Table of Contents

Summary of Contents for mercor mcr-PROLIGHT C

- Page 1 2, Grzegorza z Sanoka 80-408 Gdansk Phone No. +48 58 341 42 45 Phone / Fax No. +48 58 341 39 85 OPERATIONS AND MAINTENANCE MANUAL Spot Smoke Vents mcr-PROLIGHT - C, E, NG-A types type C type E type NG-A Gdansk Release 2.2.4 - 2014.03.28...

-

Page 2: Table Of Contents

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL TABLE OF CONTENT: 1. INTRODUCTION....................... 3 2. PURPOSE OF SMOKE EXHAUST VENTS............... 3 3. DESIGN AND OPERATING PRINCIPLES................. 3 4. TRANSPORT and DELIVERY................... 6 5. -

Page 3: Introduction

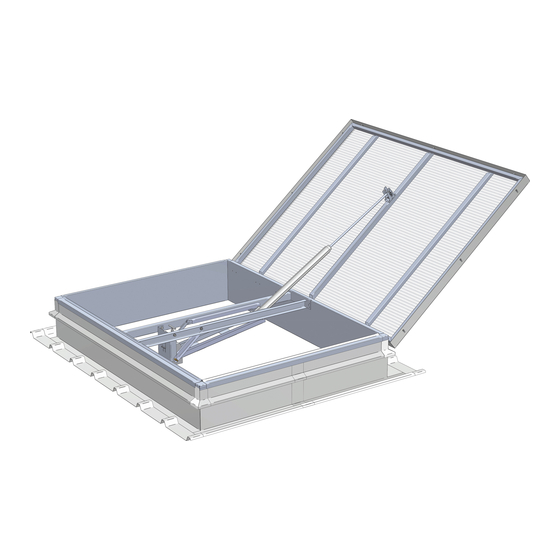

• Extension of fire routes. mcr-PROLIGHT smoke exhaust vents are integral parts of smoke control systems which include other components manufactured by MERCOR SA, such as e.g.: smoke vents in mcr- PROLIGHT roof skylights and skylights, mcr-PROSMOKE smoke curtains, mcr 9705 and mcr 0204 smoke control units, and many other products. - Page 4 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Available are active leaf filling types as follows: • Cellular polycarbonate, 10 mm through 25 mm thick, with various light transmittance values and heat transfer coefficients; • Double and triple acrylic domes; •...

- Page 5 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL (a) polycarbonate panel (b) ALU composite panel (c) polycabonate and polyester panels [Broof(t1) class] (d) double acrylic dome (e) triple acrylic dome Fig. 2. Typical filling of mcr-PROLIGHT smoke vents. Page 5 of 26...

-

Page 6: Transport And Delivery

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 4. TRANSPORT and DELIVERY. C, E, NG-A type mcr-PROLIGHT vents are delivered as assembled units. In special circumstances, however (additional external treatment, low base, etc.), vents may be supplied as detached subassemblies components, except wind deflectors which always come separately because individual elements must be protected from damages during the transport in order to ensure road traffic safety. - Page 7 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Fig. 4. Method of setting mcr-PROLIGHT vent on the roof: connector spacing. Smoke vent bases are adapted to roof works made of building felt, PVC membrane, or metal sheet.

-

Page 8: Methods Of Smoke Vent Setting

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 5.1. Methods of smoke vent setting. Fig. 5. Setting the steel base on the roof (DETAIL B) and method of sealing by means of roof membrane or building felt (DETAIL A). Detail A Steel base Base thermal insulation... - Page 9 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Detail B 1. Vent steel base 2. Base thermal insulation 3. Roof works with membrane or felt 4. Roof thermal insulation 5. Reinforced concrete slab Fig. 7. Steel base on reinforced concrete slab: (a) membrane work; (b) felt work. 1.

- Page 10 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 1. Vent steel base 2. Base thermal insulation 3. Roof works with membrane or felt 4. Roof thermal insulation 5. Roofing sheet 6. Steel supporting structure Fig. 10. Steel base on steel structure: (a) membrane work; (b) felt work. 1.

- Page 11 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 1. Vent steel overlay base 2. Base thermal insulation 3. Overlay thermal insulation 4. Base overlay 5. Roof works with membrane or felt 6. Reinforced concrete curb 7. Roof thermal insulation Fig.

-

Page 12: Wind Defelctor And Inlet Deflector

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 6. WIND DEFELCTOR AND INLET DEFLECTOR 6.1. Wind deflectors. Wind deflectors increase the active area of smoke vents. Standard models are made of aluminium sheet. Wind deflectors are delivered as customised bent elements or prefabricated products for manual bending (with pre-marked recesses at the bending points), along with wind deflectors holders fixed to the vent base. -

Page 13: Inlet Deflector

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 6.2. Inlet deflector. Inlet deflector slats will increase active aerodynamic efficiency of C and E type vents, which means increased smoke venting surface. Fixed at the bottom part of the vent base, the inlet deflector is made of zinc coated steel sheet or, as an option, of aluminium sheet, and may be painted in any RAL chart colour. -

Page 14: Vent Leaf Adjustment

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Fig. 18. Inlet deflector in working position. 7. VENT LEAF ADJUSTMENT. (HOOKED BRACKET, EYE BOLTS AND 'T' BOLTS) Vent leaf is linked with actuator via the hooked bracket which is locked on the 'T' bolt. Pneumatic actuators and electric spindle actuators are connected with the hooked bracket by means of an eye bolt which is screwed into the actuator piston rod / spindle. -

Page 15: Control

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Fig. 22. Connection of actuators with hooked bracket. 8. CONTROL. Smoke exhaust vents and smoke and ventilation dampers make use of opening and closing mechanisms which compose the systems for smoke exhaust or exhaust & ventilation control. - Page 16 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Pipe Clamping ring Sleeve (plastic tubing) Body Fig. 23. Pneumatic system flexible tubing: assembling method. Copper tube Clamping ring Body Fig. 24. Connection of union with copper / steel tube. WARNING For safety reasons, smoke vent thermal valve is not armed.

-

Page 17: Electric Control

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Fig. 25. Thermal valve. Fig. 26. Pneumatic actuator PUAV: direction of releasing the lock. Pneumatic actuator used in smoke evacuation systems are equipped with internal locks which prevent completely open vent leaves from closing. Shown below is the method of closing the vent leaves following the emergency opening when the systems have no remote closing option: 1. - Page 18 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL Typically, ventilation electric actuator is not factory installed for transport reasons. It should be mounted in the opening system bracket by means of ST12-1/8 bolts (Exxx-230 actuator) or screw bolts (JMB actuators) delivered together with the actuator. Screws ST12 should be protected from unscrewing by means of Loctite 243 or similar preparation.

-

Page 19: Installation Of Detached Opening Mechanism

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 9. INSTALLATION OF DETACHED OPENING MECHANISM. If the control system is delivered as a separate item, the installation should follow the instructions specified below: A. Align the control system with the axis of the smoke vent. Control system Smoke vent B. -

Page 20: Vents With Security Bars And Nets

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 10. VENTS WITH SECURITY BARS AND NETS. mcr-PROLIGHT PLUS smoke vents may be equipped with anti-burglar bars (C and E types) or nets (C, E, and NG types). Security nets are delivered as integrated elements along with the vents;... - Page 21 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL II. Installation of bar supporting profiles. 1. Vent opening mechanism spreader boom. 3. Bar supporting profile (sheet # 2). 4. Vent base. - Fasten bar supporting profiles at a suitable height by means of two self-tapping bolts ø 6.3.

- Page 22 C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL IV. Installation of masking profiles and reinforcement. 6. Masking profile (sheet # 1.25 mm). 7. Bar bracing with holes. - Place masking profiles and fasten them to the base through the supporting profile at two points (A);...

-

Page 23: Leaf Filling

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 11. LEAF FILLING. Filling domes are delivered as separate elements for transport reasons. Domes should be mounted on the vent leaf on site once the vent is installed. Follow the instructions below: 1. -

Page 24: Maintenance

During the operations, ensure regular maintenance and service reviews of the equipment. Service support and maintenance works are conducted by a team authorised by MERCOR SA. The time between the service reviews is 6 months. Between individual reviews, we recommend the works specified below: 1. -

Page 25: Terms And Conditions Of Warranty And Service Support

10. In addition, in the cases referred to in par. 9, responsibility of MERCOR SA for the warranty is excluded. In matters not covered by these warranty terms and conditions, the relevant provisions of the Civil Code shall be applicable. -

Page 26: Certificate Of Conformity

C, E, NG-A T mcr-PROLIGHT V ENTS (DTR) PERATIONS AND AINTENANCE ANUAL 14. CERTIFICATE OF CONFORMITY. Page 26 of 26...

Need help?

Do you have a question about the mcr-PROLIGHT C and is the answer not in the manual?

Questions and answers