Summary of Contents for BeaconMedaes Manfiold

- Page 1 Operation and Maintenance Instructions Manifold Control Systems Manual Manfiold Part number 2006230 Revision 03 May 24, 2019...

- Page 2 Operation and Maintenance Manual Manual Manifold This unit is purchased from: Date purchased: Model number: Serial number: Option(s) included: Any information, service or spare parts requests should include the serial number and be directed to: BeaconMedæs Telford Crescent, Staveley Derbyshire S43 3PF Telephone: +44 (0) 1246 474242 Email: gbn.info@beaconmedaes.com Website Contacts: www.beaconmedaes.com BeaconMedæs reserves the right to make changes and improvements to update products sold previously without notice or obligation. Atlas Copco Ltd. trading as Atlas Copco Medical Unit 18 Nuffield Way, Abingdon, Oxfordshire, UK OX14 1RL Personnel must make themselves familiar with the contents of this manual and the function of the unit before installing, operating or maintaining. Abbreviations Abbreviation Full Description Abbreviation Full Description British Standard Kilo pascals British Standard Pipe Maximum...

-

Page 3: Table Of Contents

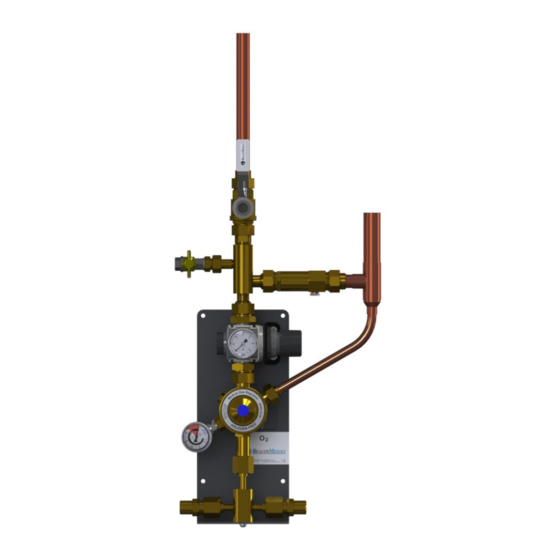

Manual Manifold Table of Contents Section Figures Tables 0. Safety Precautions 1. General Information 1 - General Arrangement 1 - Main feature & components 2 - Schematic Diagram 2 - Manifold panel plus options part numbers 3 - Relief valve set points 4 - Manifold header part numbers 2. - Page 4 Manual Manifold 0. Safety Precautions Not applicable 0.6 Cleaning This section gives safety, storage and handling information for the BeaconMedæs Emergency Reserve Manifold only. Component parts lists and The manifold should be wiped over with a damp cloth descriptions are available on request. frequently to remove any dust or foreign substances Operators should have carefully read and become 0.7 Safety Notice...

- Page 5 Manual Manifold The manual manifold can be used as either main Table 1: Main features/components supply or emergency reserve manifold (ERM). When used as a emergency backup manifold the line Item Description pressure regulator should be set slightly lower than the primary supply pressure .

- Page 6 Manual Manifold Figure 2 - Schematic Diagram Lockable line ball valve (Valve 'B') Alternative supply Medical gas pipeline source distribution system Lockable line ball Ball valve (Valve 'A') valve 'C' Test Point Exhaust (piped to safe location) Non-return valve 2nd stage relief valve Line pressure gauge 2nd stage...

-

Page 7: Relief Valve Set Points

Manual Manifold Header Extension For 2nd Stage Pressure Regulator Cylinders connection For safe operation with regard to performance, mechanical strength and contamination the unit fully The control panel is compatible with standard conforms to BS EN ISO 10524-2, the second stage BeaconMedæs cylinder headers and tail pipes. -

Page 8: Installation

Manual Manifold Installation selected fasteners are suitable for supporting the typical 15 kg weight of the panel. Installation procedure for 2.1.3 Identify the centre position of the control panel on the wall and mark. Panel 2.1.4 Check figure 3 & 4 for typical mounting CAUTION: Ensure no contaminates, oil heights and mounting hole details. - Page 9 Manual Manifold Figure 4 - Typical Installation For use with ‘VF’ Type Cylinders Note - Image shows optional exhaust and terminal box. CAUTION: Supplied fixings are for use with solid masonry type walls only. Typical panel weight is 15kg. Note - ‘VF’ size cylinders are typically used for CO2. Note - If option high pressure bank valves are used (see figure 1, item 14) the manifold width increases by 110mm per side.

- Page 10 Manual Manifold Figure 5 - Optional Cylinder Content Alarm Wiring screws and flange nut supplied with the extension kit. Secure the header stub pipe to the previously Cylinder content fitted 5/8” connector. alarm input (Wired on site) 2.3.5 Mark the wall mounting points (see figure 6), drill and secure in place.

- Page 11 Manual Manifold Note - For additional cylinders beyond 6 continue to add the above for either single or double racks. 2006230.03...

-

Page 12: Typical Tailpipe And Cylinder Connec

Manual Manifold Cylinder Connection Figure 7 - Typical tailpipe and cylinder connection CAUTION: Ensure that all tailpipes supplied Bodok Seal are the correct gas type. The gas ID is stamped onto the nut that connects to the header non-return Typical valve (see figure 7). -

Page 13: Commissioning

Manual Manifold Installation check 2.5.6 The installation must now be purged as per HTM 02-01 for UK installations, or as per relevant standards if installed outside the UK. 2.5.1 Ensure that all tailpipes are connected to the gas cylinders and manifolds on both sides and that the Commissioning restraining chains are secure around the cylinders. -

Page 14: Principles Of Operation

Manual Manifold Principles of Operation Operation as a emergency reserve manifold (ERM) General 4.3.1 In the event of the primary system failing to supply (Awareness of the Primary supply failure is The control panel line pressure is set in line with table typically from a central alarm system) the ERM line 5 depending on normal operating range and whether regulator (see figure 8) should be manually increased... -

Page 15: Maintenance Procedures

Manual Manifold Typical Cylinder Handling CAUTION: If there is any leakage of gas the cylinder should be removed from service and Checklist returned as faulty. DO NOT attempt to tighten gland nuts etc, as this may cause damage to the CAUTION: Only persons who have had valve. -

Page 16: Cylinder Connection

Manual Manifold the manifold is supplying the hospital. Figure 10 - Cylinder Connection 5.3.2 If the control panel is used as an ERM, close Bodok Seal the isolating valve slowly and check that there is no effect on the line pressure to the hospital. Open the isolation valve when finished. -

Page 17: Component Replacement Procedures

Manual Manifold CAUTION: For emergency backup 5.3.7 To test the empty cylinder contact gauge close manifolds ensure the main supply is functioning the duty bank cylinder valves and observe the alarm correctly before taking off line for maintenance. condition as the pressure drops. IMPORTANT! Open the cylinder valves on 6.1.1 Close the manifold line isolation valve... -

Page 18: Line Non-Return Valve Replacement

Manual Manifold Figure 11 - Line Non-return Valve Replacement 6.3.2 Disconnect the valve at the 1/4” connection (see figure 12). Check the bonded seal and replace if necessary. Fit the new valve. Line non-return 3 x 1” flat face 6.3.3 Follow steps in section 6.11 to bring the valve manifold connection points... -

Page 19: 1St Stage Regulator Replacement

Manual Manifold 6.4.5 Inspect the existing seals and replace if Figure 14 - 1st Stage Regulator Replacement required, see figure 13 for seal part numbers. 6.4.6 Taking care not to damage the O-ring seals replace the new regulator as shown in figure 13, and fasten the 2 flat face joints. -

Page 20: 2Nd Stage Relief Valve Replacement

Manual Manifold 6.6.2 Slowly turn the left hand 1” swivel nut Figure 16 - 1st Stage Relief Valve Replacement connection. If the you hear gas escaping do not fully unscrew the joint until the system is fully drained. 1” flat face connections (O-ring 6.6.3 Fully disconnect the 1”... -

Page 21: Line Pressure Gauge Replacement

Manual Manifold 6.8.1 Complete steps in section 6.1 before carrying 6.9.3 Replace the old seals with those supplied out any component replacement on the control panel. with the new gauge. 6.8.2 Slowly turn the swivel nut of the tailpipe 6.9.4 Fit the new gauge as per the old unit. -

Page 22: Recommended Spares

Manual Manifold 6.10.3 Start to unscrew the contact gauge, if you hear 6.10.6 Follow steps in section 6.11 to bring the gas escaping do not fully remove until the system is control panel back online. fully drained (see figure 19). 6.11 Returning the Control Panel Figure 19 - Cylinder Content Gauge Replacement Back online... - Page 23 Manual Manifold Figure 21 - Control panel item details Table 12: Spares scheduling QTY req./ Number of Item Part Description Panels Number <5 >5 Contact Gauge – 0-250 bar/25 2005961 1(2) 2(4) bar Falling Contact Gauge – 0-100 bar/14 2005772 1(2) 2(4) bar Falling...

- Page 24 Tel: +44 (0) 1246 474242 www.beaconmedaes.com Atlas Copco Airpower n.v. Boomsesteenweg 957 2610 Wilrijk - Belgium Atlas Copco Ltd. trading as Atlas Copco Medical 0088 Unit 18 Nuffield Way, Abingdon, Oxfordshire, UK OX14 1RL...

Need help?

Do you have a question about the Manfiold and is the answer not in the manual?

Questions and answers