Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Mect TPAC1008 03 Series

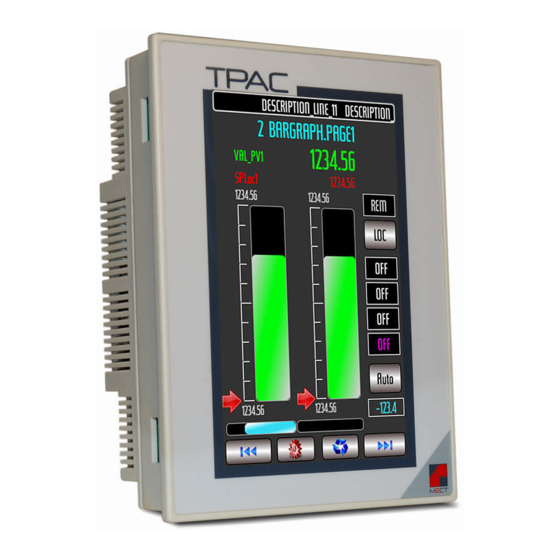

- Page 1 USER’S MANUAL for TPAC1008 03 series HMI PLC all in one ME7068_05 11/19...

- Page 2 HMI PLC all in one: TPAC1008 03 Mect srl ME7068_05 11/19...

-

Page 3: Table Of Contents

HMI PLC all in one: TPAC1008 03 Mect srl INDEX Introduction ........................ 1 1.2. Symbols ....................... 1 1.3. Terms ........................1 1.4. Security ........................ 2 1.5. Reference manual ....................2 2. System description ....................3 2.1. Specifications ....................... 4 3. Hardware installation ....................6 3.1. -

Page 4: Introduction

Products described in this manual are devoted to PLC programmers or automation experts only. MECT S.r.l. declines any responsibility about malfunctioning or damage caused by incorrect use of MECT devices, due to noncompliance to this manual information. MECT S.r.l provides an help desk service. -

Page 5: Security

HMI PLC all in one: TPAC1008 03 Mect srl 1.4. Security Attention Switch off devices before connecting them. ESD (Electrostatic discharge) Modules have electronic components that can be damaged by electrostatic discharge. Be sure to be connected to ground when handle the devices. -

Page 6: System Description

USB pen drive for software updates and data log. Through a GPRS/UMTS or Wi-Fi key (optionally sold by Mect) is possible to connect the operator panel to a Wi-Fi or Mobile network. Settings under MENU OPTIONS NETWORK_CFG tab “Wi-Fi”... -

Page 7: Specifications

HMI PLC all in one: TPAC1008 03 Mect srl Specifications Il TPAC1008 03 is based on a multiprocessor system. PLC and HMI are based on a 454MHz ARM9, I/O interface and acquisition is managed by a Cortex M3 processor. Two systems are on different boards and communicate via a CAN interface. - Page 8 HMI PLC all in one: TPAC1008 03 Mect srl PT100, TCJ, TCK, TCT, TCS, TCB, TCR, Analog outputs 10Vdc, 20mA 2.5mV Max Sensibility Cell inputs Max Frequency 40kHz Encoder inputs 4 + 1* PTO ( Pulse Train Max Frequency 65kHz...

-

Page 9: Hardware Installation

HMI PLC all in one: TPAC1008 03 Mect srl 3. Hardware installation In the following figures the mechanical dimensions of TPAC1008 03 are shown. 3.1. Mechanical dimensions Side view Rear view Figure 3 Figure 4 Side view Figure 5 ME7068_05 11/19... - Page 10 HMI PLC all in one: TPAC1008 03 Mect srl Technical specifications Table 2 MECHANICAL Material Polycarbonate, Polyamide 6.6 Dimensions W x L x H 195 mm x 145 mm x 75.5 mm Mounting plate 138mm x 188mm Installation Panel installation...

-

Page 11: Panel Mounting

HMI PLC all in one: TPAC1008 03 Mect srl 3.2 . Panel mounting 3.2.1 Distance The system must be installed with enough space for heat dissipation and cabling. Avoid cables superimposing to prevent EMC problems. Figure 6A – Horizontal mounting Figure 6B –... -

Page 12: Tpac1008 03 Wiring

HMI PLC all in one: TPAC1008 03 Mect srl 4. TPAC1008 03 wiring 4.1. Connections In the following figure the wiring diagram with the available I/O is shown. M2 verde M1 green 1 +24V 11 out I2 2 -24V 10 gnd... - Page 13 HMI PLC all in one: TPAC1008 03 Mect srl Table 3 TPAC1008 03 AD Input type Resolution Note 0.01mA Input impedance 020 mA 8 0.005V Input impedance 0V 500K Thermocouples: 1°C Cold junction J(0°C 600°C), compensation T(0°C 400°C), K(0°C ...

-

Page 14: Power Supply

HMI PLC all in one: TPAC1008 03 Mect srl Type Resolution Note Fast Inputs N°4 Frequency 1000Hz Type Resolution Note Max 200mA for each Fast Outputs N°4 Frequency output. 2 A max total 1000Hz Type Resolution Note Encoder N°5 inputs... -

Page 15: Digital Input/Output Wiring

HMI PLC all in one: TPAC1008 03 Mect srl Figure 8 Attention A wrong value for the power supply can cause a damage to the device. Digital input/output wiring The digital I/Os are PNP type, the wiring must follow the scheme below. -

Page 16: Analogue Input Wiring

HMI PLC all in one: TPAC1008 03 Mect srl 4.4. Analogue input wiring By means of the PLC program the TPAC1008 03 can be configured to connect several analog input type. Configuration is done by the setup of a system variable in the PLC program. -

Page 17: Pt100 Inputs

HMI PLC all in one: TPAC1008 03 Mect srl 4.4.2. PT100 inputs Il TPAC1008 03 can be connected to PT100. 2 different scales are possible: From –40.0 °C to 200.0°C From –40 °C to 800°C The scale from –40.0°C a 200.0°C has a resolution of 0.1°C. -

Page 18: Load Cell Inputs

HMI PLC all in one: TPAC1008 03 Mect srl 4.4.4. Load cell inputs On the TPAC1008 03 there are 3 inputs for load cells Figure 13 4.4.5. Encoder inputs On TPAC1008 03 there are 5 encoder inputs Bidirectional encoder Figure 14... - Page 19 HMI PLC all in one: TPAC1008 03 Mect srl Monodirectional encoder: Figure 15 ME7068_05 11/19...

-

Page 20: Output Current

HMI PLC all in one: TPAC1008 03 Mect srl 4.5. Analog outputs wiring 2 analog output channels are available. See in the figure 15 the analog current output wiring. 4.5.1. Output current Figure 16 4.5.2. Voltage output See in the figure 16 the analog voltage output wiring. - Page 21 HMI PLC all in one: TPAC1008 03 Mect srl 4.6. ModBus wiring (available in all models) The ModBus interface on the TPAC1008 03 is a 4 wires RS485 serial one, on M2 terminal on the pins shown in the following table.

-

Page 22: Peripherals

data storage: data logger. connecting USB peripherals as printers, mouse, etc. connecting a Wi-Fi or Mobile key (optionally supplied by Mect) to connect to a different network from LAN. Specific connection of external peripherals are implemented on request. 5.2. -

Page 23: System Variables

HMI PLC all in one: TPAC1008 03 Mect srl 6.1. System variables Here some system variables available for PLC program. Table 11 Nome Variabile Description Note PLC_Hwconf HW configuration RO 0x32 TPAC1008 03 AD PLC_Revisione Firmware revision PLC_StatusReg State register... - Page 24 HMI PLC all in one: TPAC1008 03 Mect srl 6 PT100E (1 digit Resolution) range: -40 +800°C 7 PT100R (0.1 digit Resolution) range: -40 +200°C 8 TCS (S type thermocouple) 9 TCB ( B type thermocouple) ...

- Page 25 HMI PLC all in one: TPAC1008 03 Mect srl Conf 7: -400 ÷ values: -40.0 ÷ 2000 200.0°C 1 digit resolution Conf 8: 0 ÷ 1710 values: 0 ÷ 1710°C 1 digit resolution Conf 9: 100 ÷ values: 100 ÷ 1800°C...

- Page 26 HMI PLC all in one: TPAC1008 03 Mect srl Conf 10: 0 ÷ 1500 values: 0 ÷ 1500°C 1 digit resolution PLC_AnIn_4 Analog input 4 RO Conf 1: 0 ÷ 20000 values: 0.0 ÷ value 5 digit resolution 20.000mA Conf 2: 0 ÷ 10000 values: 0.0 ÷...

- Page 27 HMI PLC all in one: TPAC1008 03 Mect srl PLC_EncoderCo_Lo Reading Encoder5 low value PLC_EncoderCo_Hi Reading Encoder5 high value PLC_CaptureT1_Lo Capture RO time (µs) between 2 edges of digital input IN7 low register PLC_CaptureT1_Hi Capture RO time (µs) between 2 edges of digital input...

- Page 28 HMI PLC all in one: TPAC1008 03 Mect srl PLC_Conf_enc_4 Encoder 4 RW 0: not configured and count is 0. Configuration 1: set monodirectional counter. To reset: 16#11 Input A (M10-58) counter direction: 0 = CUp, 1= CDown Input B (M10-59) clock 2: set bidirectional encoder.

-

Page 29: How To Order

The system can use 5472 interchange variables between HMI and automation (at maximum) which include: internal variables, interchange variables on Modbus network, retentive variables. The variables are defined by a software “Mect Suite”. 7. How to order ME7068_05 11/19...

Need help?

Do you have a question about the TPAC1008 03 Series and is the answer not in the manual?

Questions and answers