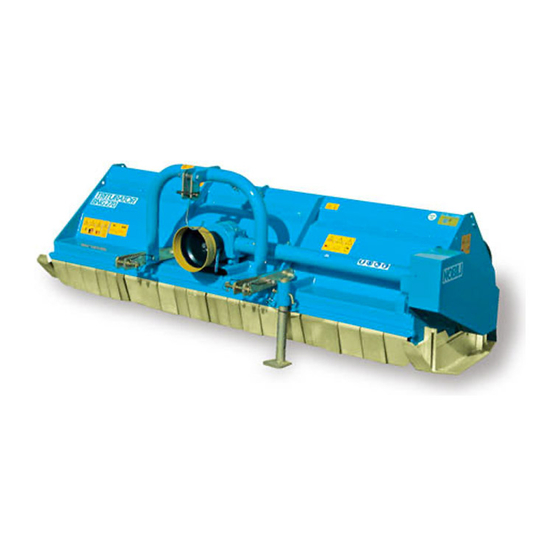

Summary of Contents for Nobili BNG 230

- Page 1 COSTRUZl O Nl MECCANICHE PERVGRICOUURA Trince Broyeur Shredder Mulchgerat " " '...

-

Page 2: Intended Use

INTENDED USE NOBlLl S.p.A. Agricultural Machinerv Manufactures wishes first of all to thank you for the wise choice you have made in purchasinq one of its machines, whilst assuring you that the maximum efforts have been put into makinq the machine as advanced and practical as possible. In order to get the best use out of the machine and prolong its working life, NOBlLl S.p.A. -

Page 3: Table Of Contents

USER'SMANUAL No. A 0 932 SHREDDERS BNG 230 CONTENTS Page Intended use Page Declaration of conformity Page Technical characteristics Page 6-7-8 Adhesive labels regarding safety and proper operation Page Safety precautions Page Hoistingthe machine Page Dangerous areas Page Recommandations for use... -

Page 4: Declaration Of Conformity

DECLARATION OF CONFORMITY ___ _ _ - - - - - _ _ _ - _ _ ~ ~ Declaration de conformite Dichiarazione di Conformita directive "machines" sensi della d i r e t t i v a CEE 89/392 ( D i r e c t i v e 8 9 / 3 9 2 / C E E m o d i f i e e ) e successive m o d i f i c a z i o n i . -

Page 5: Technical Characteristics

TECHNICAL CHARACTERISTICS TECNICAL CHARACTERISTIC BNG230 BNG270 BNG 3 1 0 270/F Front Tractor coupling Range 2" 2" P.T.O. speed 5 4 0 Power required Trasversal Trasport position 2 5 4 0 2920 2920 2 9 6 0 3330 Max trasport width Weight of standard version 6 9 5 1010... - Page 6 The machine's owner or the person in charge must be sure the operator has read the Instruction Manual carefully. Keep decals in good conditions and replace the damaaed ones. oppure The adhesive labels 7 12 BNG 230-270-310 are not applied on the series machine...

- Page 7 READ THE DO NOT REMOVE INSTRUCTION GUARDS UNTIL ALL ROTATING PARTS ARE IDLE MACHINE TURN DANGER! TRACTOR ENGINE AND THROWN OBJECTS. TAKE THE KEY STAND OFF. BEFORE SERVICING OR DO NOT WORK NEAR ADJUSTING THE BUILDINGS OR ROADS MACHINE 0012215 GREASE EVERY 4 WORKING HOURS MACHINE POWER...

- Page 8 DECALS 0012217 cmcn pour cv c tat ons dangcrcusc organcs dc LA P . O . F . Start to prevent dangerous shock oads o transmission components. anlaufcn e r A ? n ricbsorgane ATTENZIONE- Avviarc er cvitarc dannorc CU I DADO Arrancar amen para cv...

-

Page 9: Safety Precautions

SAFETY PRECAUTIONS THEREFORE, IS NECESSARY THAT ANYONE WHO CARRIES OUT OPERATIONSON THE MA- CHINE, EITHER FOR WORK OR MAINTENANCE PURPOSES, FAMILIAR WITH THE INSTRUCTIONS AND WARNINGS GIVEN IN THE MANUAL OR ON THE DECALS AFFIXED ON THE MACHINE. BEFORE PERFORMING ANY OPERATION OF CLEANING OR SERVICE, REST THE MACHINE ON A FLAT SURFACE ON THE GROUND OR ON SOLID SUPPORTS TURN OFF THE... -

Page 10: Hoistingthe Machine

HOISTING THE MACHINE /LOCK THE WHEELS. ARMS SO AS TO PREVENT THEIR ROTATION If mounted) USE HOISTING ECQUIPMENT ACCORDING TO THE RULES IN FORCE AND RAIGHT FOR THE MACHINE WEIGHT. WARNING: BE AS ACCESSOIRES AFFECT MACHINE BALANCE. NEVER LIFT UNBALANCED LOADS. -

Page 11: Dangerous Areas

DANGEROUS AREAS DANGEROUS AREAS FOR POSSIBLE THROWING OF BODIES SAFETY RANGE MACHINE IN CLOSED MODEL CULARLY CAREFUL WHEN YOU WORK ON RISES OR THE UNEVEN GROUND CAN MAKE THE GUARDS TEMPORARILY INEFFICIENT AND ALLOW THE PROJECTION OF STONES OR FRAGMENTS IN A WIDE RANGE SAFETY RANGE MACHINE IN OPEN MODEL \ \ \... -

Page 12: Checkingblades Or Rams And Their Fastening Elements

CHECK BLADES OR RAMS AND THEIR FASTENING ELEMENTS Blades or rams: to be checked always before using the machine to be checked immediately after an obstacle Shreddingquality,machine integrity andsafety depend on the care which will be devoted to these elements. They must be replaced immediately if damaged. - Page 13 Tighten fastening nuts. For any height adjustment, see page Mount guards SL) on the lateral sides. on the rear side. Mount the safety bar TYRE FEATURES 145-10 4Pr 125-160-195 BNG 230 145-10 4Pr BNG 270 70-13 BNG 310 205 170-14...

-

Page 14: Coupling To The Tractor

COUPLING TO THE TRACTOR Introducethe lift joints, checking that they are at the same height in the lower hitches. that they are at the same height in the lower hitches. the machine to better follow the undulations in case of long ways with the double freewheel gearbox unit. -

Page 15: Connecting The Propeller Shaft

CONNECTING THE PROPELLER SHAFT Measure the minimum distance (A) between the notch of the tractor PTO and that the shredder, when they are on the A- 1" Measure the distance of the propeller shaft, in the position of minimum extension (all The measureB should be smaller thanA of at least 1 inches. -

Page 16: Working Height Adjustment

WORKING HEIGHT ADJUSTMENT BLADES MUST NEVER TOUCH THE GROUND LEAVE AT LEAST 1.5" ROLLER VERSION: LIFT THE MACHINE FROM THEGROUND Loose bolts (AS on a side, remove bolts on the other side. On the support select the holes right for the desired height, then fit bolts and screw nuts do not tighten them. - Page 17 HOW TO DISPLACE THE DRAWBAR BNG230 ONLY Hitch points for drawbar in central position Remove mashine frotn the tractor. Hitch points for drawbar shifted STOP TRACTOR ENGTNE DISCONNECT TRACTOR P.T.O. TAKE THE KEY OFF THE DASHBOARD MAKE SURE ALL MOVING PARTS IDLE AD J USTMENT TO PTO SPEE D ONLY machine: BNG 270...

-

Page 18: Parkingposition

PARKING POSITION DISCONNECT TRACTOR P.T.O. TURN OFF TRACTOR ENGINE WHEN THE IS RAISED FROM THE GROUND. TAKE THE KEY OFF THE DASHBOARD. MAKE SURE ALL MOVING PARTS ARE IDLE. CHOOSE A STABLE, FLAT GROUND TO PERFORM THE FOLLOWING OPERATIONS Lower foot Lower the elevator until the machine rests on the ground. -

Page 19: Air Noise Emitted

AIR NOISE EMITTED Data taken accourding to the following rules: UNI 77 I2 TRATTRICE AFNOR S 3 1-069 NF S 3 1-027 TRACTOR ONLY TRACTOR MACHINE Tractor cab Open Closed Open Closed 89.0 81.2 94.7 83.6 Levell of acoustic pressure: operator place dB(A) Level... -

Page 20: Maintenance And Lubrication

Quantity unit L t : Every day check oil level. BNG 230-270-3 10 Every day check oil level. BNG 270F-270B Rest the machine horizontally and unscrew the main plug located on the right ),oil shall touch the lower hole edge. -

Page 21: Belttension

BELT TENSION Load Arrow A, no. 4 B, no. 1 Loosen bolts which fasten transmission to shredder frame. H and D Loosen adjusting screw counternuts T u r n adjusting screw clockwise, and turn screw anticlockwise, up to get the tension desired (See the table). - Page 22 GENERAL INSTRUCTIONS FOR BLADE OR RAM REPLACEMENT Every day check the conditionof blades or rams, and corresponding locking pins. In case of unusual wear or breaks, replace the parts immediately. USE ORIGINAL SPARE PARTS ONLY. BEFORE REPLACING ANY PART, THE MACHINE FROM THE TRACTOR AND TILT IT FORWARD, BY RESTING IT ON THE COUPLING IF THE MACHINE IS NOT EQUIPPED WITH BONNET.

-

Page 23: Accessory: Wearings Metal Sheet

ACCESSORY WEARING METAL SHEET METAL SHEETASSEMBLY Remove the lower counterblade. On machine: BNG 230 e BNG 270 with internal metal sheet ONLY counterblades low profile. Position the metal sheet the specified counterblade. Usually nuts are fitted at the external side. - Page 24 GENERAL INSTRUCTIONS FOR BLADE OR RAM REPLACEMENT Every day check the condition of blades or rams, and corresponding locking pins. In case of unusual wear or breaks, replace the parts immediately. USE ORIGINAL SPARE PARTS ONLY. BEFORE REPLACING ANY PART, THE MACHINE FROM THE TRACTOR AND TILT IT FORWARD, BY RESTING IT ON THE COUPLING IF THE MACHINE IS NOT...

-

Page 25: Fitting The Warning Signsforroad Circulation

FITTINGS OF THE WARNING SIGNS FOR ROAD CIRCULATION MACHINE BNG 230 BNG 270 BNG 310 EXAMPLE OF APPLICATION OF REFLECTOR PANELS APPROVED BY THE HIGHWAY CODE FOR EUROPE IN CASE OF ROAD HAULAGE OF THE MACHINE YOU MUST FIT THE WARNINGS SIGNS REQUIRED AND... - Page 26 MACHINE OVERALL DIMENSIONS, OPEN OR CLOSED VERSION BNG 230 BNG 270 BNG 310 MACHINE 2540 1280 BNG 230 2780 2020 2920 1350 2920 2130 BNG 270 3330 1350 3330 2130 BNG 310...

- Page 27 ACCESSORY: PRODUCT SPRAYNG FLAPS GUARDS FOR OPEN MACHINE OPERATIONS MIN SPRAYNG MAX SPRAYNG FLAPS POSITION FLAPS POSITION The flaps inclination can be changed by choosing different holes. FITTING Firts mount parts 2 with spacer and bolts, after lateral sheet 7, do not tight nuts Fit sheet and now tighen all bolts.

-

Page 28: Troubleshooting

TROUBLESHOO TING Remedy Cause Problem Replace worn-out or broken A) Blades or rams worn or Excessive vibrations broken. parts. Clean and grease pins. B) Blades or rams locked by pins. Check the weight of blade or C) Rotor balancing not correct. ram units. -

Page 29: Guarantee

Guarantee Application: The guarantee application shall be filled in by the seller and sent to Nobili within 4 weeks since the damage occurred, providing: name and address of the user, type, model and serial number, date of purchase, date on which the damage occurred, actual working hours, circumstances and supposed causes. - Page 30 nome che conta PAR: DURCH: (BO) Via Circonvallazione Sud, 46 40062 MOLINELLA ITALY TEL. 051/88.14.44--45 TELEFAX 051 88.27.03...

Need help?

Do you have a question about the BNG 230 and is the answer not in the manual?

Questions and answers

What blades types are available for bk 230 triturator.