Table of Contents

Advertisement

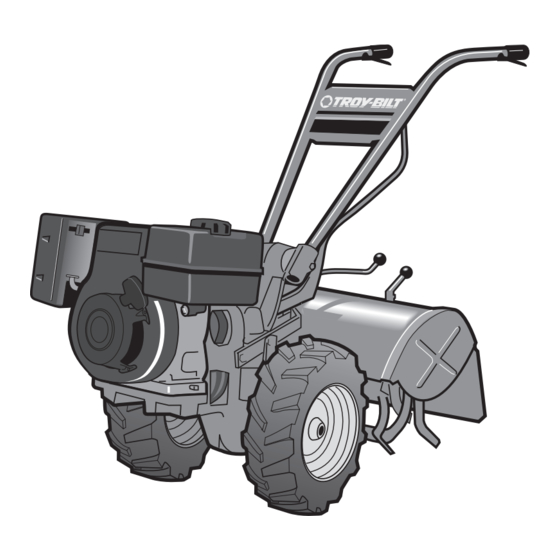

Engine styles vary by model

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA

Operator's Manual

Rear-tine PTO Tiller Models

683F — Horse

E683F — Horse

E683G — Big Red

TM

ES

TM

FORM NO. 770-10598G

(2/13/2006)

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Troy-Bilt 683-Horse

- Page 1 (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

-

Page 2: Table Of Contents

You can locate the model number by looking at the rear surface of the tine shield. A sample model plate is shown below. For future reference, please write down your model and serial number in the space provided below TROY-BILT LLC P. O. BOX 3 6 1 1 3 1 www.troybilt.com... -

Page 3: Safety

Section Safety Safety Alert Symbol This is a safety alert symbol. It is used in this manual and on the unit to alert you to potential hazards. When you see this symbol, read and obey the message that follows it. Failure to obey safety messages could result in personal injury or property damage. - Page 4 Section 1: Safety inspecting, stop the engine and make certain all moving parts have stopped. Disconnect the spark plug wire and prevent it from touching the spark plug to prevent accidental starting. 9. The flap on the tine hood must be down when operating the tiller, unless using the Hiller/Furrower attachment.

-

Page 5: Maintenance And Storage

Maintenance and Storage 1. Keep the tiller, attachments and acces- sories in safe working condition. 2. Check all nuts, bolts, and screws at frequent intervals for proper tightness to be sure the equipment is in safe working condition. 3. Never store the tiller with fuel in the fuel tank inside a building where ignition sources are present such as hot water and space heaters, furnaces, clothes... -

Page 6: Assembly

Section Assembly WARNING To prevent personal injury or property damage, do not start the engine until all assembly steps are complete and you have read and understand the safety and operating instructions in this manual. Introduction Carefully follow these assembly steps to correctly prepare your tiller for use. - Page 7 Left-Side Clamp and Nut Figure 2-3. Fully assembled handle- bars. 4. Raise handlebars to one of two height settings and tighten the height adjustment lever. Also, make sure all other mounting hardware is securely tightened. NOTE: Fully assembled handlebar assembly should appear as shown in Figure 2-3.

- Page 8 Section 2: Assembly Remove the temporary screw (J, Figure 2-7) from the forward holes and move the Wheels/Tines/PTO Lever fully forward. Install the wider hook end of the clutch pawl spring (M, Figure 2-8) down into the small hole at the end of the handle. Use pliers to insert the other end into the hole in the long link bar (N).

-

Page 9: Step 7: Add Motor Oil To Engine

IMPORTANT: Check gear oil level in both transmissions after the first 2 hours of new tiller operation, then every 30 operating hours thereafter. See Section 5 for instructions. Oil Level Hole Figure 2-12: Checking oil level on Power Unit Transmission. Figure 2-13: Checking oil level on Tine Attachment Transmission. -

Page 10: Assembling The Electric Start System

Section 2: Assembly ASSEMBLING THE ELECTRIC START SYSTEM The following steps explain how to install and charge the battery on electric start tillers. For your safety, follow all steps and observe all accompanying safety messages. Section 5 contains other general battery maintenance and recharging instructions. DANGER Battery produces explosive gases. -

Page 11: Features And Controls

Unit is then available for engine powered attachments, or for pulling or towing non- powered attachments. See Section 4, PTO Power Unit for detailed information on installing and operating TROY-BILT PTO attachments. Wheels/Tines/PTO Drive Lever Use the Wheels/Tines/PTO Drive Lever (A, Figure 3-1) to engage and disengage power to the transmission. - Page 12 Section 3: Features and Controls Verify Position of Clutch Roller When you shift between FORWARD, NEUTRAL and REVERSE, the clutch roller at the base of the Wheels/Tines/ PTO Drive Lever should be positioned as shown in Figures 3-2, 3-3 and 3-4. Verify the position of the clutch roller as you shift the lever.

-

Page 13: Keyswitch Starter

WARNING The tiller handlebars can be swung out to the right side for use only with the PTO Chipper/Shredder attachment. This is done by loosening the mounting bolt on the handlebar base. Never operate your tiller or attachments, other than the PTO Chipper/Shredder, with the handle- bars in the right side position. -

Page 14: Operation

Section Operation WARNING Before operating your machine, carefully read and understand all safety (Section 1), controls (Section 3) and operating instructions (Section 4) in this Manual, in the separate Engine Owner’s Manual, and on the decals on the machine. Failure to follow these instructions can result in serious personal injury. - Page 15 Recoil Start Rope (at front of engine) CAUTION T o h e l p p r e v e n t s e r i o u s personal injury or damage to equipment: • Always place Wheels/Tines/PTO Drive Lever into NEUTRAL before starting engine, and before engaging wheels, tines or other PTO-driven attachments.

-

Page 16: Operating The Tiller

Section 4: Operation Reconnect the cables and securely tighten to battery posts. The engine will recharge the battery if the battery is still good. • If you suspect the batter is “dead”, or if the battery is damaged, disconnect, and remove it. Have it checked by a qualified technician. - Page 17 Figure 4-3: Moving tiller forward: squeeze one Forward Interlock Lever and then move Wheels/Tines/PTO Drive Lever down to FORWARD. 6. When the tiller moves forward, relax and let the wheels power the tiller along while the tines dig. Walk behind and to one side of the tiller.

- Page 18 Section 4: Operation 4. When the turn is complete, shift to NEUTRAL and lower the handlebars. Move Tines/PTO Clutch Lever back to ENGAGE position and resume forward operation. Transporting The Tiller Around Your Property When the engine is running, the tiller’s powered wheels make moving the tiller to and from the garden easy.

-

Page 19: Changing Speed Belts

• Turn the vehicle’s engine off and apply its parking brake. • Position the loading vehicle so that the ramp angle is as flat as possible (the less incline to the ramp, the better) Loading the Tiller 1. Use loading ramps that are strong and wide enough to safely hold the weight of the tiller and the operator combined—... - Page 20 Section 4: Operation WARNING The HIGH speed belt range position combined with a FAST wheel speed setting propels the tiller at the fastest pace. Reduce the engine throttle speed when starting out to help avoid personal injury or property damage if using this speed combination.

-

Page 21: Tilling Depths

TABLE 2-4: WHEEL SPEED AND BELT RANGE SELECTION GUIDE IMPORTANT — For correct wheel speed and belt range choices when using attachments or accessories other than tines, read the Owner/Operator Manual provided with the attachment or accessory. SLOW GEAR, LOW BELT RANGE SLOW GEAR, HIGH BELT RANGE For: For:... - Page 22 Section 4: Operation Tilling Tips Avoid making footprints When possible, walk on the untilled side of the unit to avoid making footprints in the freshly tilled soil (Figure 4-4). Foot- prints cause soil compaction that can hamper root penetration and contribute to soil erosion.

-

Page 23: Tilling Tips & Techniques

Tilling Tips Figure 4-18 B. Terrace Gardening: • When a slope is too steep or too short for vertical tilling, it may be necessary to till across the slope and create terraced rows. Terraces are rows that are cut into the side of a slope, creating a narrow, but flat area on which to plant. -

Page 24: Power Composting

Section 4: Operation POWER COMPOSTING Power composting means tilling under and burying in the soil all manner of organic matter such as crop residues, leaves, grass clippings and cover crops. This material will decompose during the non-growing season and add important natural nutrients to the soil. -

Page 25: Pto Power Unit

PTO POWER UNIT Your tiller is a self-contained PTO (Power Take-Off) Power Unit that was shipped with a tine attachment installed. The tine attachment can be quickly removed and replaced with other optional attachments. The following instructions will familiarize you with your PTO Power Unit. Please read these pages carefully. -

Page 26: Operating Instructions

Section 4: Operation Figure 4-24: Loosening attachment swing-bolts. Figure 4-25: Moving swing-bolts outward. IMPORTANT: Store tine attachment in a level, upright position to prevent gear oil from leaking from the dipstick area. Figure 4-26: Pulling attachment away from power unit. 9. - Page 27 Setting Up Non-Powered Attach- ments 1. Move the Tines/PTO Clutch Lever (Figure 4-22) to DISENGAGE. 2. Move the Wheel Speed Lever (Figure 4-22) to either SLOW or FAST position To do this, roll the PTO Power Unit while shifting lever until wheels engage. 3.

-

Page 28: Required Maintenance Schedule

Section Maintenance WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key on electric start models. -

Page 29: Tiller Lubrication

WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage. Tighten Bolts and Nuts Check for loose or missing hardware every ten (10) operating hours. - Page 30 Section 5: Maintenance WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage.

- Page 31 WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage. Figure 5-7: Remove oil level check plug.

- Page 32 Section 5: Maintenance WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage.

-

Page 33: Drive Belt Maintenance

WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage. Drive Belt Maintenance Measuring and Adjusting Drive Belt Tension... - Page 34 Section 5: Maintenance WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage.

- Page 35 WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage. Figure 5-19: Move top half of belt over pulley and reverse disc.

- Page 36 Section 5: Maintenance WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage.

-

Page 37: Bolo Tine Maintenance

WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage. Adjusting Reverse Drive: 1. - Page 38 Single Tine Replacement 1. Move the Wheels/Tines/PTO Drive Lever to NEUTRAL, the Wheel Speed Lever to either FAST or SLOW position, and the Tines/PTO Clutch Lever to ENGAGE. 2. Gently tilt the tiller forward until the engine rests on the ground. 3.

-

Page 39: Ignition System Maintenance

WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage. Tine Shaft Maintenance After every 10 operating hours, remove the left- and right-side Bolo Tine holders... -

Page 40: Testing The Forward Interlock Wiring System

Section 5: Maintenance WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped. Failure to follow these instructions can result in serious personal injury or property damage. -

Page 41: Troubleshooting Procedures

CHECK OR TEST (Check or test in sequence shown until problem is resolved.) Throttle Lever in START position Wheels/Tines/PTO Drive Lever in NEUTRAL position Forward Interlock Wire Harness connector securely mated Forward Interlock Levers not being squeezed prior to shifting Wheels/ Tines/PTO Drive Lever to FORWARD position Visually inspect for bare, broken... - Page 42 Appendix A: Troubleshooting • Hardware holding tine holders to tine shaft may be missing or broken. To check, remove holders (Sect. 5). • Key for bronze worm gear on tine attach- ment main drive shaft may be missing or broken. 5 Tines Turn, But Wheels Won’t: •...

-

Page 43: Appendix B: Attachments & Accessories

Troy-Bilt PTO Log Splitter ® OEM-290-258 ® The Troy-Bilt PTO Log Splitter provides you with a convenient and easy means of splitting about a half a cord of wood per hour when working alone. When connected to the PTO Power Unit, the tiller’s engine runs the splitter’s hydraulic... -

Page 44: Parts List

Section Parts List PART DESCRIPTION 647-04006 Lever Assembly–Wheels/Tines/ PTO Drive (Includes Ref. 17) ... 1908156 Spring–clutch pawl ... 710-0805 Bolt–hex hd., 5/16-18 x 1-1/2" ... GW-2447 Bushing–3/8" ... 1177548 Lockwasher–external tooth, 5/16". 712-3010 Nut–hex, 5/16"-18... 686-04006 Roller Assembly... GW-2165-1 Yoke–left side ... WHEELS/TINES/PTO DRIVE LEVER &... - Page 45 MODELS 683F. E683G & E683F See Page 46 FORWARD INTERLOCK SYSTEM PART DESCRIPTION 725-04368 Engine Wire Harness Assy–forward interlock system (Incl. one red and one black wire, plug con- nector, neutral switch and PVC tubing. Parts not available separately ... 736-0508 Internal L-Washer 9/16"...

-

Page 46: Handlebar Assembly

Pivot Pin–forward interlock lever.. GW-9514 Retaining Ring–klip ring–forward GW-9387 Return Spring–fwd interlock lever 777D07724 Label – Troy-Bilt Horse ... 777D06527 Label – Troy-Bilt Horse “Big Red”. 712-3010 Nut-hex 5/16-18 ... 736-0119 Washer 5/16 ... 710-0805 HH Cap Screw 5/16-18 x 1.5 ... -

Page 47: Bolt-Hex Hd., 3/8-16 X 1

MODELS 683F. E683G & E683F PART DESCRIPTION 710-3005 Bolt–hex hd., 3/8-16 x 1-1/4" ... GW-1113-1 Bushing–19/64" (.300" lg.)... 710-04049 Bolt–flanged hex, 5/16-18 x 5/8"... 712-04065 Nut–hex, 3/8"-16... 1900864 Bar–depth regulator ... GW-9120 Ring–retaining ... GW-9119 Knob–depth regulator ... GW-2121 Bar–drag, depth regulator... 710-0599 Screw–thread-forming, 1/4-20 x 1/2"... - Page 48 Parts List MODELS 683F. E683G & E683F WHEEL SPEED LEVER, BELT DRIVE SYSTEM, ENGINES, WHEELS See Page 44 See Page 52...

-

Page 49: Lockwasher-Spring Lock, 3/8

Shim–engine pulley, 1/16" 736-04187 Shim–as above, 1/32" Contact an authorized engine dealer, Troy-Bilt dealer or the Factory for replacement engine information. Contact an authorized engine dealer for engine service or parts. Refer to the engine name- plate for engine model and type information. - Page 50 Parts List MODELS 683F. E683G & E683F POWER UNIT TRANSMISSION ASSEMBLIES...

-

Page 51: 712-3010 Nut-Hex, 5/16"-18

MODELS 683F. E683G & E683F PART DESCRIPTION TRANSMISSION COVER & SHIFT LEVER BRACKET ASSEMBLIES 1186299 Bolt–hex hd., #10-32 x 3/8", self-locking flange ... GW-9463 Knob–tines/PTO clutch lever, tapered, plastic ... GW-2263 Detent Plate–tines/PTO clutch lever 1 777I20945 Decal–operating instructions, detent plate... 1186349 Bolt–flanged hex hd., 3/8-16 x 1-1/2"... - Page 52 Parts List MODELS 683F. E683G & E683F POWER UNIT TRANSMISSION ASSEMBLIES (Continued from page 51)

- Page 53 MODELS 683F. E683G & E683F PART DESCRIPTION (continued from page 51) WHEEL SHAFT ASSEMBLY 721-04031 Seal–oil, wheel shaft ... 1909950 Retaining ring–external... GW-1166-1 Shim–wheel shaft, 1-1/64" inner dia., .062" thick... As GW-1166-2 Shim–as above, .030" thick GW-1166-3 Shim–as above, .015" thick ... As GW-1166-4 Shim–as above, .010"...

- Page 54 Parts List MODELS 683F. E683G & E683F TILLER ATTACHMENT TRANSMISSION ASSEMBLIES NOTE 1: THESE SCREWS HAVE A SPECIAL SEALING DESIGN THAT CAN NOT BE REUSED WITHOUT RISKING THE LOSS OF TRANSMISSION OIL. IF THESE SCREWS ARE LOOSENED OR REMOVED, THEY MUST BE REPLACED WITH NEW HARDWARE.

- Page 55 MODELS 683F. E683G & E683F PART DESCRIPTION 1915068 Screw–self-sealing,1/4"-20 x 5/8" GW-20873 Cover–tiller housing ... 711-04082 Shaft–tiller tine ... 741-3037 Ball Bearing... 1901976 Worm Gear–bronze, tiller tine shaft ... GW-1104 Key–tiller tine shaft, woodruff key. 721-04035 Seal–oil, tiller tine shaft ... TILLER DRIVE SHAFT ASSEMBLY 716-0101 Retaining Ring–external...

- Page 56 Parts List MODELS 683F. E683G & E683F BOLO TINE ASSEMBLIES...

- Page 57 MODELS 683F. E683G & E683F PART DESCRIPTION STANDARD TILLING TINES 1901975 Tine Holder–welded steel, fits left or right sides ... 710-3096 Bolt–hex hd., 3/8-16 x 2" ... 712-3000 Locknut–hex, 3/8"-16... GW-1270-1 Bolo Tine–single, left hand. Tine is stamped either “EL" or “AL".

-

Page 58: Electric Start System

Parts List MODELS E683G & E683F ELECTRIC START SYSTEM... - Page 59 MODELS E683G & E683F PART DESCRIPTION GW-96515 Cable–battery, positive and negative terminals ... GW-97020 Boot–terminal insulating... 710-0599 Screw–TT, 1/4-2 x 1/2"... 1186309 Bolt–hex hd., 1/4-20 x 5/8" ... 1901894 Wire–recharge (red) ... GW-2614 Battery Hold-down Clamp–with attached Key Switch Plate ... 777S30648 Decal–ignition switch instruc...

-

Page 60: Warranty

This warranty begins on the date of purchase and is warranted by Troy-Bilt LLC for the life of the tiller, to the original purchaser only. WHAT IS COVERED Troy-Bilt LLC will, at its option, repair or replace any part found to be defective in material BY THIS WARRANTY or workmanship without charge for parts and labor.

Need help?

Do you have a question about the 683-Horse and is the answer not in the manual?

Questions and answers