Table of Contents

Advertisement

Quick Links

Handling Instructions

For SCD4x CO

Sensors

2

Preface

For taking advantage of the SCD4x outstanding

performance, some precautions must be taken during

storage, assembly and packaging. Please read the

following instructions carefully - preferably during design-

in phase and before production release of the respective

device.

1

ESD protection

The sensor shall be protected from ESD (Electrostatic

Discharge) and only be handled in ESD protected areas

(EPA) under protected and controlled conditions (ground

all personnel with wrist-straps, ground all non-insulating

and conductive objects, exclude insulating materials

from the EPA, operate only in grounded conductive floor,

etc.). Protect sensor outside the EPA using ESD

protective packaging.

Protection against ESD is mandatory.

2

Mechanical handling

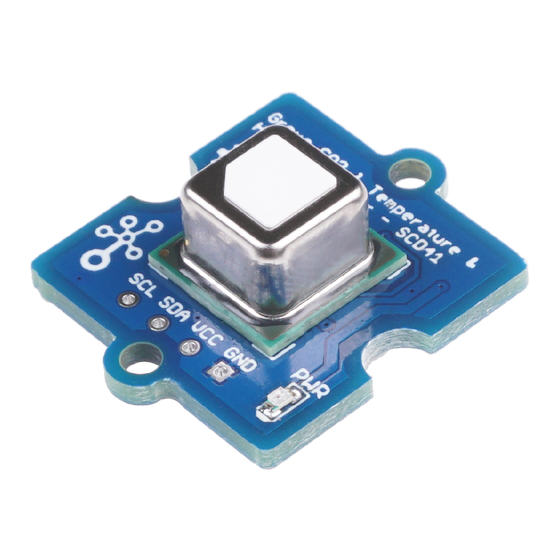

As the SCD4x is an optical system, it must not be

exposed to extreme mechanical forces at any time. Wear

clean gloves or finger cots while handling the sensor and

avoid touching the white protection membrane.

Furthermore, no excessive force must be applied to the

protection membrane on top of the metal cap. Damage

to the protection membrane such as partial removal or a

minor cut will make the sensor irreversibly defective.

Finally, the sensor must not be exposed to strong air

blasts from an air-pistol.

www.sensirion.com

The protection membrane on top of the metal

cap must not be removed or damaged.

No excessive shear force must be applied to the

metal cap.

The sensors in SMD packages are classified as

Moisture Sensitivity Level 3.

Prolonged exposure to high concentrations of

volatile organic compounds such as solvents

should be avoided.

3

Exposure to Chemicals

Some solvents might cause the protection membrane to

peel off the metal cap which results in an irreversible

defect of the SCD4x sensor. Furthermore, the SCD4x

comprises a best-in-class Sensirion relative humidity

(RH) and temperature (T) sensor that must be protected

from pollutants. While ambient environments are usually

not critical for the sensor, pollutants are known to occur

in manufacturing environments and may occur during

storage and by packaging materials. Please carefully

follow the guidelines in this application note to ensure

that the performance of the built-in RH/T sensor is not

compromised. Note that preserved accuracy of the RH/T

sensor is required to ensure precise CO

the entire relative humidity and temperature range –

even if the RH and T output is not used in the application.

The sensor shall not get in close contact with volatile

chemicals such as solvents or other organic compounds.

Especially high concentration and long exposure must

be avoided. Ketenes, acetone, ethanol, isopropyl

alcohol, toluene, etc. are known to cause drift of the

humidity reading – irreversibly in most of the cases.

Please note that such chemicals are integral part of

epoxies, glues, adhesives, etc. and outgas during baking

and curing. These chemicals are also added as

plasticisers into plastics, used for packaging materials,

and do out-gas for some period.

Acids and bases may affect the sensor irreversibly and

shall be avoided: HCl, H

ozone in high concentration or H

effect and therefore shall be avoided. Please note that

above examples represent not a complete list of harmful

substances.

The sensor shall not get in contact with cleaning agents

(e.g., PCB board wash after soldering). Applying

cleaning agents to the sensor may lead to drift of the

reading or complete breakdown of the sensor.

Version 1 – January 2021

readings over

2

SO

, HNO

, NH

etc. Also

2

4

3

3

O

have the same

2

2

1/5

Advertisement

Table of Contents

Summary of Contents for SENSIRION SCD4 Series

- Page 1 (EPA) under protected and controlled conditions (ground defect of the SCD4x sensor. Furthermore, the SCD4x all personnel with wrist-straps, ground all non-insulating comprises a best-in-class Sensirion relative humidity and conductive objects, exclude insulating materials (RH) and temperature (T) sensor that must be protected from the EPA, operate only in grounded conductive floor, from pollutants.

- Page 2 Generally speaking, if a material emits a strong odour you should not use it. Humidity sensor handling instructions: www.sensirion.com/file/handling_instructions_rht www.sensirion.com Version 1 – January 2021...

- Page 3 (protection membrane) must remain free of result in a sensor defect or can compromise SCD4x coating. sensor performance, even if heat exposure is very local and limited in time. Furthermore, no force must be www.sensirion.com/file/datasheet_scd4x www.sensirion.com/file/scd4x_testing_guide www.sensirion.com Version 1 – January 2021...

- Page 4 1-2577 Low Voc Conformal Coating This document is not to be considered complete and is Electrolube AFA (Aromatic Free Acrylic Conformal subjected to changes without prior notice. Coating) Revision History Date Version Page(s) Changes January 2021 Initial version www.sensirion.com Version 1 – January 2021...

- Page 5 Warranty SENSIRION warrants solely to the original purchaser of this product for a period of 12 months (one year) from the date of delivery that this product shall be of the quality, material and workmanship defined in SENSIRION’s published specifications of the product. Within such period, if proven to be defective, SENSIRION shall repair and/or replace this product, in SENSIRION’s discretion, free of charge to the...

Need help?

Do you have a question about the SCD4 Series and is the answer not in the manual?

Questions and answers