Summary of Contents for Raven Force Evo

- Page 1 Force Evo Injection System Installation Manual 016-0171-724 Rev. A 12/20 E36393 Copyright 2019...

- Page 2 Raven systems, or products used as components of systems, which rely upon the reception of these signals or availability of these services. Raven Industries accepts no responsibility for the use of any of these signals or services for other than the stated purpose.

-

Page 3: Table Of Contents

Charging the Carrier Line with Injected Chemical ....................16 Force® Evo System Operation ..........................16 Winterizing the Force® Evo Injection System ....................17 Chapter 5 System Diagrams and Ordering Instructions ..........19 Raven CANbus Systems ............................20 ISObus Systems ................................. 24 016-0171-724 Rev. A... - Page 4 Table of Contents Force Evo Injection System Installation Manual...

-

Page 5: Chapter 1 Important Information

• Do not operate this Raven system or any agricultural equipment while under the influence of alcohol or an illegal substance. • Be alert and aware of surroundings and remain in the operator seat at all times when operating this Raven system. -

Page 6: Agricultural Chemical Safety

• Do not connect the power leads to the battery until all system components are mounted and all electrical connections are completed. • Always start the machine before initializing this Raven system to prevent power surges or peak voltage. • To avoid tripping and entanglement hazards, route cables and harnesses away from walkways, steps, grab bars, and other areas used by the operator or service personnel when operating or servicing the equipment. -

Page 7: Recommendations And Best Practices

The word “hose” is used to describe any flexible, fluid carrying components. Use the following guidelines and recommendations when connecting and routing hoses while installing or maintaining this Raven system: • Leave protective caps/covers over hose ends until connecting the end into the hydraulic system to help prevent contaminants from entering the system. - Page 8 • Clean electrical components with pressurized air, aerosol electrical cleaning agent, or low pressure rinse. • Remove visible surface water from electrical components and connections using pressurized air or an aerosol cleaning agent. Allow components to dry thoroughly before reconnecting cables. Force Evo Injection System Installation Manual...

-

Page 9: Chapter 2 Introduction To The Force® Evo Injection System

Carrier rate control is not included with the ® Force EVO Injection system, but is available as an optional feature. NOTE: Contact a local Raven dealer for more information about adding carrier rate control to your existing ® Force Evo injection system. ®... - Page 10 HAPTER Force Evo Injection System Installation Manual...

-

Page 11: Installation And Preparation

NOTE: There are two plastic envelopes in the kit with plumbing parts. One envelope is labeled “THESE PARTS TO BE INSTALLED BY RAVEN DEALER.” The dealer will install these parts to interface the mixer and injection point to the carrier. -

Page 12: Best Installation Practices

3. Use hardware of adequate strength to fasten the fabricated mounting bracket to the brackets attached to the ® bottom of the Force Evo cabinet. Use as many mounting points as possible to ensure that the cabinet is securely fastened to the implement. Force Evo Injection System Installation Manual... -

Page 13: Injection Plumbing Installation

INSTALLATION AND PREPARATION INJECTION PLUMBING INSTALLATION ® The Force Evo injection system kit is designed to interface with existing 1” carrier product lines. The kit includes parts for installation of the “point of injection” including check valves and in-line mixer. Review the information in the following sections for assistance with assembling and installing the injection plumbing and connecting the ®... -

Page 14: Point Of Injection Plumbing Assembly Procedure

An optional pressure transducer (P/N 422-0000-090) may replace the 1/4” plug to monitor pressure during field operations. Contact a local Raven dealer for more information. 2. Thread a 1” pipe fitting (item 11) into each of the through ports of the tee fitting. -

Page 15: Point Of Injection Installation

INSTALLATION AND PREPARATION POINT OF INJECTION INSTALLATION Review the following steps for information on installing the point of injection assembly into the existing carrier product line on the implement. 1. Select a point in the carrier product line in which the point of injection plumbing assembly may be installed in the carrier line. -

Page 16: Cable Connections To The Force® Evo System

Raven Sidekick Pro™ or Sidekick Pro™ ISO manual required cabling connections to the injection pump. For additional assistance with cabling options, contact a local Raven dealer. IMPORTANT: If a Raven control console will not be installed to control the liquid carrier, the installer must provide for the following items: •... -

Page 17: Chapter 4 System Operation

S YSTEM OPERATION CHAPTER C H A P T E R 4 SYSTEM OPERATION OVERVIEW ® ® The Force Evo injection system utilizes replaceable chemical boxes housed within the Force Evo cabinet on a rack system. No chemical tank to refill or rinse between operations. When the injection system is empty, disconnect and remove the empty boxes from the cabinet racks and replace with prefilled boxes. - Page 18 Do not rinse with water. Water can have an adverse affect on the chemical. 6. If a Raven control console is installed for carrier control, enter a self test speed of 6 mph [10 km/h] and set the injection pump to automatic control mode.

-

Page 19: Charging The Force® Evo Injection System

4. Repeat the priming procedure two more times to draw chemical from the connected boxes and eliminate air pockets in the cabinet manifold. 5. Perform a pump calibration test to verify pump operation. Refer to the Raven Sidekick Pro™ or Sidekick Pro ISO manual for details on performing a calibration with the closed calibration system. -

Page 20: Charging The Carrier Line With Injected Chemical

A vacuum error may also occur if the strainer is plugged or a chemical flow restriction has occurred. Refer to the Raven Sidekick Pro™, Sidekick Pro ISO, or Sidekick PRO ICD manuals for details on using the specific control console to control the injection system. Review the console specific operation manual for details on setting up and controlling a liquid carrier during field operations. -

Page 21: Winterizing The Force® Evo Injection System

3. Place the open end of the clean out hose into a container of antifreeze designed for recreational vehicles (R.V. antifreeze). 4. If a Raven control console is installed for carrier control, enter a self test speed of 6 mph [10 km/h] and set the injection pump to automatic control mode. - Page 22 HAPTER Force Evo Injection System Installation Manual...

-

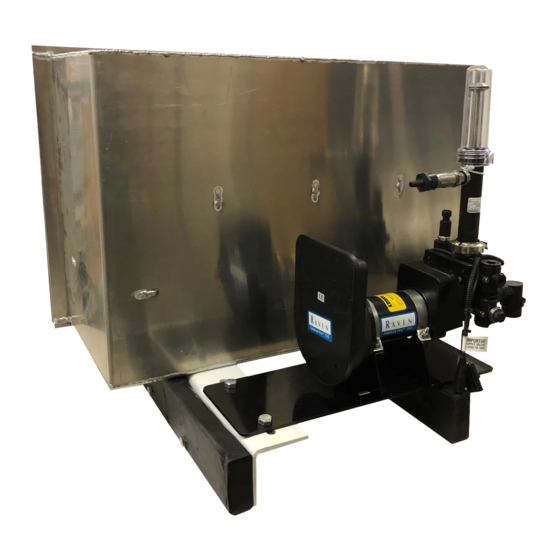

Page 23: System Diagrams And Ordering Instructions

Raven CAN 117-0171-836 ISO CAN 117-0171-837 Raven ICD CAN 117-0171-836 These kits include the chemical cabinet, injection pump, misc. plumbing, flow mixer, and basic mounting hardware. See the following system diagrams to select cables and accessories that relate to the desired type of control. -

Page 24: Raven Canbus Systems

HAPTER RAVEN CANBUS SYSTEMS FIGURE 1. Ordering Instructions for Viper 4 and Raven CAN Systems (P/N 054-2850-003 Rev. A) Force Evo Injection System Installation Manual... - Page 25 SYSTEM DIAGRAMS AND ORDERING INSTRUCTIONS FIGURE 2. Cable Connections for Viper 4 and Raven CAN Systems (P/N 054-2850-003 Rev. A) 016-0171-724 Rev. A...

- Page 26 HAPTER FIGURE 3. Ordering Instructions for Force EVO ISO Injection (P/N 054-6100-009 Rev. F) Force Evo Injection System Installation Manual...

- Page 27 SYSTEM DIAGRAMS AND ORDERING INSTRUCTIONS FIGURE 4. Raven ISO Product Control w/ Force EVO ISO Injection (P/N 054-6100-009 Rev. F) 016-0171-724 Rev. A...

-

Page 28: Isobus Systems

HAPTER ISOBUS SYSTEMS FIGURE 5. Ordering Instructions for ISOBUS Systems (D/N 054-6100-009 Rev. F) Force Evo Injection System Installation Manual... - Page 29 SYSTEM DIAGRAMS AND ORDERING INSTRUCTIONS FIGURE 6. Cabling Connections for John Deere Rate Controller 2000 with Raven Sidekick PRO ICD (P/N 054-7120-001 Rev. B) 016-0171-724 Rev. A...

- Page 30 HAPTER Force Evo Injection System Installation Manual...

- Page 31 Bring the defective part and proof of purchase to your Raven dealer. If the dealer approves the warranty claim, the dealer will process the claim and send it to Raven Industries for final approval. The freight cost to Raven Industries will be the customer’s responsibility.

- Page 32 Bring the defective part and proof of purchase to your Raven dealer. If the dealer approves the warranty claim, the dealer will process the claim and send it to Raven Industries for final approval. The freight cost to Raven Industries will be the customer’s responsibility.

Need help?

Do you have a question about the Force Evo and is the answer not in the manual?

Questions and answers