Table of Contents

Advertisement

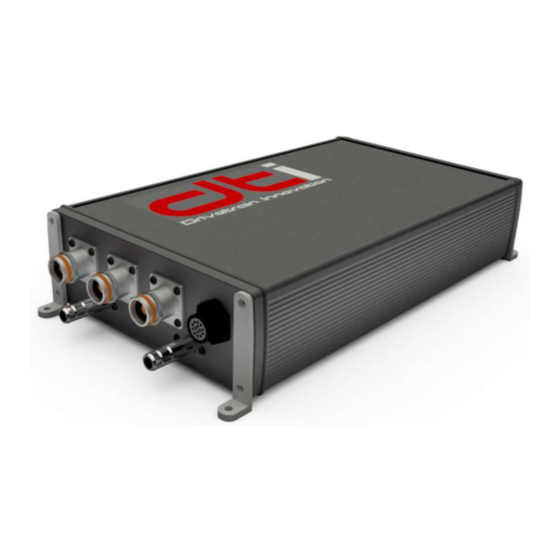

HV-500 SERIES HIGH POWER INVERTER

User manual for HV-500

Version 2.2

Please read the user manual carefully before using the controller! Electrical

systems can cause danger to humans, property and nature; therefore,

precautions shall be taken to avoid any risk.

Drivetrain Innovation kft.

Eötvös Károly street 32.

H-2750 Nagykőrös

Hungary, EU

info@drivetraininnovation.com

www.drivetraininnovation.com

Advertisement

Table of Contents

Summary of Contents for DTI HV-500 Series

- Page 1 HV-500 SERIES HIGH POWER INVERTER User manual for HV-500 Version 2.2 Please read the user manual carefully before using the controller! Electrical systems can cause danger to humans, property and nature; therefore, precautions shall be taken to avoid any risk.

-

Page 2: Table Of Contents

HV-500 USER MANUAL Table of contents History and related documents ................4 Document history ................... 4 Liability and safe use of this unit ................5 Discharge ...................... 6 Warning sign explained ..................7 Overview ......................8 Main features of the HV-500 ................8 Distinction of HV-500 models ................ - Page 3 HV-500 USER MANUAL PC connection and control ................24 14.1 DTI Tool ....................24 14.2 Firmware update ..................24 Wiring the controller ..................25 15.1 Overview ....................25 15.2 Harness connector wiring ................. 25 15.2.1 CAN Wiring ................... 27 15.3 Electrical connection schematics .............

-

Page 4: History And Related Documents

V2.2 Actualization, introducing uniformized datasheets, fixed typos, HV-500 variants diversified Added information about active air-cooled fans. 1.2 Related documents DTI HV-500 Interlock manual DTI HV-500 CAN manual DTI Tool User manual DTI Motor setup manual DTI Firmware update manual ... -

Page 5: Liability And Safe Use Of This Unit

interferences with other systems other non-intended or unforeseeable behaviour of the system DTI Tool and the DTI firmware are developer tools that for safety reasons may only be used by experts and experienced users, knowing exactly what they do. -

Page 6: Discharge

DTI inverters. Every inverter is being tested before shipping. DTI assumes no liability in case a customer uses components for the purposes for which they have not been developed or tested. -

Page 7: Warning Sign Explained

In case of the sign is being damaged, or detached from the inverter, please get in touch with DTI as soon as possible at the availability mentioned on the cover page. Figure 1. Safety note Table 1. -

Page 8: Overview

HV-500 USER MANUAL OVERVIEW 4.1 Main features of the HV-500 Sensored FOC motor control Analog and digital inputs for control CAN (ISO 11898-2) UART communication Duty-cycle, speed or torque control Regenerative braking Hand brake function ... -

Page 9: Distinction Of Hv-500 Models

HV-500 USER MANUAL 4.2 Distinction of HV-500 models Figure 2. Distinction of HV-500 models Active air-cooled variants include two high power fans along with a carbon plate for the air conduction through the integrated heatsink. Passive air-cooled variants include only an integrated heatsink. 4.3 Name plate explained Figure 3. -

Page 10: Technical Specifications

HV-500 USER MANUAL 4.4 Technical specifications 4.4.1 DC characteristics Table 3. DC Characteristics Value Unit Low voltage input range 9 – 28 Low voltage maximum input current Maximum voltage on digital outputs Maximum current on digital outputs Maximum input voltage on digital inputs Logical LOW voltage on digital inputs ≤... -

Page 11: Thermal And Mechanical Specification

HV-500 USER MANUAL Version: 2.2... -

Page 12: Hv-500Acx Air Cooling Parameters

HV-500 USER MANUAL HV-500ACX AIR COOLING PARAMETERS Fan type: BFM1012UHFF8 Number of Fans used: 2 pieces. Note: The fans need external power source, and its characteristics are the following: Table 6. HV-500ACx Cooling fan parameters Parameter Value Unit Rated voltage Operation Voltage 10,8-12,6 Nominal Input Current... -

Page 13: Hv-500Lcx Liquid Cooling Connection

HV-500 USER MANUAL HV-500LCX LIQUID COOLING CONNECTION Table 8. HV-500LCx Liquid cooling connection Value Unit Liquid tube connection outer diameter Pipe material copper Maximum pressure: Coolant flow 15,1 Litre/Min Compatible coolant Glycol – Distillate water mixture Coolant dilution ratio Please refer to the coolant manufacturer for the best dilution ratio for the weather conditions where the system is being applied. -

Page 14: Power Losses

HV-500 USER MANUAL POWER LOSSES The dissipated power depends on: PWM switching frequency AC frequency (motor rotation frequency) AC current DC voltage The calculation of the total power dissipation is shown here: Table 9. Power losses AC current 50 Arms 100 Arms 150 Arms... -

Page 15: System Efficiency

HV-500 USER MANUAL 9. SYSTEM EFFICIENCY The efficiency of the system is influenced by many factors. In order to achieve good efficiency, the voltage difference between inverter AC and DC must be taken into account. Lower voltage difference means better efficiency. The AC voltage is determined by the motor-generated voltage. -

Page 16: Hv-500Lcn-Mechanical Drawings

HV-500 USER MANUAL HV-500LCN-MECHANICAL DRAWINGS Dimensions are shown in mm. Figure 7. HV-500LCx endplate mechanical drawings Version: 2.2... - Page 17 HV-500 USER MANUAL Figure 8. HV-500LCx top and side view mechanical drawings Version: 2.2...

-

Page 18: Compatible Motor Position Sensors

Maximum encoder resolution: 8192 (counts per revolution) Maximum input frequency: 400 kHz 11.2 Resolver Compatible resolver type: TS2620N21E11 For Resolver support, DTI Resolver Interface is required. 11.3 HALL-Sensors Latching type Hall-effect sensors input Maximum input signal voltage: 5 V ... -

Page 19: Compatible Motors

HV-500 USER MANUAL 12. COMPATIBLE MOTORS Any 3 phase PMSM motor can be set up for the inverter knowing the following parameters: Number of poles Motor inductance Motor resistance Compatible motor temperature sensor: kty 81/210 Maximum ERPM: 100000 Version: 2.2... -

Page 20: Electrical Connections

HV-500 USER MANUAL 13. ELECTRICAL CONNECTIONS 13.1 Harness connector pinout (H) (Inverter side) Figure 9. HV-500 Harness connector Connector type: TE CONNECTIVITY AMPSEAL 770680-1 16-20 AWG crimp type: TE CONNECTIVITY AMPSEAL 770520-1 Table 10. HV-500 Harness connector pinout description Pin name Pin description 12_VIN Auxiliary voltage plus, 9 V –... -

Page 21: Motor Sensor Connector Pinout (M)

HV-500 USER MANUAL 13.2 Motor sensor connector pinout (M) Figure 10. HV-500 Motor sensor connector Harness side connector type: SOURIAU UTS6JC12E14P Table 11. HV-500 Motor connector pinout description B+ / Hall U ABI encoder „B” differential signal positive or A hall sensor ABI encoder „B”... -

Page 22: Hall Sensor

HV-500 USER MANUAL 13.3 HALL sensor Only connect the wires which found in the sensor connection diagram. Leave the other pins free on the connector. The internal circuit contains the hall sensor pull up resistors. Figure 11. HALL sensor wiring diagram 13.4 High power connection Table 12. -

Page 23: Case Grounding

HV-500 USER MANUAL 13.5 Case grounding The inverter casing must be electrically connected to the chassis which is the potential of the low voltage ground. Use any of the aluminium feet as a grounding point and connect it to the chassis with at least 10 AWG wire with a short-as-possible distance. -

Page 24: Pc Connection And Control

You can connect the inverter with a USB to RS-232 adapter (for example: ATEN UC232A) to the PC, where the inverter can be parameterized. Use the „H” connector 5. and 13. pins and ground to common potential. The DTI Tool software can be run on the PC. -

Page 25: Wiring The Controller

HV-500 USER MANUAL 15. WIRING THE CONTROLLER 15.1 Overview Analog and digital signal inputs and outputs are provided for switches, sensors, contactors, hydraulic valves, CAN communications, RS232 communications and SSI communications. The wiring must be carried out by a qualified person. Attention must be paid to the equipotential bonding for components which are connected to the unit and which do not have isolated inputs and outputs (equalizing connection GND). - Page 26 HV-500 USER MANUAL Figure 12. Typical HV-500 wiring scheme Version: 2.2...

-

Page 27: Can Wiring

HV-500 USER MANUAL 15.2.1 CAN Wiring CAN is required for firmware updates using the DTI-COM diagnostic tool. The tool is not based on OBD-II standard, only the connector. CAN 1 is used for firmware updates and configuration; CAN 2 is used for interfacing the inverter. -

Page 28: Electrical Connection Schematics

HV-500 USER MANUAL 15.3 Electrical connection schematics 15.4.1 Input supply Reverse polarity protection Overvoltage protection Resettable overcurrent protection Power supply: 9-28V Figure 14. Input supply schematic diagram 15.3.2 Analog input High frequency filter Overvoltage protection ... -

Page 29: Can Peripheral

HV-500 USER MANUAL 15.3.5 CAN peripheral Common mode choke filter ESD protection Figure 18. CAN peripheral schematic diagram 15.3.6 RS 232 peripheral ESD protection Internal serial transceiver Figure 19. RS-232 peripheral schematic diagram Version: 2.2... -

Page 30: Minimal System Schematic

HV-500 USER MANUAL 15.4 Minimal system schematic Figure 20. HV-500 minimal system example Using contactors on both positive and negative side of the high voltage and a fuse are must for safety reasons. Version: 2.2... -

Page 31: List Of Tables

HV-500 USER MANUAL 16. LIST OF TABLES Table 1. Safety notes explained ................. 7 Table 2. HV-500 Nameplate explained ............... 9 Table 3. DC Characteristics ..................10 Table 4. AC Characteristics ..................10 Table 5. Thermal and mechanical specifications ............11 Table 6. -

Page 32: List Of Figures

HV-500 USER MANUAL 17. LIST OF FIGURES Figure 1. Safety note ....................7 Figure 2. Distinction of HV-500 models ..............9 Figure 3. HV-500 Nameplate ..................9 Figure 4. HV-500LCx Thermal resistance and water flow correlation ....... 13 Figure 5. Power dissipation ..................14 Figure 6.

Need help?

Do you have a question about the HV-500 Series and is the answer not in the manual?

Questions and answers