Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sensoray 518

- Page 1 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

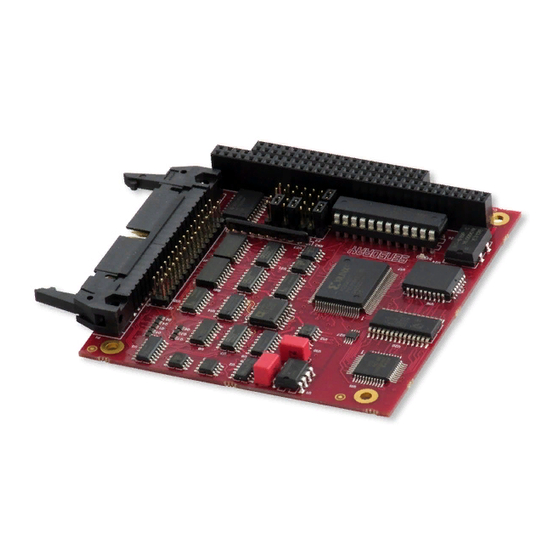

- Page 2 INSTRUCTION MANUAL Sensoray Model 518 PC104 Sensor Coprocessor Revised June 9, 1997 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 3: Table Of Contents

Read Product I.D. . . 29 Limited Warranty . . 1 Set Coefficients . . 30 Special Handling Instructions . . 1 Calibrate 518 . . 32 Sensor Tables . . 33 Chapter 2: Introduction . . 2 Back Compatibility . . 34 Functional Description . -

Page 4: Chapter 1: Basics

Sensoray specifications for two years from the date of shipment to purchaser. Sensoray will, at its option, repair or replace equipment that proves to be defective during the warranty period. This warranty includes parts and labor. -

Page 5: Chapter 2: Introduction

Introduction Functional Description The 518 interfaces eight process sensors directly to the PC104 bus. Each of the eight sensor channels may be independently configured (via software) to accept thermocouples, RTD’s, strain gages, thermistors, resistors, 4 to 20 milliamp current loops, or DC voltage inputs. -

Page 6: Specifications

5VDC in series w/4K (other ranges) Input protection Up to 70VAC CMV < 2 seconds Data format 16-bit 2’s complement PC104 Interface 8-bit module, stackthrough bus Sensoray Model 518 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 7 Table 2: Sensor Specifications Sensor Type Range Resolution Accuracy Thermocouple 0.1C 0.2C 0C to 1820C 0C to 1820C -270C to 990C -210C to 760C -270C to 1360C -270C to 1347C -270C to 400C 0C to 1760C 0C to 1760C Thermistor Omega 44006 -55C to 145C 0.01C...

-

Page 8: Chapter 3: Hardware Configuration

It is not necessary to install any IRQ shunts if you will not be using interrupts. Port Mapping The 518 may be mapped to any four-byte address block within the range 000 to 3FF hex. Although the board occupies a four-byte block of I/O space, it uses only the first two address locations in the block. - Page 9 Option shunts E1 through E8 are used to select the 518 base address. Shunts are factory set to locate the board at base address 2B0H. This address should not conflict with any stan- dard I/O address assignments. If you require a different base address, use the following table to determine the correct shunt programming for your target base address.

-

Page 10: Hardware Filters

Table 5: For example, install shunts E12 and E20 to enable the filter for channel 3. Sensoray Model 518 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 11: Chapter 4: Programming

The data port (base address) consists of two hardware registers: command and data. When the host sends a command to the 518, it is really storing a byte in the command register. When the host reads a command response from the 518, it is reading a byte from the data register. -

Page 12: Status Register

IMPORTANT NOTE: The CRMT, DAV, and ALARM status bits are not valid when the FAULT bit is active. After resetting the 518 board (by means of either soft or hard reset), the host processor should not attempt to handshake to or from the 518 until the FAULT bit changes to the inactive (logic 0) state. -

Page 13: Control Register

INT/RST Specifies the control function to be performed. When set to logic zero, the 518 board is reset and all other control register bits are ignored. When set to logic one, the other control register bits behave as described below. -

Page 14: Sample Low-Level Drivers

; EXIT DATA REGISTER DRIVER ‘ ******************* QUICKBASIC DRIVERS ********************* ‘ This subprogram handshakes a byte to the 518 command register: SUB Send518Byte (BasePort As Integer, CommandByte As Integer) DO : LOOP WHILE (INP(BasePort + 1) AND &H80) = 0 ‘wait for CRMT... - Page 15 END FUNCTION ‘This subprogram writes a 16-bit integer value to the 518. SUB Send518Word (BasePort%, Value%) CALL Send518Byte (BasePort%, (Value% \ 256) AND &HFF)‘send high byte to 518 CALL Send518Byte (BasePort%, Value% AND &HFF) ‘send low byte to 518 END SUB...

-

Page 16: Commands

The sequence is defined from left to right. For example, the byte string (95+CHAN),(5),(0) contains three bytes. 4. A command consists of a byte string which is passed from host to 518 in the proper sequence. 5. A command response consists of a byte string which is passed from 518 to host in the proper sequence. -

Page 17: Declare Channel Sensor

‘DEFINE CHANNEL SENSOR command opcode SensorCode% = 3 ‘K thermocouple sensor definition code (from table) CALL Send518Byte (BasePort%, Channel% + Opcode%) CALL Send518Byte (BasePort%, SensorCode%) Sensoray Model 518 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 18: Set Filter Time Constant

‘filter percentage FilterConstant% = FilterPercent% * 2.55 ‘compute filter constant CALL Send518Byte (BasePort%, Channel% + Opcode%) ‘send channel & opcode to 518 CALL Send518Byte (BasePort%, FilterConstant%) ‘send filter constant to 518 Instruction Manual Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 19: Read Board Temperature

518 installation. The returned temperature value is scaled to 0.10 degrees C/bit. If no 7409TC is connected to the 518, the Read Board Temperature command will return a meaningless value. COMMAND:... -

Page 20: Read Channel Data

‘from Sensor Tables, scalar = 500uV CALL Send518byte (BasePort%, Channel%) ‘send command to 518 ChanData% = Read518word (BasePort%) ‘read scaled data from 518 V! = ChanData% * Scalar! ‘convert scaled data to volts PRINT “Channel 6 data: “; V!; “Volts”... -

Page 21: Read Data From All Channels

(CH5 MSB), (CH5 LSB), (CH6 MSB), (CH6 LSB), (CH7 MSB), (CH7 LSB) EXAMPLE: ‘ Read sensor data from all eight 518 channels into a linear array. SUB Read8Channels (BasePort%, DataArray%()) CALL Send518byte (BasePort%, 88)‘send command to 518 FOR Channel% = 0 TO 7 ‘read scaled data from 518 into array... -

Page 22: Set Channel Alarm Limits

‘ extruder. The extruder temperature must fall between 400 and 450 | ‘ degrees C for proper operation. This code segment programs the | ‘ channel 7 alarm limits so that the 518 alarm flag will be raised | ‘ if the temperature strays outside operating limits. |... -

Page 23: Set Open Sensor Data Values

‘send flags to 518: (x,x,x,x,x,x,1,x) EXAMPLE: ‘ Prompt the operator for the desired open-sensor conditions for all | ‘ eight sensor channels, then send the required command to the 518. | Flags% = 0 ‘initialize open-sensor flags FOR Channel% = 0 TO 7 INPUT “Enter channel”;... -

Page 24: Read Alarm Flags

RESPONSE: (HIGH ALARM LIMIT FLAGS), (LOW ALARM LIMIT FLAGS) EXAMPLE: ‘ Read alarm flags from 518 and print messages for any alarming channels. | CALL Send518byte (48) ‘send command to 518 HiFlags% = Read518byte (BasePort%) ‘read high alarm flags from 518 LoFlags% = Read518byte (BasePort%) ‘read low alarm flags from 518... -

Page 25: Set Gage Zero

This command sets the zero-load value on a strain gage channel. In effect, the Set Gage Zero command tells the 518 that there is presently no load on the channel load cell. Typi- cally, this command is issued just prior to a Set Gage Span command. Together, the Set Gage Zero and Set Gage Span commands may be used to calibrate a strain gage channel. -

Page 26: Set Gage Span

NONE EXAMPLE: ‘ Calibrate the load cell connected to channel 1. Full-load is ‘ 40,000 pounds, and the 518 output units are to be scaled to 10 ‘ lbs/bit. At full-load, therefore, 518 output will be 4,000. Channel% = 1 ZeroCmd% = 176 ‘SET GAGE ZERO command opcode... -

Page 27: Tare Gage

‘ previously calibrated using the SET GAGE ZERO and SET GAGE SPAN commands. | Channel% = 7 TareCmd% = 112 CALL Send518byte (BasePort%, TareCmd% + Channel%) Sensoray Model 518 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 28: Read Gage Calibration

‘ calibrated before calling this procedure. | SUB ReadGageParameters (BasePort%, Channel%, ParmArray%()) CALL Send518byte (BasePort%, 128 + Channel%) ‘send opcode to 518 FOR Parm% = 0 TO 5 ‘read 6 parameter bytes from 518 ParmArray%(Parm%) = Read518byte (BasePort%) NEXT Parm% END SUB Instruction Manual... -

Page 29: Set Gage Calibration

NONE EXAMPLE: ‘ This subprogram copies gage parameters from a linear array back ‘ onto a 518 coprocessor. Assume that the ReadGageParameters ‘ procedure (previous example) was used to load the array. SUB WriteGageParameters (BasePort%, Channel%, ParmArray%()) CALL Send518byte (BasePort%, 144 + Channel%) -

Page 30: High Speed Mode

COMMAND: (240), (8), (0) RESPONSE: NONE EXAMPLE: ‘ This code fragment switches the 518 to High Speed Mode. CALL Send518byte (BasePort%, 240) CALL Send518byte (BasePort%, 8) CALL Send518byte (BasePort%, 0) Instruction Manual Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 31: Low Power Standby

CALL Send518byte (67) ’ Switch the 518 to Low Power Standby mode After releasing the 518 from the low power standby mode, the host should wait at least 600 milliseconds before communicating again with the coprocessor. This delay will give the 518 time to self-calibrate and acquire good sensor data before any data requests from the host. -

Page 32: Read Firmware Version

CALL Send518byte (BasePort%, 240) CALL Send518byte (BasePort%, 5) CALL Send518byte (BasePort%, 0) Version% = Read518word (BasePort%) PRINT USING “518 firmware version = ##.##”, Version% / 100! Instruction Manual Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 33: Read Product I.d

Chapter Read Product I.D. This command returns an identifier specific to the addressed Sensoray product. The prod- uct identifier specifies the Sensoray product model number; the value 518 will be returned by a model 518 sensor coprocessor. COMMAND: (240), (4), (0) -

Page 34: Set Coefficients

Set Coefficients This command defines the linearization coefficients for a channel previously declared as a USER-DEFINED RESISTIVE SENSOR. Three coefficients are specified. The three val- ues belong to a polynomial of the form: Each coefficient is represented by four bytes coded in the coprocessor’s internal floating point format. - Page 35 ‘ previously been declared as a “User-defined Resistive Sensor”) for ‘ linearizing the potentiometer’s measured resistance value: CALL Send518Byte (192 + 2) ‘ send command & opcode to 518 CALL Send518Real (0) ‘ send A coefficient to 518 CALL Send518Real (.01) ‘...

-

Page 36: Calibrate 518

5 volt range 500 millivolt range 400 ohm range Example: This code fragment will assist you in calibrating the 518. FOR calCode% = 0 TO 2 SELECT CASE calCode% CASE 0: refName$ = “5 volt”: scalar% = 5000: sensorCode% = 0 CASE 1: refName$ = “500 mV”: scalar% = 50: sensorCode% = 13... -

Page 37: Sensor Tables

0.01 C Current Loop 4 - 20 mA 0.01% (4mA=0%, 20mA=100%) Pressure/Strain Gage >120 ohm full bridge defined by programmer Disabled Channel not applicable Sensoray Model 518 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 38: Back Compatibility

Back Compatibility In addition to the sensor definition codes listed above, several additional codes exist to maintain compatibility with the earlier Sensoray products. Use of these codes is not rec- ommended for new designs. Table 13: back-compatible sensor codes Sensor Type... -

Page 39: Chapter 5: Sensor Connections

Chapter Sensor Connections All sensors are connected to the 518 by means of connector P1. Optionally, sensors may be connected to the Sensoray model 7409TC screw termination board which in turn con- nects to 518 connector P1. Sensors may be electrically connected and disconnected from the coprocessor or 7409TC without removing the 518 or power from the PC104. -

Page 40: Thermocouple And Dc Voltage

Four-wire connection V – I – Sensoray recommends the four-wire hookup for all installations. Regardless of the chosen hookup scheme, you should always use shielded cable. The cable shield must be con- nected only to the S terminal on the 7409TC. -

Page 41: Thermistor/Custom Resistive Sensors

Thermistors should be connected using shielded cable. The shield should be connected only to the 7409TC S terminal. Sensoray Model 518 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 42: Strain And Pressure Gages

250-ohm 0.01% resistor must be installed as shown in the following diagram. These resis- tors are available as an option for the 518: order Sensoray part number 7408R. Make sure that any current loop sensors are at the grounded end of the loop so that the common-mode voltage does not exceed 5 volts. -

Page 43: Chapter 6: Sensor Specifics

Application Example A non-linear resistive position transducer is to be interfaced to the 518 on channel 5. Posi- tion data is to be acquired from the sensor and displayed in centimeters with resolution of one millimeter. The following data have been determined empirically:... -

Page 44: Thermocouples

This transducer, because of its close physical proximity to the thermocouple termi- nations, represents an accurate measurement of the thermocouple cold-junctions. Periodi- cally, the 518’s CPU measures the I.C. transducer signal and computes the corresponding thermocouple voltage, known as the “cold-junction compensation voltage”. -

Page 45: Verifying Thermocouple Calibration

(ice cubes and water) or into boiling water. Time is given to allow the thermocouple to reach thermal equilibrium. The operator then verifies that 518 output data is consistent with the water temperature (0 degrees C for an ice bath, 100 degrees C for boiling water). -

Page 46: Strain And Pressure Gages

Measurement Resolution Strain gage excitation is supplied by the 518 coprocessor in the form of a strobed DC volt- age. This voltage varies slightly from one coprocessor board to another, but is on the order of 10 volts in amplitude. -

Page 47: Calibration

Load Resolution ----------------------------------------- - × × 200000 As an example, suppose a gage is rated at 3 mV/V at 100 PSI full scale. The 518 coproces- sor would be able to resolve a load to: --------------------------------------------------------- - 0.017pounds × ×... - Page 48 (whichever you are using to calibrate your gage with). During normal operation, the L signal is applied to the 518 input channel. When it is time to calibrate the gage zero and span, the following procedure is used: 1.

-

Page 49: Chapter 7: Theory Of Operation

Chapter Theory of Operation Software Execution of the internal coprocessor software is managed by a resident multi-tasking ker- nel. The kernel is responsible for scheduling and executing concurrent foreground tasks, processing intertask communication requests, and servicing real-time communication interrupts from the system bus interface. The following paragraphs describe the inner-workings of tasks that are controlled by the kernel. -

Page 50: Command Processor

RAM and used to null offset and gain errors in the external sensor measurements. A phenomenon known as warm-up noise occurs when the 518 is warming up from cold start or when subjected to a thermal transient. When the coprocessor is exposed to chang- ing ambient temperatures, sensor data will appear somewhat noisy. -

Page 51: Excitation Section

Channel scan rate is defined as the number of conversions per channel per second. The scan rate is influenced primarily by the number of active channels in the scan loop. A sec- ondary influence is the frequency of communication between host and 518 coprocessor. Sensoray Model 518... -

Page 52: Communication Latency

13 milliseconds at the High Speed Mode scan rate. This is the amount of time required for the 518 to configure its analog section, allow the front end to settle and digitize the input signal. Note that the software linearization and filtering func- tions don’t require any additional time as they execute concurrently with digitization. -

Page 53: Processor Speed

As it turns out, acquisition latency actually takes somewhat longer than the theoretical maximums discussed here. Additional time is consumed by the host processor itself, either by polling the 518’s handshake status port or by interrupt overhead in the case of inter- rupt-driven host processors. -

Page 54: Chapter 8: Command Summary

Chapter Command Summary READ CHANNEL DATA - read linearized sensor data from one channel command command: (CHAN) response: (HIGH DATA),(LOW DATA) DEFINE CHANNEL SENSOR - declare channel sensor type command command: (16 + CHAN),(SENSOR DEFINITION CODE) response: NONE DEFINE CHANNEL ALARM LIMITS - declare normal data limits for one channel command: (32 + CHAN), (HILIMIT MSB), (HILIMIT LSB), (LOLIMIT MSB), (LOLIMIT LSB) - Page 55 READ DATA FROM ALL CHANNELS command: (88) response: (CH0 MSB), (CH0 LSB), (CH1 MSB), (CH1 LSB), (CH2 MSB), (CH2 LSB), (CH3 MSB), (CH3 LSB), (CH4 MSB), (CH4 LSB), (CH5 MSB), (CH5 LSB), (CH6 MSB), (CH6 LSB), (CH7 MSB), (CH7 LSB) SET FILTER TIME CONSTANT - specify filter factor for one channel command: (96 + CHAN), (FILTER CONSTANT) response:...

- Page 56 CALIBRATE 518 command: (224 + CHAN), (CAL_CODE), (CAL_DATA_MSB), (CAL_DATA_LSB) response: (DON’T_CARE) READ PRODUCT I.D. - read Sensoray product identifier command: (240), (4), (0) response: (ProductID_MSB), (ProductID_LSB) READ FIRMWARE VERSION - return coprocessor firmware version number times 100 command: (240), (5), (0)

- Page 57 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

Need help?

Do you have a question about the 518 and is the answer not in the manual?

Questions and answers