Subscribe to Our Youtube Channel

Summary of Contents for Riftek RF602 Series

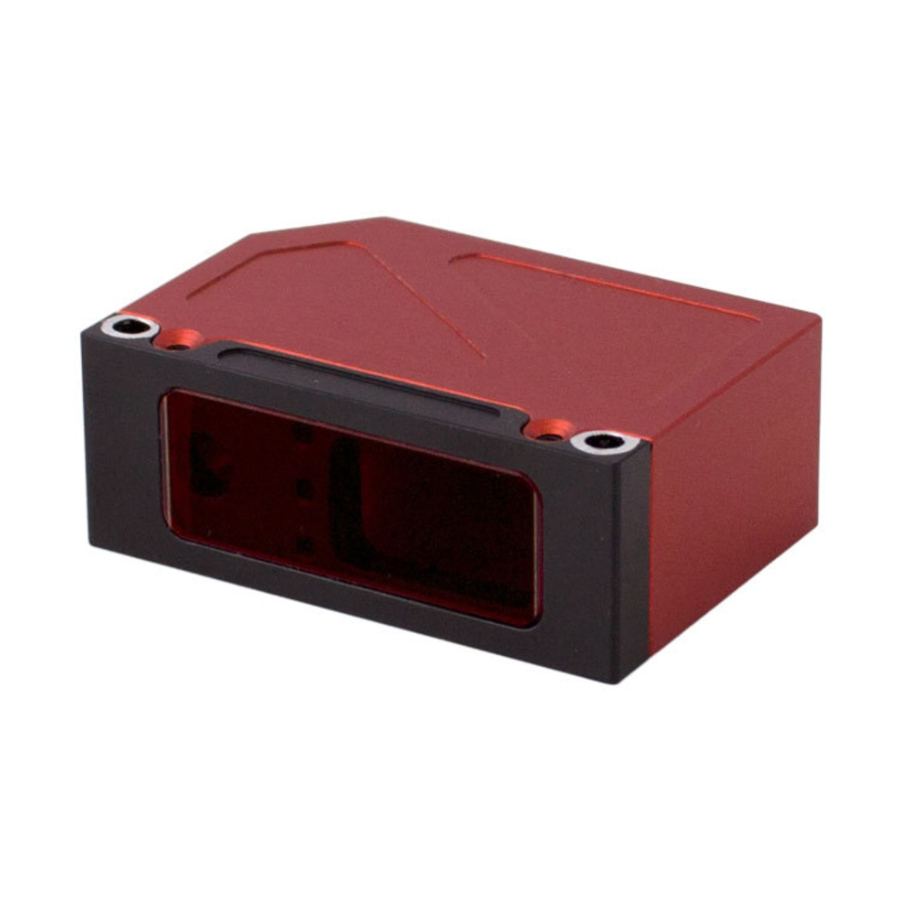

- Page 1 LASER TRIANGULATION SENSORS RF602 Series User's manual 22, Logoisky tract, Minsk 220090, Republic of Belarus tel/fax: +375 17 357 36 57 info@riftek.com www.riftek.com Certified according to ISO 9001:2015...

-

Page 2: Table Of Contents

Laser Triangulation Sensors. RF602 Series Contents Safety precautions .............................4 CE сompliance .............................4 Laser safety .............................4 General information .............................4 Basic technical data .............................5 Example of item designation when ordering .............................6 Structure and operational principle .............................6 Dimensions and mounting .............................6 8.1. Overall and mounting dimensions ............................ - Page 3 Laser Triangulation Sensors. RF602 Series 13.1............................21 Function 13.2............................22 Program setup 13.3............................22 Obtaining connection to sensor (RS232/RS485) 13.4............................23 Checking of the sensor operability 13.5............................24 Connection via the ASCII interface 13.6............................25 Connection via the Modbus RTU protocol 13.7.

-

Page 4: Safety Precautions

Laser Triangulation Sensors. RF602 Series Safety precautions · Use supply voltage and interfaces indicated in the sensor specifications. · In connection/disconnection of cables, the sensor power must be switched off. · Do not use sensors in locations close to powerful light sources. -

Page 5: Basic Technical Data

Laser Triangulation Sensors. RF602 Series Basic technical data RF602- 20/10 20/25 30/50 55/100 65/250 105/500 Base distance, mm Range, mm Linearity ±0.05 % of the range ±0.1 % Resolution 0.01 % of the range (for the digital output only) 0.02 % Temperature drift 0,02 % of the range/°... -

Page 6: Example Of Item Designation When Ordering

Laser Triangulation Sensors. RF602 Series Example of item designation when ordering RF602(BLUE)-X/D-SERIAL-ANALOG-IN-AL--M Symbol Description (BLUE) Blue laser option (405 nm or 450 nm) Base distance (beginning of the range), mm Measurement range, mm SERIAL The type of serial interface: 232 (RS232) or 485 (RS485) ANALOG Attribute showing the presence of analog output: 4…20 mA (I) or 0…10 V (U) -

Page 7: Overall Demands For Mounting

Laser Triangulation Sensors. RF602 Series Figure 2 8.2. Overall demands for mounting The sensor is positioned so that the object under control has to be placed in the working range of the sensor. In addition, no foreign objects should be allowed to stay on the path of the incident and reflected laser radiation. -

Page 8: Configuration Parameters

Laser Triangulation Sensors. RF602 Series Configuration parameters The nature of operation of the sensor depends on its configuration parameters, which can be changed only by transmission of commands through serial port RS232 or RS485. The basic parameters are as follows: 10.1. -

Page 9: Sampling Period 10.4

Laser Triangulation Sensors. RF602 Series arrives. The above-mentioned parameters determine the method of the readout of the result form the buffer. Note 2. If the bit-serial interface is used to receive the result, the time required for data transmission at selected data transmission rate should be taken into account in the case where small sampling period intervals are used. -

Page 10: Line Al Operation Mode

Laser Triangulation Sensors. RF602 Series In the "Reset of the Ethernet packets counter" mode, connection AL input to the ground potential resets the counter (Fig. 3.3)*. *Note. A low level of the AL line is holding for 100 s or more, and a high level of the AL line is holding for 100 s. -

Page 11: Number Of Averaged Values/Time Of Averaging

Description of RS232 and RS485 interfaces Data exchange with the sensor is carried out over the RIFTEK or Modbus RTU protocols in binary format or in the ASCII format. The protocol and the data format are selected using the parametrization program. -

Page 12: Configuration Parameters

Note. The network data communication protocol assumes the presence of a ‘master’ in the net, which can be a computer or other information-gathering device, and from 1 to 127 ‘slaves’ (RF602 Series sensors) which support the protocol. Each ‘slave’ is assigned a unique network identification code – a device address. -

Page 13: Answer

Laser Triangulation Sensors. RF602 Series 11.7.2. Answer 'Answer' is the data burst that can be transmitted by ‘slave’ in the course of the session. All messages with a message burst contain 1 in the most significant digit. Data in a message are transferred in tetrads. -

Page 14: List Of Parameters

Laser Triangulation Sensors. RF602 Series Write a parameter — code of parameter - value of parameter Store current parameters to FLASH- (1) - constant constant memory Recover default values of parameters in (1) - constant constant FLASH-memory Latch a current result —... -

Page 15: Notes

Laser Triangulation Sensors. RF602 Series Lower byte of maximum integration 2…3200 (default – 3200) time The limiting time of integration by CMOS-array in increments of 1 s. Higher byte of maximum integration time Lower byte for the beginning of 0…16383 (default – 0) - Page 16 Laser Triangulation Sensors. RF602 Series (0050h), measurement range - 50 mm (0032h), packet number (CNT) - 1, result update flag (SB) - 0. Request ('master'): Byte Bits Value Description Network address Request code Answer ('slave'): Byte Bits Value Description Lower tetrad of the device type...

- Page 17 Laser Triangulation Sensors. RF602 Series Byte Value Description Network address Request code Answer ('slave'): Byte Value Description Lower tetrad of the 0th byte of the result value Higher tetrad of the 0th byte of the result value Lower tetrad of the 1st byte of the result value...

-

Page 18: Modbus Rtu Protocol (Binary Format)

Laser Triangulation Sensors. RF602 Series 11.8. Modbus RTU protocol (binary format) 11.8.1. Input Registers (Read only) Register / Address Description Example Device type Firmware version Serial number 19999 Base distance Measurement range Measured value 15894 11.8.2. Holding Registers (Read / Write) -

Page 19: Ascii Format

Laser Triangulation Sensors. RF602 Series The time interval in increments of 1 s with which sensor automatically communicates the results on streaming request (sampling mode = 0). 2) 1…65535 (default — 5000) Divider ratio of trigger input (sampling mode = 1). -

Page 20: Analog Outputs

Laser Triangulation Sensors. RF602 Series Analog output 0 – “OK” line analog output is ON 1 – “OK” line analog output is OFF Control of 0 - averaging over a number of results (default); 0 – “OK” line averaging mode 1 - time averaging (5 ms). -

Page 21: Voltage Output 0

Window Parameterization program 13.1. Function The RF60 -SP software is intended for: 1) Testing and demonstration of work of RF602 series sensors; 2) Setting of the sensor parameters; 3) Reception and gathering of the sensor data signals Download link: https://www.riftek.com/media/documents/rf60x/rf60x-sp.zip... -

Page 22: Program Setup

Laser Triangulation Sensors. RF602 Series 13.2. Program setup Run setup.exe and follow the instructions of the installation wizard. 13.3. Obtaining connection to sensor (RS232/RS485) Once the program is started, the main window appears: To obtain connection via RS232/RS485 interfaces, go to RS232/RS485 PC settings in the Interface configuration parameters panel: ·... -

Page 23: Checking Of The Sensor Operability

Laser Triangulation Sensors. RF602 Series If connection is not established, a prompt window will appear asking to make the automatic search for the sensor: · Set the range of transmission rate search in the Baud rate line. · Set the range of network address search in the Net address line. - Page 24 Laser Triangulation Sensors. RF602 Series 13.5. Connection via the ASCII interface Select File > Run the ASCII format: Use the emerged window to send commands: After closing the window, the sensor continues to work in the ASCII data format. To switch to the binary data format, click the Disable ASCII format button: RF602 [Revision 1.2.0] 28.01.2019...

-

Page 25: Connection Via The Ascii Interface

To write to the register, select Write Single Register, specify the address and required value, then click Send. To change the protocol, write the required value to register 39 (0 - RIFTEK protocol, 1 - ASCII format, 2 - MODBUS protocol). -

Page 26: Display, Gathering And Scanning Of Data

Laser Triangulation Sensors. RF602 Series 13.7. Display, gathering and scanning of data Measurement result is displayed in digital form and in the form of oscillogram and is stored in the PC memory. · The number of points displayed along the X coordinate can be set in the Number of points in buffer window. -

Page 27: Setting And Saving Parameters Of The Sensor Setting Parameters

Laser Triangulation Sensors. RF602 Series 13.8. Setting and saving parameters of the sensor 13.8.1. Setting parameters Setting of parameters for all interfaces can be done using the respective tabs on the Interfaces configuration parameters panel: RS232/RS485 Analog outputs Setting of all configuration parameters of the sensor is possible with the help of the respective panel (Sensor configuration parameters): 13.8.2. -

Page 28: Saving And Writing A Set Of Parameters

Mathlab. Firmware Firmware for RF602 sensors. http://www.riftek.com/media/documents/rf602/Firm ware.zip Warranty policy Warranty assurance for Laser Triangulation Sensors RF602 Series – 24 months from the date of putting in operation; warranty shelf-life – 12 months. List of changes Date Revision Description 30.11.2017 1.0.0... -

Page 29: Distributors

Laser Triangulation Sensors. RF602 Series Distributors AUSTRIA AUSTRALIA BENELUX MBM Industry & Rail Tech Applied Measurement Althen Sensors & Controls BV GmbH Australia Pty Ltd Vlietweg 17a 2266KA Leidschendam RAILWAY INSTRUMENTS ONLY RAILWAY INSTRUMENTS ONLY The Netherlands Tullnerbachstra e 36,... - Page 30 Laser Triangulation Sensors. RF602 Series FRANCE GERMANY GERMANY BLET Measurement Group Disynet GmbH Finger GmbH & Co. KG S.A.S. Breyeller Str. 2 OPTICAL MICROMETERS ONLY 41379, Brueggen Sapelloh 172, 1 avenue du President Georges Tel: +49 2157 8799-0 31606 Warmsen, Germany...

- Page 31 Laser Triangulation Sensors. RF602 Series POLAND PORTUGAL RUSSIA MTL ASCO Sp. z o.o. Campal Inovacoes Sensorika-M LLC RAILWAY INSTRUMENTS ONLY Ferroviarias Lda. Dmitrovskoye shosse 64-4 ul. Wielowiejska 53 44-120 127474, Moscow, Russia RAILWAY INSTRUMENTS ONLY PYSKOWICE (k/ GLIWIC), Tel: +7 499 487 0363 Lagoas Park, Edificio 7, 1°...

- Page 32 Laser Triangulation Sensors. RF602 Series UKRAINE UNITED KINGDOM, USA, CANADA, MEXICO IRELAND KODA International Electronic Frunze st 22 Machines Corporation Ix thus Instrumentation Ltd 61002, Harkov, Ukraine RAILWAY INSTRUMENTS ONLY The Stables, Williams' Barns Tel/fax: +38 057 714 26 54...

Need help?

Do you have a question about the RF602 Series and is the answer not in the manual?

Questions and answers