Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for herdstar BinTrac Breeder Control

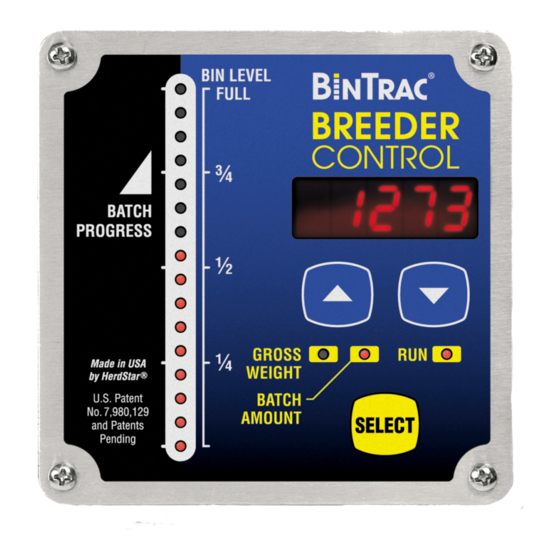

- Page 1 Installation Manual Breeder Control Installation Manual Patented U.S. Patent No. 7,980,129, Patent No. 8,581,122, Patent No. 8,853,566 U.S. Patent No. 9,310,243, Patent No. 9,651,413, Patent No. 10,082,421 Canada Patent No. 2,822,294 Korea Patent No. 1900521 Version 2.0 Part Number MAN-000015...

-

Page 2: Table Of Contents

Wiring the BinTrac Breeder Control .......................... 11 Setting Up and Wiring a BinTrac Indicator as a Remote Display ................12 Setting Up and Wiring a BinTrac Breeder Control Indicator as a Remote Breeder Control Indicator ...... 13 Addendum A - Unload Relay Wiring Diagram ........................ 14 Addendum B - Load Relay Wiring Diagram ........................ -

Page 3: Installation Overview

Load Cell Bracket Four or more load cell brackets allow the BinTrac Breeder Control to accurately measure the feed level in your bins. The Smart Summing Box averages the signals from all brackets to minimize errors that could result from voids (holes) in the feed. -

Page 4: Preparation

• Communication Wire (4 Cond. 20 – 22 AWG, shielded) Steps to Come There are several steps to install the BinTrac Breeder Control system. To give an overview of the installation process, these steps are outlined below. • Mounting the ‘A’ frame •... -

Page 5: Configurations

Gain-In-Weight (Load Batch Method) The BinTrac Breeder Control System allows the user to select the amount of feed required for the day. The BinTrac Breeder Control System controls a conveying system to deliver feed from the Fill Bin to the Weigh Bin. The Weigh Bin weighs the feed delivered and the BinTrac Breeder Control System stops the delivery when the required amount of feed has been delivered to the Weigh Bin. -

Page 6: Loss-In-Weight (Unload Batch Method)

The Loss-In-Weight (Unload Batch Method) allows the user to select the target batch amount of feed required for the day. The BinTrac Breeder Control System will enable the hopper or feed line fill system allowing the feed line system to transfer the feed into the house until the required amount of feed has been delivered. In this configuration, this system batches and unloads until the batch target amount is unloaded from the bin. -

Page 7: Weigh Bin With Dual Breeder Consoles For Programmed Fill And Batch Configuration

Installation Manual Weigh Bin with Dual Breeder Consoles for Programmed Fill and Batch Configuration This configuration provides automated filling and batching of Hen feed using a weigh bin. A Remote Breeder Console provides automated filling of a programmed gross weight amount into a weigh bin. A Master Breeder Console provides automated loss-in-weight batching of a programmed amount for the Hen feeding. -

Page 8: Installation

Installation Manual Installation Mount the Bracket Assembly 1. Remove all bolts connecting the leg to the footpad. Loosen the original anchor bolt but leave it intact at the bottom of the footpad. The footpad can and should be removed if it is binding or interfering with lifting the leg. -

Page 9: Anchor The Bin

Installation Manual Figure 4: Lift until there is a 1/2" (+/- 1/8”) gap. Figure 5: Leave 1/4” (+/- 1/8”) gap between C- channel and bracket. Repeat Steps 1 – 13 for all bin legs. After completing steps 1-13 for each leg (and before continuing to step 14), re-examine each leg to ensure proper clearances as noted and adjust as needed. -

Page 10: Wiring The Smart Summing Box

Figure 8: Connect wires following the above chart. 25. Run the communication wire to the next SSB or to the BinTrac Breeder Control. 26. Tighten every strain-relief (“dome nut”) on the box. First, tighten the nuts to attach the strain reliefs to the box. -

Page 11: Wiring The Bintrac Power Supply

Control unit. 30. Once the cable is routed from the Power Supply to the BinTrac Breeder Control and has been tied up out of the way, cut off any excess cable and connect into Breeder Control unit as shown below. -

Page 12: Setting Up And Wiring A Bintrac Indicator As A Remote Display

A Remote Display is a BinTrac Indicator (BT200 / BT260) programmed as a Remote Display which displays the same weight data as the local BinTrac Breeder Control. The Remote Display receives all its settings (with the exception of enabled bins) from the Master BinTrac Breeder Control. Calibration and Zero must be done on the Master BinTrac Breeder Control. -

Page 13: Setting Up And Wiring A Bintrac Breeder Control Indicator As A Remote Breeder Control Indicator

Control Indicator. Calibration and Zero must be done on the Master Indicator. Follow the wiring steps below to wire up as a Remote Display. Connect the wiring between the Remote Display and the Master BinTrac Breeder Control Indicator. Power is typically supplied to the Remote Display from the Master BinTrac Breeder Control Indicator. -

Page 14: Addendum A - Unload Relay Wiring Diagram

Installation Manual Addendum A - Unload Relay Wiring Diagram Below is a reference diagram for wiring up the Breeder Control for an Unload Batch Method. Please reference BinTrac Part # KIT-000028 Item # Part Number Part Description REL-000017 RELAY GEN PURPOSE DPDT 10A 125V (K1) CON-000126 SOCKET RELAY 8 OCTAL DIN RAIL ASY-000213... -

Page 15: Addendum B - Load Relay Wiring Diagram

Installation Manual Addendum B - Load Relay Wiring Diagram Below is a reference diagram for wiring up the Breeder Control for a Load Batch Method. Please reference BinTrac Part # KIT-000028 Item # Part Number Part Description REL-000017 RELAY GEN PURPOSE DPDT 10A 125V (K1) CON-000126 SOCKET RELAY 8 OCTAL DIN RAIL ASY-000213... -

Page 16: Addendum C - Complete Wiring Diagrams

Installation Manual Addendum C - Complete Wiring Diagrams Version 2.0 Part Number MAN-000015... - Page 17 Installation Manual Version 2.0 Part Number MAN-000015...

- Page 18 Installation Manual Version 2.0 Part Number MAN-000015...

- Page 19 Installation Manual Version 2.0 Part Number MAN-000015...

- Page 20 Installation Manual Version 2.0 Part Number MAN-000015...

-

Page 21: Herdstar Bintrac Product Warranty

HerdStar, LLC, although such parts may be covered by separate warranties of the respective manufacturers. This warranty set forth above does not apply if all components of a system are not supplied by HerdStar, LLC or if the goods are not purchased from and installed by an authorized distributor or company warehouse, or installed and operated in accordance with HerdStar, LLC’s specifications and instructions. -

Page 22: Bintrac Breeder Control Startup And Warranty Validation Checklist

☐ ☐ Inspect load cell cables for damage from Smart Summing Box to load cell BinTrac Breeder Control(s) – Refer to Operator’s manual for Controller setup & installation scenarios ☐ ☐ “Setup” – Reference the manual to verify the controller is correctly set as a Master or Remote depending on your installation scenario ☐... - Page 23 If “No” is checked for any of these items, please consult your dealer as it may affect the performance and warranty on this system. Site Name and Location ______________________________________________________________ Inspected by _______________________________________________________________________ Date _____/_____/_____ Please fill out and return a copy to: BinTrac by HerdStar 1400 Madison Ave Suite 504 Mankato, MN 56001 Phone - 507-344-8805 Fax – 507-344-8009 Email –...

Need help?

Do you have a question about the BinTrac Breeder Control and is the answer not in the manual?

Questions and answers