Table of Contents

Advertisement

Quick Links

DL500-Manuel-E

DL 500 Conveyorized Etching and Developing Machine

Translation of the original instructions

Content

Leaflet................................................................2

Technical Data...................................................4

EG-Declaration of Conformity..........................4

Intended Use of Machine...................................5

Safety instructions.............................................5

Composition.......................................................7

Setup..................................................................8

Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck - Germany

Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de

Operating.........................................................10

Spare part list...................................................14

Amendment 1 Closed-Loop Rinsing Unit........18

Amendment 2 Stripper.....................................18

Guarantee.........................................................19

Disclaimer of Warranty....................................19

Copyright.........................................................20

Page 1 / 20

Advertisement

Table of Contents

Summary of Contents for Bungard DL 500

-

Page 1: Table Of Contents

Amendment 1 Closed-Loop Rinsing Unit..18 Intended Use of Machine........5 Amendment 2 Stripper........18 Safety instructions..........5 Guarantee............19 Composition............7 Disclaimer of Warranty........19 Setup..............8 Copyright............20 Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de... -

Page 2: Leaflet

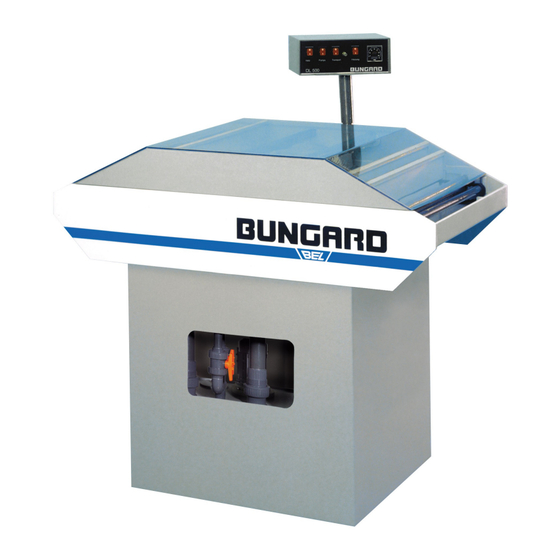

Page 2 / 20 Leaflet The DL 500 is a double sided conveyorised spray etching machine with integrated rinsing zone. This ma - chine is easy to maintain and fits perfectly to a modern PCB laboratory. The maximum capacity within one hour is 10 m². - Page 3 Option #8: Filter unit On request you can equip your DL 500 with one or two 10 " filter units to remove residues from the etching process. You can easily adjust the filter throughput via cock valve.

-

Page 4: Technical Data

DIN EN 60204-1 Sicherheit von Maschinen - Elektrische Ausrüstung von Maschinen - Teil 1: Allgemeine Anfor- derungen / Safety of machinery - Electrical equipment of machines - Part 1: General requirements Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de... -

Page 5: Intended Use Of Machine

The I/O-labelled red main switch disconnects the machine from the power supply. We presuppose that the safety fuses of the circuit and the residual current circuit are provided by the building's power supply. Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de... - Page 6 (and other heavy metals) in the waste water (usually 0.5 mg copper / liter of water). After etching Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

-

Page 7: Composition

Neutralization of the rinsing water or even the etchant can and should be left to a spe - cialist! Composition Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de... -

Page 8: Setup

2m x 2m. Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de... - Page 9 Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

-

Page 10: Operating

Control Panel All electric functions of the DL 500 are controlled from the front panel of this unit (compare Composition). From the left to the right, there are: The switches for the main supply, for the pump motor, the heater and the conveyor. - Page 11 The rinse compartment can either be used with fresh water or, with an op- tional tank and pump, as a closed loop rinse. Closed-Loop rinsing Unit Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 12 Fill the machine with 15% HCl. Close the cover. Run the machine with heating switched on for several hours. Repeat if necessary the cleaning run the next day. Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 13 The etching machine itself was predominantly made from recyclable materials and is to be supplied at the end of use to a proper and environmentally sound disposal. Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

-

Page 14: Spare Part List

Downholder with roller f. belt DL 500 6000 Niederhalter f. Riemen ohne Röllchen Downholder without roller f. belt DL DL 500 Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de... - Page 15 . incl. PVC teeth wheel for belt drive 690312 Thermostat f. DL 500 Thermostat f. DL 500 690313 Ätzmittelpumpe f. DL 500 ohne Motor pump body for DL 500 without motor 690314 Spülwasserpumpe f. DL 500 Rinse water pump f. DL 500 690315 Magnetventil f.

- Page 16 690323 Kühltank mit Pumpe für DL 500 S. cooling tank (w. pump) for DL 500S Kühlt die machines. Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 17 DL500 230VAC/12VDC/22VA 230VAC/12VDC/22VA 6000 Motorwelle PVC PVC motor gear wheel 6000 Hauptschalter mit Relais Main Switch for DL500 Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

-

Page 18: Amendment 1 Closed-Loop Rinsing Unit

Setup The module is designed for installation behind the DL500 and under the delivery table of the etching machine DL 500. You can also place the rinsing tank at any other place near the machine, as long as both Installation Tubes and connectors that are necessary to connect tank with the rinsing section of the DL500 are part of delivery. -

Page 19: Guarantee

Old parts change into our possession. Disclaimer of Warranty Bungard GmbH & Co. KG reserves the right to change or enhance its machines or machine specifications according to its judgement, if necessary. Bungard cannot be held responsible to implement aforesaid changes into machines sold already. -

Page 20: Copyright

Running the machine in corroding, humid, dusty, extremely hot or explosive atmosphere happens at the oper - ator's own risk and responsibility. We explicitly exclude any warranty for damages resulting from running the machine in in corroding, humid, dusty, extremely hot or explosive atmosphere. Copyright © 2016 Bungard Elektronik GmbH & Co. KG...

Need help?

Do you have a question about the DL 500 and is the answer not in the manual?

Questions and answers