Summary of Contents for Josef prusa PRUSA RESEARCH SL1 KIT

- Page 1 3D PRINTING HANDBOOK USER MANUAL FOR 3D PRINTERS: – ORIGINAL PRUSA SL1 KIT – ORIGINAL PRUSA SL1...

- Page 2 Original Instructions: Basic info Please always refer to the http://www.prusa3d.com/drivers/ for an updated version of this 3D printing handbook (PDF download). Translated versions of the handbook are available at: • Czech: www.prusa3d.cz/ovladace/ • French: www.prusa3d.fr/drivers/ • German: www.prusa3d.de/treiber/ • Polish: https://www.prusa3d.pl/sterowniki/ •...

- Page 3 About the author Josef Prusa (born Feb 23rd, 1990) became interested in the 3D printing phenomenon before joining Prague’s University of Economics in 2009 - at first it was a hobby, a new technology open to changes and improvements. The hobby soon became a passion and Josef grew into one of the leading developers of Adrien Bowyer’s international, open source, RepRap project.

- Page 4 1 Introduction 2 Glossary 2.1 Accessories - bundled and optional 3 Quick-start information 3.1 How to contact tech support and send log files 4 Your First Print 4.1 Unpacking 4.2 First start and Calibration 4.3 Navigating the menus 4.4 Updating the printer’s firmware 4.5 Network connection - recommended 4.5.1 Internet connection - Ethernet cable 4.5.2 Internet connection - Wireless connection...

- Page 5 9 Material Guide 9.1 Important information about resins 9.2 Which resins to buy? 9.3 Types of resins 9.4 Custom resin calibration 10 Software/driver package 11 Controlling the printer via a web browser 12 Optional Accessories 12.1 Original Prusa Curing and Washing Machine - CW1 12.2 FEP Films - Original and Aftermarket 12.3 Additional accessories 13 Regular Printer Maintenance...

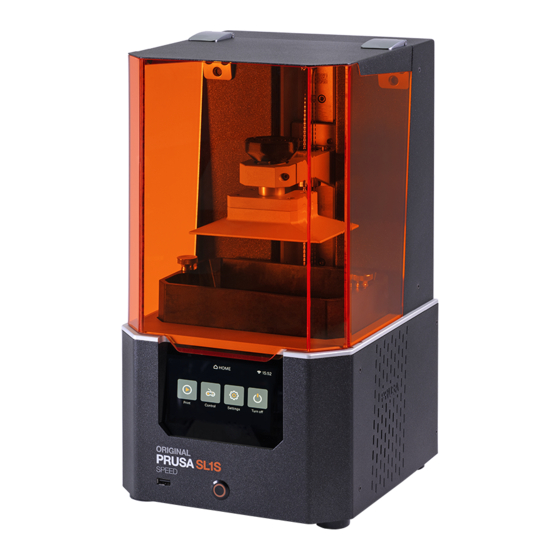

- Page 6 About this handbook This handbook is designed to help you start printing with the Original Prusa SL1 as fast as possible. It’s divided into several main parts - pay close attention to chapters about correct usage, health risks, calibration and first print. Product details •...

- Page 7 500 hours of printing - the SLA 3D printing process on the Original Prusa SL1 is considered the standard way of using and wearing the original display. The lifespan of the FEP foil is 10 cycles. When used properly in accordance to the instructions in the official guides (such as this handbook), the life expectancy of the FEP foil can be several times longer.

- Page 8 1 Introduction Thank you for purchasing the Original Prusa SL1 printer! No matter which version you’ve bought, an assembled unit or a kit, your purchase supports us in the further development of our machines. Please, read this handbook carefully, since all chapters contain valuable information regarding the use, maintenance, and troubleshooting of the SL1 printer.

- Page 9 2 Glossary Print platform - Print platform is made of a single-block of aluminum and it is connected via a cantilever to the motorized tower. The large flat part is the area to which the printed object is attached to. The print platform can be easily removed by loosening the Knob without affecting the calibration Knob - Large black knob at the top of the cantilever is designed for an easy mounting/dismounting of the print platform.

- Page 10 Touchscreen Display / Touch screen - The main control interface of the SL1. The capacitive touchscreen is used to navigate through the menus, start prints, adjust settings, or calibrate the printer. Power Button - Turns the printer on or off. This button won’t disconnect the power supply. To cut off power completely, always disconnect the power cord from the back of the printer.

-

Page 11: Quick-Start Information

3 Quick-start information The SL1 requires maintenance and regular care. It doesn’t take a lot of time and it’s not complicated, however, there are several parts on the 3D printer that can be potentially damaged as a result of incorrect use. Please keep that in mind - failure to follow the instructions in this manual may lead to severe damage to your printer and/or to a loss of warranty. - Page 12 Print display and UV LED panel Use a soft paper towel Do not look directly in UV or cloth and an LCD screen light, use a camera to check cleaning spray to clean the the UV panel! protective glass Do not leave spilled resin on You can test the LCD from the print screen the Advanced Settings Menu...

-

Page 14: Your First Print

4 Your First Print We know that you are eager to start printing immediately, however, there are a couple of steps users need to take before they can start printing. Read these chapters carefully. v.1 Unpacking After you open the box, remove the accessories case first (1), then remove the top foam (2). Grab the box using the two handles on the side and pull it up (3). - Page 15 Peel off the sticker on the right side of the printer and open the cover Remove the foam protectors Remove the tank and the foam layer underneath it Carefully peel off the sticker from the display Once the 3D printer is fully unpacked, the Selftest starts. This procedure will make sure your printer arrived in a good shape: Remove the resin tank Remove the print platform...

- Page 16 Take a look through the top of the cover. Do you see the Prusa Research company logo? Do not open the cover! Return the tank to its original position and tighten both resin tank screws. Insert the print platform rotated by 60° and tighten the black knob (Optional) Set a timezone Sound test - can you hear music coming from the printer? All done! You can move onto the Calibration Wizard...

- Page 17 That’s it! The printer is now calibrated and doesn’t have to be calibrated again unless you transport it to a new location or replace certain parts of the printer (e.g. the FEP foil). The print platform is secured by the black knob at the top of the cantilever and removing it from the printer won’t affect the calibration.

- Page 18 v.v Updating the printer5s 4r’ware We recommend keeping the printer updated at all times. Updated firmware packages bring various benefits, such as new features, bug fixes and various improvements. There are two ways to update the printer’s firmware: It’s a good practice to keep the firmware up-to-date all the time because newer versions come with new features, bugfixes, and improvements.

- Page 19 v.z Ti’e and ti’e (one con4guration )optional7 You can configure the printer’s time zone and current time in Settings - Advanced Settings - Time Settings. If you have the printer connected to the internet, you can use Automatic time settings to have the time updated automatically depending on your time zone.

- Page 20 The max resin level mark in the tank. Do not overfill the tank! Any time you are asked to refill the resin to the max, it always means adding it up to the 100% mark, not to the edge of the tank! v./ Running out of resin 9 Adding resin ’id-print The SL1 features a built-in resin level sensor, which measures the amount of resin in the tank before every print.

- Page 21 v.0 Starting the First print One last check before you start the first print: • Is the printer updated to the latest firmware version? • Did you calibrate the printer using the wizard? • Have you checked the FEP film in the tank? •...

- Page 22 After the printing process finishes, open the lid and place the black plastic tray on the printer as depicted in the picture. Use a plastic spatula or paper towels to wipe the top part of the print platform clean. Then, unscrew the black knob at the top of the tower to unlock the platform.

- Page 23 v.11 Re’oming a print stuck to the botto’ of the tank In case the first layer did not stick to the print platform, it remained stuck at the bottom of the tank. No matter how big or how small the stuck layer is, there’s a quick safe way that will help you remove it from the FEP film without damaging it - see chapter 15.1 - Removing an object stuck to the bottom of the tank.

- Page 24 5 After-print checks and actions The SL1 needs to be cleaned up after every print to avoid potential damage to the printer. Failure to maintain your printer properly may lead to severe damage and loss of warranty. • Never leave the resin in the tank after a print finishes. There may be tiny bits of solidified resin left in the tank, which could potentially damage the FEP foil or the display the next time the print platform would go all the way down.

- Page 25 6.1.2 Drying and curing Use a soft paper towel to dry your print and/or put it on the windowsill - ideally in direct sunlight. Curing the model without a strong UV light source can take a long time. One of the common practices is to place the model in direct sunlight for an extended period of time (e.g.

- Page 26 6.3 ?enu structure and admanced functions • Print • Project browser • Print settings • Control • Home Platform - performs the homing procedure • Home Tank - performs the homing procedure • Disable Steppers - cuts off the power to stepper motors •...

-

Page 27: Printing Your Own Models

6 Printing your own models Once the printer is fully calibrated (see the previous chapter) and the sample models are looking good, you will probably want to print your own model. There are various ways how to do that. Slicing procedure overview in 6 steps 1. - Page 28 z.2 Creating your own ’odels To create a 3D model, you need a dedicated program - a 3D editor. There are a number of various 3D programs and your choice will usually depend on what type of model you wish to create. The easiest place to start is TinkerCad (www.tinkercard.com) - it’s an online editor that runs in your browser’s window, so no installation is required.

- Page 29 z.v PrusaSlicer PrusaSlicer is our own open-source tool for slicing models. It’s the only slicer you will ever need for your Original Prusa printers! It contains print profiles and recommended settings for the entire range of Original Prusa devices. You can download the latest version of PrusaSlicer from www.prusa3d.com/drivers (stable releases) as a part of the Apps &...

- Page 30 z.6 Slicing ob,ects for the SL1 Every 3D model is different, so an individual approach is needed for every single object. However, we can still offer several tips, tricks and hints that will make the slicing and printing processes easier. If you already have experience with FFF/FDM printing, you will notice that the preparation of models for SLA printers is slightly different.

- Page 31 z.z I’porting an ob,ect into PrusaSlicer Once you start PrusaSlicer, select the Original Prusa SL1 in the Printer menu on the right side of the window. If it’s not listed, you can add it either by selecting Add a new printer option in the same menu, or by going to Configuration ->...

- Page 32 z.8 Positioning an ob,ect Move tool (M) - moves the object in XYZ axes. Click and drag the object to move it in XY axes, use the blue arrow to move it in Z axis (up and down). Scale tool (S) - scales the object, either uniformly or in a single axis. You can adjust the values in the right-side menu by entering numbers in Scale factors section.

- Page 33 Comparison of SLA supports (left) and FFF supports (right) Each print will require a slightly different approach based on the shape, size and details present on the model. In this chapter, we’ll explain the basics of support creation in general. For more examples, see next chapters.

- Page 34 ?anual editing Clicking the Manual editing button opens a new menu and a new set of tools, which enable you to manually add, remove and modify support points on the object. Use Left mouse click to add a support, right mouse click to remove a support, and combine Shift+Left mouse to drag a selection box to select more supports.

- Page 35 z.0.1 Pad The pad is a structure generated under the print - it’s the base for supports. You can easily detach the pad along with the print from the print platform with a spatula. The pad is recommended, however, it’s also possible to print certain objects without it, depending on the object’s shape.

- Page 36 PrusaSlicer can estimate the printing time and amount of resin needed z.0.v EJposure ti’e eJplained PrusaSlicer allows you to change the exposure time (the number of seconds for which a single layer is cured) for standard layers and first layers separately. There are no “universally usable” numbers, so we recommend using the preconfigured PrusaSlicer profiles.

- Page 37 Important information about print times Keep in mind that no matter how many objects (or how big) you place on the print platform, the exposure time remains constant, so each layer will be finished in the same amount of time. In other words, printing a single 10 cm tall object or a dozen of 10 cm tall objects placed next to each other will always take the same amount of time.

- Page 38 z.11.2 Ei!el tower This is another model that is very easy to slice. Disable the Pad and Supports and use the Place on face function along with move/rotate/scale tools to position the object until it’s green (meaning it fits the print platform). z.11.3 #ewelry The Original Prusa SL1 is perfect for printing tiny, highly-detailed models.

- Page 39 You can check the examples below to see how we positioned them before printing. z.11.v Characters and props Characters and props are often some of the most complex objects you can find. The Original Prusa SL1 can handle the details on character models without any issue, so you can produce high-quality figures or props from your favorite movie or game.

- Page 40 Incorrectly rotated object - the SL1 will print it without issue, however, removing the supports may leave small marks on the detailed (and most important) part of the object. Bridging doesn’t work the same way as with FFF/FDM 3D printers. The SL1 cures a single layer at a time, which in this case would most likely lead to layer separation due to peeling forces.

- Page 41 z.13 Printing large and heamy ob,ects When printing large and heavy objects, you may find out that the standard supports are not strong enough to support the weight of a large object. There are two ways how to deal with large and heavy objects: Change the settings for supports, make them thicker and sturdier Hollow the object in Meshmixer - see the next chapter You can easily modify the support parameters by opening the Print Settings tab in PrusaSlicer and...

- Page 42 Hollowing can be configured for each model individually using the Hollowing tool in the left toolbar. Alternatively, you can configure hollowing for all models at once in Print Settings - Hollowing. The hollowing and drainage hole workflow is non-destructive. Hollowing can be canceled and drainage holes can be moved or removed at any time.

- Page 43 Solid model: 237 ml, $13.75 resin cost (left), Hollowed model: 81 ml, $4.70 resin cost (right) 7 Connecting PrusaSlicer to the SL1 over the network PrusaSlicer can be connected to the SL1 3D printer directly, either via ethernet or Wi-fi connection, enabling you to send sliced models into the printer’s internal storage over the network.

-

Page 44: Updating The Printer's Firmware

Connecting to the SL1 with PrusaSlicer Press the Test button to check the connection. If everything is configured correctly, the test will be successful. Go back to PrusaSlicer’s main window with the 3D view. There should be a new button labeled “Send to printer”. -

Page 45: Material Guide

9 Material Guide Liquid resins are photosensitive materials used for printing on SLA 3D printers. Resins are also known as photopolymers and they are cured (solidified) by UV light - this also includes sunlight. Compared to filaments for FFF/FDM printers, the major difference is that there are not various materials such as PLA, PETG or ASA. - Page 46 • Do not store in dusty areas • Resin produces fumes - keep the room ventilated during printing • Some people may be allergic to resins - in case you experience any kind of discomfort (itching, rash), stop using the machine and contact a doctor Do not throw resin bottles (empty or full) into regular waste.

- Page 47 Heat-resistant resin Highly temperature-resistant Used for injection forms Expensive Bio-compatible resins Non-toxic Suitable for dental implants manufacturing Abrasion-resistant Expensive Flexible resin Similar to rubber (70A hardness) Lower resolution of printed parts 0.v Custo’ resin calibration We are continuously testing and growing the number of supported resins for the SL1 printer. Starting with firmware 1.3.0, we are adding an option for experienced users, who are using special resins and would like to tune their settings.

-

Page 48: Optional Accessories

12 Optional Accessories There’s a couple of things you might want to consider buying to make your 3D printing experience better, safer and more convenient. 12.1 Original Prusa Curing and Washing ?achine - CW1 Objects printed from liquid resin are usually a bit soft and sticky. To clean them and reach optimal surface properties, the objects need to be washed, dried and cured. - Page 49 12.2 FEP Fil’s - Original and After’arket The Original Prusa SL1 comes with a spare FEP film, which acts as a transparent bottom of the resin tank. Since this part is a consumable (it will degrade over time by continuous use), you will have to replace it from time to time.

- Page 50 • Respirator / protective glasses 13 Regular Printer Maintenance Although the Original Prusa SL1 has a number of smart sensors and has been carefully designed to be easy to use, it’s still a machine and requires regular maintenance and care. There are several key areas that require attention if you want to keep your printer in good shape for a long time.

- Page 51 If the FEP film has a grey-ish tint, you can restore it to its original look by washing it with warm water with a bit of dishwashing soap (or even regular soap) before you start printing again. Don’t print with a dirty or damaged FEP film, as it will negatively impact the print quality.

- Page 52 13.6 Acrylic lid The lid has three major functions: it protects the printed model from potential damage, helps to contain resin fumes inside the box and blocks a significant amount of UV light so it doesn’t reach the printing chamber. Especially the last part is important - if you leave the resin in the tank and keep the lid open, it can start to solidify quickly depending on the environment.

- Page 53 Dust can also accumulate on the underside of the display and on the reflector. You can clean these parts carefully with compressed air. First, unscrew the eight screws holding the display in place, then slowly and carefully remove the display - be careful not to damage the display’s wires. Use compressed air from the distance of about 30 cm to clean out the dust particles gently.

-

Page 54: Hardware Troubleshooting

14 Hardware troubleshooting Please note that detailed hardware troubleshooting articles will be available only online through https://manual.prusa3d.com or https://help.prusa3d.com. 1v.1 FEP 4l’ 9 Tank botto’ replace’ent Please note: Every time you replace the FEP film, tighten the screws properly, but don’t use excessive force. - Page 55 Remove all screws and gently press your fingers against the FEP film to release it After you remove the FEP film, take a spatula and scrape all bits of leftover resin from the edges. The edges must be perfectly clean, otherwise, the tank will leak Clean the tank and frame using isopropyl alcohol...

- Page 56 Align the frame with the new FEP film, so the holes match. Start adding screws one by one. Place the assembly onto the tank body and align the screws with the holes. Don’t create holes for resin tank screws yet! Start tightening the screws in a criss-cross pattern to ensure that the film will be stretched evenly.

-

Page 57: Print Quality Troubleshooting

15 Print quality troubleshooting When you print on SLA printers, you may encounter several print quality issues. The following section will help you recognize them and solve them. 16.1 Re’oming an ob,ect stuck to the botto’ of the tank In case the first layer did not stick to the print platform, it remained stuck at the bottom of the tank. No matter how big or how small the stuck layer is, there’s a quick safe way that will help you remove it from the FEP film without damaging it: Unscrew the resin tank screws and remove the tank... - Page 58 b) The bottom of the tank is cloudy/dirty Before you pour the resin into the tank, make sure that the bottom of the tank (the FEP film) is completely clear. A cloudy, dirty or damaged FEP film will have a negative impact on the printing quality and it may even block UV light enough to stop the resin from solidifying properly.

- Page 59 Solution: Please refer to the online troubleshooting section at https://help.prusa3d.com to learn more about diagnosing the function of these two parts. 16.3 Printed ob,ect has ’issing parts In some cases, a print can finish even if some parts of the object weren’t fully printed, but a missing part of an object will more often cause the whole print job to fail.

- Page 60 16.v Printed ob,ect is ’issing s’all details The Original Prusa SL1 3D printer can produce objects with an incredible amount of details - tiny wrinkles on clothes of a figure, structure of a skin, thin railings on buildings… however, in case the printed object is missing incredibly tiny details (not entire parts of the model), it can be due to incorrect exposure times.

- Page 61 Solution: Try printing one of the sample objects to see whether the issue remains. If the sample object was printed without trouble, reset your PrusaSlicer settings. If the sample object has the same sort of trouble, inspect the FEP film in the resin tank - it may be dirty. In very rare scenarios, a faulty UV LED panel can be the cause.

- Page 62 16./ Print doesn5t appear 9 resin does not solidify If the print does not appear on the print platform, nor at the bottom of the resin tank, there are a couple of possible causes: insufficient exposure times, faulty UV panel, faulty LCD screen, or there’s too much isopropyl alcohol in the resin.

- Page 63 Solution: Try printing a sample object and see if the issue persists. If it does, clean the resin tank properly and try again. Continuous issues with separated / missing layers can be caused by a faulty UV LED panel - check whether it works correctly. Otherwise, the cause is most likely a broken object file.

-

Page 64: Faq - Frequently Asked Questions

Solution: Make sure the FEP foil on the bottom of the tank is perfectly clean. Carefully remove any dirt / solidified bits. If the FEP foil is cloudy, use hot water and dishwashing soap to clean it and restore it to the original look. 16 FAQ - Frequently Asked Questions Q: UV LEDs don’t light up A: If you want to check whether the UV LED panel works correctly, NEVER LOOK DIRECTLY IN... - Page 65 Q: Wifi / LAN does not connect A: There can be various reasons why the printer won’t connect to your network, but since every network is different, it’s difficult to pinpoint the exact cause. • Can you see the list of other wifi networks in the browser? •...

- Page 66 Print and share! Do not forget to tag your prints with #prusasl1 while sharing so we can find, pin and showcase them with our http://www.prusa3d.com/original-prusa-i3-prints/ Happy Printing :) ...

Need help?

Do you have a question about the PRUSA RESEARCH SL1 KIT and is the answer not in the manual?

Questions and answers