Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Unical Ufly P

- Page 1 Ufly P TOUCH CONTROL INSTALLATION AND SERVICING MANUAL...

- Page 2 DICHIARAZIONE DI CONFORMITA’ DECLARATION OF CONFORMITY Il Fabbricante DICHIARA The manufacturer DECLARE sotto la propria esclusiva responsabilità che il prodotto sotto riportato soddisfa i requisiti delle Direttive e Norma- tive sotto menzionate under our sole responsibility that the below indicated product meets the requirements of the following indicated Directives and Standards Prodotto: TERMOREGOLAZIONE Product: HEATING SYSTEM...

-

Page 3: Table Of Contents

Attention: The manufacturer will not be held liable in case of damage to persons, animals or objects resulting from failure to comply with the instructions contained in the manuals supplied with the boiler. 1 DESCRIPTION ..............................4 Reading Icons in Home page ........................ 4 Part description ............................ -

Page 4: Description

Status INFO MENU 1 2 3 4 5 6 7 8 9 10 11 Terminal access cover (if present) Magnets for fixing Terminal connection for Ufly P coming from boiler board. Removable terminals for connection Display Touch (if present) -

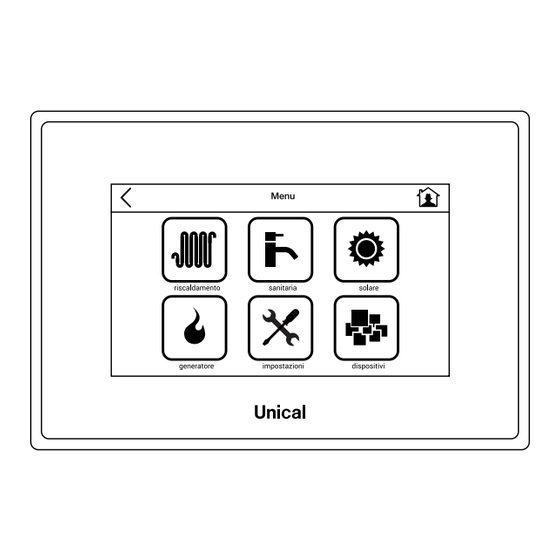

Page 5: Display And Functions Description

Display and functions description 2.1 - Display mode 6 Display Mode 7 Display Mode 8 Display Mode Stand-by Home page Menù page 2.2 - Button One page back and Button Home 2.3 - Display in Home page 18:28 thur 30 may 2015 °C °C °C... -

Page 6: Set Up Menù

2.4 - Set up Menù First start - Setting Time and Date... -

Page 7: Compensation

Setting temperature Eco and Comfort for continuous programs in Heating circuit (H24) Enable room thermostat, only with room sensor connect to the boiler (at Ufly or at additional modules on the bus). In this case Ufly is used as cronothermostat. Ch 13 = Name of heating circuit editable DEFAULT VALUE: comfort 20°C / eco 5°C (see page 12) -

Page 8: Modbus

Brightness and Stand by setting Note: Do not change the value configured for Modbus boiler. In Homepage the screen turn off after the set time (Default 20 sec.) while the screen is on in other page. if the switch is active No stand by, in case of fault message screen also in Home page doesn’t turn off. - Page 9 Password To change password - Enter current password and confirm - Delete current password with - Enter new password and confirm Note: for security and protection, default password is only avaible to the Authorized Service Center. Software information and restore default UflyBox settings To restore default values set at the factory.

-

Page 10: Heating Menù

2.5 - CH Heating Menù 2.5.1 - Hot keys Change heating temperature: Change confort / eco temperature with keys as indicated Choose CH program:... -

Page 11: Summer

To switch ON continuous heating at comfort Switch OFF CH Heating (SUMMER) temperature previously set at 22°C select select STANDBY: COMFORT: To switch ON continuous heating at comfort To switch ON heating at the times as in the example: temperature previously set at 18°C select Ignition from 06.00 at 07.30 Temp. -

Page 12: Programming And Possible Adjusting At Preset Programs

2.5.2 - Programming and possible adjusting at preset programs Selezione Circuito Ch Is possible change Name of heating circuit in the system - Delete Ch... current circuit - Rename Zone circuit...and confirm Creation / modification of typical days Set Type Days Eventually rename Day 1..Day5 example: Working day, Weekday, Holiday... -

Page 13: Day 1 2 3

Set periods Max 3 time slots. Set Week Type (1) Set Week Type (2) Eventually rename Week 1..Week 3 Insert day of the week join the day example: Autumn, Winter, Jolly. (mon-fri-sat-sun) the day type Day1..Day5 Insert day of the week separately (mon-tue-wed.-thu.-fri.-sat-sun) the day type Day1..Day5. -

Page 14: Modulation Temperature

Showing temperature in CH Heating Keys room = Current temperatur request real = Water temperatur of circulation in radiators request = Flow temperature + compensation modulation = Modulation level of the boiler in the moment Choose Heating program Standby (only frost protection) Comfort Week1 Week2... -

Page 15: Period 1 - 2 - 3

View detail CH heating program (1) Example By touching Icon shown Heating at times: It shows only the details of the program in the Period 1 1-2-3 ... period. From 06.00 at 07.30 at 21° temperature Period 2 From 16.30 at 20.30 at 19° temperature Period 3 From 20.30 at 22.30 at 21°... -

Page 16: External Compensation Chart

Adjust parameters heating program Adjust parameters heating program. By touching Settings icon is possible to adjust the para- meters. For those highlighted in gray, password is required. For other parameters, dotted, no need password. Parameters displayed are relative to the heating pro- gram, those with (*) are displayed only if activated external compensation (outdoor sensor present) Note: Then to adjust heating parameters is not ne-... -

Page 17: Manual Function

Ch Heating Manual request Enabling Function Manual Enabling Function Manual - set parameter Back to the set program. View detail CH heating program (2) Is possibile to view and modify program and HEATING At Home page parameter Reset If the boiler is in Error (Block) Reset as shown For other faults that can not be reset with the Reset button, contact the service center... -

Page 18: Dhw Domestic Hot Water Menù

2.6 - DHW Domestic Hot Water Menù 2.6.1 - Hot keys Temperature displaying in DHW mode real = Temperature at the moment of DHW (draw off) hot water request = Water temperature request modulation = Modulation level boiler Choosing DHW (hot water) program Standby (inactive) Comfort Week 1... -

Page 19: Legionella

To change Hot water temperature press icon: Change Hot water temperture: confort / eco as shown. example: COMFORT may be set in the Winter period, and ECO in the Summer period. To activate the Eco function previously set set at 39 ° C Select Eco as shown: To settings DHW circuit of: - Days slot (p. -

Page 20: Rogramming And Possible Adjusting At Preset Programs

2.6.2 - Programming and possible adjusting at preset programs View detail DHW hot water program (1) By touching Icon shown It shows only the details of the program in the 1-2-3 ... period. Adjust parameter DHW mode Adjust parameter DHW mode Parameters displayed are relative to the DHW (hot water) circuit. - Page 21 View detail DHW hot water program (2) In Home page Is possibile to view and modify program and DHW parameter Reset If the boiler is in Error (Block) Reset as shown...

-

Page 22: Solar Menù

2.7 - Solar Menù If this this service is active Is possible to activate this service and where the he pump will start conditions t Is possible to force manually (with password) the pump run. -

Page 23: Devices Menù

2.8 - Devices Menù WARNING! Function reserved exclusively to authorized service centers. At every boiler lighting, UFLY BOX scans devices, if new devices are recognized, such as: hcm / Heating / Burner Control Manager System manager / Cascade Slave Heating Controller Multifunction module Burner Modul Manager They are displayed on the next screen, and is... - Page 24 BMM / HCM Parameter List of parameter in par. 4.2 instruction manual of the boiler To change the parameters is required password. Hystorical Error Delete history with Button Clear (password).

-

Page 25: Burner Menù

2.9 - Burner Menù WARNING! Function reserved exclusively to authorized service centers. Sweeper function 1 - Insert psw and select sweeper again Vary % mod. request from 10 % to 100 % 2 - Activation Chose burner among those available, eg: usually 1 / modulex (from 1 to 8). - Page 26 6 - Vary % of modulation request to the minimum 5 - Burner operating to maximum power (modulation 100%). 10% and select the burner 7 - Boiler operating with modulation min. (modulation 0%). 8 - Disable SWEEPER function. Exit by pressing Home icon. Change parameter This displayed parameter are relevant to burner Note:...

- Page 27 Manual Activation of Boiler Manual Activation of Boiler Touching inicated Icon, you manually activate the boiler, without possibility to set the time. Reset counter (ignitions work hours) Reset to clear the counters. Password is required.

-

Page 28: Error Code

2.10 - Error Codes WARNING! Function reserved exclusively to authorized service centers. Failure that causes the stop of the boiler: Failure that could NOT cause stop of the boiler: - The error code is displayed, the boiler is in lock. After - Error code is displayed, the boiler is in CH demand, resolving the fault press Reset to restart the boiler. -

Page 29: Screen Calibration

ALARM_21 Flapper stuck open ALARM_22 Lack air for ignition ALARM_23 Unexpexted air flux Check the fan and pressure switch wiring Disconnect the air pressure switch: - if the error code disappears, replace the pressure switch. If the problem persists, replace the BMM. - Page 30 ALARM_63 CC: internal error ALARM_64 CC: calibration ALARM_65 CC: calibration ALARM_66 CC: missing calibration ALARM_67 CC: iono setpoint ALARM_68 CC: offset GPV ALARM_69 CC: adaptation error ALARM_70 DHW Tank#1: sensor ALARM_71 DHW Tank#2: sensor ALARM_72 DHW Tank#3: sensor ALARM_73 Flow sensor ALARM_74 Temp.

-

Page 31: Info

Info Key INFO Touching indicated icon, you can select the parame- ter to be displayed in the HOME page. changed from a value PRESSURE to RETURN temp. Note: FILL icon appears only if the boiler is equipped with automatic (water) loading, (see installation boiler instructions). -

Page 32: Screen Calibration

Screen Calibration (To be made in event of difficulties in use of buttons) Operation Display log: every time you see the Remove power from the boiler X on the display, touch with a pencil the center Touch the display and at the same time switch of the X (1 to 5) and press OK on the boiler. -

Page 33: Wiring Conenction

(Y1) Through the Modbus interface is possible the access Allows communication with the UNICAL acquisition to all the Ufly P functions. and control equipment installed: • Acquisition of operating information of all • BMM: “Burner module manager”, controls the connected devices. - Page 34 External Probe (Ext Sensor): The external temperatu- re value ExtTemp can be acquired by the local sensor connected to the HSCP (ExtSensor) terminal or can be received from eBUS through another device on which the external probe is connected (eg. BCM). If the information is not available, the value of ExtTemp is considered equal to 0 °C.

- Page 36 - export@unical-ag.com - www.unical.eu Unical declines every responsibility for the possible inaccuracies if owed to errors of transcript or press. Also reserves the right to bring those changes that it will hold necessary to it own products or profits, without jeopardizing its essential characteristics.

Need help?

Do you have a question about the Ufly P and is the answer not in the manual?

Questions and answers