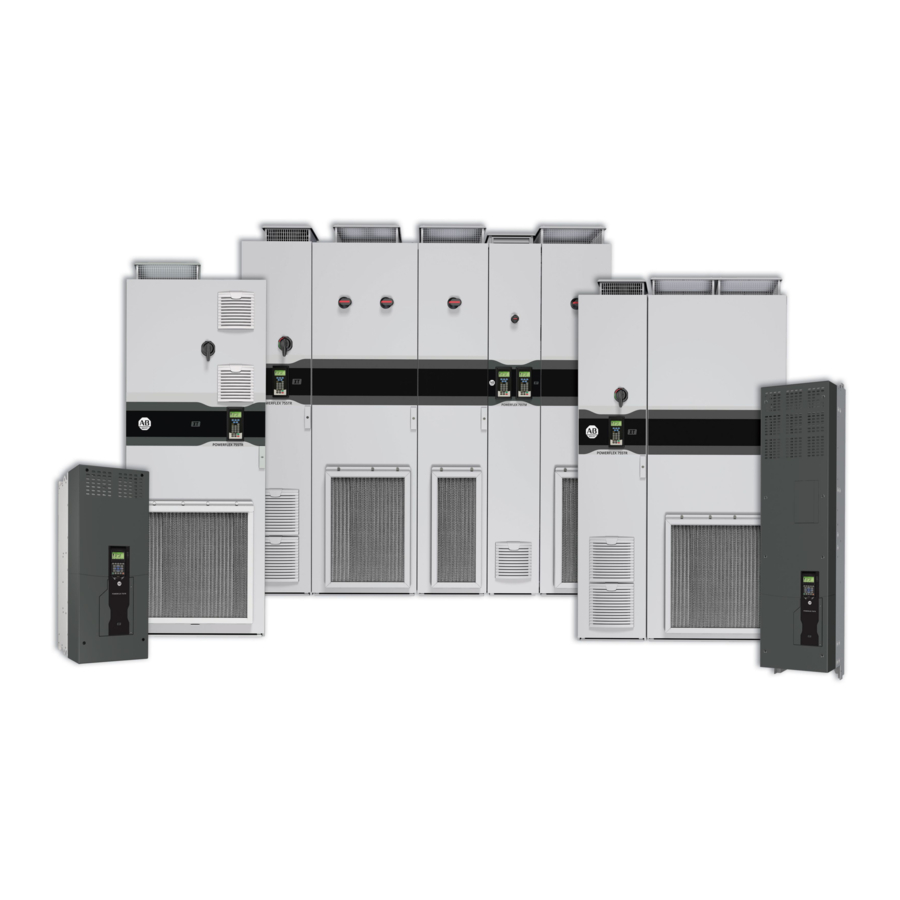

PowerFlex 755T Frames 5 and 6 Marine Discharge Kits

Catalog Numbers 20-750-CMRN-F5, 20-750-CMRN-F6

Topic

Product Advisories

Required Tools

Frame 5 Marine Discharge Module and Conduit Box Kit Contents (Cat. No. 20-750-CMRN-F5)

Frame 5 Marine Discharge Module Installation

Frame 6 Marine Discharge Module Kit Contents (Cat. No. 20-750-CMRN-F6)

Frame 6 Marine Discharge Module Installation

Additional Resources

Product Advisories

ATTENTION: Only qualified personnel, who are trained and approved to install PowerFlex® 755T products and familiar with associated machinery, should plan or

implement the installation, startup, and subsequent maintenance of the system. Failure to comply can result in personal injury and/or equipment damage.

ATTENTION: The information that is contained in this publication is merely a guide for proper installation. Rockwell Automation®, Inc. cannot assume

responsibility for the compliance or the noncompliance to any code, national, local or otherwise for the proper installation of this drive or associated equipment.

A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

ATTENTION: This product contains Electrostatic Discharge (ESD) sensitive parts and assemblies. Static control precautions are required when you install these

assemblies. Component damage can result if ESD control procedures are not followed. If you are not familiar with static control procedures, reference any

applicable ESD protection handbook.

Required Tools

Tool Description

Allen (hex) socket wrench

Electric drill and bits

Flat-nose screwdriver

Torx, star, or hexalobular screw driver/bit

Torque wrench

Torque wrench

Details

4 mm

(Bit sizes to meet conduit size requirements)

6.4 mm (0.25 in.)

#20, #25, #30

1...12 N

m (8.8...106 lb

in)

•

•

6...50 N

m (53...443 lb

in)

•

•

Page

1

1

2

3

10

10

15

Advertisement

Summary of Contents for Allen-Bradley PowerFlex 755T Frame 5

- Page 1 Installation Instructions Original Instructions PowerFlex 755T Frames 5 and 6 Marine Discharge Kits Catalog Numbers 20-750-CMRN-F5, 20-750-CMRN-F6 Topic Page Product Advisories Required Tools Frame 5 Marine Discharge Module and Conduit Box Kit Contents (Cat. No. 20-750-CMRN-F5) Frame 5 Marine Discharge Module Installation Frame 6 Marine Discharge Module Kit Contents (Cat.

- Page 2 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits Frame 5 Marine Discharge Module and Conduit Box Kit Contents (Cat. No. 20-750-CMRN-F5) The frame 5 marine discharge module and conduit box kit contains the following components. The debris hood is only required for IP20 Type 1 installations.

- Page 3 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits Frame 5 Marine Discharge Module Installation Follow these steps to install the frame 5 marine discharge module and conduit box. 1. Use the pilot holes in the conduit box bottom plate to drill the required holes for control and input/output power wire conduit fittings. Pilot holes for control power wire conduit fittings.

- Page 4 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits Frame 5 Drive Terminal Identifications Frame 5 shown with cover removed for clarity only. Item Name Description PE grounding stud Termination point to chassis ground for the AC line shield R/L1, S/L2, T/L3 AC line input power terminals.

- Page 5 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 5. Loosen the four M4 captive screws that secure the cover to the assembly, and remove the cover. M4 (Captive) F - 6.4 mm (0.25 in.) or 4 mm hex 2.6 N m (23 lb •...

- Page 6 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 6. Place the conduit box onto the chassis of the drive, so that the conduit box flanges are located on the inside of the drive chassis. 7. Insert and tighten the four M5 x 10 mm slotted-torx screws in the holes on the bottom sides of the chassis to secure the conduit box with marine discharge module to the chassis.

- Page 7 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 9. Secure the DC+ wire from the marine discharge module to the small DC+ terminal on the drive. 10. Secure the DC- wire from the marine discharge module to the small DC– terminal on the drive. M2.5 9, 10 Flat...

- Page 8 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 12. Route the appropriate cables through the bottom plate of the conduit box and connect them to the appropriate input and output power terminals.See the PowerFlex 750-Series Products with TotalFORCE® Control Installation Instructions, publication 750-IN100, for power wiring information.

- Page 9 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 16. For IP20 Type 1 installations only, place the debris hood on the top of the chassis and tighten the four M5 captive Phillips-head screws. M5 (Captive) 3.6 N•m (32 lb•in) Rockwell Automation Publication 750-IN114A-EN-P - July 2019...

- Page 10 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits Frame 6 Marine Discharge Module Kit Contents (Cat. No. 20-750-CMRN-F6) The frame 6 marine discharge module kit contains the following components. Marine Discharge Module Item Quantity Description M4 nut and conical spring washer Marine discharge module WARNING: Remove power before you remove or make cable connections.

- Page 11 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits Frame 6 Drive and Bus Supply Power Terminal Identification Frame 6 Shown with the Cover Removed for Clarity Only. Item Name Description Item Name Description PE Grounding Stud Termination point to the chassis ground for the AC line shield U/T1, V/T2, W/T3 AC output motor terminals R/L1, S/L2, T/L3...

- Page 12 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 4. Loosen the eight M4 captive screws that secure the cover to the assembly, and remove the cover. M4 (Captive) F - 6.4 mm (0.25 in.) or 4 mm hex 2.6 N m (23 lb •...

- Page 13 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 5. Loosen the three M4 captive, slotted-torx screws that secure the fan power supply circuit board assembly to the chassis and lift the assembly off the chassis to allow access to terminal block J27 on the power board. M4 (Captive) T20 or F - 6.4 mm (0.25 in.) 2.3 N...

- Page 14 PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 6. Route the marine discharge module wire harness under the perforated plate and along the left side of the drive chassis. 7. Use four M4 hex nuts to secure the mounting bracket and marine bus conditioner to the chassis. 7 mm 2.6 N m (23 lb...

-

Page 15: Additional Resources

PowerFlex 755T Frames 5 and 6 Marine Discharge Kits 9. Replace the fan power supply circuit board assembly that was removed in step 5 on page and secure the three M4 x 10 mm captive, slotted-torx screws on the assembly to the chassis. 10. - Page 16 Rockwell Automation maintains current product environmental information on its website at http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page. Allen-Bradley, PowerFlex, Rockwell Automation, Rockwell Software, and TotalForce are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies. Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400...

Need help?

Do you have a question about the PowerFlex 755T Frame 5 and is the answer not in the manual?

Questions and answers