Table of Contents

Advertisement

Quick Links

Manufacturer / Technical Support

Elimko Electronic Production and Control Co. Ltd.

8. Avenue 21. Street No:16 06510 Emek- Ankara / TURKEY

Phone: + 90 312 212 64 50 Fax: + 90 312 212 41 43

www.elimko.com.tr / e-mail:elimko@elimko.com.tr

User Manual

Manufacturer / Technical Support

Elimko Electronic Production and Control Co. Ltd.

8. Avenue 21. Street No:16 06510 Emek- Ankara / TURKEY

Phone: + 90 312 212 64 50 Fax: + 90 312 212 41 43

www.elimko.com.tr / e-mail:elimko@elimko.com.tr

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Elimko E-PR-110

- Page 1 User Manual Manufacturer / Technical Support Elimko Electronic Production and Control Co. Ltd. 8. Avenue 21. Street No:16 06510 Emek- Ankara / TURKEY Manufacturer / Technical Support Phone: + 90 312 212 64 50 Fax: + 90 312 212 41 43 Elimko Electronic Production and Control Co.

- Page 2 1 - INDEX 1. INDEX ....................... 1 - 2 2. WARNINGS ...................... 3. EU DIRECTIVE COMPLIANCE ................ 4. DESCRIPTION ....................4.1. Type Coding ....................4.2. Technical Specification .................. 6 - 7 4.3. Dimensions ....................4.4. Panel Mounting ..................... 5. USAGE ......................

- Page 3 1 - INDEX 2 - WARNINGS E-PR-110 recorder is designed for panel mounting and should be used in 6.5.2. Ethernet Adjustments ................industrial environment. 6.5.3. Serial Port Adjustment ................The package of E-PR-110 recorder contains; 6.5.4. Screen Adjustment .................. Recorder 6.6.

-

Page 4: Type Coding

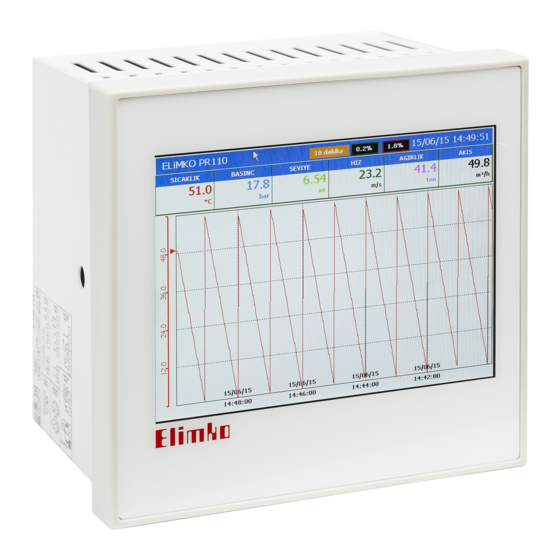

4.1 - Type Coding E-PR-110 series industrial recording and control devices complies with IEC/TR 60668 E-PR-110 - S1 - S2 - S3 - S4 - Y - Z standard with its 144x144 mm front panel. These series has a high brightness and high resolution, 640x480 pixel TFT touch panel and features several analog and digital interfaces. -

Page 5: Technical Specification

4.2 - Technical Specification 4.2 - Technical Specification Digital Input Max. 64 Digital Inputs (B, E, J, K, L, N, R, S, T, U) Digital Output Max. 64 Digital Outputs, 24 V DC, 40 mA (Pt-50, Pt-100, Pt-500, Pt-1000, Ni-100, Ni-200, Ni-500, Input Types Ni-1000) Max. -

Page 6: Panel Mounting

(panel). This must prevent the live parts being accessible to human hands and metal tools. (See Section 7. CONNECTION DIAGRAMS) E-PR-110 does not include a power switch. Therefore, the power supply of the device and power outputs must be wired through the proper fuse or circuit breaker. -

Page 7: Front Panel

5 - USAGE 5.1 - Front Panel 5.1 - Front Panel During normal operation, the operation buttons are hidden to increase the display area. Hidden operation buttons can be made visible by touching the bottom of the screen (see Figure 5.2). Explanations are give in Figure 5.2 regarding the In the event of a new alarm, the background color of the title area flashes between red operation buttons. - Page 8 5.1 - Front Panel 5.2 - Trend Page Traces, process values, and alarm states of the channels in selected group are viewed. By pressing button the menu given Figure 5.5 is opened. This button selects one of the groups and is active only In Trend Page while not in History mode, newest recorded data is drawn on the screen TREND, BAR, DIGITAL and DIGITAL 2 views.

- Page 9 5.2 - Trend Page 5.2 - Trend Page Historical mode must be selected for this key to be active. One Grid Forward This button scrolls the graph forward by a grid interval. Historicaly mode must be selected for this key to be active. One Grid Back This button scrolls the graph backwards by a grid interval.

- Page 10 5.2 - Trend Page 5.3 - Bar Graphic Page Recording can be made continuously or batch base. To start a batch in any time, Start Batch is selected in Operator Menu Start Batch screen will be opened as Channel shown below. In this screen Batch Name, Operator, Part No Serial No can be...

- Page 11 5.4 - Digital View Page 5.4 - Digital View Page Channel Name Process Value Process Unit Totalizer Alarm and Unit States Operator Menu for Digital View Page is opened by pressing In Digital View Page, totalizer values, process values, and alarm states of Reset Totalizer button.

-

Page 12: Overview Page

5.5 - Overview Page 5.6 - Alarm Log All channels can be viewed in this page together. Process values of all available sources can be viewed in a single page. Each row in the page corresponds to a process group from one of the available slots, Modbus Channels or Math Analog Channels. -

Page 13: Totalizer Log

5.7 - Totalizer Log 5.8 - Instrument Log Source Name, record date, totalizer value and unit of the last recorded 10000 totalizer The date and definition of last recorded 1000 events of the device are listed in values are listed in Totalizer Page. The last recorded totalizer is displayed at the top of Instrument Log Page. -

Page 14: Operator Log

5.9 - Operator Log 5.10 - Digital Log Source Name, record date and definition of the last recorded 65536 digital log values are listed in Digital Log Page. The last recorded digital log value is displayed at the top Operators can add messages anytime while operating the device in order to assert of the list. - Page 15 5.11 - Digital 2 Pressing key accesses to Menu page. Upon pressing key authentication window opens and user name/ password are asked. After selecting UserName and Password, main menu is reached by either pressing MENU or LOGIN button. LOGIN access does not require authentication on subsequent entries until LOGOUT is pressed from Main Menu.

-

Page 16: Adjusting Parameters

6.1 - Adjusting Parameters 6.2 - Main Menu All of the parameters can be adjusted by touch panel. An example of a parameter Detailed descriptions of the pages that can be accessed from the main menu are editing screen is given below. described in the sections indicated in Figure 6.2 OS button allows access to the... -

Page 17: Device Page

6.3 - Device Page 6.4 - Security Page User names, passwords and access rights of users are determined in Security In Device Page, Device Type Page. There is no restriction for ADMIN user rights and access rights of other and Version are shown. Date and users are determined by ADMIN user. -

Page 18: Hardware Page

6.5 - Hardware Page 6.5.1 - Slot Adjustments Relay Output and Digital Output Test Page The hardware adjustments are made in this page. HARDWARE Page consists of 4 tabs Slot, Ethernet, Serial Port Screen 6.5.1 - Slot Adjustments The calibration parameter adjutment resides in this tab. Any erroneous operation in Analog Input Card Calibration Page will corrupt the calibration parameter and measurements become faulty. - Page 19 6.5.1 - Slot Adjustments 6.5.1 - Slot Adjustments Analog Input Card Calibration Adjustments Analog Input Card Calibration Adjustments For the calibration of Analog Input cards, firstly, the channel to be calibrated should be selected from window. The calibration parameters are explained below. From Channel 50 mV: Set the calibrator as a millivolt source and adjust the calibrator output 50.000 mV.

- Page 20 6.5.1 - Slot Adjustments 6.5.1 - Slot Adjustments Analog Output Card Calibration Adjustments Analog Output Card Calibration Adjustments The current and voltage outputs of analog ouput channels provided with Analog Output cards can be calibrated on the screen given in Figure 6.10. For each current and voltage outputs, 2 LOW and 2 HIGH calibration values must be saved.

- Page 21 6.5.2 - Ethernet Adjustments 6.5.3 - Serial Port Adjustment TCP/IP settings are done by defining the IP Address Subnet Mask Default Communication parameters of the RS-485 port (Boud Rate, Parity and Stop Bit) are Gateway . Definitions of these parameters are made either manually or automatically by adjusted in this tab.

-

Page 22: Channels Page

6.6 - Channels Page 6.5.4 - Screen Adjustment Language: The language of the device can be chosen either Turkish or English. After selecting the slot from top window and the channel from the left buttons, related This parameter determines the brightness of the screen. content is loaded to the screen. - Page 23 6.6.1 - Relay Output Card Adjustments 6.6.2 - Digital Output Card Adjustments The name of the related Relay Output can be written by this Name: Please see section 6.6.1 for a description of parameters. parameter. (maximum length of 12 characters) Description: Maximum 50 characters long description.

- Page 24 6.6.3 - Analog Input Card Adjustments 6.6.3 - Analog Input Card Adjustments The channel can be named with using maximum 12 characters. Name: Shift Value: Determines shift value of process value. Maximum 50 characters long description. Determines the unit of the input. Description: Unit: Determines input type.

- Page 25 6.6.3 - Analog Input Card Adjustments 6.6.3 - Analog Input Card Adjustments CJ Type, CJ Source and CJ temperature parameters are active only TC inputs( See Figure 6.25 For TC sensor connection, E-CJ-NTC-01 compensation sensor should be used when the CJ Type is selected as EXTERNAL.

- Page 26 6.6.3 - Analog Input Card Adjustments 6.6.4 - Analog Output Card Adjustments The related channel input can be named with using maximum CJ Type Name: 12 character. Maximum 50 characters long description. Description: Determines the analog source by which the analog output is Source: controlled .

- Page 27 6.6.4 - Analog Output Card Adjustments 6.6.5 - Alarm adjustments For each Math Analog Analog Input Modbus channels, two alarms are defined and can be configured to several ouput forms ( See Figure 6.29, Figure 6.30 Figure 6.31 Maximum 12 characters long alarm name. Any character string can Name: be entered in order to name the alarm.

- Page 28 6.6.5 - 6.6.5 - Alarm adjustments Alarm adjustments Working forms of alarm types are described below. High Alarm Low Alarm Hysteresis Hysteresis Slow / Fast Rate Alarm Deviation Deviation Derivation Time Slow Rate Fast Rate...

- Page 29 6.6.6 - Totalizer Adjustments 6.6.7 - Record Adjustments Determines whether the channel recording is activated or not. Enable: One totalizer is defined for each slot analog input, math analog and Modbus analog The parameter can be selected as channels. Totalizer of related channel can be named with using 12 characters. Sampling: Determines the recording period.

- Page 30 6.6.7 - Record Adjustments 6.6.8 - Digital Input Card adjustments Changing the recording period parameter causes losing of the relevant channel's State changes in all digital input channels are recorded to DIGITAL LOG . In addition, archived data recorded in that day at which the modification takes place. Daily memory the channels can also be recorded periodically.

- Page 31 6.6.9 - MODBUS Channels Page 6.6.9 - MODBUS Channels Page Up to 16 MODBUS RTU channels can be configured by this page. Firstly, channel When the Address Reg. Start Adr. Reg. Count parameters are number is clicked from the left of the screen before starting the configuration. MODBUS set to the same values for more than one channel, the Index channel process values are transferred from slave MODBUS RTU devices over the...

- Page 32 Math Channel djustments 6.6.9 - MODBUS Channels Page 6.6.10 - Equation assignable 16 Analog Mathematics and 16 Digital Mathematics channel are available on device. Analog math channel parameters are same as the slot analog channel parameters except the input parameters. Instead of input selection, equations are assigned for math.

- Page 33 6.7 - Real Time Channels Page 6.7 - Real Time Channels Page Period, Start , and parameters determine the real time interval in which the related real time source will be active as shown below. For example Period, Start , and are adjusted as Every Minute 0 5 respectively,...

-

Page 34: Groups Page

6.8 - Groups Page 6.8.1 - Changing Alarm Set Values in Trend View 6 process groups with 6 channels can be defined in the device. The channels of the While the user is in Trend view, the alarm set value can be changed by touching the process groups can be chosen from slot analog channels, modbus channels or math defined channel (See Figure 6.49). - Page 35 6.8.1 - Changing Alarm Set Values in Trend View 6.8.2 - Batch Start Input Batches can be initiated manually via the OPERATOR MENU on TREND VIEW or automatically by digital inputs which is enabled in the group configuration by assigning the Start Input parameter of the relevant group to one of the digital inputs available in the device.

- Page 36 6.8.2 - Batch Start Input 6.8.2 - Batch Start Input Figure 6.56 shows the typical view of a running batch in which the batch number is When the Batch Start Input key is pressed, the window shown in Figure 6.55 appears. shown in pink at the top of the page.

- Page 37 6.8.2 - Batch Start Input 6.8.2 - Batch Start Input Previously recorded batches can be reached using trend view operator menu. Open/Stops Batch opens batch management window in which user can stop running batches and open completed batches for review. Figure 6.61 GROUP-1 Batches with a running Figure 6.62 GROUP-1 Batches after stop batch...

- Page 38 The data stored in the device can be downloaded to the computer via USB or Up to 10 custom linearization tables can be defined for linear channels. These tables ETHERNET connection with the E-PR-110 DATA EXPLORER program and the printer define input and output relations for non standart sensors.

- Page 39 Directory name selected directory located on the external disc. Directory Synchronization reads or writes the data to/from the directory Name: [Selected Directory]\E-PR-110-[Tag]\Archive depending on synchronization direction. Three different data transfer options are available for synchronization. COMPLETE option transfers all data available for synchronization.

- Page 40 6.10 - Archive 6.11 - E-mail Recorder can be configured to send e-mail reports contaning instanteneous process values and states up to 4 recipients at adjustable periodic times or by multiple configurable triggers such as sources and general events. 6.11.1 - Server Adjustments Server: SMTP incoming mail server Port:...

- Page 41 Recipient 1-4: Up to 4 recipient can be defined for e-mail reports. Unused recipients Source 1-8: Up to 8 sources which will trigger e-mail notification to the recipients can should be left blank. be defined. For periodic e-mail notification, one of the real time channels with required interval should be assigned to any of the sources.

- Page 42 6.12 - PID On New ON or OFF selectable. If ON is selected, a new e-mail is sent when PID configuration window is accessed from MAIN MENU by pressing PID button. an alarm occurs. Alarm: 12 PID control loop with different control parameters can be defined for various control applications On New ON or OFF selectable.

- Page 43 6.12 - PID 6.12 - PID Cycle time determines the PID PWM ouput period and is only applied PID Source: PID Source to be configured. to the digital outputs and is entered in seconds. Short values of cycle Maximum 12 characters can be entered. Cycle Time: times result more precisional and accurate contol but may cause Name:...

- Page 44 6.12 - PID 6.12 - PID PID Sources can be directed to analog outputs, relay or digital output channels. When When the fisrt group channel of a group is assigned to a PID source, usual Trend View the analog outputs are used for control signal, Zero and Span parameter of the analog appears different and turns to PID control page form which provides a clear display of output should be assigned 0 and 100 respectively.

- Page 45 6.12 - PID 6.12 - PID Proses Value Set Value Output Value Figure 6.76 PID Control Page...

- Page 46 6.13 - PROFILE 6.12 - PID To change the value of a PID source , click SET v alue of the PID source from 16 different profile sources can be configured in the device and used for TREND view s or click PID Source window...

- Page 47 6.13 - PROFILE 6.13 - PROFILE Explanations about the parameters are given below. The screenshot is as If the profile is connected to a process, the profile is associated given in Figure 6.13.2. with that process. - Profile initial value can be synchronized to the process. Process Source: - The Maximum Shift parameter in curves can be activated to Profile Source:...

- Page 48 6.13 - PROFILE 6.13.1 - Curves Explanations about the parameters are given below. The screenshot is as given in Figure 6.13.3 Curve: It can be configured by selecting one of the 10 curves. The curve related to this parameter can be named. Name: A maximum of 12 characters can be used.

-

Page 49: Connection Diagrams

6.13.1 - Curves 7 - CONNECTION DIAGRAMS The back panel view of E-PR- device is shown at the below figure. There are slots at the back panel. Figure 7.1 E-PR- Before making any connection, Rear Panel the protective earth terminal should be connected. - Page 50 7 - CONNECTION DIAGRAMS 7 - CONNECTION DIAGRAMS The connection of Analog Input, Digital Input/Output or Relay Output cards are given Figure 7.3 Figure 7.4 Figure 7.5 Figure 7.6 respectively. In order to change the cards on 1- slots, dismantle top and bottom screws of the related slot and pull out the card.

- Page 51 7 - CONNECTION DIAGRAMS 7 - CONNECTION DIAGRAMS Digital Input Digital Output Üst +24 V +24 V -24 V -24 V (ohm) Digital Input and output cards must be supplied with +24 V, an extarnal 24V DC source, max. otherwise the cards can not 40 mA be detected by the recorder and do not function.

- Page 52 7 - CONNECTION DIAGRAMS 7 - CONNECTION DIAGRAMSI Snubber Relay Outputs can be used with snubbers. To use with snubber, the terminals 2 and 3 should be short circuited with a suitable cable. Snubber consist of serially connected a capacitor (10nF, 630 V) Ù...

- Page 53 E-PR- series recording devices has several standard connectivity options for easy 5) Barcode Scanner Connection transfer of recorded data. Standard of the shelf USB Mass storage disks up to 4 GB can Please check Appendix 4 for detailed explanation. be plugged from front panel USB ports and all data can be synchronized with a couple of click on the screen.

- Page 54 Appendix 1 - Ethernet Connection Appendix 1 Ethernet Connection RJ45 Pins E-PR- 0 recorder can connect to the Ethernet networks with its standard 10/100 M Bit PIN NUMBER SIGNAL Ethernet port ( Section 7. ONNECTION DIAGRAMS ). Communication is performed TD + (Transmit +) using standard TC/IP.

- Page 55 Appendix 2 - Equation Creation Using Math Editor Appendix 2 - Equation Creation Using Math Editor microvolt(): Microvolts (Slotno, ChannelNo) is used with parameters. Parameters of Equation for Math Analog and Math Digital can be easily created using Math the analog input channels of the slot referred to as raw data the value of reading Editor.

- Page 56 Appendix 2 - Equation Creation Using Math Editor Appendix 3 - Modbus RTU Communication Addresses FUNCTION USAGE DESCRIPTION Modbu RTU Register addresses can be reached from MODBUS TABLE window < Op1 < Op2 If Op1 is smaller than Op2 “1”, other states “0” Main Menu by presing the MODBUS TABLE button in the .

- Page 57 E-PR-110 E-PR-110 Ek 3 - Modbus RTU Communication Addresses Ek 3 - Modbus RTU Communication Addresses Group Name Size Type Group Name Size Type Address Address 0650 ----- 4 Byte (Integer) DIGITAL 0694 MATHTOT_C1 8 Byte (Float) ANALOG REAL TIME...

- Page 58 E-PR-110 E-PR-110 Ek 3 - Modbus RTU Communication Addresses Ek 3 - Modbus RTU Communication Addresses Group Name Size Type Group Name Size Type Address Address 0770 MODBUS_C7 4 Byte (Float) ANALOG 0832 MODBUSTOT_C10 8 Byte (Float) ANALOG MODBUS ANALOG...

- Page 59 E-PR-110 E-PR-110 Ek 3 - Modbus RTU Communication Addresses Ek 3 - Modbus RTU Communication Addresses Group Name Size Type Group Name Size Type Address Address 0890 PRFL_C16 4 Byte (Float) ANALOG 0934 AIN_S1C6 4 Byte (Float) ANALOG PROFILE SLOT 1 ANALOG INPUTS...

- Page 60 E-PR-110 E-PR-110 Ek 3 - Modbus RTU Communication Addresses Ek 3 - Modbus RTU Communication Addresses Group Name Size Type Group Name Size Type Address Address 8 Byte (Float) 0978 ----- 4 Byte (Integer) DIGITAL 1048 SLOT 3 AIN TOTS...

-

Page 61: Appendix 4 - Barcode Reader

E-PR-110 E-PR-110 Ek 3 - Modbus RTU Communication Addresses Appendix 4 - Barcode Reader Group Name Size Type Address Rear panel USB port serve as a hub to 2D Barcode scanners which are prevalently 4 Byte (Integer) DIGITAL 1114 SLOT 4 DIGITAL OUTPUTS ----- adapted in certain industrial application for easy and secure data input devices. - Page 62 K - Q TSE-ISO-EN 9000 TS EN ISO 9001 Quality Management System Certificate KY-PR110-0420-0...

Need help?

Do you have a question about the E-PR-110 and is the answer not in the manual?

Questions and answers