Summary of Contents for Senoven SEN 1602

- Page 1 MODEL SEN 1602 MICROPROCESSOR CONTROL BLOWING OVEN USER & MAINTENANCE MANUAL ŞENGÜN MAKİNA İNŞAAT ve KIRTASİYE SAN. TİC. LTD. ŞTİ...

- Page 2 - The failures and damages given by external factors are out of the warranty terms. - Any failure of the product warranty period is added to the product warranty time. The repair time is until 20 working days. AUTHORIZED PERSON STAMP –SIGNATURE SEN 1602 / SENOVEN...

- Page 3 Do not use paper when placing food product through the oven! Usage of flammable materials may cause a fire and should never be placed in the oven. WARNING! Do not put any object to anywhere of the oven except the conveyor. WARNING! Always be careful while you are working. SEN 1602 / SENOVEN...

- Page 4 Cleaning and maintenance are the most important factors of oven performance. The processes which are not available in the manual can cancel the appliance of warranty, cause property damage, injury or death. Read and understand the instructions in the manual SEN 1602 / SENOVEN...

-

Page 5: Table Of Contents

2.4 Stopper Sheet (Optional) 2.5 Belt Assembly 2.6 Belt Wire Assembly 2.7 Hıgh Chassis Assembly 2.8 Low Chassis Assembly 2.9 Chassis-Oven Assembly 2.10 Double Floor Oven Assembly 2.11 Triple Floor Oven Assembly 2.12 Air Duct Disassembly / Assembly SEN 1602 / SENOVEN... - Page 6 3.1 Distance Requirements 3.2 Ventilation 3.3 General Information of Ventilation 3.4 Ventilation Advice 3.5 Gas Connection 3.6 Installation Elements 3.7 SEN 1602 Oven Technical Specifications Table SECTION 4: PROGRAMMING-START & STOP 4.1 Utility Programs 4.2 Manual Operation 4.3 Standby Mode 4.4 Warnings 4.5 Shutdown...

- Page 7 8.1 Temperature Limit Exceeded 8.2 Low Battery Warning 8.3 Belt Engine Failure 8.4 Temperature Determine Failure 8.5 Temperature does not Rise 8.6 Burner Failure 8.7 Products do not Cooked 8.8 Contact with Technical Services SECTION 9: LABELS NOTES SEN 1602 / SENOVEN...

-

Page 8: Section 1: Introduction

GAS ENTRANCE Note: Entrance of product depends for the cooking style. The out sheet can be attached other side of the oven. 1.2 Functions of parts 1.2.1 Oven Body Every SEN series oven has a main body. SEN 1602 / SENOVEN... -

Page 9: Overlap Assembly

Conveyors provide the input and output of the product. Belt is controlled by microprocessor. Cooking time can be set between 1 - 30 minutes. The speed of belt determines the Products cooking time. The width of belt is 562 mm and consist by interlocking wires. SEN 1602 / SENOVEN... -

Page 10: General Information

IMPORTANT: Electrical input connection must be connected according to the order of the input terminals. (PHASE TO PHASE, NEUTRAL TO NEUTRAL, – GROUNDING TO GROUNDING) Note: Specifications can be changed by Şengün Makina. Above Specifications are given for information. SEN 1602 / SENOVEN... -

Page 11: Dimensions

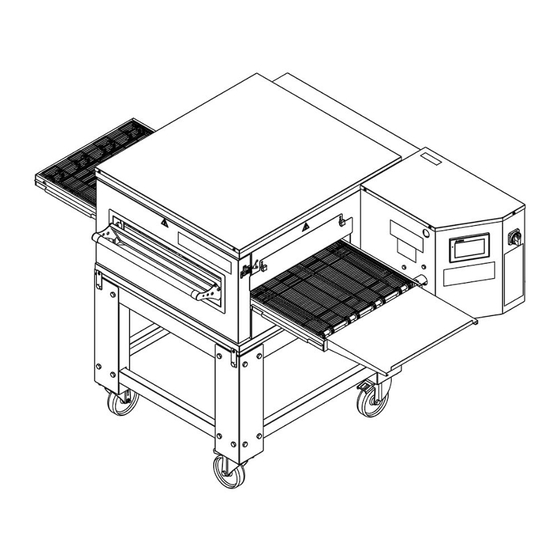

1.10 Dimensions: Single Oven (Isometric) Front View Duplex (Side View) SEN 1602 / SENOVEN... - Page 12 Triplex (Side View) SIDE COVER DISTANCE BETWEEN WALL GAS ENTRANCE ELECTRICAL INPUT Top View SEN 1602 / SENOVEN...

-

Page 13: Section 2: Assemble

SECTION 2: ASSEMBLE PART NAME UNIT Product Out Sheet Forward/Back Waste Collecting Sheet Entry and exit cover plate Stopper (Optional) SEN 1602 / SENOVEN... -

Page 14: Front/Back Waste Collecting Sheet

2.1 Forward/Back Waste Collecting Sheet: Attach the product out sheet to the conveyor chassis as shown in the figure. And Push it. 2.2 Front/Back Waste Collecting Sheet: Front and back waste collecting sheets are taken out as shown in pictures. SEN 1602 / SENOVEN... -

Page 15: Entry And Exit Cover Sheet

Covers are set as desired through holes which are different levels. Covers are attached by bakelite bolts. 2.4 Stopper (Optional): Stopper, blocks the products and keep them into the belt. Stopper is attached to the belt. SEN 1602 / SENOVEN... -

Page 16: Belt Assembly

2.5 Belt Assembly: The conveyor is mounted inside the machine as shown in the picture. The drive shaft is centered on the clutch pipe. SEN 1602 / SENOVEN... - Page 17 Clutch pipe is attached by the drive shaft spring as shown in the figure. Belt assembly is completed. For disassembly, use every steps in reverse order. SEN 1602 / SENOVEN...

-

Page 18: Belt Wire Assembly

3. If belt wire problem appears, remove a 4. The final wire assembly wire as shown in the figure. For disassembly, use every steps in reverse order. Not: Clean the belt wire once a week or month for better performance. SEN 1602 / SENOVEN... - Page 19 01981 CHASSIS LEG SHEET 01957 BOLT 01785 BRACKET SHEET 01787 BRACKET SHEET 00039M BRACKET 01959 01977 BRACKET SHEET 01961 WASHER 01786 BRACKET SHEET 00051 WASHER 01958 BOLT 00048 BOLT 01960 WASHER 01964 WHEEL 01965 01963 WASHER SEN 1602 / SENOVEN...

-

Page 20: Low Chassis Assembly

2.8 Low Chassis Assembly: 00040M (SEN 1602) LOW CHASSIS SPARE PARTS LIST SPARE PART SPARE PART ITEM SPARE PARTS DESCRIPTION UNIT ITEM SPARE PARTS DESCRIPTION UNIT NUMBER NUMBER 01797 CHASIS LEG SHEET 01959 02059 BRACKET SHEET 01960 WASHER 00041M BRACKET... -

Page 21: Chassis-Oven Assembly

2.9 Chassis-Oven Assembly: SEN 1602 / SENOVEN... -

Page 22: Double Floor Oven Assembly

2.10 Double Floor Oven Assembly: Note: Bolts are included in the package ITEM SPARE PART NUMBER SPARE PART DESCRIPTION UNIT 02056 HOLDER 00046 BOLT SEN 1602 / SENOVEN... -

Page 23: Triple Floor Oven Assembly

2.11 Triple Floor Oven Assembly: Note: Bolts are included in the package. ITEM SPARE PART NUMBER SPARE PART DESCRIPTION UNIT 02056 HOLDER 00046 BOLT SEN 1602 / SENOVEN... -

Page 24: Air Duct Disassembly / Assembly

Pillar Cover Pillar Cover Finger Guard Finger Guard Bottom Air Duct Assembly Upper Air Duct Assembly 5. For reassembly, use every steps in 4. Slide the air duct cover and remove the reverse order. middle sheet. SEN 1602 / SENOVEN... -

Page 25: Ventilation

Ventilation is very important especially gas ovens. Determine your ventilation system according to your country fire and safety rules. 3.3 General Information About Ventilation: Air duct and hood, should be wide enough. Be sure that you are having the proper ventilation for the oven. SEN 1602 / SENOVEN... -

Page 26: Ventilation Advice

Getting caught in the belt could result in serious injury. DANGER! If the power supply cord appears to be damaged, do not attempt to operate the unit. Contact a service agent or qualified electrician to repair! SEN 1602 / SENOVEN... -

Page 27: Installation Elements

NOTE: TTR Cable is Flexible, shatterproof and loosen proof Grounding has to be proper. Use regulator if voltage is high or low. NOTE: If you fallow the above steps, assembly process can be made smoothly and quickly. SEN 1602 / SENOVEN... -

Page 28: Sen 1602 Oven Technical Specifications Table

3.7 SEN 1602 Oven Technical Specifications Table OVEN ELECTRICITY-GAS TECHNICAL SPECIFICATIONS TABLE Ampere Gas Inlet Capacity Full Average Voltage Faze T (PE) Loading Pressure (Kw) Performance Gas Usage Gas Usage 21 mbar 13 kW 1,375 m³/ 0,65 m³ 40,000 hour... - Page 29 Touch the logo, cooking menu will appear on the screen. MENU − Cooking Menu COOKING TIME PAUSE 123,4 STOP 123,4 START STOP APPLY LIST You must programming the oven at the first usage. Touch the “MENU” the main menu will appear on the screen. SEN 1602 / SENOVEN...

-

Page 30: Utility Programs

Touch the “PROGRAM PAGE”. The password screen will appear on the screen Also you can change the language at the main menu. PASSWORD PAGE PLEASE ENTER YOUR PASSWORD PASSWORD MENU Touch the Password box. Enter the 5555 code and apply. Wait until the PROGRAM PAGE appears. SEN 1602 / SENOVEN... - Page 31 Not: You can save more than one program. Touch the “NO” box at the up left corner and enter a new number for a new product. Set your cooking programs after than touch the “MENU” box and return the “MAIN MENU” and touch the “COOKING PAGE” SEN 1602 / SENOVEN...

- Page 32 When the oven warming enough, “READY” appears on the screen. Than you can start cooking your product. Note: if you press the “PAUSE” button when your product cooking, belt stops but temperature does not change. Touch to “LIST” icon if you want to see the product programs list with their numbers. SEN 1602 / SENOVEN...

-

Page 33: Manual Operation

MENU LAHMACUN PITA BREAD PIZZA LAVAS FISH MEATBALL 4.1 Utility Programs: Touch the “UTILITY PROGRAMS” on main menu. “OPERATION STYLE” will appears on your screen. MENU OPERATION STYLE MANUAL OPERATION STANDBY MODE SEN 1602 / SENOVEN... - Page 34 Than enter the cooking temperature at the box where is above of the “FAN” text. Touch the “APPLY” and “START” buttons. Oven will start cooking with your manual settings. 4.3 Standby Mode: Touch the “STANDBY MODE” on “OPERATION STYLE” page. Oven cooks on standby mode with %25 energy saving. SEN 1602 / SENOVEN...

-

Page 35: Warnings

4.6.5 Low Battery Warning: “Low Battery Warning” message appears, when battery low. 4.6.6 Ready: “Ready” message appears when oven temperature has reached desired degree. 4.6.7 Burner Failure: “Burner Failure” message appears when burner system has fault. SEN 1602 / SENOVEN... -

Page 36: Functions

1. All Poles connect switches have 3mm wide. 2. Grounding cable head is back on the oven. 3. If you use more than one oven (double or triple) each oven must has its own switch and all switches should be close together. SEN 1602 / SENOVEN... -

Page 37: Limitation Requirements - Gas Ovens

If the oven fails to operate, check the circuit breaker to be sure it is turned on. Be sure that circuit breaker is ok before you call the Authorized Service Agency. The name and phone number of the Authorized Service Agency should be located at the bottom of the data plate SEN 1602 / SENOVEN... -

Page 38: Cleaning Instructions

The periodic intervals for preventative cleaning may vary greatly depending upon the environment in which the oven is operating. You must discuss the need for Preventive Maintenance with your Authorized Service Company to establish a proper program. SEN 1602 / SENOVEN... -

Page 39: Section 5: Cooked Products

SEN series ovens, show much better performance than other ovens (Especially pizza cooking). 5.2 Cooking Time and Temperature: PİZZA - ALUMINIUM PAN - TIME: 6 MINUTES - 260 °C - FRESH PİDE - OVER CONVEYOR - TIME: 5 MINUTES - 260 °C - FRESH SEN 1602 / SENOVEN... -

Page 40: Total Cooking Calculation

/Hour Total Production 85,2 170,4 Amount /Hour Sample 2: Oven Chamber Length: 710 mm. Cooking Time: 5 dk. Pan Length: 500 mm. Producti 5 dk. 17,4 Amount/ Hour Total Producti 17,4 52,2 Amount Pan Length /Hour SEN 1602 / SENOVEN... -

Page 41: Sample Capacity Table

4 Minutes ½ 30 cm 36 cm 41 cm Pizza Diameter 5 Minutes ½ 6 Minutes ½ 30 cm 36 cm 41 cm ½ Pizza Diameter 7 Minutes 8 Minutes 30 cm 36 cm 41 cm SEN 1602 / SENOVEN... - Page 42 SECTION 6: SPARE PARTS MANUAL SPARE PARTS MANUAL SEN 1602 / SENOVEN...

- Page 43 SEN 1602 / SENOVEN...

- Page 44 SEN 1602 (FRONT) SPARE PARTS LIST SPARE PARTS SPARE PARTS SPARE PARTS ITEM SPARE PARTS DESCRIPTION UNIT ITEM UNIT NUMBER NUMBER DESCRIPTION 00093 WEDGE 02194 CONDENSER 00087 WEDGE 00046 BOLT 02183 BOLT 01184 RECORD 01647 REDUCTOR SHEET 01089 RECORD NUT...

- Page 45 SEN 1602 M00319 SEN 1602 (FRONT COVER) SPARE PARTS LIST ITEM SPARE PARTS NUMBER SPARE PARTS DESCRIPTION UNIT 01551 OPEN/CLOSE CONNECTION 01552 OPEN/CLOSE CONNECTION 01558 BOLT 01548 WATCHING WINDOW 01543 WINDOW FRAME EDGE BRACKET 01555 BOLT 01554 015531 BOLT 01530...

- Page 46 SEN 1602 / SENOVEN...

- Page 47 SEN 1602 (BACK COVER) SPARE PARTS LIST ITEM NO. SPARE PARTS LIST SPARE PARTS DESCRIPTION UNIT 01100M BACK ISOLATION PACKAGE 01075M BACK COVER 01076M ENGINE 01078M 01718 FAN GUARD SHEET 01717 STUD 01961 WASHER 01959 WASHER 01317 REZISTANCE OUTPUT TUBE...

- Page 48 SEN 1602 / SENOVEN...

- Page 49 SEN 1602 M00245 SPARE PARTS LIST ITEM NO. SPARE PART NUMBER SPARE PART DESCRIPTION UNIT SEN1602 M00321 FRONT COVER 01764 ENTRY AND EXIT COVER SHEET 01596 BAKELITE 01765 IZOLATION PACKAGE 00046 BOLT SEN1602 M00247 BODY 01778 FINGER PLASTERING SHEET 00015M...

- Page 50 SEN 1602 M00251 SSR BOX SSR KUTUSU SEN 1602 / SENOVEN...

- Page 51 SEN 1602 M00251 (SSR BOX) SPARE PARTS LIST ITEM SPARE PART ITEM SPARE PART SPARE PART DESCRIPTION UNIT SPARE PART DESCRIPTION UNIT NUMBER NUMBER 01011 SSR SHEET 02632 BOLT 01290 00288 TERMINAL RAIL 01271 BOLT 01296 WASHER 01306 SPONGE 01294...

- Page 52 SEN 1602 / SENOVEN...

- Page 53 01791 PRODUCT OUT SHEET 00007M BELT CHASSIS 01807M BELT WIRE 00096 SPLIT PIN 01810 LIMITER SHEET 01812 BELT WIRE 01813 BELT WIRE 01814 BELT WIRE 01841 BELT DRIVE SHAFT 01840 BELT IDLE SHAFT 01837 DRIVE GEAR SEN 1602 / SENOVEN...

- Page 54 SEN 1602 / SENOVEN...

- Page 55 SEN 1602 M00286 (BURNER) SPARE PARTS LIST ITEM NO. SPARE PARTS NUMBER SPARE PARTS DESCRIPTION UNIT 01666 BURNER ENGINE 01668 NOZZLE 01681 RECORD 02581 00048 BOLT 01685 WASHER 02640 NOZZLE 01687 ELBOW 02639 RECORD 02649 ELBOW 01686 GAS VALVE 02541...

- Page 56 SECTION 7: ELECTRICAL DIAGRAM SEN 1602 / SENOVEN...

- Page 57 SEN 1602 / SENOVEN...

- Page 58 SEN 1602 / SENOVEN...

- Page 59 SEN 1602 / SENOVEN...

- Page 60 SEN 1602 / SENOVEN...

- Page 61 SEN 1602 / SENOVEN...

- Page 62 SEN 1602 / SENOVEN...

-

Page 63: Section 8: Troubleshooting

SSR Valve Relay (3-4 numbered DC) Check the Out Relay Voltage (1-2 numbered) Check the 12 Volt DC card 200-230 V Change Relay Check the above steps with a qualified electrician. If problem does not solve, contact with our service. SEN 1602 / SENOVEN... -

Page 64: Low Battery Warning

You must change the battery of the screen in one month. The changing battery without energy, cause the software losses. Not: Battery can be supplied by electronical markets, services and producer. SEN 1602 / SENOVEN... -

Page 65: Belt Engine Failure

If motor speed control device hasn’t a to foreign materials problem contact with the service Remove the foreign materials. Turn switch off and on. Press the RUN button and start If oven still doesn’t work contact with the service SEN 1602 / SENOVEN... -

Page 66: Temperature Determine Failure

If any temperature value couldn’t detected by control panel, “Temperature Determine Failure” message appears. Temperature determine failure Turn switch off and on Failure continues Check the thermocouple connections Change the thermocouple Change the card If failure still continues, contact with the service SEN 1602 / SENOVEN... -

Page 67: Temperature Does Not Rise

If Oven temperature doesn’t rise for five minutes, “Temperature does not Rise” message appears. Temperature does not rise Turn switch off and on Check the gas valve Check the relays İf failure continues, contact with the service SEN 1602 / SENOVEN... -

Page 68: Burner Failure

Check the electrical connections for the rules in page 26 Check the ignition electrode and electrode connections Check the multiblock valve Check the entrance gas pressure (Min: 17 mbar) İf failure continues, contact with the service SEN 1602 / SENOVEN... -

Page 69: Products Do Not Cooked

Authorized Service Agency. The name and phone number of the Authorized Service Agency should be located on the oven or contact the factory for the name of the nearest Authorized Service Agency. SEN 1602 / SENOVEN... -

Page 70: Section 9: Labels

SECTION 9: LABELS (High Temperature) Entrance Pressure (Grounding) Warning Labels Warning Labels CE (Conformité Européene) SEN 1602 / SENOVEN... - Page 71 Technical Label (Product Card) Warning Labels SEN 1602 / SENOVEN...

- Page 72 NOTE: SEN 1602 / SENOVEN...

- Page 73 Phone : +90 212 671 23 23 (Pbx) Phone 2 : +90 212 671 84 24 Fax : +90 212 671 88 28 GSM : +90 533 957 14 53 E-Mail : info@sengunmakina.com www.sengunmakina.com – www.acpisir.com SEN 1602 / SENOVEN...

Need help?

Do you have a question about the SEN 1602 and is the answer not in the manual?

Questions and answers