Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Buchi E-800

- Page 1 UniversalExtractor E-800 Operation Manual...

- Page 2 CH-9230 Flawil 1 E-Mail: quality@buchi.com BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experi- ence, especially with respect to structure, illustrations and technical details. This manual is copyrighted. Information from it may neither be reproduced, distributed, or used for com- petitive purposes, nor made available to third parties.

-

Page 3: Table Of Contents

3.2.5 Lower connections on the rear side .................. 20 Type plate ............................ 20 Scope of delivery .......................... 21 Technical data ........................... 21 3.5.1 UniversalExtractor E-800 ....................... 21 3.5.2 Ambient conditions......................... 21 3.5.3 Materials .......................... 22 Transport and storage ...................... 23 Transport ............................ 23 Storage .............................. - Page 4 5.16.2 Installing one protection shield (Extraction glass chamber ECE only)........ 40 5.17 Preparing the condenser ........................ 40 5.18 Preparing the tank bottle........................ 42 5.19 Selecting a configuration ........................ 44 5.20 Disassembling the condenser circuit .................... 44 Operation Manual UniversalExtractor E-800...

- Page 5 Adding solvent through the condenser .................. 65 Ending an extraction .......................... 67 Shutting down the instrument ...................... 67 Exporting extraction parameters...................... 67 7.7.1 Exporting extraction parameters without cloud connection............ 67 7.7.2 Exporting extraction parameters with cloud connection............ 67 Operation Manual UniversalExtractor E-800...

- Page 6 12.3.1 Accessories.......................... 81 12.3.2 Spare parts .......................... 82 12.3.3 Conversion kits ........................ 84 12.3.4 Chiller............................. 84 12.3.5 Consumables ......................... 85 12.3.6 Glass sample tubes and extraction thimbles ................. 85 12.3.7 Holder for extraction thimbles .................... 86 Operation Manual UniversalExtractor E-800...

-

Page 7: About This Document

Indicates a danger that could result in damage to property. Symbols The following symbols are displayed in this operation manual or on the device: 1.2.1 Warning symbols Symbol Meaning General warning Hot surface Breakable items Hand injuries Flammable substances Operation Manual UniversalExtractor E-800 7/88... -

Page 8: Mark-Ups And Symbols

Signals are marked-up like this. Trademarks Product names and registered or unregistered trademarks that are used in this docu- ment are used only for identification and remain the property of the owner in each case. 8/88 Operation Manual UniversalExtractor E-800... -

Page 9: Safety

The UniversalExtractor E-800 is designed for the extraction (solid-liquid extraction) of samples with known solvents or solvent mixtures and the reduction or drying of the extract. The UniversalExtractor E-800 can be used in laboratories for the following tasks: — Economic Continuous Extraction (without chamber heater) —... -

Page 10: Location Of Warning Signs On The Product

— Safety-related incidents that occur while using the device should be reported to the manufacturer (quality@buchi.com). BUCHI service technicians Service technicians authorized by BUCHI have attended special training courses and are authorized by BÜCHI Labortechnik AG to carry out special servicing and repair measures. -

Page 11: Protection Devices

If faults occur: — Switch off the device immediately. — Unplug the power cord. — Inform the operator. — Cool the device before taking any further action. Do not continue to use devices that are damaged. Operation Manual UniversalExtractor E-800 11/88... -

Page 12: Glass Breakage

Technical modifications to the device or accessories should only be carried out with the prior written approval of BÜCHI Labortechnik AG and only by authorized BUCHI technicians. BUCHI accepts no liability whatsoever for damage arising as a result of unauthorized modifications. 12/88... -

Page 13: Product Description

BÜCHI Labortechnik AG Product description | 3 Product description Description of function The UniversalExtractor E-800 is designed to carry out the following solid-liquid extrac- tion methods: — Economic Continuous Extraction (without chamber heater). See Chapter 3.1.1 "Economic Continuous Extraction (without chamber heater)", page 13 —... -

Page 14: Soxhlet Extraction (With And Without Chamber Heater)

— The magnetic valve is open, the solvent extracts the analyte and flows back into the beaker. Step 2 drying — The solvent is heated, vapor rises up to the condenser, condenses and flows into the tank bottle. — The analyte remains in the beaker. 14/88 Operation Manual UniversalExtractor E-800... -

Page 15: Hot Extraction (With Chamber Heater)

— This flushes traces of analyte into the beaker. Step 3 drying — The solvent is heated, vapor rises up to the condenser, condenses and flows into tank. — The analyte remains in the beaker. Operation Manual UniversalExtractor E-800 15/88... -

Page 16: Twisselmann Extraction (With Chamber Heater)

Presence of beaker Presence of solvent (Level check) Extraction X¹ X¹ X¹ X¹ X¹ X¹ step Rinse step X¹ X¹ X¹ X¹ Dry step X¹ X¹ X¹ X¹ X¹ X¹ ¹ optional activation Inertgas 16/88 Operation Manual UniversalExtractor E-800... -

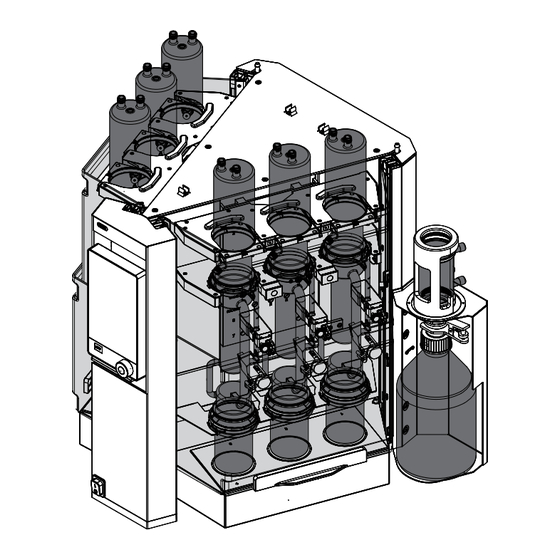

Page 17: Configuration

Fig. 2: Front view Protection shield Condenser rack Chamber rack Condenser tank bottle Installation board Tank bottle Heating plate Analyte protection sensor Beaker rack 10 Chamber heater 11 Inert gas connection 12 On/Off master switch 13 Pro Interface Operation Manual UniversalExtractor E-800 17/88... -

Page 18: Front View (Without Chamber Heater)

Front View (without chamber heater) Fig. 3: Front view Protection shield Condenser rack Chamber rack Condenser tank bottle Tank bottle Beaker rack Installation board Analyte Protection sensor (Option) Heating plate 10 On/Off master switch 11 Pro Interface 18/88 Operation Manual UniversalExtractor E-800... -

Page 19: Rear View

3.2.4 Upper connections on the rear side Fig. 5: Connections on the top Standard BUCHI communication port Standard BUCHI communication port (COM) (COM) LAN port Port for the cooling water valve Operation Manual UniversalExtractor E-800 19/88... -

Page 20: Lower Connections On The Rear Side

Symbol for "electronics recycling" Initial product code Approvals Symbol for "Do not dispose of as household waste" Year of manufacture Power consumption maximum Frequency Input voltage range Serial number 10 Instrument name 11 Company name and address 20/88 Operation Manual UniversalExtractor E-800... -

Page 21: Scope Of Delivery

Allowed water pressure 6 bar ( nominal value) Allowed water pressure 8 bar (maximum) Number of extraction positions Solvent tank volume Allowed inert gas pressure 3 bar (maximum) 3.5.2 Ambient conditions For indoor use only. Operation Manual UniversalExtractor E-800 21/88... -

Page 22: Materials

Steel 1.4301/304 with powder coating Exhaust Aluminium coated Protection shield PMMA GS Glass ware Borosilikat 3.3 Sealings glassware PTFE (with FKM core) Tank bottle Borosilikat 3.3 Tank bottle valve PTFE / FFKM Sealing solvent connection PTFE Tubing 22/88 Operation Manual UniversalExtractor E-800... -

Page 23: Transport And Storage

The instrument should be transported by two persons at the same time. Lift the instrument at the points indicated. NOTICE Dragging the instrument can damage the feet of the instrument. Lift the instrument when positioning or re-locating. Operation Manual UniversalExtractor E-800 23/88... - Page 24 4 | Transport and storage BÜCHI Labortechnik AG Fig. 8: Lifting the instrument Lift the instrument – this requires two persons each lifting at the points indicated on the left and right side of the instrument. 24/88 Operation Manual UniversalExtractor E-800...

-

Page 25: Installation

1. Provide the mains voltage and frequency specified on the type plate of the instru- ment. 2. Be designed for the load imposed by the instruments connected. 3. Be equipped with suitable fuses and electrical safety features. 4. Be equipped with proper earthing. Operation Manual UniversalExtractor E-800 25/88... -

Page 26: Securing Against Earthquakes

Risk of property damage and diminished performance due to use of un- suitable power cables. The power supply cables supplied with the product by BUCHI precisely match the re- quirements of the device. If other power cables that do not meet those requirements are used, the device may be damaged and/or its performance diminished. -

Page 27: Connecting The Solvent Tubes To The Condenser Tank Bottle

Attach the solvent connection nuts onto the connection marked OUT and IN (SOLVENT) . Attach the inlet tube onto the connection marked OUT . Attach the drain tube onto the connection marked IN (SOLVENT) . Operation Manual UniversalExtractor E-800 27/88... -

Page 28: Connecting The Coolant Tubes To The Condenser Tank Bottle

R Make sure that the instrument is not con- nected to the power supply. Attach the inert gas tube onto the connection marked INERT. 5.8.2 Connecting inert gas to the extraction glas chamber (option) Attach the inert gas tube onto the connection. 28/88 Operation Manual UniversalExtractor E-800... -

Page 29: Preparing The Economic Continuous Extraction (Without Chamber Heater)

For Economic Continuous Extraction use the following positions: Device Position on the installation board Beaker rack lower Chamber rack Nr. 7 Condenser rack Nr. 5 Preparing the instrument Switch the On/Off master switch to Off. Operation Manual UniversalExtractor E-800 29/88... -

Page 30: Preparing The Economic Continuous Extraction Chamber (Without Chamber Heater)

Select the Economic Continuous Extraction method on the interface. See Chapter 5.19 "Selecting a configuration", page 44 5.9.1 Preparing the Economic Continuous Extraction chamber (without chamber heater) Pull the chamber rack. Put the extraction glass chamber in the instru- ment. 30/88 Operation Manual UniversalExtractor E-800... -

Page 31: Preparing The Soxhlet Extraction (With And Without Chamber Heater)

Preparing the instrument Switch the On/Off master switch to Off. Attach the condenser rack to the instrument with screws. Prepare the condenser. See Chapter 5.17 "Preparing the condenser", page 40 Attach the chamber rack to the instrument with screws. Operation Manual UniversalExtractor E-800 31/88... -

Page 32: Preparing The Chamber For A Soxhlet Extraction

Preparing the chamber for a Soxhlet Extraction Prepare the extraction glass chamber universal. See Chapter 5.15 "Prepar- ing the extraction glass chamber uni- versal", page 38 Pull the chamber rack. Put the extraction glass chamber in the chamber rack. 32/88 Operation Manual UniversalExtractor E-800... - Page 33 Turn the extraction glass chamber 90° counterclockwise. Make sure, that the extraction glass chamber is installed correctly. Connect the valve with the connection on the installation board. Push the chamber rack in the instru- ment. Operation Manual UniversalExtractor E-800 33/88...

-

Page 34: Preparing The Continuous Extraction (With And Without Chamber Heater)

Pull the chamber rack. Put the extraction glass chamber universal in the chamber rack. Connect the valve with the connection on the installation board. Push the chamber rack in the instrument. 34/88 Operation Manual UniversalExtractor E-800... -

Page 35: Preparing The Hot Extraction (With Chamber Heater)

Pull the chamber rack. Put the extraction glass chamber universal in the chamber rack. Connect the valve with the connection on the installation board. Push the chamber rack in the instrument. Operation Manual UniversalExtractor E-800 35/88... -

Page 36: Preparing The Soxhlet Warm Extraction (With Chamber Heater)

Pull the chamber rack. Put the extraction glass chamber universal in the chamber rack. Connect the valve with the connection on the installation board. Push the chamber rack in the instrument. 36/88 Operation Manual UniversalExtractor E-800... -

Page 37: Preparing The Twisselmann Extraction (With Chamber Heater)

Pull the chamber rack. Put the extraction glass chamber universal in the chamber rack. Connect the valve with the connection on the installation board. Push the chamber rack in the instrument. Operation Manual UniversalExtractor E-800 37/88... -

Page 38: Preparing The Extraction Glass Chamber Universal

NOTICE! Make sure that the lips of the sealing show in the direction of the glass. Put the sealing on the bottom of the extraction glass chamber universal. The extraction glass chamber universal is pre- pared. 38/88 Operation Manual UniversalExtractor E-800... -

Page 39: Installing The Protection Shields

Hold both protection shields on both sides at the point indicated. Hold both protection shields on both sides at the point indicated. Put the rear protection shield on both sides into the rear slot at the same time. Operation Manual UniversalExtractor E-800 39/88... -

Page 40: Installing One Protection Shield (Extraction Glass Chamber Ece Only)

Put the protection shield on both sides into the front slot at the same time. 5.17 Preparing the condenser NOTICE Risk of broken parts by using tools Using tools for preparing the instrument can break parts. Tighten all parts with your hands. 40/88 Operation Manual UniversalExtractor E-800... - Page 41 Put the sealing on the bottom of the con- denser. Attach the solvent connection nut to the con- denser. Connect the solvent collector tube. Put the condenser in the condenser rack. Secure the condenser with the flange lock. Operation Manual UniversalExtractor E-800 41/88...

-

Page 42: Preparing The Tank Bottle

Make sure that the condenser circuit is com- plete. See Chapter 12.1 "Schematics", page 79 5.18 Preparing the tank bottle NOTICE Risk of broken parts by using tools Using tools for preparing the instrument can break parts. Tighten all parts with your hands. 42/88 Operation Manual UniversalExtractor E-800... - Page 43 Switch the On/Off master switch to Off. Put the bottle cap on the bottle. Put the tank bottle in the instrument. Attach the ball joint clamp. Tighten the knurled nut at the ball joint clamp. Operation Manual UniversalExtractor E-800 43/88...

-

Page 44: Selecting A Configuration

ð The dialog box closes. 5.20 Disassembling the condenser circuit Disconnect the indicated condenser connec- tion. Make sure, that there is no coolant in the con- denser circuit. Disconnect the other condenser connections. Remove the flange lock. 44/88 Operation Manual UniversalExtractor E-800... - Page 45 BÜCHI Labortechnik AG Installation | 5 Pull the condenser out of the condenser rack. Disconnect the solvent collector hose. Disconnect the solvent collector tube from the installation board. Operation Manual UniversalExtractor E-800 45/88...

-

Page 46: Operating The Interface Pro

The function bar shows available functions according to the current operation. The functions on the function bar are executed by tapping the relevant function but- tons. Symbol Description Meaning [ Back ] The display reverts to the previous view. 46/88 Operation Manual UniversalExtractor E-800... -

Page 47: Menu Bar

[ Setup ] menu settings for the extrac- tion positions — For saving extraction [ Method ] menu methods — Editing and activating — Change settings [ Configuration ] menu — Service menu — System information Operation Manual UniversalExtractor E-800 47/88... - Page 48 On the home menu the following control buttons are available: Button Meaning Skips the actual step at the selected position. Skips the actual step for all positions. Aborts extraction on the selected extraction position. Editing the running method. 48/88 Operation Manual UniversalExtractor E-800...

-

Page 49: Setup Menu

The following parameters can be edited: Device name/DHCP/MAC address/ System IP address/Subnet mask/ Gateway [ Delete app con- Confirmation question Resets external connections to the nection ] instrument. [ Demo Mode ] On/Off Simulate an extraction. Operation Manual UniversalExtractor E-800 49/88... - Page 50 — Lift current — Beeper On/Off — Chiller On/Off (option) Submenu System Information The submenu [ System information ] contains details of the connected devices and in- formation on network connection diagnosis. Action Option Explanation 50/88 Operation Manual UniversalExtractor E-800...

-

Page 51: Solvent Menu

Solvent menu The solvent menu contains the available solvents for the extraction methods. The solvent menu allows editing individual solvents. See Chapter 6.7 "Editing a sol- vent", page 58 Status bar Shows the actually used solvent and configuration. Operation Manual UniversalExtractor E-800 51/88... -

Page 52: Selecting A Method For An Extraction Position

ð The dialog box closes. Editing a method The Pro interface can save up to 40 extraction methods. 6.6.1 Creating a new method Navigation path ➔ Navigate to the [ Method ] menu via the navigation path. 52/88 Operation Manual UniversalExtractor E-800... -

Page 53: Changing The Name Of A Method

ð The dialog box closes. Tap the function [ Save ] on the function bar. ð The solvent is saved. 6.6.4 Setting the analyt protection Navigation path ➔ Navigate to the [ Method ] menu via the navigation path. Operation Manual UniversalExtractor E-800 53/88... -

Page 54: Setting The Inert Gas (Option) (Soxhlet, Soxhlet Warm, Continuous, Hot And Twisselmann Extraction Only)

Tap the function [ Edit ] on the function bar. Tap the action [ Extraction time ]. ð The display shows a dialog box with a numeric input box. Enter the value in the numeric input box. 54/88 Operation Manual UniversalExtractor E-800... -

Page 55: Setting The Extraction Cycles Of A Method (Soxhlet And Soxhlet Warm Extraction)

Tap the function [ Edit ] on the function bar. Tap the action [ Extraction heating level ]. ð The display shows a dialog box with a numeric input box. Enter the value in the numeric input box. Operation Manual UniversalExtractor E-800 55/88... -

Page 56: Setting The Chamber Heater (Soxhlet Warm, Hot And Twisselmann Extraction)

Navigate to the [ Method ] menu via the navigation path. Tap the name of the method that you wish to edit. ð The display shows the view Method. Tap the function [ Edit ] on the function bar. 56/88 Operation Manual UniversalExtractor E-800... -

Page 57: Setting The Rinse Time Of A Method (Soxhlet, Soxhlet Warm, Hot And Twisselmann Extraction)

Tap the function [ Edit ] on the function bar. Tap the action [ Rinse heating level ]. ð The display shows a dialog box with a numeric input box. Enter the value in the numeric input box. Operation Manual UniversalExtractor E-800 57/88... -

Page 58: Setting Dry Step

Tap the function [ Save ] on the function bar. ð The dry step configuration is saved. Editing a solvent 6.7.1 Creating a new solvent Navigation path ➔ Navigate to the [ Solvent ] menu via the navigation path. 58/88 Operation Manual UniversalExtractor E-800... -

Page 59: Changing The Name Of A Solvent (Own Created Solvents Only)

Tap the function [ Save ] on the function bar. ð The new name is saved. ð The dialog box closes. 6.7.4 Changing the heating level of a solvent Navigation path ➔ Navigate to the [ Solvent ] menu via the navigation path. Operation Manual UniversalExtractor E-800 59/88... -

Page 60: Changing The Boiling Point Of A Solvent

ð The display shows the view Solvent. Tap the action [ Enthalpy ]. Tap the function [ OK ] on the function bar. ð The display shows a dialog box with a numeric input box. Enter the enthalpy for the solvent. 60/88 Operation Manual UniversalExtractor E-800... -

Page 61: Changing The Molecular Weight Of A Solvent

ð The display shows a dialog box with a numeric input box. Enter the density for the solvent. Tap the function [ OK ] on the function bar. ð The value for the density is saved. ð The dialog box closes. Operation Manual UniversalExtractor E-800 61/88... -

Page 62: Performing An Extraction

Put the glass sample tube with frit into the holder in the extraction chamber. 7.1.2 Adjusting the optical sensor (Twisselmann and Continuous Extraction only) Adjusting the optical sensor on the extraction glass chamber universal. — White line below the sample. Sample 62/88 Operation Manual UniversalExtractor E-800... -

Page 63: Adjusting The Optical Sensor (Soxhlet, Soxhlet Warm And Hot Extraction)

Selecting a method for all extraction positions Navigation path ➔ Navigate to the [ Home ] menu via the navigation path. Tap the method. ð The display shows a dialog with the selectable configurations. Select the method you wish to use. Operation Manual UniversalExtractor E-800 63/88... -

Page 64: Selecting Different Methods For Each Extraction Position

R The extraction positions are prepared. Chapter 7.2 "Preparing the extraction posi- tions", page 63 R The sample is prepared (in the glass sample tube or in the paper thimbles). Switch on the connected chiller. Pull the chamber rack out of the instrument. 64/88 Operation Manual UniversalExtractor E-800... -

Page 65: Task During Performing An Extraction

A beaker is placed under the position. An extraction glass chamber is installed at the position. The lift is in the lower position. NOTE Boiling retardation 4 Make sure that the solvent is at ambient temperature. Operation Manual UniversalExtractor E-800 65/88... - Page 66 An extraction glass chamber is installed at the position. The lift is in the lower position. NOTE Boiling retardation 4 Make sure that the solvent is at ambient temperature. Put a funnel on the condenser. Add solvent with a beaker. 66/88 Operation Manual UniversalExtractor E-800...

-

Page 67: Ending An Extraction

Scan the QR code on the display with the camera function of the App. 7.7.2 Exporting extraction parameters with cloud connection Precondition: R The App is installed on a mobile device. R An extraction is finished. The extraction parameters are automatically transferred to the App. Operation Manual UniversalExtractor E-800 67/88... -

Page 68: Mobile Connection

The following port has to be enabled in the firewall settings on the internet gate- way: — TCP (HTTPS) traffics through remote port 443 In order to use the BUCHI Cloud a DNS server must be configured on the instru- ment. NOTE If there is no DNS server available enter the IP address for the BUCHI Cloud connec- tion manually. -

Page 69: Connecting The Instrument And App Using A Password

Mobile connection | 8 Connecting the instrument and app using a password Navigate to the action [ Mobile connection password ]. ð The display shows a password. Enter the password in the app. Tap [ OK ] Operation Manual UniversalExtractor E-800 69/88... -

Page 70: Cleaning And Servicing

Users may only carry out the servicing and cleaning operations described in this sec- tion. Any servicing and repair work which involves opening up the casing may only be car- ried out by BUCHI service technicians. Regular maintenance work CAUTION Hot surfaces. -

Page 71: Removing The Tank Bottle

Switch the On/Off master switch to Interface Wipe down the display with a damp Monthly cloth. Removing the tank bottle Switch the On/Off master switch to Off. Open the knurled nut at the ball joint clamp. Operation Manual UniversalExtractor E-800 71/88... -

Page 72: Draining Solvent From The Instrument

R A tank bottle is installed. See Chapter 5.18 "Preparing the tank bottle", page 42 Navigate to [ Actors ] via the navigation path. ð The display shows the view Actors. Enable the action [ Pump ]. 72/88 Operation Manual UniversalExtractor E-800... -

Page 73: Open The Tank Valves

Changing the membrane with anchor NOTE Make sure that the spring remains in the valve during the hole changing process. Open the screws indicated. Remove the level sensor. Loosen the screw indicated. Remove the valve holder. Operation Manual UniversalExtractor E-800 73/88... - Page 74 Remove the membrane with anchor. NOTICE! Make sure that the spring is inside the casing. Place unused membrane with anchor. Attache the valve holder with the screw indi- cated Attach the level sensor to the valve with the screws indicated. 74/88 Operation Manual UniversalExtractor E-800...

-

Page 75: Help With Faults

Heater power is set too low Adapt the heating power to the ambient conditions (temperature, level above sea). Choose correct solvent. Not enough solvent Add solvent. See Chapter "Adding solvent through the condenser with a beaker", page 66 Operation Manual UniversalExtractor E-800 75/88... -

Page 76: Draining Solvent From Extraction Glass Chamber (Soxhlet, Soxhlet Warm, Hot And Twisselmann Extraction Only)

Replacing the gliding elements and magnets Positions of the magnet Replacing procedure Attach the back part of the gliding ele- ments to the protection shield. NOTICE! Insert the magnet at the po- sitions indicated. Insert the magnet. 76/88 Operation Manual UniversalExtractor E-800... - Page 77 BÜCHI Labortechnik AG Help with faults | 10 Attach the front part of the gliding ele- ments to the protection shield. Operation Manual UniversalExtractor E-800 77/88...

-

Page 78: Taking Out Of Service And Disposal

When disposing, observe the disposal regulations of the materials used. Materials used see Chapter 3.5 "Technical data", page 21 11.3 Returning the instrument Before returning the instrument, contact the BÜCHI Labortechnik AG Service Depart- ment. https://www.buchi.com/contact 78/88 Operation Manual UniversalExtractor E-800... -

Page 79: Appendix

Water out Connection Condenser CW OUT Condenser Condenser Flow meter (inside instrument) Condenser Condenser Connection CW Tank OUT Condenser solvent tank CW IN Condenser Connection solvent tank CW Tank IN CW OUT Fig. 12: Condenser circuit Operation Manual UniversalExtractor E-800 79/88... -

Page 80: Solvent Collector Schematic

Acetone (Propanon, 56.05 29.1 58.08 0.791 AcMe) Acetonitril (MeCN) 81.65 29.75 41.05 0.78 Benzene 80.09 30.72 78.11 0.8765 Butanon 79.59 31.3 72.11 0.805 (Methylethylketon, AcEt) Chloroform 29.24 119.38 1.48 (Trichloromethane) Cyclohexane 80.73 29.97 84.16 0.78 80/88 Operation Manual UniversalExtractor E-800... -

Page 81: Spare Parts And Accessories

0.86 12.3 Spare parts and accessories Use only genuine BUCHI consumables and spare parts in order to ensure correct, safe and reliable operation of the system. NOTE Any modifications of spare parts or assemblies are only allowed with the prior written permission of BUCHI. -

Page 82: Spare Parts

Order no. Image Extraction beaker LSV carrier 11067715 Allows to carry 6 beakers LSV 11067714 Set condenser insulations E-800, 6 pcs. 11069077 The insulation of the condensers prevent condensing water and is recommended in high humidity environ- ment Set insulation cooling water hoses... - Page 83 Soxhlet assembly cpl. 11067065 One part constiting of magnetic valve and level sensor for extraction glass chamber Soxhlet Set of seals E-800, PTFE, 2 pcs. 11067483 Membrane with anchor for magnetic valve unit 037534 Protection shield top, cpl. 11067832...

-

Page 84: Conversion Kits

6 pcs. Set of draining tubes ECE, FEP 11067479 12.3.3 Conversion kits The UniversalExtractor E-800 can be converted into another configuration with an easy change of glass assembly. Order no. Conversion kit from Soxhlet / Universal to ECE 11068488... -

Page 85: Consumables

1167490 (d33 mm) Extraction thimbles 43 x 150 mm, 25 pcs. 11067447 The extraction thimbles with 150 mm length fit perfectly into the Universal glass extraction chamber, they need the holder 1167491 (d 43 mm) Operation Manual UniversalExtractor E-800 85/88... -

Page 86: Holder For Extraction Thimbles

11068485 Holders for thimbles d43, stainless steel, 6 pcs. 11068486 Set of holders for glass sample tubes with frit, PTFE, 3 pcs. 11067485 Set of holders for LSV glass sample tubes, PTFE, 3 pcs. 11067486 86/88 Operation Manual UniversalExtractor E-800... - Page 88 T +971 4 313 2860 T +52 55 9001 5386 F +66 2 862 08 54 F +971 4 313 2861 latinoamerica@buchi.com bacc@buchi.com middleeast@buchi.com www.buchi.com/es-es www.buchi.com/th-th www.buchi.com We are represented by more than 100 distribution partners worldwide. Find your local representative at: www.buchi.com...

Need help?

Do you have a question about the E-800 and is the answer not in the manual?

Questions and answers