Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Wilton 4103

-

Page 1: Cover Page

Operating Instructions — Parts Manual Square Wheel Belt Grinder Models : 4103, 4106, and 4126AC WHM TOOL GROUP 2420 Vantage Drive Elgin, Illinois 60123 Ph.: 800-274-6848 www.wmhtoolgroup.com This Manual is Bookmarked Part No. 5507796 Revision C2 09/04 Copyright © WMH Tool Group... -

Page 3: Table Of Contents

Table of Contents Cover Page ...1 General Specifications ... 4 Operating Precautions ... 5 Setup and Operation...7 Maintenance ... 10 Wiring Diagrams ... 12 Replacement Parts ... 13 Troubleshooting ... 13 Accessories ... 17... -

Page 4: General Specifications

Belt tension and tracking are easily adjustable. The Square Wheel Belt Grinder is available in either single speed (Models 4103 and 4106) or variable speed model (Model 4126AC). The variable speed model is controlled by an inverter that provides belt speeds ranging from 0 to 6000 SFPM. -

Page 5: Machinery General Safety Warnings

Read and follow these simple rules for best results and full benefits from your machine. Used properly, Wilton’s machinery is among the best in design and safety. However, any machine used improperly can be rendered inefficient and unsafe. It is absolutely mandatory that those who use our products be properly trained in how to use them correctly. -

Page 6: Safety Requirements For Abrasive Grinding Machines

17. Keep hands in sight and clear of all moving parts and cutting surfaces. 18. All visitors should be kept at a safe distance from the work area. Make workshop completely General Electrical Cautions This machine should be grounded in accordance with the National Electrical Code and local codes and ordinances. -

Page 7: Setup And Operation

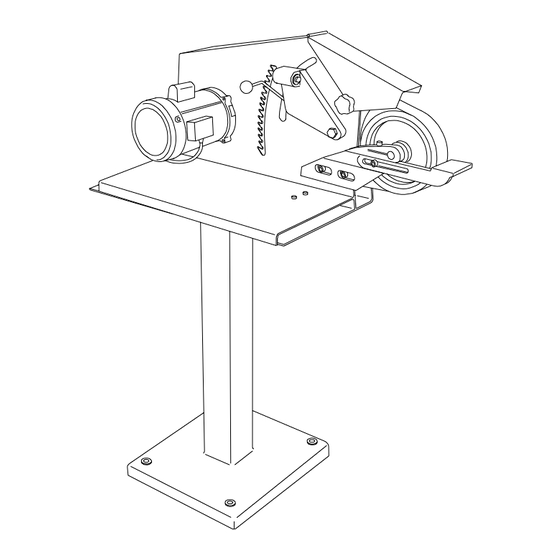

Introduction This manual includes operating and maintenance instructions for the Wilton Model 4103, 4106 and 4126AC Square Wheel Belt Grinder. The manual also includes parts listings and illustrations of replaceable parts. Refer to Figures 1 and 2 for key features of the Square Wheel Belt Grinder. -

Page 8: Operating Controls

Observe local electrical codes when connecting the machine. Operating Controls Model 4103/4106 The ON/OFF switch for the Model 4103/4106 grinder is located in a switch box mounted on the drive motor. Model 4126AC NOTE: Refer to Figure 4. Use only the inverter controls defined in the following procedures. -

Page 9: Typical Uses For The Square Wheel Belt Grinder

Typical Uses for the Square Wheel Belt Grinder Flat or angular Shaping — For stock — Platen grinding and finish- setting is the perfect ing cylindrical angle for high speed, shapes. The yoke precision, flat and surface conforms to level grinding of the shape of the tools, knives, plas- surface to produce... -

Page 10: Maintenance

Maintenance Cleaning Shutoff the machine before cleaning. Keep the exterior of the machine clean and free of chips. Use a brush for cleaning. Periodically empty grinding dust and particles from the dust collection system. Lubrication Lubrication of the grinder is not required. The drive motor and contact wheel are fitted with sealed bearings. - Page 11 Replacement of Grinding Belt WARNING: DO NOT OPERATE THE MACHINE WITH THE SIDE PANEL OPEN. DISCONNECT ELECTRI- CAL POWER TO THE MACHINE BEFORE PERFORM- ING ANY MAINTENANCE. 1. Refer to Figure 7. Lower the belt tension lever to release tension on the belt. 2.

-

Page 12: Wiring Diagrams

Wiring Diagrams Model 4103 Model 4106 Model 4126AC... -

Page 13: Replacement Parts

1. Excessive grinding pressure. Replacement Parts This section provides exploded view illustrations that show the replacement parts for the Wilton Models 4103, 4106 and 4126AC Square Wheel Belt Grinder. Also provided are parts listings that show part number, descrip- tion and quantity. The item numbers on the illustration relate to the item number in the facing page of the parts listing. - Page 14 Exploded View - Square Wheel Belt Grinder...

- Page 15 Parts List - Square Wheel Belt Grinder...

- Page 16 Parts List - Inverter Ref. Part No. Number Description 5550874 Screw, Socket head Cap, 10-32NF x 3/8 5507817 inverter (1ph, 120V, 50/60Hz) 5507818 Inverter (3ph, 220V, 50/60Hz) 5511447 Inverter (3ph, 440V, 50/60Hz) 9128571 Screw, Hex Head 1/2-13 x 1 5515215 Mount, Inverter 9119481 Terminal, Full Closed Ref.

-

Page 17: Accessories

Another option is to use the dust collection system as a base for the Model 4103 grinding machine in lieu of placing the machine on a bench or on the pedestal. The second inlet duct on the side of the system is available for connecting another grinding machine. - Page 18 Exploded View - Vacuum Scoop A vacuum scoop connects the machine to the vacuum system. The mounting provisions for the scoop are shown in the exploded view below. Ref. Part No. Number Description 5053531 Scoop Assembly 5052471 Adapter, Hose 5053601 Reducer, 4 x 3 in. (Woodworkers) 5053611 Reducer, 4 x 3 in.

- Page 19 Air Cushioned Dead Head Assembly Refer to Figures 10 and 11. The air-cushioned dead head is for use on very small radius grinding. When connected to a source of shop air (80-90 psi), the belt rides on a cushion of air to decrease head and belt wear.

- Page 20 Hub and Wheel Assembly Refer to Figures 12 and 13. The hub and wheel assembly Small Diameter Contact Wheels can be used to adapt a number of other optional attachments for use on the belt grinder. The assem- bly consists of a pre-balanced hub shaft, collar, and V-belt and a special wrench to enable quick change of the optional attachments.

- Page 21 Small Diameter Contact Wheels Small diameter contact wheels are useful for grinding or contouring difficult, hard to reach areas (refer to Figure 15). The small diameter contact wheels are available in several sizes. Refer to Figure 14 for a listing of small diameter contact wheels. Dia.

- Page 22 Ref. No. Part Number 5248081 9062121 5511051 Figure 16: Assembly of Grinding Machine and Pedestal Motor Side Holes 20 inches apart Install two 1- inch long screws Description Pedestal Socket Head Cap Screw (5/16-18 x 1) Socket Head Cap Screw (5/16-18 x 1 3/4) Belt Guard Holes Approximately 1/2-inch from...

-

Page 23: Cover

Dust Collection System (Optional) Installation Transport the shipping container to the installation site. Unpack the dust collection system and check for damage. Contact the carrier if damage is found. Open the installation kit (refer to Optional Accessories in the parts listing for installation kits). Install cover and debris collection drawer if removed. - Page 24 Disassembly Disassembly of the dust collection system is re- quired only to replace the motor or the fan compo- nents. The motor switch, if failed, can be replaced without removal of the motor. 1. Remove chip drawer (2) and cover (4) from base (1).

- Page 25 Exploded View – Model 5511885 Dust Collection System REAR VIEW FRONT VIEW...

- Page 26 Screw, Set 5514752 5514753 Housing, Inner Fan 5514754 Motor 5514755 Screw, Hex Head 5514756 Seal, Tape 5-feet long 5514757 Switch, Motor Connection Kits: Refer to Wilton catalog for appropriate connection kit for your grinding machine or contact Wilton for assistance.

- Page 28 WMH TOOL GROUP 2420 Vantage Drive Elgin, Illinois 60123 Phone: 800-274-6848...

Need help?

Do you have a question about the 4103 and is the answer not in the manual?

Questions and answers