Table of Contents

Advertisement

Quick Links

Assembly Instructions

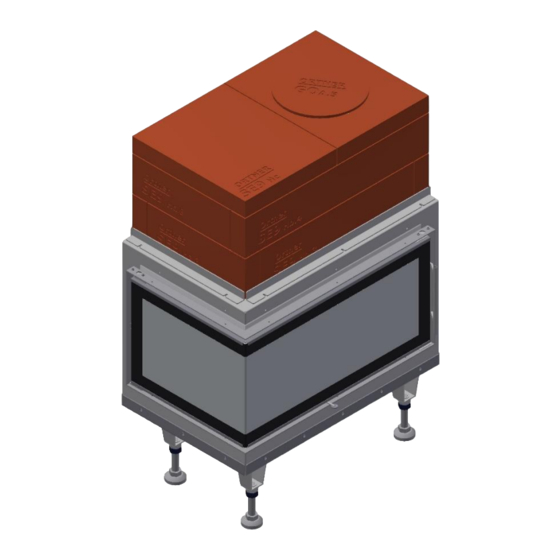

ORTNER SE9 73/46/38 L

Manual and automatic operation

A sufficient quantity of combustion air must be provided (calculation is required). Use

caution in regard to the utilisation of ventilation systems, fume hoods, etc.!

To avoid any errors, please first carefully read our assembly instructions!

The respective national or local regulations and general provisions, stipulations and

codes of practice must be complied with!

CAUTION: Due to the thermal expansion of the door unit, a space of at least

4 mm must be provided all around the mounting frame and the stove shell. The

space must be filled with a soft sealing strip.

Version: 11_2017

Advertisement

Table of Contents

Summary of Contents for ORTNER SE9 73 L

- Page 1 Assembly Instructions ORTNER SE9 73/46/38 L Manual and automatic operation A sufficient quantity of combustion air must be provided (calculation is required). Use caution in regard to the utilisation of ventilation systems, fume hoods, etc.! To avoid any errors, please first carefully read our assembly instructions!

- Page 2 ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

-

Page 3: Table Of Contents

Mounting surfaces NOT TO BE PROTECTED ........................13 General ....................................14 Schematic sketch ..................................15 Exploded view ..................................17 ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at... -

Page 4: The Following Materials Are Required For The Assembly Of The Ortner Storage Corner

Mean exhaust temperature (downstream of the ceramic storage unit KMS 300) 147 °C Mean required discharge pressure with rated heat output 14 Pa ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at... -

Page 5: Important Information Before The Installation

All grey refractory concrete parts have already been cut to the correct dimensions. ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at... -

Page 6: Initial Steps

Insert the provided fibre strips on the connection points between metal and ceramic. ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at... - Page 7 HK. ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

- Page 8 The designation of the bricks relates to the GOS6 number of segments. GOS6 GOS12 GOS12 ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

- Page 9 However, the parts of the post- combustion chamber should not be bonded with each other. ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

- Page 10 GO4.1 SE1.6.3 GO1.7 Now position the cover of the post- combustion chamber. ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

- Page 11 Caution: The minimum distance between the cover of the post-combustion chamber and the jacket cover must be at least 12 mm. ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

-

Page 12: Technical Dimensioned Drawing

Technical dimensioned drawing (applies to both automatic as well as manual operation) ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at... -

Page 13: General Information

The construction and dimensions of the ceramic hot gas flue may be designed in an individual manner. The design of the ceramic hot gas flues must be performed for the Ortner KMS using the Ortner calculation programme (storage mass of the ceramic hot gas flue approx. 380 kg, will significantly affect the assembly situation), and for the construction of chamotte flues in accordance with the technical directive on stove and air heating construction (applies to Germany) or the tiled stove calculation programme (EN 15544). -

Page 14: Fire And Heat Protection

In the event of the use of Ortner Isoboard: 10 cm brick lining + 9 cm Ortner Isoboard. Or 3 cm Isoboard at the mounting wall + active back ventilation (at least 5 cm gap width) + 6 cm Ortner Isoboard (towards the stove, with offset joints). -

Page 15: General

In the event that more stringent provisions / stipulations apply in regard to fire protection at the installation site than those specified here, then these must be strictly observed! ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at... -

Page 16: Schematic Sketch

Schematic sketch ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at... - Page 17 13) Back ventilation: If required 14) Firebox ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

-

Page 18: Exploded View

Exploded view ORTNER GmbH | Hürmer Straße 36 in A-3382 Loosdorf | Tel +43 2754 2707 | Fax +43 2754 2708 office@ortner-cc.at | www.ortner-cc.at...

Need help?

Do you have a question about the SE9 73 L and is the answer not in the manual?

Questions and answers