Table of Contents

Advertisement

Quick Links

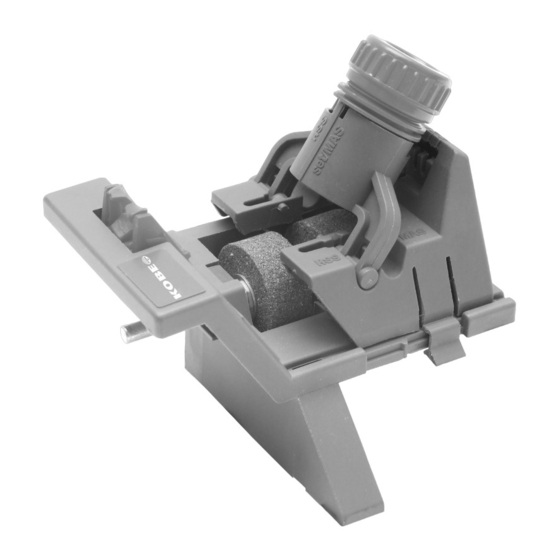

HANDY DRILL BIT SHARPENER

INSTRUCTION LEAFLET

KOBe PROFeSSIONAL TOOLS have been specifically designed to help you work

SAFeLY and eFFICIeNTLY. Your care and good judgment are the best protection against

injury, but always ensure that the appropriate safety equipment is worn.

All possible hazards cannot be covered here, but the most relevant ones have

been highlighted.

This product must only be used for the purposes specified in this

instruction manual and used in the manner described. It is not intended for

industrial/work use or conditions. Please read and follow these instructions

carefully before using and keep this document for later use.

GeNeRAL OPeRATING HAZARDS

l ALWAYS store the tool in a dry, secure place away from children.

l ALWAYS check for damaged or loose parts and fittings.

l ALWAYS use recommended attachments or parts.

l ALWAYS wear suitable eye protection at all times.

l NeveR touch, allow hair, rags, clothing near the rotating wheels and drill chuck.

l DO NOT leave the chuck key in the drill.

l ALWAYS ensure the power drill cable is placed safely away from any hazards.

l DO NOT continue using the drill sharpener if sharpening guides/rests become

damaged, the wheels are chipped/damaged or of any other signs of abnormality occur

you must stop using at once, remove from service and repair before using again.

l ALWAYS use the correct KOBE replacement wheels to avoid possible injury.

CAUTION!

Our products are very carefully inspected. Nevertheless as a safety

precaution after setting up the drill sharpener stand away from the wheels,

turn on the drill for 30 seconds to double check the wheels for safety.

l NeveR operate the tool when tired or under the influence of alcohol /prescription or

non-prescription drugs.

l NeveR operate if any parts are missing or damaged.

l NeveR leave the tool running whilst unattended.

l NeveR modify the tool or accessories and only use it for the task for which it has

been designed.

l NeveR force or apply excessive pressure on the tool.

l NeveR touch moving or active parts of the tool or accessories.

l NeveR work in a combustible atmosphere.

l NeveR allow children to use or play with the tool.

WARNING: Do not leave the drill plugged in whilst tool is not in use or

whilst setting up. Do not use the hammer or reverse setting. Do not leave

the drill running for more than five minutes at any one time.

Fig. 2

Slide

back

Approx. 125mm

(5inches) from edge

of bench

OPeRATION - SHARPeNING HSS TWIST DRILL BITS

Fig. 4

Turret Holder

Fig. 5

Flip 'Setter' down

Table: HSS drill bit shape; 118° tip angle

Tip clearance

Incorrect

Incorrect

Correct

insufficient

excessive

Drill point

Incorrect

Correct

Unequal edges

Remedy

Sharpen slightly more

on shorter side

ORDER CODE:

KBE-280-8520K

SAFeTY INSTRUCTIONS

General set up:

1. To securely fix the sharpener to a

flat surface use the screws provided

fix the locating foot about 125mm

(5 inches) from the front edge of the

bench or suitable board (see Fig.2).

2. Before securing the sharpener onto

the locating foot, fit the sharpener

spindle into the drill chuck ensuring

it is centered in the jaws and that

the chuck does not touch the chuck

guard. Tighten the chuck.

3. Now place the sharpener along with

the drill attached, over the locating

foot and slide it back to lock it into

position, placing the drill with the

handle forward so that there is no

strain on the foot.

Power drill:

Ensure that the mains wall socket is

within easy reach. During use, lock the

drill 'on' using the trigger catch. Run

the drill at maximum speed but no more

than 3000rpm, maximim power 850 watt.

1. Set up the carriage for 'HSS drill

sharpening' see above.

2. Place the turret holder into the

'HSS' slots on the carriage

pushing the support legs until they

click into position (see Fig. 4).

3. Flip the drill setter down so it

touches the grinding wheel then

hold it lightly and slide the carriage

to the left until it clicks and locks

into position with the drill setter

(see Fig. 5).

4. Select the correct size collet for

your drill bit then see 'Changing

the collet' section above if a

change of collet is needed.

5. Tilt the turret holder onto the right,

resting it on the upright part of the

carriage.

6. Insert the drill bit into the turret

and turn the nut until the bit is a

loose fit and centred in the collet

(for 13mm drill bits insert by

disassembling the turret).

7. Insert the turret (without the drill

bit in it) into the turret holder,

slotting either rib on the side of the

turret into the 'SeT/MAS' on the

turret holder and push down fully

(see Fig. 6).

8. Now insert the drill bit into the

turret (see Fig. 6) and push down

Remedy

firmly so it comes into contact with

Repeat

the drill setter and the grinding

sharpening

wheel. Then twist the drill bit

operation,

ensuring

anti-clockwise until it lifts slightly

correct

and then it will drop down into

alignment.

position.

9. Press the drill bit towards the

grinding wheel and then turn it

clockwise until you feel it stop.

Hold the drill bit in this position

with one hand and tighten the nut

with the other.

Fig. 1

Carriage

Aluminium oxide

grinding wheel (grey)

HSS drill setter

Chuck

guard

Spindle

Locating foot

l ALWAYS comply with Health & Safety regulations.

l ALWAYS ensure that all long hair, loose clothing & jewellery, etc., are secured or

removed.

l ALWAYS wear suitable eye protection at all times.

l DO NOT use without the locating foot.

l ALWAYS plug the drill into the mains power supply which is protected by an MCB or

earth leakage circuit breaker, if this is not possible plug into an adaptor-type RCD and

then plug the adaptor into the mains power supply.

l DO NOT have the drill plugged in when not in use. Only plug in when wanting to use

the drill sharpener.

Drill life:

l Drill bits should be regularly sharpened and not allowed to become blunt especially

on masonry drill bits as the carbide tip wears much quicker when blunt.

Grinding wheel life:

l The grinding wheels should not be allowed to wear down to below 8mm from the grey

spacer (the plastic part between them) because the smaller diameter of the wheel

cannot produce the correct geometry and therefore it needs to be replaced before

continuing the sharpening of the drill bits.

NOTe: Always use the correct KOBE replacement wheels to avoid possible injury.

These are available from your local KOBE stockist.

Grinding wheel surface:

l If the grinding wheel becomes unevenly worn, their surface can be restored by, for

example, an old masonry drill and simply running it from side to side across the wheel

while its rotating until the surface of the wheel is square again.

After use care:

l To prevent the collet from developing a permanent 'set' unscrew the nut after use.

l Remove all abrasive dust.

SeT UP

General sharpening:

Use the grinding bed on it's own. See 'General grinding and sharpening' in the

'Operation' section.

HSS drill sharpening:

Hook the carriage under the rear rail and place the other side of the carriage over the

front rail and lightly press down until you hear a click (see Fig.4).

Slide the carriage to the right until it reaches the stop.

See 'Sharpening HSS Twist Drill Bits' in the 'Operation' section.

Masonry drill sharpening:

Starting with the carriage at the right-hand edge of the grinding bed (see Fig.9),

repeat the procedure for the 'HSS

drill sharpening' above then

See 'Sharpening masonry drill

bits' in the 'Operation' section.

Wood bit sharpening:

See overleaf.

Changing the collet:

Select the correct size collet for

your drill bit. The collet that comes already in

the turret is the tighter of the two and is for 3mm

to 7mm diameter drill bits. The other collet is for

the 8mm to 13mm drill bits. When changing

between the two collets unscrew the nut,

remove the collect ring and insert the correct

collet. Replace the collet ring with the lugs

downwards and replace the nut.

10. Remove the turret from the holder

and check that the drill bit's cutting

edges are parallel with the turret

nose index marks (see Fig. 7).

NOTe: If the drill bit position is not

correct, remove and repeat the

aligment procedure. Do not simply

turn it by hand.

11. Once the alignment is correct slide

the cariage to the right and flip the

setter up.

12. Replace the turret and drill bit in

the holder so either of the ribs

slots down into the wide slot

marked 'HSS' with the drill bit fully

over the left-hand grey grinding

wheel. Switch on the drill.

13. Now press the red cam on the

turret up against the upright part of

the carriage and slowly and evenly

rotate the turret from one end of

the slot to the other about 10

times or until you hear that the

grinding has stopped

(see Fig. 8).

14. Finally remove the drill bit from the

turret and compare it to the table

on the left and if necessary make

the adjustments following the

table.

NOTe: Broken drill bits can be ground

to approximate shape (see table) on

the silicon carbide (green) wheel, then

follow the instructions above. Whilst

sharpening to avoid uneven wear in

the grinding wheels slowly move the

carriage across the whole width of the

wheel with your left hand whilst

rotating the turret with your right.

If the grinding wheel is not flat it will

not grind the correct tip geometry,

see 'Grinding wheel surface' in the

'maintenance' section above.

COMPONeNTS

Catch

Silicon carbide

grinding wheel

(green)

Grinding bed

Wood bit guide

WORKPLACe HAZARDS

PeRSONAL PROTeCTION

SPeCIFIC OPeRATING HAZARDS

MAINTeNANCe

Stop

Fig. 6

Fig. 7

Fig. 8

Nut

Collet

Ring

2 collets:

3-7mm dia.

8-13mm dia.

Turret

Turret

holder

Fig. 3

Rear

Rail

Catch

Front rail

Rib

Align cutting

edges of

tip with

index

marks

slowly &

evenly

rotate

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KOBE KBE-280-8520K

- Page 1 ALWAYS use the correct KOBE replacement wheels to avoid possible injury. Grinding wheel life:...

- Page 2 OPeRATION - SHARPeNING MASONRY DRILL BITS 1. Set up the carriage for ‘Masonry drill sharpening’ see ‘Set Up’ overleaf. Masonry drill bits: The drill bit sharpener accurately sharpens Tip geometry; 132° tip angle all 3 main types of masonry drill bits: 2.

Need help?

Do you have a question about the KBE-280-8520K and is the answer not in the manual?

Questions and answers