Table of Contents

Advertisement

Quick Links

PAW NA Limited Partnership

45 Davis Street, Webster, Ma 01520, USA

phone: +1-508-943-4240, fax: +1-508-943-4141

email: support@paw.eu, web: www.paw.eu

Installation and Operation

Installation and O

Installation and O

Installation and O

Zone Module K32

Zone M

Zone M

Zone M

peration I I I I nstr

peration

peration

odule K32 - - - - ¾ ¾ ¾ ¾ " ( " ( " ( " (DN

odule K32

odule K32

nstructions

nstr

nstr

uctions

uctions

uctions

DN 2 2 2 2 0 0 0 0 ) ) ) )

DN

DN

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for PAW K32-3/4

- Page 1 PAW NA Limited Partnership 45 Davis Street, Webster, Ma 01520, USA phone: +1-508-943-4240, fax: +1-508-943-4141 email: support@paw.eu, web: www.paw.eu Installation and O Installation and O Installation and O Installation and Operation peration peration I I I I nstr peration nstr...

-

Page 2: Table Of Contents

Item no. 9932053WI21NA – Version V02 – Issued 2012/02 PAW NA Limited Partnership We reserve the right to make technical changes without notice! 45 Davis Street Printed in Germany – Copyright by PAW NA Limited Partnership Webster, Ma 01570, USA 9932053WI21NA – V02 2012/02... -

Page 3: For Your Safety

Only use PAW accessories for the zone module. of the corresponding manufacturer. The wrapping materials are made of recyclable materials that can be recycled by standard recycling operations. -

Page 4: Qualification Of The Installer

1 For your safety Qualification of the installer Qualification of the installer Qualification of the installer Qualification of the installer Installation and commissioning of this equipment should The following must also be observed during installation be done by qualified installers [Specialist] in accordance and commissioning: with local, state and federal codes which may be Relevant regional and national regulations (for... -

Page 5: General Safety Instructions

1 For your safety General General General General safety safety safety safety instructions instructions instructions instructions Before installing and putting the product into operation, you must read and observe the following safety instructions: Risk of burns! Risk of burns! Risk of burns! Risk of burns! The valves, fittings and the pump may heat up to more than 212 °F (100 °C) during operation. -

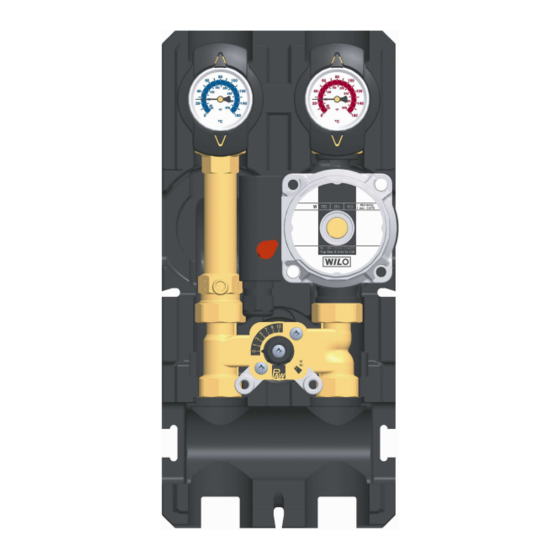

Page 6: Product Description And Functions

2 Product description and functions 2 2 2 2 Product description and functions Product description and functions Product description and functions Product description and functions K32 – – – – zone module zone module zone module zone module with 3 with 3 with 3 with 3- - - - way mixing valve... -

Page 7: Flow Check Valve [Specialist]

2 Product description and functions Flow check valve [Specialist] Flow check valve [Specialist] Flow check valve [Specialist] Flow check valve [Specialist] The zone module is equipped with an openable flow check valve (D-1) that is integrated in the return pipe. Operation Operation Operation... -

Page 8: 3-Way Mixing Valve [Specialist]

2 Product description and functions 3 3 3 3 - - - - way mixing valve way mixing valve way mixing valve way mixing valve [S [S [S [Specialist] pecialist] pecialist] pecialist] The motor-powered 3-way mixing valve (C) controls the supply temperature of the consumer circuit to the required value by means of a supply sensor and a controller. - Page 9 2 Product description and functions Changing the supply line Changing the supply line Changing the supply line Changing the supply line [Specialist] [Specialist] [Specialist] [Specialist] Dismounting the mixing valve Dismounting the mixing valve Dismounting the mixing valve Dismounting the mixing valve Remove the temperature gauge handles (A-2, F-2) and withdraw the front shell.

- Page 10 Mixing valve with supply on the right Mixing valve with supply on the left 12. Turn the cover plate (4) such that the designation PAW is on the bottom and the scale is positioned according to the figure above. 13. Screw down the cover plate (4) using the screws (3).

-

Page 11: Mounting And Installation [Specialist] Mo Unting And Installation [Specialist]

Mounting of the modular distribution manifold/fastening bracket with mounting plate [Specialist] [Specialist] [Specialist] [Specialist] The zone module must be mounted on a PAW modular distribution manifold or on a fastening bracket set with mounting plate. The modular distribution manifold, the fastening bracket and the mounting plate are not included in the scope of delivery. -

Page 12: Mounting The Zone Module [Specialist]

This avoids an unintentional start of the motors. The zone module can be installed Option 1: Option 2: • • on a PAW modular distribution manifold. on a fastening bracket with mounting plate. Consumer circuit Consumer circuit Return Return... - Page 13 3 Mounting and installation [Specialist] Flange (top view) Remove the temperature gauge handles (A-2, F-2) and withdraw the front shell of the zone module. Unscrew the nuts of the lower connections of the zone module and remove the O-rings. Put both nuts over the flanges. Flange (side view) gasket...

-

Page 14: Start-Up [Specialist]

4 Cleaning 3.3 Start Start Start Start- - - - up up [Specialist] [Specialist] [Specialist] [Specialist] Open the ball valves by means of the temperature gauge handles (A-2, F-2). Fill the system with treated heating water. Adjust the operating pressure. Ball valve closed Ball valve open 4 4 4 4... -

Page 15: Maintenance And Decommissioning [Specialist]

5 Maintenance and decommissioning [Specialist] 5 5 5 5 Maintenance and decommissioning [Specialist] Maintenance and decommissioning [Specialist] Maintenance and decommissioning [Specialist] Maintenance and decommissioning [Specialist] Before maintaining and decommissioning the product, you must read and observe the following safety instructions: Risk of electric shock! Risk of electric shock! Risk of electric shock! -

Page 16: Spare Parts

6 Spare parts 6 6 6 6 Spare parts Spare parts Spare parts Spare parts 9932053WI21NA – V02 2012/02... -

Page 17: Technical Data And Pressure Drop Characteristics

7 Technical data and pressure drop characteristics 7 7 7 7 Technical data and pressure drop characteristics Technical data and pressure drop characteristics Technical data and pressure drop characteristics Technical data and pressure drop characteristics K32 2 2 2 - - - - ¾ ¾ ¾ ¾ " " " " Dimensions Dimensions Dimensions... -

Page 18: Pressure Drop Characteristic

7 Technical data and pressure drop characteristics Pressure drop characteristic Pressure drop characteristic Pressure drop characteristic Pressure drop characteristic Flow rate [US gpm] Flow rate [l/h] 9932053WI21NA – V02 2012/02... - Page 19 Insulation PAW products specified in Imperial or metric units are approximate and are provided for reference only. For precise measurements, please contact PAW Technical Service. PAW reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on PAW products previously or subsequently sold.

- Page 20 7 Technical data and pressure drop characteristics 9932053WI21NA – V02 2012/02...

- Page 21 PAW NA Limited Partnership www.paw.eu 45 Davis Street Phone: +1-508-943-4240 Webster, Ma 01570, USA Fax: +1-508-943-4141...

Need help?

Do you have a question about the K32-3/4 and is the answer not in the manual?

Questions and answers