Table of Contents

Advertisement

Quick Links

Translation of the manual

English

Nederlands

Deutsch

Português

Español

Français

Italiano

Česky

Magyar

Polski

Pусский

Dansk

Suomi

Norsk

Svenska

中国

To get the translation of the manual in your language,

use the disc or scan the QR code.

Gebruik de schijf of scan de QR code om de vertaling van de

handleiding in uw taal te krijgen.

Um die Übersetzung des Handbuchs in Ihrer Sprache zu erhalten,

verwenden Sie die Disk oder scannen Sie den QR-Code.

Para obter a tradução do manual no seu idioma,

use o disco ou faça a leitura do código QR.

Para obtener la traducción del manual en su idioma,

utilice el disco o escanee el código QR.

Pour accéder à la traduction du manuel dans votre langue,

utilisez le disque ou scannez le code QR.

Per ottenere la traduzione del manuale nella propria lingua,

utilizzare il disco o acquisire il codice QR.

Chcete-li získat překlad příručky ve vašem jazyce,

použijte disk nebo naskenujte QR kód.

Ha a kézikönyvet saját nyelvén szeretné, akkor használja

a lemezt vagy szkennelje be a QR kódot.

Aby pobrać instrukcję przetłumaczoną na Państwa język,

prosimy skorzystać z płyty lub zeskanować kod QR.

Для получения руководства на своем языке установите

диск или отсканируйте QR-код.

For at se en oversættelse af vejledningen på dit sprog,

skal du bruge disken eller scanne QR-koden.

Saadaksesi käyttöoppaan omalla kielelläsi,

käytä levykettä tai skannaa QR-koodi.

For å lese håndboken oversatt til ditt eget språk,

bruk platen eller scan QR-koden.

För att få en översättning av handboken på ditt språk,

använda skivan eller skanna QR-koden.

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Bredel APEX35

- Page 1 Translation of the manual English To get the translation of the manual in your language, use the disc or scan the QR code. Nederlands Gebruik de schijf of scan de QR code om de vertaling van de handleiding in uw taal te krijgen. Deutsch Um die Übersetzung des Handbuchs in Ihrer Sprache zu erhalten, verwenden Sie die Disk oder scannen Sie den QR-Code.

- Page 2 Available documents For the models APEX28 and APEX35, the following documents are available on disc and website: • User manual in multiple languages • Quick reference instructions for the replacement of the pump hose The replacement instructions are only for users that are familiar with the replacement procedures in the user manual.

- Page 3 Hose pump series APEX28 and APEX35 Installation, Operation and Maintenance Manual 9001 14001 Quality Environmental Management Management...

- Page 4 Watson-Marlow Bredel B.V. The information provided can be changed without prior notification. Watson-Marlow Bredel B.V. or one of its representatives cannot be held liable for possible damage resulting from use of this manual. This is an extensive limitation of the liability which...

-

Page 5: Table Of Contents

CONTENTS GENERAL How to use this manual ................8 Original instructions ................8 Other supplied documentation ..............8 Service and support ................8 Environment and disposal of waste ............9 SAFETY Symbols ....................10 Intended use ..................10 Use in potentially explosive atmospheres ..........11 Responsibility .................. - Page 6 Installation conditions ................21 5.3.1 Ambient conditions ..............21 5.3.2 Setup ..................21 5.3.3 Pipework ................... 22 5.3.4 Motor ..................23 5.3.5 Frequency controller ..............23 Lifting and moving the pump ..............24 Placing the pump .................. 24 COMMISSIONING Preparations ..................25 Commissioning ..................

- Page 7 TROUBLESHOOTING SPECIFICATIONS 11.1 Pumphead .................... 58 11.1.1 Performance ................58 11.1.2 Materials ..................59 11.1.3 Surface treatment ..............60 11.1.4 Lubricant table pump ..............60 11.1.5 Weights ..................61 11.1.6 Torque figures ................62 11.2 Lubricant table gearbox ................ 63 11.3 Gearbox ....................

-

Page 8: General

Service and support For information with respect to specific adjustments, installation, maintenance or repair jobs which fall beyond the scope of this manual, contact your Bredel representative. Make sure you have the following data at hand: • Serial number of the hose pump •... -

Page 9: Environment And Disposal Of Waste

GENERAL You will find these data on the identification plates or stickers on the pumphead, the pump hose, the gearbox and the electric motor. Refer to § 4.1.1. Environment and disposal of waste CAUTION Always observe the local rules and regula- tions with respect to processing (non reus- able) parts of the hose pump. -

Page 10: Safety

SAFETY SAFETY Symbols In this manual the following symbols are used: WARNING Procedures which, if not carried out with the necessary care, may result in serious bodily harm. CAUTION Procedures which, if not carried out with the necessary care, may result in serious damage to the hose pump, the surrounding area or the environment. -

Page 11: Use In Potentially Explosive Atmospheres

Use in potentially explosive atmospheres requires special configuration of the pump. Contact your Bredel representative for use in explosive atmospheres. See Bredel’s ATEX Instruction manual which is supplied with pumps configured as mentioned above. Responsibility The manufacturer does not accept any responsibility for... -

Page 12: Qualification Of The User

SAFETY Qualification of the user The installation, use and maintenance of the hose pump should only be performed by well-trained and qualified users. Temporary staff and persons in training may use the hose pump only under the supervision and responsibility of trained and qualified users. Regulations and instructions •... -

Page 13: Warranty Conditions

The safety form is required even if the parts have not been used. Warranties purporting to be on behalf of Bredel B.V. made by any person, including representatives of Bredel B.V., its subsidiaries, or its distributors, which do not accord with the terms of this warranty shall not be binding upon Bredel B.V. -

Page 14: Description

DESCRIPTION DESCRIPTION Identification of the product 4.1.1 Identification of the product The hose pump can be identified by identification plates or stickers on: Pumphead Gearbox Electric motor Pump hose Frequency controller (option) 4.1.2 Identification of the pump The identification plate on the pumphead contains the following data: Pump type and rotor type (low or medium pressure) -

Page 15: Identification Of The Electric Motor

Power factor Current 4.1.5 Identification of the frequency controller The identification of the Bredel Variable Frequency Drive (VFD) can be found inside the VFD. Remove the cover by loosening the two screws. The identification sticker contains the following data: Article number... -

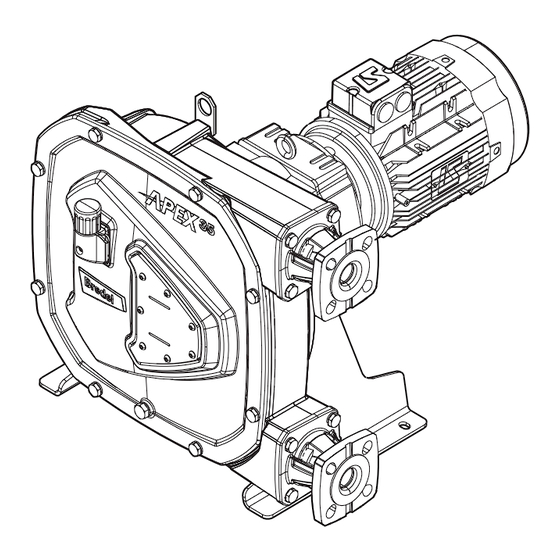

Page 16: Construction Of The Pump

DESCRIPTION Construction of the pump Cover Rotor Pump hose Pump housing Supports Gearbox Electric motor Frequency controller... -

Page 17: Operation Of The Pump

DESCRIPTION Operation of the pump The heart of the pumphead consists of a specially constructed pump hose (A) which lies against the inside of the pump housing (B). The ends of the hose are connected to the suction and discharge lines (C). A bearing-mounted rotor (D) with two facing integral pressing shoes (E) is in the center of the pumphead. -

Page 18: Pump Hose

Bredel pump hoses have been carefully machined to achieve minimum tolerances in wall thickness. It is very important to guarantee the correct compression of the pump hose, because: •... -

Page 19: Hose Compression Force Adjustment

If you want to change the application of your hose pump, contact your Bredel representative. 4.4.3 Lubrication and cooling The pumphead is filled with Bredel Genuine Hose Lubricant. This lubricant lubricates the shoes and dissipates the heat generated by the movement of the pressing shoes against the pump hose. -

Page 20: Gearbox

Refer to the documentation supplied with the electric motor for installation and maintenance information. In case of doubt consult your Bredel representative. Refer to § 5.3.4 and § for installation and connection information. -

Page 21: Installation

Check that your delivery is correct and check it for any transport damage. When replacing parts, check that the delivery is correct and check these parts for any transport damage. Refer to § 4.1.1. Report any damage immediately to your Bredel representative. Installation conditions 5.3.1 Ambient conditions... -

Page 22: Pipework

It is recommended that the bore size of the suction and discharge lines is larger than the bore size of the pump hose. For more information consult your Bredel representative. • Limit the presence of sharp bends in the discharge line. Make sure that the radius of any bend is as large as possible. -

Page 23: Motor

The motor connection must meet the local applicable regulations. A thermal safety device should reduce the risk of a motor overload. For connecting PTC thermistors (if present) a special thermistor relay must be used. In case of doubt, contact your Bredel representative advice. Refer §... -

Page 24: Lifting And Moving The Pump

(23 and 18 AWG). The shielding must be connected to earth at just one end. In case of doubt, consult your Bredel representative. Lifting and moving the pump The pump supports each have a lifting eye (A) for lifting and moving the hose pump. -

Page 25: Commissioning

Check that the lubricant level is above the minimum level line in the inspection window. If necessary refill with Bredel Genuine Hose Lubricant via the breather plug. Also refer to § 8.4. Commissioning Connect the pipework. - Page 26 Check the capacity of the hose pump. If the capacity differs from your specification, follow the instructions in chapter or consult your Bredel representative. If a frequency controller is present, check the capacity range. In case of any deviations consult the supplier’s documentation.

-

Page 27: Operation

OPERATION OPERATION Temperature The pump will heat up during normal operation. Heat is generated as the pump hose is compressed and released. The heat is removed by the lubricant and transported to the pump housing and cover. This will result in a temperature higher than the ambient temperature. -

Page 28: Performance Graphs

OPERATION Performance graphs Useful operating duties found performance graphs in which discharge-pressure curves are displayed in a speed-power diagram. Even at 0 kPa (0 psi) discharge pressure a certain torque is required to let the pump rotor rotate. The pump and hose are designed to handle a discharge pressure up to 800 kPa (116 psi). - Page 29 OPERATION 7.3.1 How to use the graphs Required motor power [kW] 2.00 1.75 Product temperature 1.50 [°C] 1.25 1.00 0.75 0.50 Con nuous Intermi ent Duty Duty* 0.25 100 kPa = 1 bar 0.00 Pump speed [rpm] Capacity [L/h] 1290 3020 3450 1730...

- Page 30 Duty 1.75 1.50 1.25 1.00 0.75 0.50 0.25 0.00 Pump speed [rpm] Capacity [USgpm] 0 15.2 13.3 11.4 7.3.3 Performance graph APEX35: Required motor power [HP] 3.00 2.75 Intermi ent Duty* 2.50 Product temperature 2.25 Con nuous [°F] Duty 2.00 1.75...

-

Page 31: Dry Running

OPERATION Dry running Dry running is a running condition of the pump when no fluid is flowing through the pump hose. Bredel hose pumps are very suitable for dry running. Dry running imposes an additional thermal load on the pump hose, because a part of the internal heat associated with repetitive hose compression is normally removed by the process fluid. - Page 32 • Hazardous situations WARNING Avoid direct contact between a strong oxi- diser or a strong acid and Bredel Genuine Hose Lubricant. This can cause unwanted chemical reactions. Use an alternative lubricant to avoid hazardous situations. Contact your Bredel representative for more details.

-

Page 33: Fluid Leakage

OPERATION Fluid leakage The APEX pump uses a lubricated rotor to compress the hose. This means the pumphead must be filled with sufficient lubricant during operation. This lubricant is contained in the pump housing by the front cover and by a dynamic seal on the back. The gearbox is filled with gearbox lubricant. -

Page 34: Maintenance

Do not connect the power cable to the motor if the pump cover is removed. Only use original Bredel parts when maintaining the hose pump. Bredel cannot guarantee correct operation and any consequential damage that occurs from the use of non-original Bredel components. - Page 35 Checking the gearbox Before starting the pump In case of leakage con- for any leakage. and at scheduled inter- sult your Bredel repre- vals during operation. sentative. Checking the pump for At scheduled intervals Refer to § 10. deviating temperature or during operation.

-

Page 36: Cleaning The Pump Hose

MAINTENANCE Point Action To be carried out Remark Replacing the rotor with Wear on the running sur- Refer to § 8.6.1. integral pressing shoes. face of the pump hose and/or seal ring. Replacing the bearing. If necessary. Refer to § 8.6.2. Cleaning the pump hose Running the pump with clean water can clean the inside of the pump hose. -

Page 37: Replacing The Pump Hose

MAINTENANCE The pump housing can be filled with lubricant via the breather (A) on the cover. For this purpose remove the breather cap (B) and position a funnel (C) in the breather. Pour the lubricant into the pump housing through the funnel. - Page 38 MAINTENANCE Disconnect the suction and discharge lines from the brackets. WARNING When disconnecting the suction and dis- charge lines, process fluid can escape. The pump hose may still contain process fluid, after the suction and discharge lines are disconnected. Loosen the four bolts (A) of the bracket (B) and remove the bolts and the washers.

-

Page 39: Cleaning The Pumphead

MAINTENANCE Drive out the hose (A) from the pump housing by jogging the drive motor. WARNING During jogging the drive: Do not stand in front of the pump ports. Do not try to guide the hose by hand. 8.5.2 Cleaning the pumphead Isolate the pump from the electrical supply. -

Page 40: Fitting The Pump Hose

8.5.3 Fitting the pump hose Clean the (new) pump hose on the outside and fully lubricate the outside with Bredel Genuine Hose Lubricant. Fit the pump hose (A) via one of the ports. Run the motor so that the rotor pulls the hose into the pump housing. - Page 41 (A) is pressed against its end position in the bracket (B). Lubricate the insert (A) with Bredel Genuine Hose Lubricant. Manually spread the lubricant over the insert. Push the insert (A) in the bracket (B) and the hose (C).

-

Page 42: Exchanging Replacement Parts

(D). Now fit the other port in the same way. Fill the pump housing with Bredel Genuine Hose Lubricant. Refer to § 8.4. Connect the suction and discharge lines. If applicable: before the pump is put into operation, open any shut-off valves in the suction and discharge lines. - Page 43 MAINTENANCE Remove the cover (B) by loosening the retaining bolts (A). Check the cover seal (C) and replace it if necessary. Remove the three retaining bolts and washers (A) and take the rotor (B) off the pump shaft (C). Check the outside of the dynamic seal (A) for deformation or damage as far as possible.

-

Page 44: Replacing The Bearing, Seal Ring, Shaft And Coupling Bush

MAINTENANCE Refit the cover (B) and the seal (A) (if it was removed). Make sure that the eight bolts (C) are refitted and that they are tightened in the correct order, diagonally opposite each other. Refer to § 11.1.6. Switch on the electrical supply to the pump. Fit the (new) pump hose. - Page 45 MAINTENANCE Use circlip pliers to remove the circlip (A) from the pump shaft (B) and, if the bearing must be replaced, to remove the circlip (C) from the pump housing (D). Circlip (A) locks the inner ring of the bearing. Circlip (C) locks the outer ring of the bearing.

- Page 46 MAINTENANCE Make sure that all parts are clean before assembly. At the back of the pump housing, position the (new) bearing in the bore. Place a suitable bush (A) against the outer ring (B) of the bearing. The outer diameter of the bush (A) must be 109 ±1 mm (4.29 ±0.04 in).

- Page 47 MAINTENANCE Install the (new) O-ring (A) in the pump shaft. At the back of the pump housing, use circlip pliers to install the circlip (A) in the groove of the pump shaft (B). Circlip (A) locks the inner ring of the bearing.

-

Page 48: Fitting Options

MAINTENANCE Position the gearbox on the pumphead. Make sure that the spline coupling engages correctly. Position the four washers and bolts (A) and tighten the bolts to the correct torque. Refer to § 11.1.6. Install the rotor, the cover and the hose. Refer to §... -

Page 49: Replacing The Revolution Counter

MAINTENANCE Connect the high-level float switch to the auxiliary power circuit via the 1.5 meter (5 ft) long PVC cable (2 x 0.34 mm , 2 x 22 AWG). Bear in mind that the electrical contact of the float switch is normally closed (NC). The knob is upwards for normally closed operation. - Page 50 MAINTENANCE Remove the cover (B) and the O-ring (C) by loosening the retaining bolts (A). Remove the nut (A) and the old sensor (B). Mount the nut (B) and the sealing ring (A) on the new sensor (C). Install the sensor (C) in the pump housing. Turn the sensor so that the distance between the sensor and the rotor (X) is between 0.75 mm (0.03 in) and 1.25 mm (0.05 in).

- Page 51 MAINTENANCE Replace the O-ring (C) if necessary. Refit the cover (B) and the O-ring (C). Make sure that the eight bolts (A) are refitted and that they are tightened in the correct order, diagonally opposite each other. Refer to § 11.1.6. Refill the pump housing with lubricant.

-

Page 52: Storage

STORAGE STORAGE Hose pump • Store the hose pump and pump parts in a dry area. Make sure that the hose pump and pump parts are not exposed to temperatures lower than -40 °C (-40 °F) or higher than +70 °C (+158 °F). -

Page 53: Troubleshooting

If the hose pump does not function (correctly), consult the following checklist to see if you can remedy the error yourself. If you cannot, contact your Bredel representative. Problem Possible cause Correction Failure to operate. - Page 54 Low lubricant level. Add Bredel Genuine Hose Lubricant. For the required amount of lubricant refer to § 11.1.4. Fluid temperature too high. Consult your Bredel repre- sentative about the maxi- mum temperature range of the fluid. Internal friction on the hose...

- Page 55 Connections not correctly Check the connections. mounted, which makes the Tighten if necessary. pump suck air. Consult your Bredel repre- The filling degree of the pump hose is too low, sentative for a recommen- because the speed is too dation.

- Page 56 Short hose life. Chemical attack of the Check the compatibility of hose. the hose material with the fluid to be pumped. Con- sult your Bredel represent- ative for correct hose selection. High pump speed. Reduce pump speed. High discharge pressures.

- Page 57 TROUBLESHOOTING Problem Possible cause Correction Lubricant leakage at Hose blocked by an incom- Remove hose, check for bracket. pressible object in the blockages and replace if hose. The hose cannot be necessary. compressed and will be pulled into the pump hous- ing.

-

Page 58: Specifications

SPECIFICATIONS SPECIFICATIONS 11.1 Pumphead 11.1.1 Performance Description Unit APEX28 APEX35 ∅ 28 mm ∅ 35 mm Max. capacity, continuous US gpm 13.3 23.4 Max. capacity, intermittent US gpm 15.2 27.3 Capacity per revolution l/rev 0.36 0.74 US gal/rev 0.095 0.195 Max. -

Page 59: Materials

SPECIFICATIONS 11.1.2 Materials Pos Description Material Pump housing Cast-iron Cover Aluminium Cover window PMMA Pump rotor Aluminium Pump supports Galvanised steel (AISI 316 optional) Brackets Cast iron Fasteners Galvanised steel (AISI 316 optional) Dynamic seal behind the rotor Cover seal Pump shaft Steel Coupling bush... -

Page 60: Surface Treatment

Bredel Genuine Hose Lubricant Lubricant Required quantity liters gallons 0.53 1.06 Bredel Genuine Hose Lubricant is registered at NSF: NSF Registration N 123204; Category Code H1. Also refer to: www.NSF.org/USDA. Components: Glycerol ) 50-100% w/w Glycol ) 2.5-10% w/w Water Consult your Bredel representative if you require additional information with respect to the safety data sheet. -

Page 61: Weights

SPECIFICATIONS 11.1.5 Weights Description Unit Weight [kg] APEX28 APEX35 Pumphead (including hose, lubricant and pump supports) Pump supports (total weight for 2 supports) 12.1 Rotor 12.8 Hose Pump cover (complete) Shaft and coupling Gearbox 13.3 18.7 29.3 41.2 Electric motor 11.7 ... -

Page 62: Torque Figures

SPECIFICATIONS 11.1.6 Torque figures Pos Description Unit Torque [Nm] APEX28 APEX35 Cover lbf in Bracket lbf in Supports lbf in Gearbox lbf in Inspection window lbf in... -

Page 63: Lubricant Table Gearbox

VG460 Foodgrade Biology For a complete overview of the recommended lubricants contact your Bredel representative. For use in the foodstuffs industry. Meets the requirements of the USDA (United States Department of Agriculture): lubricant is suited for unforeseen contact with foodstuffs. -

Page 64: Gearbox

Voltage/frequency Refer to identification plate on motor. 11.5 Variable Frequency Drive (VFD) (optional) The Bredel Variable Frequency Drive (VFD) has been preprogrammed and only needs to be connected to the mains. RFI filter Integrated RFI filter B (industrial applications). Control Manual control for setting the speed and the keys for starting forward, stop and starting reverse. -

Page 65: Parts List

• 400-480 V ± 10%; 50/60 Hz ± 5%; 3 ph 11.6 Parts list 11.6.1 Ordering parts Specify the item number, description and pump size (APEX28 or APEX35) to identify the component you need. Also specify the quantity you need. -

Page 66: Overview

SPECIFICATIONS 11.6.2 Overview Pos. Description Cover assembly. Refer to § 11.6.3. Pumphead assembly. Refer to § 11.6.4. Pump supports assembly. Refer to § 11.6.5. Flange assembly. Refer to § 11.6.6. Lubricant. Refer to § 11.6.7. -

Page 67: Cover Assembly

SPECIFICATIONS 11.6.3 Cover assembly Pos. Qty. Description APEX28 APEX35 Cover bolt M8x20 M10x30 Cover bolt washer Drain plug O-ring Drain plug Breather screw M6x40 M6x40 Breather Breather gasket Cover Inspection window Inspection window gasket Inspection window screw M6x16 M6x16 Sticker ‘Bredel’... -

Page 68: Pumphead Assembly

SPECIFICATIONS 11.6.4 Pumphead assembly Pos. Qty. Description APEX28 APEX35 Hose NR Hose NBR Hose EPDM Pump housing Rotor, low-pressure (L) Rotor, medium-pressure (M) Pump shaft O-ring Rotor screw M10x30 M10x30 Rotor washer Pump shaft Dynamic seal... - Page 69 SPECIFICATIONS Pos. Qty. Description APEX28 APEX35 Bearing Circlip, inner bearing Circlip, outer bearing Circlip, inner, coupling bush Coupling bush Circlip, outer, coupling bush Gearbox bolt (standard mounted) or stud + M8x30 M10x30 nut (alternative, refer to § 4.5) Gearbox washer...

-

Page 70: Support Assembly

SPECIFICATIONS 11.6.5 Support assembly Pos. Qty. Description APEX28 APEX35 Pump support, left Pump support, right Support bolt M8x20 M10x30 Support bolt washer... -

Page 71: Flange Assembly

Compression ring Insert stainless steel Bracket Bracket bolt M8x30 M10x30 Bracket bolt washer 11.6.7 Lubricant Bredel Genuine Hose Lubricant is available in 0.5, 1, 2, 3, 5, 10 and 20 litre cans. Refer to § 11.1.4 for specifications of this lubricant. -

Page 72: Safety Form

In compliance with the Health and Safety Regulations, the user is required to declare those substances that have been in contact with the item(s) you are returning to Watson-Marlow Bredel B.V. or any of its subsidiaries or distributors. Failure to do so will cause delays in servicing the item or in issuing a response. Therefore, please complete this form to make sure we have the information before receipt of the item(s) being returned. - Page 73 NOTES NOTES...

- Page 74 NOTES...

- Page 75 NOTES...

- Page 76 Watson-Marlow Pumps Group 37 Upton Technology Park Wilmington, MA 01887 Telephone: 800 - 282 - 8823 978 - 658 - 6168 Fax: 978 - 658 - 0041 E-mail: support@wmftg.us Internet: http://www.wmftg.com 9001 14001 Quality Environmental Management Management © 2015 Watson-Marlow Bredel B.V.

Need help?

Do you have a question about the APEX35 and is the answer not in the manual?

Questions and answers