Table of Contents

Advertisement

AUTHORISED SERVICE AGENTS:

CARBA-TEC Pty. Ltd.

40 Harries Road

Coorparoo, QLD 4151

Ph: (07) 3397 2577

Fax: (07) 3397 2785

CARBA-TEC (NSW) Pty. Ltd.

32 Percy Street

Auburn, NSW 2144

Ph: (02) 9649 5077

Fax: (02) 9649 7044

CARBA-TEC (MELB) Pty. Ltd.

80 - 82 Osborne Avenue

Springvale, VIC 3171

Ph: (03) 9558 4200

Fax: (03) 9558 5133

CARBA-TEC (WA)

151 Balcatta Road

Balcatta, WA 6021

Ph: (08) 9345 4522

Fax: (08) 9240 1014

CARBA-TEC NZ Ltd.

110 Harris Road

East Tamaki, Auckland

Ph: (09) 274 9454

Fax: (09) 274 9455

Advertisement

Table of Contents

Summary of Contents for Carba-Tec CTJ-350

- Page 1 AUTHORISED SERVICE AGENTS: CARBA-TEC Pty. Ltd. 40 Harries Road Coorparoo, QLD 4151 Ph: (07) 3397 2577 Fax: (07) 3397 2785 CARBA-TEC (NSW) Pty. Ltd. 32 Percy Street Auburn, NSW 2144 Ph: (02) 9649 5077 Fax: (02) 9649 7044 CARBA-TEC (MELB) Pty. Ltd.

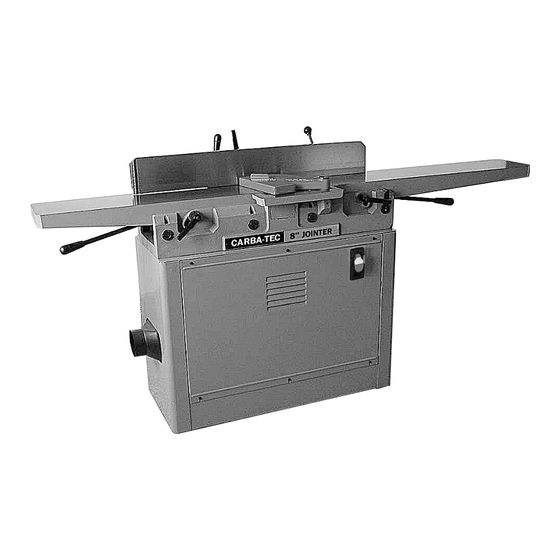

- Page 2 8” JOINTER MODEL CTJ-350 ®...

-

Page 3: Safety Warning

SAFETY WARNING: This list of do’s and do nots is not exhaustive and is not a substitute for common sense and best practices. Woodworking machines are potentially dangerous, it is important to observe all safety instructions while operating this machine. •... -

Page 4: Motor Pulley Assembly

MOTOR PULLEY ASSEMBLY Fix the motor pulley Fig. 1 (A) onto the motor shaft mak- ing sure the hub of the pulley is facing out. Insert key into the keyway of the pulley and motor shaft. Make sure you tighten the set screw Fig. 1 (C) with the allen wrench supplied. - Page 5 FENCE To move the fence, loosen the fence locking lever Fig. 5 (A) and slide across table to desired position. As the fence moves across, the cutterhead is guarded behind to avoid any exposed blades. Do not forget to tighten fence locking lever securely before operating machine.

-

Page 6: Infeed Table

TABLE ADJUSTMENTS. INFEED TABLE The infeed table adjustment determines the depth of cut, by raising or lowering the table in relation to the cut- terhead. The lower the infeed table the larger the cut. Loosen the table lock handle Fig. 9 (A) at the back of the machine and raise the table by pushing the handle up or down Fig. -

Page 7: Knife Setting

KNIFE SETTING The 3 blades in your jointer are factory set, and there- fore should be set to the right height and parrallel to the cutterhead. If for some reason you need to adjust the blades These are the steps to follow. Disconnect machine from power source. -

Page 8: Turning The Machine On And Off

TURNING THE MACHINE ON & OFF This machine is fitted with a switch that needs to be pulled out to switch the machine on, and pushed in to switch the machine off. You can also lock the switch in the off position Fig. 18, by removing the yellow key Fig. 17 (A). - Page 9 PLANING OR SURFACING FACE Surface the widest face first to establish one, totally straight face. This then becomes the reference which goes against the fence allowing squaring of the edge of the board. Always use a push block when planing or surfacing. Fig.

- Page 12 ALL ELECTRICAL WORK SHOULD BE UNDERTAKEN BY A LICENSED ELECTRICAL CONTRACTOR.

Need help?

Do you have a question about the CTJ-350 and is the answer not in the manual?

Questions and answers