Advertisement

Quick Links

Advertisement

Summary of Contents for Walvoil DPC130X

- Page 1 DPC130X Pre-compensated Load Sensing Sectional Valve ATEX version...

- Page 2 This catalogue shows the product in the most standard configurations. Please contact Sales Dpt. for more detailed information or special request. WARNING! All specifications of this catalogue refer to the standard product at this date. Walvoil, oriented to a continuous improvement, reserves the right to discontinue, modify or revise the specifications, without notice. WALVOIL IS NOT RESPONSIBLE FOR ANY DAMAGE CAUSED BY AN edition - September 2018 INCORRECT USE OF THE PRODUCT.

-

Page 3: Table Of Contents

DPC130X Service Manual Table of contents _________________________________________________________________________________________ Introduction ..........page Valve description . -

Page 4: Introduction

DPC130X Service Manual Introduction _______________________________________________________________________________________________ This manual has been conceived to provide the necessary instructions for a correct and safe usage and handling of DPC130X control valve, in compliance with ATEX directive. It contains: • the control valve description; • the general specifications;... -

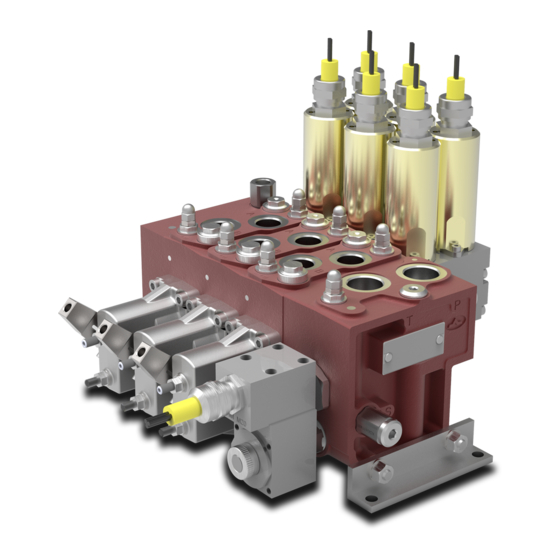

Page 5: Valve Description

Valve description _________________________________________________________________________________________ ATEX DPC130X is an open/closed circuit sectional valve: • its operating principles are based on the precompensated Load Sensing technology; • which has been conceived to be adequate to work in potential explosive areas according to the requirements of ATEX Directive 2014/34/UE. - Page 6 DPC130X Service Manual Valve desctription ________________________________________________________________________________________ ATEX Directive 2014/34/UE The ATEX Directive 2014/34/UE is applied, with the aim to reduce the risk of use, to the manufacture specifications of all those products to be used in potentially explosive atmosphere due to the presence of dust or gas. According to this directive an explosive atmosphere is made up from a mixture of inflammable substances (like gas, vapours, mists and dust) with air in determined atmospheric conditions in which, after triggering, the combustion propagates together with unburned substances.

- Page 7 DPC130X Service Manual Valve description __________________________________________________________________________________________ ATEX Directive 2014/34/UE Group I Group II Includes the equipment destined to be used in underground jobs in the Includes the equipment to be used in different environments (from the mines and their surface plants, exposed to the risk of release of fire- mines) with possible explosive atmosphere. Their subdivision into cate- damp and/or combustible dust. The subdivision into categories depends...

- Page 8 DPC130X Service Manual Valve description _________________________________________________________________________________________ Dimensional data 3.19 2.01 1.97 2.09 9.06 54.5 37.1 2.15 1.46 0.63 0.63 0.39 0.197 Ø 8.5 Ø 0.33 130.4 5.13 0.31 5.98 manufacturer reference Via Adige 13/D 42124 Reggio E. Italy product name...

-

Page 9: General Specifications

+0.8 to + 1.1 bar - pressure for working conditions NOTES: ( ) According to NFPA T 2.6.1., fatigue rating verified for 1 million cycles on 6 sample valves with test Pressure = 1.23 x Max. pressure 275°F indicated - ( ) DPC130X can operate with gases with an ignition temperature above 135°C - and powders with an ignition temperature 266°F above 130°C - Standard thread REFERENCE STANDARD... -

Page 10: Storage

• in zones where a potential explosive atmosphere can occur also with a very low probability. • remove the packaging only just before assembling the product; WARNING • Walvoil is not responsible for any damage due to a storage not in compliance with our prescriptions; • for any doubt, please contact our After-sales Department. D1WWTD02E... -

Page 11: Installation

Service Manual Installation _________________________________________________________________________________________________ When you receive these Walvoil products, please check: • if there are signs of damage of the packaging; • that the dimensions of the product seat are compatible with those of the product itself; • that the assembly seat is compatible with the part dimensions and that it has been prepared for the valve set-up (connection hoses ready etc.);... - Page 12 • in case the hoses are not connected to the correspondent ports, unintentional movements might cause a serious accident; • Walvoil is not responsible for any damage due to an installation procedure not in compliance with our prescriptions; • in case the control valve has to be painted, make sure that surface paint on the control valve does not exceed the maximum 7.87x10...

- Page 13 Disassembly and assembly procedures _____________________________________________________________ Disassembly and assembly should be carried out by Walvoil technicians. In case the control valve doesn’t work properly, we advise you to contact our After-sales Department. However in case the disassembly and assembly operations are absolutely unavoidable, you must observe the following prescrip- tions and assign these operations to highly qualified technicians in the field of hydraulics.

- Page 14 • Walvoil is not responsible for any damage due to disassembly and assembly procedures not in compliance with our prescriptions; • please remember that all these operations have to be carried out in a non potential explosive atmosphere at the environmental conditions required;...

- Page 15 DPC130X Service Manual Standard maintenance rules ___________________________________________________________________________ Do not carry out maintenance operations on the control valve when an explosive atmosphere is present and the control valve surface temperature is outside the environmental temperature range as specified before. It is advisable to periodically check the parts shown in the table below.

- Page 16 - September 2018 WWW.WALVOIL.COM D1WWTD02E...

Need help?

Do you have a question about the DPC130X and is the answer not in the manual?

Questions and answers