Table of Contents

Advertisement

Quick Links

Operator's Manual

r®

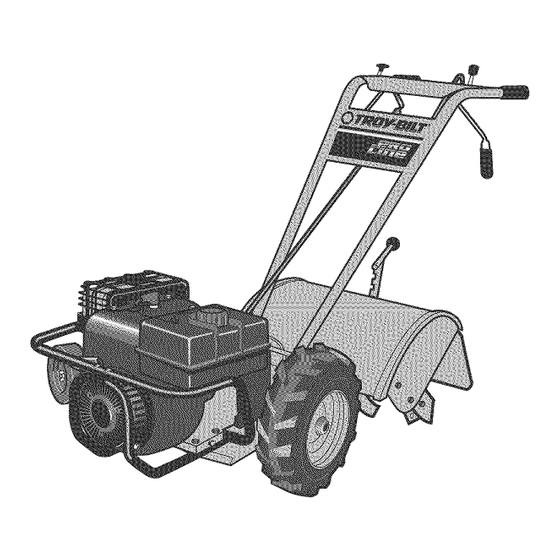

Rear-tine Tiller

Model 675B

Model 675B Shown (bumper styles vary)

IMPORTANT:

READ SAFETY RULES AND INSTRUCTIONS

CAREFULLY

WARNING:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered or

grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it

should be maintained in effective working order by the operator. In the State of California the above is required by law (Section 4442 of the California Public

ResourcesCode). Other states may have similar laws. Federallaws apply on federal lands. A spark arrester for the muffler is available through your nearest engine

authorized service dealer or contact the service department P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT

LLC, P.O. BOX 361131 CLEVELAND,

OHIO 44136-0019

PRINTEDIN U.S.A.

FORMNO. 769-00586B

9/13/04

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Troy-Bilt REAR-TINE TILLER 675B

- Page 1 ResourcesCode). Other states may have similar laws. Federallaws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department P.O. Box 361131 Cleveland, Ohio 44136-0019. TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, PRINTEDIN U.S.A.

-

Page 2: Customer Support

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of this unit, you can seek help from the experts. Choose from the options below: Visit troy-bilt.com will get the four options reproduced here. Click on the appropriate button and help is immediately available. -

Page 3: Safety Alert Symbol

SECTION 1: SAFETY This machine meets voluntary safety stan- dard B71.8-1996, which is sponsored by the Outdoor Power Equipment Institute, Inc., and is published by the American National Standards Institute. WARNING The engine exhaust from this productcontains chemicals known to the State of California to cause cancer, birth defects or other reproduc- tive harm. -

Page 4: Maintenance And Storage

5.Ifthe unit s hould start tovibrate abnormally, stop the engine, disconnect the spark p lug wire and prevent itfrom touching the spark plug, and check immediately forthe cause. Vi- bration i sgenerally awarning o ftrouble. 6.Stop theengine, disconnect thespark plug wire and prevent itfrom touching the spark p lug whenever youleave t heoperat- ingposition, before u nclogging the tines, orwhen m aking a nyrepairs, adjustments... -

Page 5: Safety Decals

SafetyDecals For your safety and the safety of others, various safety and operational decals are located on your unit (seeFigure 1-2 be- low). Keepthe decals clean and legible at all times. Contactyour local service dealer or the factory for replacements if any decals are damagedor missing. -

Page 6: Step2: Attach Handlebars

SECTION 2: ASSEMBLY WARNING: To prevent personal injury or property damage,do not start the engine until all assembly steps are complete and you have read and understand the safety and operating instructions in this Manual. Introduction Carefully follow these assembly steps to correctly prepare your tiller for use. - Page 7 Figure2-4: Attach handlebars. 5. Move the handlebars up or down to align the threaded hole in the cross-brace with one of the four slots in the curved height adjustment bracket. Placethe keyed washer (E, Figure 2-3) on the flange head height adjustment screw (F) with the raised keys (edges) of the washer facing down.

-

Page 8: Step6: Attach Wheelgearlever

CAUTION: Incorrect cable adjustment could cause the wheels and tines to rotate unexpectedly.Follow adjustment procedures carefully. Failureto do so could result in personal injury or property damage. 4. Checkfor correct spring/caNe tension as instructed in Section 5, Checkingand Adjusting Forward Clutch Belt Tension. 5. -

Page 9: Section 3: Features A Ndcontrols

SECTION 3: FEATURES A NDCONTROLS operating your machine, ARNING: Before carefully readand understand all safety, controls and operating instructions in this Manual, the separateEngine Owner's Manual,and on the decals on the machine. Failure to follow these instructions can result in serious personal injury. -

Page 10: Engine Controls

3.To move t he tiller i nreverse, first s top all forward m otion. Liftupthehandlebars til thetines clear t heground a nd pull t he Reverse Clutch l ever o ut. The wheels will r otate i nareverse direction aslong as thelever i sheld inREVERSE. stop thewheels and tines, release the lever and itwillreturn t oNEUTRAL. -

Page 11: Section 3: Operation

SECTION 3: OPERATION WARNING: Before operating your machine, carefully readand understand all safety (Section 1), controls (Section 3) and operating instructions (Section 4) in this Manual, in the separate Engine Owner's Manual,and on the decals on the machine. Failure to follow these instructions can result in serious personal injury. - Page 12 7. Choke or prime the engineas instructed in the separate Engine Owner's Manual. 8. Checkbehind you to avoid contacting any obstacles when pulling the starter rope. Placeone hand on the fuel tank to stabilize the unit and usethe recoil starter to start the engine as instructed in the En- gine Owner's Manual.

-

Page 13: Changingbelt Rangespeeds

Stopping theTiller andEngine 1. Tostop the wheels and tines, releasethe Forward Clutch levers or the Reverse Clutch Control (whichever is engaged). 2. Tostop the engine, move the Engine Throttle Lever to STOR 3. If the engine is equipped with a fuel shut- off valve,close the valve as instructed in the Engine Owner's Manual. -

Page 14: Tillingtips& Techniques

Tilling Depths WAHNING: Before tilling, contact your telephone or utilities company and inquire if underground equipment or lines are usedon your property. Do not till near buried electric cables, telephone lines, pipes or hoses. • Whencultivating (breakingup surfacesoil around plants to destroyweeds,seeFig.4-9), a just the tines to dig only 1"to 2" deep.Using shallow tilling depths helps prevent injury to plants whose roots often grow close to the surface. -

Page 15: Loading And Unloadingthetiller

TILLINGTIPS & TECHNIQUES (CON'T) Tilling On Slopes Read the followingrecommendationsbeforetilling on slopes: If you must gardenon a moderateslope,pleasefollow two very importantguidelines: 1. Till only on moderateslopes,neveron steepground wherefooting is difficult (review safe- ty rulesin Section 1: Safetyof this manual). 2. We recommendtilling up and down slopes ratherthan terracing. Tilling vertically on a slopeallows maximum plantingarea and also leavesroomfor cultivating. -

Page 16: Section 5: Maintenance

SECTION 5: MAINTENANCE inspecting, cleaning or WARNING: Before servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Removeignition key on electric start models. Failureto follow these instructions can result in serious personal injury or... -

Page 17: Air Cleaner Service

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from WARNING: spark plug. Failureto follow these instructions can result in serious personal injury or property damage. A. ToCheck Transmission 1. Checkthe gear oil level when the trans- mission is cool. - Page 18 moving parts to come to a complete stop, disconnect spark plug wire and move wire away from WARNING: spark plug. Failureto follow these instructions can result in serious personal injury or property damage. Carburetor / Governor Adjustment shall not tamper with the engine WARNING: Operators governor settings;...

-

Page 19: Checkingandadjustingtension On Drivebelts

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from WARNING: spark plug. Failureto follow these instructions can result in serious personal injury or property damage. ENGINE OF TINE ENOTES CUTTING EDGE Figure5-7: Complete tineassemblies--holders, tinesand hardware. (counter-rotating tine) tiller ARNING: This is a CRT... - Page 20 moving parts to come to a complete stop, disconnect spark plug wire and move wire away from WARNING: spark plug. Failureto follow these instructions can result in serious personal injury or property damage. (E) Removebelt Figure 5-9: Disconnect ForwardClutch Rod and move forward drive belt out of groove in engine forward drive pulley.

- Page 21 moving parts to come to a complete stop, disconnect spark plug wire and move wire away from WARNING: spark plug. Failureto follow these instructions can result in serious personal injury or property damage. front of the unit (not the operator's posi- tion).

- Page 22 moving parts to come to a complete stop, disconnect spark plug wire and move wire away from WARNING: spark plug. Failureto follow these instructions can result in serious personal injury or property damage. 3. Slip the forward drive belt down and over the front of the transmission pulley (C, Figure 5-16).

-

Page 23: Troubleshooting

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from WARNING: spark plug. Failureto follow these instructions can result in serious personal injury or property damage. PROBLEM Enginedoes not start Spark plug wire disconnected Engine Throttle Control Lever incorrectly set. -

Page 24: Section 6: Parts List

SECTION 6: PARTS LIST HANDLEBAR ASSEMBLY and CONTROL LEVERS TOP COVER... - Page 25 MODEL675B * Specify GRADE5 if ordering part locally. PARTNO. DESCRIPTION 1918801 Handlebars GW-9126 Grip 777122217 Decal, Control Panel 777D07888 Decal, Model Name/Logo 1916784 ReverseClutch Control Cable 710-04042 HexFlangeScrew, 3/8-16 GW-9955 Washer, Keyed 1900475 Bracket, Handlebar Height Adjustment 710-0514 HexHd. Screw, 3/8-16 x 1" 736-3050 Washer, Plain (flat) 3/8, S.A.E 712-3000...

- Page 26 MODEL675B 19¢ ...,_Reve I CluichCable 39 _ (Screw, Ref. 47, secures ForwardClutchCable- page 25, Ref. 10)

- Page 27 MODEL675B PART NO. 710-0395 HexHd.Screw,546-18 x 2-1/4 1917326 Bracket, C lutchCable Lockwasher-54 6 736-0119 710-0107 HexHd.Screw,546-24 x 1/2 777S30651 Decal,HotSurfaces / BeltWarning Cover 1916659 712-3004A Flange LockNut,546-18 1108841 Key,34 6 x 1-1/2 GW-1138-1 Shim,1.0x.7656x.062 1916520 Pulley, E ngine Drive GW-9944 Washer,.827 x.331x.098 GW-9572 HexHd.Screw,546-24 x 1-1/8...

- Page 28 MODEL675B See Note 1 PARTNO. 721-04031 Oil Seal 1105620 Pipe Plug, 1/4 721-04001 Seal,Transmission Bore 710-04043 Hex FlangeScrew, 5/16-18 x 3/4" 1983632 Oil Seal,Input Pinion Shaft1 GW-20910 Transmission Cover (Incl. four Ref. 18) GW-20694 Gasket,Transmission Top Cover 619-04010 Transmission CaseAssy. GW-9467 Plug 1917101...

- Page 29 MODEL675B PARTNO. GW-1714 Bearing,Tapered Roller with Race GW-9400 Drive Shaft Bearing Cup GW-9401 Drive Shaft Bearing Cone GW-20718 Spur Gear GW-9301 Key, 34 6 sq. x 1 1916597 Rolled Drive Shaft (Drive shaft is one-piece with integral, single-lead, work-hardened front worm, and integral, six-lead work- hardenedrear worm.

- Page 30 MODEL675B Assembled _'_J Internally SHAFT ASSEMBLY PARTNO. Oil Seal 721-04031 1909950 Retaining Ring(heavy-duty, external) GW-1166-1 Shim,1-1J64 I.D.,.O62"thick ( A/R) GW-1166-2 Shim,asabove, b ut.030" thick (A/R) GW-1166-3 Shim,asabove, b ut.015" thick (A/R) GW-1166-4 Shim,asabove, b ut.OlO"thick(A/R) GW-1086 Bushing 711-04091 Wheel S haft(Incl.Ref.6) GW-9373 Hi-ProKey,1/4x 1-546 GW-20914...

- Page 31 MODEL675B OFDENOTEST, NECUTT,NG I1 WHEEL SHAFT PART NO. 1100068 HexHd. Screw, 3/8-16 x 3/4" 1985101 Tine - right-hand 1110108 Hex Lock Nut, 3/8-161 1916693 Tine Holder, left-side 1916694 Tine Holder, right-side 710-3096 Hex Hd. Screw, 3/8-16 x 2, Grade8 EDGE TINE SHAFT ENGINE...

- Page 32 MODEL675B Transmission (618-04002)

- Page 33 MODEL675B * Specify GRADE5 if ordering part locally. PARTNO. DESCRIPTION 686-04021 Hood,Tine 736-0169 Lockwasher,3/8 GW-2525 Bracket, H ood& DepthRegulator 710-04049 HexHd.Fig.Screw,546-18 x 5_8" 712-0291 HexLockNut,1/4-20 710-0597 HexHd.Screw,1/4-20x 1* GW-9384 Spring,DepthRegulator P lunger GW-9534 Spacer 1185469 RollPin(spiral),1/4x 1 1916186 BarAssembly, DepthAdjustment GW-9120 Retaining Ring(Tolerance Ring) GW-9119...

- Page 34 MODEL675B ROW MARKER ATTACHMENT (OPTIONAL) BUMPER ATTACHMENT BUMPER 0EM-290-254...

- Page 35 MODEL675B Note: Most common hardware listed above as can be found at most hardware stores. * Specify GRADE5 if ordering part locally. PARTNO. DESCRIPTION GW-1594 MarkerBlade-blade only MarkerArm-mainarm GW-1600 GW-1595 MarkerArm-extension armwith pin HitchPin GW-9347 Thumbscrew-I/4-20 x 1/2 GW-9786 NutBar GW-1596 GW-9828 Nut-hex,10-24w/attachedstarwashers...

-

Page 36: Limited Warranty

All Troy-Bilt branded rear tine walk-behind tillers with gear drive transmissions. IS COVERED This warranty begins on the date of purchase and is warranted by Troy-Bilt LLC for the life of the tiller, to the original purchaser only. WHAT IS COVERED...

Need help?

Do you have a question about the REAR-TINE TILLER 675B and is the answer not in the manual?

Questions and answers