Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ep CQD12R

- Page 2 EP EQUIPMENT CO.,LTD. is one of the world’s leading companies manufacture, With business all over the world, EP has design material handling equipment and thousands of employees and hundreds provide related service. With over of agents worldwide to provide our...

- Page 3 2. Manual pictures for reference only, the real car shall prevail, and shall not affect the manual use. 3.Manual pictures only sign for one of the models in this series models. COPYRIGHT OF THESE OPERATING INSTRUCYIONS REMAINS WITH EP CO.,LTD OM3316 12.15...

- Page 4 WARNING! TO PREVENT SETIOUS RISK OF INJURY TO YOUORSELF AND OTHERS OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS. These trucks may become hazardous if adequate maintenance is neglected. Therefore, adequate maintenance facilities, trained personnel and procedures should be provided. Maintenance and inspection shall be performed in conformance with the following practices: 1.

- Page 5 assure that "drift" has not developed to the extent that it would create a hazard. 10. Truck shall be kept in a clean condition to minimize fire hazards facilitate detection of loose or detective parts. 11. Modifications and additions which affect capacity and safe truck operation shall not be performed by the customer or user without manufacturers prior written approval.

-

Page 6: Table Of Contents

Catalog Correct use and Application....................1 1. Truck Description......................2 1.1Application........................2 1.2 Truck Assemblies..................... 3 1.3 Standard Version Specifications................5 1.3.1 Performance data for standard trucks............5 1.3.2 Dimensions....................5 1.4 Identification points and data plates..............10 1.4.1 Truck data plate..................12 1.4.2 Capacity chart..................... - Page 7 5.Truck Maintenance......................29 5.1 Operational safety and environmental protection..........29 5.2 Maintenance Safety Regulations................. 29 5.3 Servicing and inspection..................30 5.3.1 Maintenance Checklist................31 5.3.2 Lubrication Schedule................. 33 5.3.3 Maintenance Instructions................34 5.4 Decommissioning the truck...................36 5.4.1 Prior to decommissioning................36 5.4.2 Restoring the truck to operation after decommissioning......36 5.5 Safety checks to be performed at regular intervals and following any unusual incidents...................37 5.6 Final de-commissioning, disposal................37...

-

Page 8: Correct Use And Application

Correct use and Application The truck described in the present operator manual is an industrial truck designed for lifting and transporting load units. It must be used, operated and serviced in accordance with the present instructions. Any other type of use is beyond the scope of application and can result in damage to personnel, the truck or property. -

Page 9: Truck Description

1. Truck Description 1.1Application The series is a three wheel electric side seat, clear view reach truck. It is designed for internal and external use to lift and transport goods. Open bottom pallets or pallets with transverse boards can be lifted inside or outside the area of the load wheels or roll cage. -

Page 10: Truck Assemblies

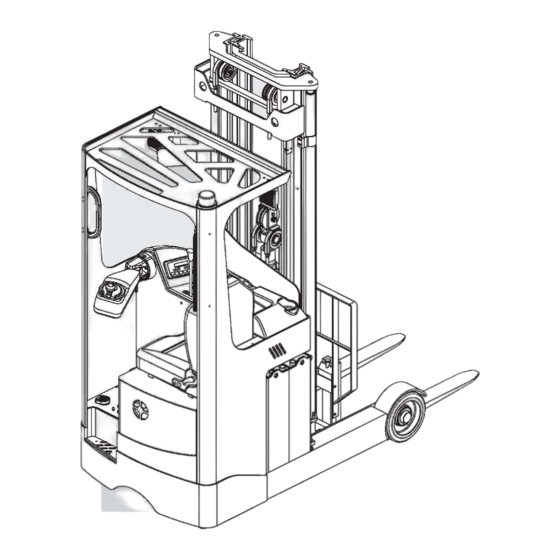

1.2 Truck Assemblies Item Component Item Component Mast Tank Overhead guard Drive wheel Free lift cylinder 10 Driver's seat Controller 11 Drive pedal Load wheel 12 Accelerator pedal Outriggers 13 Star-shaped handle Battery 14 Control panel... - Page 11 Safety mechanisms: An enclosed truck geometry with rounded edges ensures safe handling of the truck. The driver is protected by the overhead guard (2). Pressing the Emergency brake switch disconnects all electrical functions in hazardous situations.The drive wheel (9) and the load wheels (5) are protected by a solid skirt. Line brake safety devices in the lift cylinders limit the load lowering speed in the event of a hydraulic system failure.

-

Page 12: Standard Version Specifications

1.3 Standard Version Specifications Technical specification details in accordance with VDI2198. Technical modifications and additions reserved. 1.3.1 Performance data for standard trucks CQD12R/RF Item Description Unit Drive unit Battery Operator type Seated Load capacity 2645 Load center 23.6 Travel speed, laden/ unladen 5.0/5.2... -

Page 13: Dimensions

1.3.2 Dimensions Item Description CQD16 CQD20 单位 Wheelbase 53.3 Track width, Load end 35.2 α/β Mast/fork carriage tilt, forward/backward 2 / 4 ° Overall length See Form1 b1 /b2 Overall width 40/40 Height, mast lowered See Form3 Free lifting height See Form3 Lifting height See Form3... - Page 14 Form 1 CQD12R/RF Model designation CQD12R/RF Sidesway 2-stage 3-stage 2-stage 3-stage Mast Type Overall length (minimum) l 89.96 90.94 91.34 92.32 Length to face of forks 47.83 48.82 49.21 50.2 Reach distance 21.06 19.69 Aisle width for pallets 1000 104.53 105.12...

- Page 15 Form 3 Height, mast Height, mast Lift height(in.) Free lift (in.) lowered(in.) extended(in.) Mast Type h2(*) h4(*) 98.43 71.46 137.8 121.06 106.3 75.39 145.67 128.94 118.11 81.3 157.48 140.75 2-stage 129.92 87.2 169.29 152.56 141.73 93.11 181.1 164.37 157.48 100.98 196.85 180.12 169.29...

-

Page 17: Identification Points And Data Plates

1.4 Identification points and data plates... - Page 18 Item Description “Never put your hands in inner and outer mast.“ warning Warning decal “Don't drive in rain.“ warning Operator warning Operator decal Operator warning decal Truck data plate Security mark Hydraulic pressure decal Model decal Capacity chart “Never stand ” warning CE decal Strap points for crane lifting...

-

Page 19: Truck Data Plate

1.4.1 Truck data plate Item Description Item Description Model Rated Capacity Serial no. Mass without battery Service weight without load Max. Battery Mass Production Date Min. Battery Mass Battery Voltage Lifting Height Capacity Load weight Lifting height(max.) Load center For queries regarding the truck or ordering spare parts please quote the truck serial number(2). -

Page 20: Commissioning

2. Commissioning 2.1 Using the truck for the First Time Only operate the truck with battery current. Preparing the truck for operation after delivery or transport. Procedure • Check the equipment is complete. • Check the hydraulic oil level. • Install the battery if necessary (where required), (see "4.5 Battery removal and installation"... -

Page 21: Operation

3.Operation 3.1 Safety Regulations for the Operation of trucks Driver authorisation: The truck may only be used by suitably trained personnel, who have demonstrated to the proprietor or his representative that they can drive and handle loads and have been authorised to operate the truck by the proprietor or his representative. -

Page 22: Controls And Displays

3.2 Controls and Displays 3.2.1 Control panel controls and displays... - Page 23 Item Control / Display Function Function operation: • Load handler lift/lower Hydraulic control switch/ • Mast support extend / retract Hydraulic control handle • Fork forward or backward tilt • Sideshift left / right Switches control current on and off. Removing the key prevents Key switch the truck from being switched on by unauthorised personnel.

-

Page 24: Display Unit Controls And Displays

3.2.2 Display unit controls and displays 1. Switch Set the controller parameter of truck used by authorised service personnel) 2. Display... -

Page 25: Run The Truck

Item Component Function Steering display area Steering angle display in arrow form. Power display area Battery discharge status and energy recovery display. Information display Warning and fault indication and data registration area Height display area Real time display of fork height Steering fault alarm When the steering system when problems arise, the symbols will zone... -

Page 26: Adjusting The Steering Wheel

1. Adjusting the driver's weight Rotary switch (1) as far as it will go in the arrow direction. • Clockwise rotation for setting the seat to a higher weight. • Counterclockwise rotation for setting the seat to a lower weight. 2. -

Page 27: Industrial Truck Operation

3.4 Industrial Truck Operation 3.4.1 Safety regulations for truck operation Travel routes and work areas: Only use lanes and routes specifically designated for truck traffic. Unauthorised third parties must stay away from work areas. Loads must only be stored in places specially designated for this purpose. Driving conduct: The driver must adapt the travel speed to local conditions. -

Page 28: Travel, Steering, Braking

3.4.2 Travel, Steering, Braking Do not drive the truck unless the panels are closed and properly locked. When you start up the truck the drive pedal must be applied. 1.Driving • Insert the key in the key switch and turn it to the “ON” position . •... - Page 29 2.Steering Use steering wheel (7) to steer the truck in the required direction.The drive wheel position is indicated in the driver’s display. 3.Braking The brake pattern of the truck depends largely on the ground conditions. The driver must take this into account when operating the truck. The driver must be looking ahead when travelling.

-

Page 30: Lifting And Depositing Loads

3.4.3 Lifting and depositing loads Before raising a load, the driver must ensure that it is correctly palletised and that the capacity of the truck is not exceeded. • Insert the forks as far as possible underneath the load. 1.Lifting - Lowering Do not reach into the mast. -

Page 31: Parking The Truck Securely

4.Left - Right Sideshift The references to left and right are based on the load handler as viewed from the operator’s position. Sideshift Left Push the control switch/lever (4) in direction (X). Sideshift Right Push the control switch/lever (4) in direction (Y). 3.5 Parking the truck securely When you leave the truck it must be securely parked even if you only intend to leave it for a... -

Page 32: Battery Maintenance & Charging

Battery equipment may only be replaced with the agreement of the manufacturer. 4.2 Battery type & dimension Battery type & dimension as follow form : Form 4.1 CQD12R CQD12RF Tuck type 4HPzS320 4HPzS320 Battery type... -

Page 33: Exposing The Battery

4.3 Exposing the battery • Preparing for Operation (See 3.3.4 To prepare the truck for operation ). • Move the control switch/lever (2) in the arrow direction (U). Move the mast holder as far as the stop in the battery direction and release the control switch/lever (2) (the mast is now in its limit position). -

Page 34: Charging The Battery

4.4 Charging the battery • Expose the battery(See 4.3 Expose the battery ). Safety regulations for Charging • Please charge in the well-ventilated and appointed site. • Mark ‘no smoking’ on charging. • ahead of charging,please examine wire and pin whether good or not. When wire and pin are damaged,please do not charge. -

Page 35: Battery Maintenance

4.6 Battery maintenance Do not overuse battery: • If you use up the energy of battery till the forklift immovability, you will shorten its working hours. • Shower for battery appears need for charge,please charge it quickly. Battery maintenance: The battery cell covers must be kept dry and clean. The terminals and cable shoes must be clean, secure and have a light coating of dielectric grease.Batteries with non insulated terminals must be covered with a non slip insulation mat. -

Page 36: Truck Maintenance

5.Truck Maintenance 5.1 Operational safety and environmental protection • The servicing and inspection operations contained in this chapter must be performed in accordance with the intervals indicated in the servicing checklists. • Any modification to the truck assemblies, in particular the safety mechanisms, is prohibited. -

Page 37: Servicing And Inspection

Electrical System Only suitably trained personnel may operate on the truck’s electrical system. Before working on the electrical system, take all precautionary measures to avoid – electric shocks. For battery-operated trucks, also de-energise the truck by removing the battery connector. Welding To avoid damaging electric or electronic components, remove these from the truck before performing welding operations. -

Page 38: Maintenance Checklist

5.3.1 Maintenance Checklist Maintenance interval ● W A B Braking Check magnetic brake air gap. ● Test service and load brakes. ● Electrical Test instruments, displays and control switches. ● system Test warning and safety device. ● Make sure wire connections are secure and check for ●... - Page 39 Maintenance interval ● W A B Lifting Check lifting chains and chain guides for wear, adjust and ● grease Check fork tines and fork carrier for wear and damage. ● Perform sight check of rollers, sliding elements, and stops ● Steering Test electric steering.

-

Page 40: Lubrication Schedule

5.3.2 Lubrication Schedule... -

Page 41: Maintenance Instructions

Consumables Handling consumables type material: Consumables must always be handled correctly. Follow the manufacturer’s instructions. Improper handling is hazardous to health, life and the environment. Consumables must only be stored in appropriate containers. They may be flammable and must therefore not come into contact with hot components or naked flames. Only use clean containers when filling up with consumables. - Page 42 Check the hydraulic oil level It is going to add hydraulic oil when you heard explosion sound from pipe during lifting. • Prepare the truck for maintenance and Warning! repairs ( See 5.3.3 Maintenance Instructions). Forbid adding hydraulic oil within •...

-

Page 43: Decommissioning The Truck

5.4 Decommissioning the truck If the truck is to be decommissioned for more than two months , e.g. for operational reasons,it must be parked in a frost-free and dry location and all necessary measures must be taken before, during and after decommissioning as described. On decommissioning the truck must be jacked up so that all the wheels are clear of the ground. -

Page 44: Safety Checks To Be Performed At Regular Intervals And Following Any Unusual Incidents

5.5 Safety checks to be performed at regular intervals and following any unusual incidents Carry out a safety check in accordance with national regulations. We have a special safety department with trained personnel to carry out such checks. The truck must be inspected at least annually (refer to national regulations) or after any unusual event by a qualified inspector. -

Page 45: Troubleshooting

6.Troubleshooting This chapter is designed to help the user identify and rectify basic faults or the results of incorrect operation. When locating a fault, proceed in the order shown in the table. Fault Possible cause Action Truck does • Battery connector not •...

Need help?

Do you have a question about the CQD12R and is the answer not in the manual?

Questions and answers