Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Wittenstein Alpha INIRA ZST 200-334-1000-R1 С-35

- Page 1 ® INIRA Assembly instructions 2022-D050733 Revision: 02...

- Page 2 +41 81 300 10 30 info@wittenstein.tw +886 3 287 0191 WITTENSTEIN Güç Aktarma Türkiye info@wittenstein.com.tr +90 216 709 21 23 Sistemleri Tic. Ltd. Şti. © WITTENSTEIN alpha GmbH 2018 Subject to technical and content changes without notice. 2022-D050733 Revision: 02...

-

Page 3: Table Of Contents

® INIRA Table of Contents About this manual ....................2 1.1 Information symbols and cross references ............2 1.2 Scope of delivery ....................2 Safety........................2 2.1 EC/EU Directive ....................3 2.1.1 Machinery Directive..................3 2.2 Personnel ......................3 2.3 Intended use ......................3 2.4 Reasonably foreseeable misuse ................3 2.5 General safety instructions ..................3 2.6 Structure of warning instructions................3 2.6.1 Safety symbols ....................4... -

Page 4: About This Manual

Check the completeness of the delivery against the delivery note. Missing parts or damage must be notified immediately in writing to the carrier, the insurance company, or WITTENSTEIN alpha GmbH. Safety These instructions, especially the safety and warning notices as well as the rules and regulations valid for the operating site, must be observed by all persons working with the racks. -

Page 5: Ec/Eu Directive

® INIRA Safety EC/EU Directive 2.1.1 Machinery Directive The racks are considered a "machine component" and are therefore not subject to the EC Machinery Directive 2006/42/EC. Startup is prohibited within the area of validity of the EC directive until it has been determined that the machine in which these racks are installed corresponds to the regulations within this directive. -

Page 6: Safety Symbols

® Safety INIRA 2.6.1 Safety symbols The following safety symbols are used to indicate possible hazards, prohibitions, and important information: General hazard Environmental Information protection 2.6.2 Signal words The following signal words are used to indicate possible hazards, prohibitions, and important information: This signal word indicates an imminent danger that will cause serious injuries or even death. -

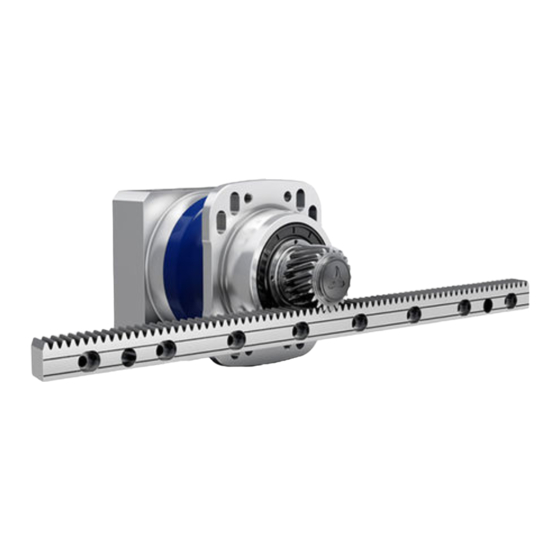

Page 7: Description Of Racks

For the assembly described in this operating manual, additional tools/materials are required. Additionally, WITTENSTEIN alpha GmbH offers a tool kit INIRA. Further information and the material number of the tool kit INIRA can be found in the "alpha Linear Systems" catalog. -

Page 8: Assembly

® Assembly INIRA Assembly Read the general safety instructions before beginning to work (see Chapter 2.5 "General safety instructions"). If you have questions about correct mounting, consult our Customer Service department. Requirements in respect of installation location and mounting base Requirements in respect of installation location: - The racks must be installed in a clean and dry environment. -

Page 9: Required Tools And Assembly Material

Tool / Material Task / Purpose Additional information Fastening screws To bold the racks to the Included in the scope of delivery of (WITTENSTEIN alpha screw-on surface the racks cylinder head screws) Required size, see Chapter 9.2.1 "Overview of the required fastening screws"... -

Page 10: Preparations

® Assembly INIRA Pos. Tool / Material Task / Purpose Additional information Assembly bushings To press the racks onto Included in the tool kit INIRA the stop surface Further information and the material number can be found in the "alpha Assembly jig To align the transition point Linear Systems"... -

Page 11: After The Cleaning

® INIRA Assembly Remove all traces of the anti-corrosion agent before mounting the racks. Use a clean, lint-free cloth and a grease-dissolving, non-aggressive cleaning agent. Clean the stop surface (N) and the screw-on surface (O) with a dressing stone (H), a suitable cleaning agent (G), and a lint-free cloth. -

Page 12: Mounting The Racks

® Assembly INIRA Mounting the racks 5.4.1 Assemble first rack with INIRA clamping Position the first rack in the middle of the machine bed. The through-holes (Q) of the rack have to be centered above the corresponding threaded holes (R) of the screw-on surface. -

Page 13: Assembling Subsequent Racks

® INIRA Assembly 5.4.2 Assembling subsequent racks Position the rack (T) to be assembled beside the previously assembled rack. Make sure the through-holes of the rack are centrically above the corresponding threaded holes of the screw-on surface. Insert a fastening screw into the first two ... -

Page 14: Checking The Transition Between The Racks

® Assembly INIRA 5.4.3 Checking the transition between the racks Magnetize the needle rollers (M) with a suitable magnet. Insert the magnetized needle rollers into positions 1, 2 and 3, as shown in the diagram. Due to the magnetization, the needle rollers remain attached to the positions. -

Page 15: Correct The Transition Between The Racks With Inira Adjusting

® INIRA Assembly 5.4.4 Correct the transition between the racks with INIRA adjusting Carry out the following steps in case the transfer between the racks exceeds the tolerance range. Position the adjustment tool (L) on the two racks, as shown in the adjacent diagram picture. ... -

Page 16: Mounting Additional Racks

® Assembly INIRA 5.4.5 Mounting additional racks Mount all additional racks in the same manner as described in the sections above. Checking the parallelism of all racks Attach the dial gauge holder to the guiding carriage and move this to the end of the axle. Place a magnetized needle roller (M) if possible at ... - Page 17 ® INIRA Assembly Only use the mounting pins included in the scope of delivery for pinning the racks. Apply threadlocker all around the upper part of the pin bore (Z ) and the mounting pin (B) (e.g. ® Loctite 243).

-

Page 18: Startup And Operation

® Startup and operation INIRA Push a hex key (Y) through the assembly bushing (V) and insert it into the hex socket of the mounting pin. Size hex socket mounting pin, see Chapter 9.2.2 "Overview of the mounting kit MKP (mounting pin)". -

Page 19: Maintenance And Disposal

® INIRA Maintenance and disposal Maintenance and disposal Read the general safety instructions before beginning to work (see Chapter 2.5 "General safety instructions"). Disassembly / replacement To allow easy disassembly, the mounting pins have an interior thread. Remove the mounting pins (B) with an ... -

Page 20: Appendix

® Appendix INIRA Appendix Weight of racks Weight of racks [kg] Length [mm] Module 2 mm Module 3 mm Module 4 mm Module 5 mm Module 6 mm 1000 10.7 13.1 19.9 1500 19.5 27.1 2000 21.4 36.2 Tbl-2: Weight Information for mounting the racks 9.2.1 Overview of the required fastening screws The special fastening screws with optimized screw heads are included in the scope of delivery of... -

Page 21: Overview Of Tool Sizes

® INIRA Appendix 9.2.3 Overview of tool sizes Tool Rack module [mm] Fastening screw width across flats (Hex socket) Assembly bushing width across flats (Hex head) SW10 SW13 SW17 SW19 SW24 Tbl-5: Overview of tool sizes 9.2.4 Tightening torques for assembly bushings The specified tightening torques must be complied with when tensioning the assembled rack through the assembly bushings (see Chapter 5.4 "Mounting the racks"): Assembly bushing... -

Page 22: Permissible Parallelism Deviation Of The Assembly Surface

® Appendix INIRA Permissible parallelism deviation of the assembly surface Rack module [mm] Parallelism deviation [μm] Requirements in respect of positioning accuracy and smooth running High moderate Tbl-9: Permissible parallelism deviation of the assembly surface Permissible roll size fluctuation at the rack transition Rack module [mm] Measurement over pins deviation [μm] Requirements in respect of positioning accuracy and smooth... -

Page 23: Overview Of The Assembly Accessory Kit

® INIRA Appendix Overview of the assembly accessory kit The assembly accessory kit is needed for the rack assembly and is not included in the scope of delivery of the racks. The assembly accessory kit includes: - Assembly jig - Adjustment tool - Assembly bushings - Needle rollers / Cylinder rollers Further information can be found in the "alpha Linear Systems"... - Page 24 ® INIRA Revision history Revision Date Comment Chapter 31.03.14 New version 07.12.18 INIRA pinning Revision: 02 2022-D050733...

- Page 25 WITTENSTEIN alpha GmbH ꞏ Walter-Wittenstein-Straße 1 ꞏ 97999 Igersheim ꞏ Germany Tel. +49 7931 493-0 ꞏ info@wittenstein.de WITTENSTEIN ‒ with the future www.wittenstein-alpha.de AC: XXXXXXXX 2022-D050733Revision: 02...

Need help?

Do you have a question about the INIRA ZST 200-334-1000-R1 С-35 and is the answer not in the manual?

Questions and answers