Table of Contents

Advertisement

Quick Links

- 1 Series 2000 Slide Operator Quick Start Instructions

- 2 Adjusting Parameters (Procedure for Changing Preset Parameters)

- 3 Lock Error Codes (Trouble Shooting Guide)

- 4 Reed Switch Diagnostics

- 5 Actuating and Control Switch Connections

- 6 In Case of Difficulty (Trouble Shooting the C2150)

- Download this manual

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Horton 2000 Series

- Page 1 C2150 CRM Control with Version 1.41 Software and REED Switches for Series 2000 Clean Room Electric Slide Door Operators SETUP INSTRUCTIONS & TROUBLESHOOTING To be used with G200 Installation Instructions 1.0011d A U T O M A T I C S H201C, OCTOBER 2005...

-

Page 2: Table Of Contents

LEDs and actual control of the motor, autolocks etc. This manual is written for the C2150 control with Version 1 software which is used in the controls of the 2000 series linear drive operators. -

Page 3: Series 2000 Slide Operator Quick Start Instructions

1. SERIES 2000 SLIDE OPERATOR QUICK START INSTRUCTIONS C2150 Control with version 1software (Revision E or later hardware) To get the operator up and running, check the items outlined below- 7th Step Check incoming voltages from power supply +120 to +100 +27 to + 35 VDC from F2 VDC from F3... -

Page 4: C2150 Initialization

2. C2150 INITIALIZATION RESET Start with the door in the closed position. Press the DOWN button to actuate the door to open at factory selected DOWN default settings. 1st Step - Power up The chart below shows the position of the door and the display code for each position. Be sure the toggle circuit is completed and apply AC power to the unit. -

Page 5: Adjusting Parameters (Procedure For Changing Preset Parameters)

-Set the reversing sensitivity as required using R10. Do not ! Prior to 1.17, sidelite protection device was wired to 10 & 11 of CN2. 1.17 and later leave this adjustment at minimum. Horton recommends setting is wired to 6 &7. -

Page 6: Actuation Features

5. ACTUATION FEATURES 6. AUTOLOCK SET UP AND INITIALIZATION CODE LOCK DISPLAY Press SET and RESET simultaneously, release (Orange) RESET RESET, wait 5 seconds,then release SET - version number will displayed. Set jumpers or key LOCK During initialization the control clears all ports and switch for the type of the solenoid becomes inactive. -

Page 7: Setting Lock Parameters

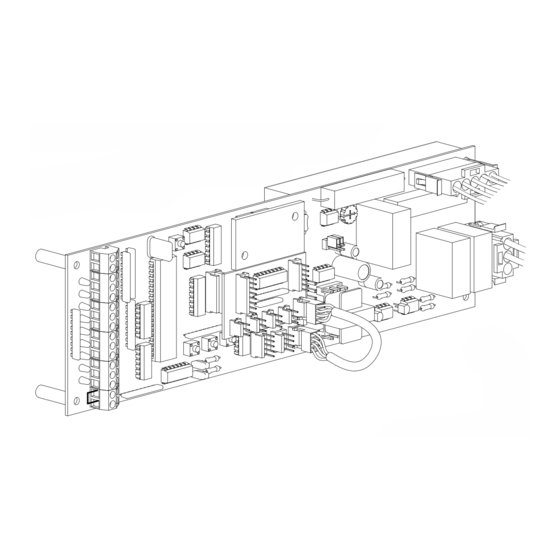

Auto lock circuit board 7. SETTING LOCK PARAMETERS To set up the lock parameters on the C2150 turn off the toggle circuit or double click the -When the solenoid initially energizes there SET button. Use the UP / DOWN buttons to locate dL & L1. COIL should be 25 to 33 VDC at TS2. -

Page 8: Reed Switch Diagnostics

11. REED SWITCH DIAGNOSTICS Running a Reed switch test In software Version 1.00 or later, press the RESET & the DOWN button, release the OR... RESET and hold the DOWN button until Power up the control while the display shows ut holding the DOWN button. - Page 9 +100 3 EXTERIOR SW 4 COMMON REVERSING 5 +24VDC SENSITIVITY 6 SAFTY BEAM 7 COMMON INTERIOR 8 TOGGLE SW HORTON 9 COMMON C215 10 RESERVED 11 COMMON 12 PART'L OPEN 13 2WAY / 1WAY MOTOR 14 NIGHT SW DOWN EXTERIOR...

-

Page 10: H201C.8

H201C.8 DIAGRAM 2 ACTUATING and CONTROL SWITCH CONNECTIONS INTERIOR +24VDC (BLK) 1 +24VDC ACTUATING SIGNAL (RED) 2 INTERIOR SW. SENSOR 3 EXTERIOR SW COM (WHT) [See Lower Right for Sensors] 4 COMMON EXTERIOR +24VDC (BLK) 5 +24VDC ACTUATING 6 SAFTY BEAM SIGNAL (GRN) SENSOR 7 COMMON... -

Page 11: In Case Of Difficulty (Trouble Shooting The C2150)

-If the fuse does not blow, plug the motor in and try again. -If the fuse blows again and the motor checked good, check for a mechanical bind. Check the br parameter in appendix A which can help prevent fuse blowing. -Consult Technical Assistance at the Horton factory. - Page 12 APPENDIX B1 CODE DISPLAYS Codes are arranged in alphanumeric order (NOTE: D = Display, P = Parameter, E = Error) CODE DISPLAY MEANING TYPE VERSION Control is braking - door always brakes when opening. Close braking can be turned on at the parameter 1.00 Control has failed - must be replaced...

- Page 13 APPENDIX B2 CODE DISPLAYS CODE DISPLAY MEANING TYPE VERSION This parameter should be turned on when using a 1/4 HP motor and a light door. (Reduces abruptness of closing ) 1.08 Use only with APEX system - see APEX instruction G550 1.16 Use only with APEX system - see APEX instruction G550 1.16...

- Page 14 1.00 When this is turned on it tells the software not to wait for the lock monitor but try to open after a brief delay. Rarely used, only for non Horton locks Use only with APEX system - see APEX instruction G550 1.16...

-

Page 15: Terminal Cn2 (Description Of Terminal Block Connections)

A U T O M A T I C S A Division of Overhead Door Corporation, A Sanwa Shutter Company Form H201C, OCT 2005, printed in U.S.A. Horton Automatics reserves the right to improve the product and change its specifications without notice.

Need help?

Do you have a question about the 2000 Series and is the answer not in the manual?

Questions and answers

What to do if there is no digital display and door only holds open

If the Horton 2000 Series has no digital display and the door only holds open, check for a hold code. An actuator or device may be holding the door open. The updated software displays a specific hold code number instead of d1 or d2 to show which device is causing this. Once all hold devices are cleared, the display will return to d1 or d2 and the normal time delay will start.

This answer is automatically generated

@Mr. Anderson : no digital display.

Tried calling tech support multiple and it immediately hung up on me when I made the tech support selection.