Subscribe to Our Youtube Channel

Summary of Contents for Magnaflux Universal WE TOUCH with TCODE

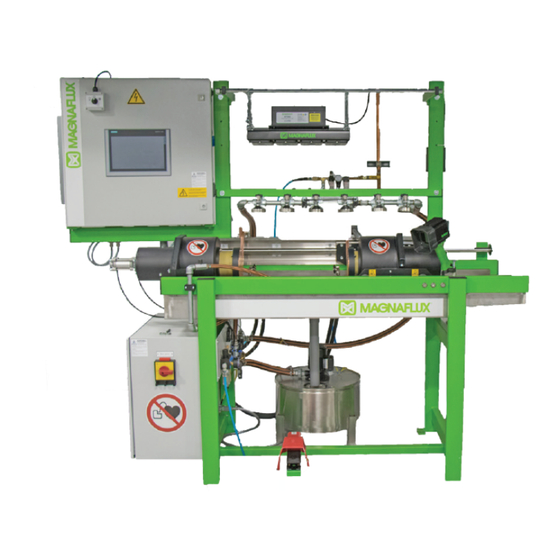

- Page 1 Operating Manual Universal WE TOUCH with TCODE Multi-Directional Magnetic Wet Bench Part number 022690...

- Page 2 UNIVERSAL WE TOUCH TCODE 2 / 85 MX UWETOUCH_v.3 2019-05-03...

-

Page 3: Mx Uwetouch_V

Document No.: MX UWETOUCH_v.3 Version: Issue date: 2019-05-03 © Copyright 1934-2019 MAGNAFLUX GmbH All rights reserved. Reprinting, even in part, only permitted with the approval of MAGNAFLUX GmbH. Manufacturer MAGNAFLUX GmbH Bahnhofstrasse 94-98 73457 Essingen Germany P: +49 7365 81-0 F: +49 7365 81-449 support.de@magnaflux.com... - Page 4 Structure of these operating instructions UNIVERSAL WE TOUCH TCODE (600/900) v.3 Structure of these operating instructions Chapter 1 Information for your safety starting page 9 Machine description Chapter 2 starting page 17 Operation and application Basis of operation Chapter 3 starting page 36 Machine adjustments Chapter 4...

- Page 5 Hand-held shower with push button (option) Large-area shower or spray nozzles/shower heads (option) Nozzles in the 5agnetizing coil (option) UV lighting UV hand-held lamp Model: Magnaflux EV6000 (option) UV panel lamp Model: Magnaflux UV-LED 365-30 (option) UV panel lamp Model: Magnaflux ST700 (option)

-

Page 6: Table Of Contents

Table of contents UNIVERSAL WE TOUCH TCODE (600/900) v.3 Table of contents General safety instructions ................9 Operating Manual ..................... 9 Hazards when handling the machine ..............12 Emergency measures ..................... 12 Magnetic loads at the workplace ................13 Mechanical hazards caused by driven machine parts ..........14 Risk of crushing due to heavy workpieces.............. - Page 7 UNIVERSAL WE TOUCH TCODE (600/900) v.3 Table of contents 3.4.1 Emergency shut-down .................. 50 3.4.2 Before switching the machine ON ..............50 3.4.3 Switching the machine ON ................50 3.4.4 Reactivating the machine after an emergency stop ........51 3.4.5 Switching off the machine ................

- Page 8 Table of contents UNIVERSAL WE TOUCH TCODE (600/900) v.3 10.4.1 Safety instructions ..................82 10.4.2 Preparatory tasks ..................83 10.4.3 Checking functions and magnetising ............83 Decommissioning and disposal ..............84 11.1 Safety instructions for decommissioning ..............84 11.2 Temporary machine decommissioning ..............84 11.3 Final machine decommissioning ................

-

Page 9: General Safety Instructions

UNIVERSAL WE TOUCH TCODE General safety instructions General safety instructions Operating Manual The operation manual must be stored at the operating location at all times! The operating manual must be freely accessible for operating and maintenance personnel at all times. You must read the general safety instructions. - Page 10 General safety instructions UNIVERSAL WE TOUCH TCODE Action instructions All tasks of the operating personnel are presented in a numbered list. Follow the prescribed sequence of actions! Operating action step 1 Operating action step 2 → System response to operating action 2 Safety instructions Safety instructions •...

- Page 11 UNIVERSAL WE TOUCH TCODE General safety instructions Hazard symbols in warning instructions Danger due to high voltage. Possibility of electric shock currents and burns. Comply with preventive measures and safety rules. Danger due to self-starting machines or components. Do not remove or render inoperative any safety features. Danger due to lifted loads.

-

Page 12: Hazards When Handling The Machine

General safety instructions UNIVERSAL WE TOUCH TCODE Hazards when handling the machine Machine operation may pose hazards and adverse effects • to the life and limb of operators or third parties, • to the machine itself, • and to other material assets. Familiarity with the safety regulations and user instructions contained in this manual forms the basis for safe handling and trouble-free operation of this machine. -

Page 13: Magnetic Loads At The Workplace

UNIVERSAL WE TOUCH TCODE General safety instructions Magnetic loads at the workplace WARNING Magnetising may interfere with the proper function of pacemakers and other medical implants, e.g. insulin pumps. Lingering in the vicinity of the machine or within a perimeter of 5 m around the magnetising station is prohibited for •... -

Page 14: Mechanical Hazards Caused By Driven Machine Parts

General safety instructions UNIVERSAL WE TOUCH TCODE The operating company is required to determine, document and mark areas of increased exposure. It must be ensured that • only authorised and trained personnel work in these areas and • the permitted values for brief and partial bodily exposure are not exceeded or •... -

Page 15: High Fire Risk Due To Oily Test Liquids

UNIVERSAL WE TOUCH TCODE General safety instructions High fire risk due to oily test liquids Test oils are highly flammable! Fire hazard! • Only use flame-retardant test oils with a flash point > 100°C. (>212°F) When using oily test liquids •... -

Page 16: Defective Protective And Safety Features

General safety instructions UNIVERSAL WE TOUCH TCODE Personal protection equipment (PPE) The following PPE is required when operating the machine. • Safety gloves • Safety boots • Skin protecting agents The operating company is required to make available all necessary PPE. 1.10 Defective protective and safety features Faulty or dismantled safety features may result in hazardous situations. -

Page 17: Machine Description

UNIVERSAL WE TOUCH TCODE Machine description Machine description Intended use Operational safety of this machine/system can only be guaranteed for the intended use. The machine/installation is intended solely for materials testing • of specified workpieces; • using the magnetic powder process according to –... -

Page 18: Specification Of The Workpieces

Machine description UNIVERSAL WE TOUCH TCODE 2.1.1 Specification of the workpieces Only workpieces complying with the following specification may be tested with the machine using the magnetic particle inspection method: Workpieces Workpieces made of ferromagnetic materials with a magnetic conductivity of µ>100. Clamping 600/900 mm (23”/35”) length... -

Page 19: Structure Of The Machine

UNIVERSAL WE TOUCH TCODE Machine description Structure of the machine Machine components (standard version) Magnetising mandrels(central conductor), installed in the left sleeve Coil of the magnetisation yoke in the right sleeve Magnetisation yoke right sleeve Clamping cylinder right sleeve (If installed) Test liquid tank Test liquid pump Right tailstock... -

Page 20: Safety Equipment

Machine description UNIVERSAL WE TOUCH TCODE Magnetising station Magnetising station Clamping cylinder left sleeve Coil of the magnetisation yoke in the left sleeve Magnetising mandrels magnetising circuits 1 and 2 Workpiece supports Mating contacts for magnetising mandrels Coil of the magnetisation yoke in the right sleeve Clamping cylinder right sleeve 1 Clamping cylinder right sleeve 2 [10]... -

Page 21: Technical Data

UNIVERSAL WE TOUCH TCODE Machine description Technical data 2.4.1 Dimensions and weights For the type and equipment on your individual machines, refer to Page 5. Magnetising station, depending on the type of machine approx. 2075 mm (81.5”) Width approx. 950 mm (37.4”) Depth Height approx. -

Page 22: Magnetising Circuits

Machine description UNIVERSAL WE TOUCH TCODE 2.4.3 Magnetising circuits Magnetising equipment Coil of the magnetisation yoke in the left sleeve Contact plate for axial (contact) current flow at the left spindle sleeve. Optional holder for magnetising mandrel. Optional attachable magnetising mandrel (central conductor) Contact plate for axial (contact) current flow at the right spindle sleeve, alternatively counter contact for operation with magnetising mandrel... -

Page 23: Clamping Devices For The Workpiece

2.4.5 Workpiece holders Model Prism-shaped supports made of non- magnetisable material Workpiece holders for different workpieces are available. As required, please contact the MAGNAFLUX GmbH sales department for more information. 2.4.6 Pneumatics Air pressure 6 bar (90 psi) Air quality... -

Page 24: Uv-Led Lamp (Sample)

UV-LED lamp (sample) For this, refer to the separate documentation for the UV lamp! Technical data at this point only for non-committal information! Manufacturer and type Magnaflux UV-LED PANEL RADIATOR TYPE 365/30 Supply voltage 85-265 V AC / 47-63 Hz Power input approx. -

Page 25: Operator Work Stations

UNIVERSAL WE TOUCH TCODE Machine description Operator work stations The machine must only be operated by one person. The work station for standard operation is at the front of the machine. Work station at the machine Markings and type plate on the machine CE marking Indicates conformity with applicable EU regulations regarding the product, which require... -

Page 26: Testing Liquid System And Spraying Of The Workpiece

Machine description UNIVERSAL WE TOUCH TCODE Testing liquid system and spraying of the workpiece CAUTION Test oils are highly flammable! Fire hazard! • Only use flame-retardant test oils with a flash point > 100 °C (212 °F) When using oily test liquids •... - Page 27 UNIVERSAL WE TOUCH TCODE Machine description Spraying with hand-held shower or hose You can spray the workpiece with test liquid manually, using the hand-held hose or shower. The tap at the work station allows the machine operator to shut off the test liquid line to the hand-held hose/ hand-held shower, and to adjust the throughput volume individually.

- Page 28 Machine description UNIVERSAL WE TOUCH TCODE Test liquid system The test liquid unit consists of: • the test liquid tank, • the connecting lines, • the hand-held hose or shower. The test liquid flows in a closed circuit via the test liquid collection basin and a dirt trap back to the test liquid tank.

-

Page 29: Pneumatic Maintenance Unit

UNIVERSAL WE TOUCH TCODE Machine description Test liquid circuit Test liquid circuit Test liquid tank Pump Stopcock, mounted on the test liquid tank (optional) Solenoid valve Stopcock at the workstation or the magnetising station (optional) Test liquid nozzle Test liquid collection basin Return flow from the magnetising station with dirt trap Pneumatic Maintenance Unit Pneumatic Maintenance Unit... -

Page 30: Individual Test Sequence

Machine description UNIVERSAL WE TOUCH TCODE Individual test sequence The machine can magnetise the workpiece with alternating current (AC). In AC operation, the circuit magnetisation (e.g. axial (contact) current flow) and the longitudinal magnetisation (yoke (coil) magnetisation) can be operated separately or together. Thus, workpieces are checked for cracks in the longitudinal direction, as well as for cracks around the circumference. -

Page 31: Magnetising The Workpiece

UNIVERSAL WE TOUCH TCODE Machine description 2.11 Magnetising the workpiece 2.11.1 Constant current control The strength of the actual magnetising current depends on the resistance in the circuit. The magnetic field strength in the workpiece is a result of the current output. -

Page 32: Magnetising Types In Accordance With En Iso 9934-1

Magnetising types in accordance with EN ISO 9934-1 The magnetising types available on the machine depend on the machine model and accessories installed. Contact the Magnaflux GmbH sales department for information regarding required machine components. DIN EN ISO 9934-1 deals with magnetic particle inspection in general, and covers the magnetising types available for workpiece magnetising. -

Page 33: Demagnetising Of Workpieces

• externally - here the workpiece is demagnetised by an external coil (see Magnaflux products, type ETT). The workpiece is continuously moved out of the magnetic field. Electronic demagnetising A magnetising with alternating current must be followed by an AC demagnetising. -

Page 34: Lighting On The Workstation

Avoid glare from reflective surfaces on the workpiece and unfavourably positioned light sources. Magnaflux UV-LED panel lamp ST700 If you are using test liquids without fluorescent dyes, an illumination intensity of at least 500 lux on the workpiece is recommended. -

Page 35: Visual Inspection

UNIVERSAL WE TOUCH TCODE Machine description 2.13 Visual inspection Visual inspection is frequently used as the method of inspection for the workpieces. As a rule, the machine operator inspects the workpieces visually directly in the machine or at a special assessment station. The accumulations of test liquid typical for cracks in the workpiece are clearly visible as a result of the fluorescent test liquid and the UV lighting. -

Page 36: Basis Of Operation

Basis of operation UNIVERSAL WE TOUCH TCODE Basis of operation Option: Two-handed operation Two-had operation on the workstation Where any power-driven components might pose a hazard to operating personnel, their operation is triggered by the two-handed control. Function To clamp the sleeves. Carry out the function: Simultaneously press and hold the two push-buttons until the function ends, e.g. -

Page 37: Touch Control Panel On The Main Control Panel

UNIVERSAL WE TOUCH TCODE Basis of operation Touch control panel on the main control panel 3.3.1 Screen layout The most important buttons and displays [1] Control buttons: Selection of the operating mode and screens [2] Display: Event and alarm messages [3] Display: Current operating mode or name of current screen [4] Currently logged in user Note: No user login is required for test operation. -

Page 38: Automatic Mode

Basis of operation UNIVERSAL WE TOUCH TCODE 3.3.2 Automatic mode Operation in AUTO mode Display The image is displayed automatically after the controller is switched on and in automatic mode. Automatic operation Press the Automatic button at the bottom of the screen. - Page 39 UNIVERSAL WE TOUCH TCODE Basis of operation Status display for clamping device Clamp blue Workpiece clamping devices (sleeves) are relaxed and can be clamped. Depending on the version, press the two-hand control or foot switch until the status display changes to green. In automatic mode, the magnetisation cycle is started after clamping.

-

Page 40: Automatic T-Code Mode

Basis of operation UNIVERSAL WE TOUCH TCODE 3.3.3 Automatic T-Code mode Operation in AUTO mode Display The screen is shown in Automatic T-Code mode. Prerequisite: The T-Code option is enabled on the machine. Please contact the sales department if necessary. Automatic T-Code Press the Automatic T-Code button at the mode... - Page 41 UNIVERSAL WE TOUCH TCODE Basis of operation Actual values for magnetisation Digital displays actual Display of the current magnetising currents of the values preselected magnetising circuits. Status display for clamping device Clamp blue Workpiece clamping devices (sleeves) are relaxed and can be clamped. Depending on the version, press the two-hand control or foot switch until the status display changes to green.

-

Page 42: Edit T-Code" Screen

Basis of operation UNIVERSAL WE TOUCH TCODE “Edit T-Code” screen 3.3.4 Edit T-Code data record Open Prerequisite: The T-Code option is enabled on the machine. Please contact the sales department if necessary. Edit T-Code Prerequisite: Login as user (user or administrator) required! Press the Automatic T-Code button at the bottom of the screen. -

Page 43: Manual Operation Mode

UNIVERSAL WE TOUCH TCODE Basis of operation 3.3.5 Manual operation mode Operation in “Manual mode” Display The screen is shown in Manual mode. Manual Press the Manual button at the bottom of the screen. → Manual mode is active. Back Close screen and display the last displayed image. - Page 44 Basis of operation UNIVERSAL WE TOUCH TCODE Status display for clamping device Clamp blue Workpiece clamping devices (sleeves) are relaxed and can be clamped. Depending on the version, press the two-hand control or foot switch until the status display changes to green. Clamping green Clamping devices are tensioned and can be relaxed.

-

Page 45: Options" Screen

UNIVERSAL WE TOUCH TCODE Basis of operation “Options” screen 3.3.6 Settings and diagnosis Display The screen can be shown in Manual mode or Automatic mode. Options Press the Options button at the bottom of the screen. → Example at top: The Manual mode stays active. - Page 46 Basis of operation UNIVERSAL WE TOUCH TCODE Start PLC Start machine control. Only necessary if the PLC control is in STOP state. We strongly recommend: Carefully determine the cause of the STOP and take the necessary measures. Reset Button lights up bright red: Fault detected and message not acknowledged.

- Page 47 Activation of further modules is also possible on site by the machine operator via an activation code. If required, please contact MAGNAFLUX sales department. You will then receive a unique unlock code associated with the machine number and the desired module.

-

Page 48: Screen "User Administration

Back Close screen and display the last displayed image. Changes only possible after logging in as administrator! If required, please contact Magnaflux service. Before making any changes, it is essential to observe the notes in chapter 4.6. 48 / 85 MX UWETOUCH_v.3... -

Page 49: Commissioning (Ibn)" Screen

Press the IBN button at the bottom of the screen. Back Close screen and display the last displayed image. The screen is only accessible after logging in as administrator! If required, please contact Magnaflux service. Min/Max values Individual limit values for the magnetising currents MX UWETOUCH_v.3 49 / 85... -

Page 50: Switching The Machine On And Off

Basis of operation UNIVERSAL WE TOUCH TCODE Switching the machine ON and OFF 3.4.1 Emergency shut-down In addition to a controlled shut-down, the machine can be switched off immediately, forced shut-down, in case of emergency. • Immediately switch off the main switch during emergencies or when damage on the electric system are detected. -

Page 51: Reactivating The Machine After An Emergency Stop

UNIVERSAL WE TOUCH TCODE Basis of operation 3.4.4 Reactivating the machine after an emergency stop Only relevant if the machine is equipped with an emergency stop button! WARNING Before reactivating the machine on after an emergency stop • determine the cause for the emergency stop, •... -

Page 52: Select Operating Mode

Basis of operation UNIVERSAL WE TOUCH TCODE Select operating mode Start screen for automatic operation When the machine is switched on, the automatic mode is activated and the associated image is displayed. To switch to manual mode, click on the Manual button at the bottom of the screen. -

Page 53: Machine Adjustments

UNIVERSAL WE TOUCH TCODE Machine adjustments Machine adjustments Filling the test liquid tank The test liquid tank must be filled with appropriate test liquid before operation. It is imperative that you read and comply with the manufacturer instructions and data sheet provided. If you have already added test liquid, verify the concentration and indication capability of the test liquid before running the test operation. - Page 54 Machine adjustments UNIVERSAL WE TOUCH TCODE The mobile tailstock allows for large clamping widths. Adjust the position of the tailstock to set the sleeve distance for the accommodation of workpieces. Adjustment of the sleeve distance Workpiece length Workpiece Distance between the sleeves Clamping lever for fixing the cart Manual valve for releasing the clamping device on the sleeve carriage Switch off the main switch and compressed air...

-

Page 55: Replacing The Magnetising Mandrel (Central Conductor)

UNIVERSAL WE TOUCH TCODE Machine adjustments Replacing the magnetising mandrel (central conductor) CAUTION A heavy magnetising mandrel can crush hands and fingers. • Hold the magnetising mandrel securely with both hands. • Where a magnetising mandrel is to be lifted with hoisting equipment, ensure that appropriate slinging gear is used for safe transportation. - Page 56 Machine adjustments UNIVERSAL WE TOUCH TCODE Example: Magnetising mandrel with spray nozzle for test liquid (option) Left or right magnetising sleeve Valve for test material (optional) Spray nozzle for test material (optional) Magnetising mandrel (central conductor) Fastening bolt for holding the magnetising mandrel Fastening bolts for the magnetising mandrel Procedure Move the machine to the home position.

-

Page 57: Setting The Magnetising Parameters

UNIVERSAL WE TOUCH TCODE Machine adjustments Setting the magnetising parameters Manual or automatic operation without T-Code Set the magnetisation parameters via the control panel in the images of the respective operating mode. Ensure that sufficient field strength is achieved in the workpiece. - Page 58 Machine adjustments UNIVERSAL WE TOUCH TCODE Description of setpoints Preselection of current Switch the magnetisation circuit for axial (contact) flow current flow or auxiliary flow on or off. Preselection of yoke Switch the magnetising circuit for yoke (coil) magnetising magnetising on or off. Preselection of Switch automatic demagnetising on or off.

-

Page 59: Manage Users

Manage users User Administration Changes only possible after logging in as administrator! If required, please contact Magnaflux service. As administrator, the user names, passwords, groups and logout time can be adjusted. CAUTION: Entries in the user administration can be blocked by... -

Page 60: Inspecting Workpieces

Inspecting workpieces UNIVERSAL WE TOUCH TCODE Inspecting workpieces Safety instructions CAUTION Machine operation is reserved for trained personnel only. Read and comply with the operating and safety instructions provided for the machine and third-party components! CAUTION Test oils are highly flammable! Fire hazard! •... -

Page 61: Testing The Workpiece In Automatic Mode

UNIVERSAL WE TOUCH TCODE Inspecting workpieces Testing the workpiece in automatic mode WARNING High magnetic field strengths and powered components may cause personal injury. • Only one person must operate the machine and inspect the workpieces! • No other personnel is permitted in the immediate vicinity of the machine during magnetising. -

Page 62: Manual Mode

Inspecting workpieces UNIVERSAL WE TOUCH TCODE Manual mode The workpiece can be magnetised or demagnetised in manual mode at any time independent of the pre-set spray or remagnetising time. Note on magnetising: Magnetising time must not exceed max. activation time. A fault will be generated, once a magnetising time of 30 seconds is exceeded. -

Page 63: Replacing The Test Liquid

UNIVERSAL WE TOUCH TCODE Inspecting workpieces Replacing the test liquid WARNING Powered components in the area of the lifting equipment may snag and crush extremities. Severe injury hazard! Before accessing the dug-out: • Remove workpiece from the lifting equipment • Lower lifting equipment into its home position •... -

Page 64: What To Do In The Event Of A Fault

What to do in the event of a fault UNIVERSAL WE TOUCH TCODE What to do in the event of a fault Establish a safe condition The machine will be automatically brought to a safe condition and testing operation is stopped if the controls detect a fault. There are, however, a number of faults and errors that cannot be detected by the controls, or it may no longer possible to establish an entirely safe machine state. -

Page 65: Machine Cleaning

Empty the tank again completely. Replace the test liquid tank cover and test liquid pump. Clean the dirt screen inside the tank cover. Replace screen if you detect any damage. Magnaflux Order No. 62600-009126. MX UWETOUCH_v.3 65 / 85 2019-05-03... -

Page 66: Maintenance

Maintenance UNIVERSAL WE TOUCH TCODE Maintenance Maintenance includes all technical and administrative actions to maintain and re-establish the machine's functional state. Carry out the described tasks periodically at the intervals specified in the inspection and maintenance schedule. Maintenance schedule Overview maintenance intervals Interval Period Operating hours daily... - Page 67 UNIVERSAL WE TOUCH TCODE Maintenance Inspection and maintenance interval 2 Entire machine Clean with a mild industrial detergent, no solvents or acids and alkaline solutions. Visual check for damage. Replace any damaged Workpiece supports parts as needed. Magnetising workpiece Check magnetising by measuring the field strength in the workpiece.

-

Page 68: Inspection Instructions

Maintenance UNIVERSAL WE TOUCH TCODE Inspection instructions 8.2.1 Where available: Checking the EMERGENCY STOP button Procedure Activate the controls. Press the EMERGENCY STOP button. → The control system must deactivate immediately. Where available: Repeat steps 1 and 2 for each EMERGENCY STOP button. -

Page 69: Measuring The Magnetising Field Strength

Tangential field strength measurement instrument FSM-2 Requirements Tools required • Tangential field strength measurement instrument FSM-2, Magnaflux Order No. 133 032. Procedure Magnetise workpiece. Place measuring probe on the workpiece. Read magnetic field strength in A/cm on display. MX UWETOUCH_v.3... -

Page 70: Magnetising Testing

Professor Berthold's test block Requirements Tools required: • Prof. Berthold's test block, Magnaflux Order No. 135 005. Procedure Magnetise workpiece. Place test block on the workpiece. → Some of the field lines will flow through the soft-iron core of the test block. -

Page 71: Checking The Test Liquid Concentration

ASTM bulb Requirements Tools required • ASTM bulb, Magnaflux Order No. 135 015. Procedure Fill the ASTM bulb with freshly mixed test liquid. Allow the ASTM bulb to settle for 30 minutes. Check the settled magnetic particles against the graduation marks on the ASTM bulb. -

Page 72: Verifying The Test Liquid Indication Capability

Requirements Tools required • Comparison block 1, in accordance with EN ISO 9934-2 Magnaflux Order No. 135 011. Procedure Spray test block evenly with test liquid. Hold the test block by the edge and inspect under a UV light. Compare indications on the test block with the illustrations in the test block manual. -

Page 73: Checking The Uv Intensity

Check the of the UV light intensity with manual UV meter readings. Requirements Tools required • J221 UV meter, Magnaflux Order No. 134 001. Procedure Switch on the UV lighting. Wait about 10 minutes for the lamp to reach max. light intensity. -

Page 74: Maintenance Instructions

Maintenance UNIVERSAL WE TOUCH TCODE Maintenance instructions 8.3.1 Drain the compressed air water separator Depending on the quality of the compressed air, more or less water will collect in the water separator of the compressed air maintenance unit. Check the fill level of the water separator: •... -

Page 75: Cleaning The Magnetising Contacts

Requirements Tools required: • Contact grease Tungrease VC563, MAGNAFLUX Item No. 71100-140483 • Steel wool, medium fine Procedure Switch off machine and secure against unauthorised reactivation. Clean the contact points with steel wool to a metallic bright finish. -

Page 76: Machine Transport

Machine transport UNIVERSAL WE TOUCH TCODE Machine transport Transport preparation Decommission the machine prior to transport. Inspect the condition and load bearing capacity of the floor at the intended installation location and along the entire transport route. • The machine must only be installed on a level and firm surface. •... -

Page 77: Unpacking The Machine

• Disconnect the power supply. Machine disassembly, transport and subsequent reassembly must only be carried out by relevantly trained technicians. Please contact the Magnaflux service department with any questions you may have. Transport instructions • Take note of the instructions contained in the operating manual, the general safety instructions, accident prevention regulations and local requirements for transport. -

Page 78: Transporting The Magnetising Station With A Forklift

Machine transport UNIVERSAL WE TOUCH TCODE 9.4.1 Transporting the magnetising station with a forklift WARNING Lifted loads can fall and result in severe injury or damage to material assets. • Machines and machine components must only be lifted or transported with appropriate lifting equipment suitable for the weight and dimensions of the machine. -

Page 79: Transporting The Magnetising Station With A Crane

UNIVERSAL WE TOUCH TCODE Machine transport 9.4.2 Transporting the magnetising station with a crane WARNING Lifted loads can fall and result in severe injury or damage to material assets. • Machines and machine components must only be lifted or transported with appropriate lifting equipment suitable for the weight and dimensions of the machine. -

Page 80: Setting Up The Machine And Commissioning It

Place the machine where unrestricted air flow to the ventilation grilles is ensured. Installation must only be carried out by relevantly trained personnel. Please contact the Magnaflux service department with any questions you may have. The correct set-up positions of the individual components is documented in the installation plan. -

Page 81: Connecting The Power Supply

UNIVERSAL WE TOUCH TCODE Setting up the machine and commissioning it 10.2 Connecting the power supply WARNING High voltages can cause lethal electric shock and burns. Electric connections are to be created • in accordance with the wiring diagram and the information provided on the type plate •... -

Page 82: Connecting The Test Liquid Pump

Setting up the machine and commissioning it UNIVERSAL WE TOUCH TCODE 10.3 Connecting the test liquid pump The test liquid pump is installed next to the test liquid tank and comes equipped with a plug-in supply line. The socket [1] for the test liquid pump is located in the dug-out that also contains the test liquid tank. -

Page 83: Preparatory Tasks

UNIVERSAL WE TOUCH TCODE Setting up the machine and commissioning it 10.4.2 Preparatory tasks Remove unauthorised personnel from the vicinity of the machine. Carry out a visual inspection of the entire machine. Check power supply. Check the fill levels of lubricants and consumables. Set up the machine. -

Page 84: Decommissioning And Disposal

Decommissioning and disposal UNIVERSAL WE TOUCH TCODE Decommissioning and disposal 11.1 Safety instructions for decommissioning WARNING High voltages can cause lethal electric shock and burns. Power terminals on drive controllers may continue to store dangerous voltages up to 3 minutes after disconnecting. Work on the electrical system •... -

Page 85: Final Machine Disposal

UNIVERSAL WE TOUCH TCODE Decommissioning and disposal 11.4 Final machine disposal Requirements Check before disposal that all supply lines to the machine have been disconnected. Request information regarding locally applicable disposal regulations. Separate machine components by: • Metals • Plastics •... - Page 86 Faraday Road, South Dorcan Industrial Estate, Swindon, SN3 5HE, UK Telephone: + 44 (0)1793 524566 Fax: +44 (0)1793 490459 Email: sales.eu@magnaflux.com Web: eu.magnaflux.com Bahnhofstr 94-98, 73457 Essingen, Deutschland Telephone: +49 (0) 7365 81-0 Fax: +49 (0) 7365 81-449 Email: sales.de@magnaflux.com Web: eu.magnaflux.com/de...

Need help?

Do you have a question about the Universal WE TOUCH with TCODE and is the answer not in the manual?

Questions and answers