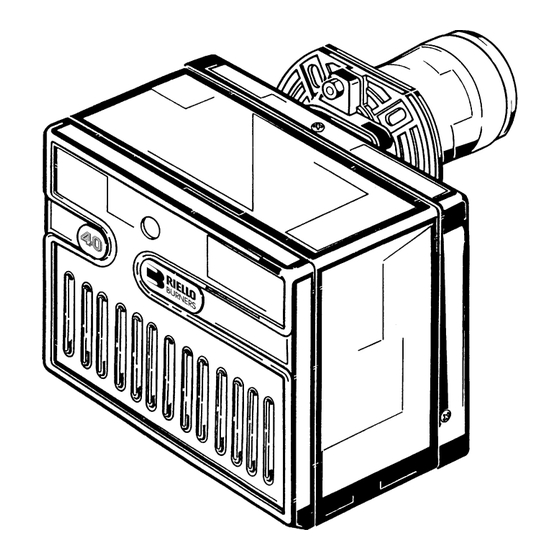

Riello G3B FIREBIRD 70K Installation, Use And Maintenance Instructions

Kerosene and light oil burners

Hide thumbs

Also See for G3B FIREBIRD 70K:

- Installation, use and maintenance instructions (28 pages) ,

- Operation instructions manual (28 pages)

Summary of Contents for Riello G3B FIREBIRD 70K

- Page 1 Installation, use and maintenance instructions Kerosene and light oil burners One stage operation CODE MODEL TYPE 3743757 G3B FIREBIRD 70K 510 T1K 3743771 G3B FIREBIRD 90K 510 T3K 3743772 G3B FIREBIRD 90D 510 T3K 2902809 (2) - 05/2011...

-

Page 3: Table Of Contents

INDEX BURNER DESCRIPTION ....1 WORKING ......6 1.1 Burner equipment . -

Page 4: Burner Equipment

BURNER EQUIPMENT Flange with insulating gasket ..No. 1 4 pole socket ......No. 1 Screw and nut for flange . -

Page 5: Working Field

WORKING FIELD (as EN 267) 510T1K 510T3K Fuel output - kg/h D4361 Thermal power - kW INSTALLATION THE BURNER MUST BE INSTALLED IN CONFORMITY WITH LEGISLATION AND LOCAL STANDARDS. MOUNTING THE BURNER Fix the flange (1) to the boiler door using screw and nuts, interposing the insulating gasket (see fig. 2). The insulating gasket has six holes, which, if necessary, can be modified as shown in the figure 3. -

Page 6: Hydraulic Systems

HYDRAULIC SYSTEMS Fig. 5 WARNING Check periodically the flexible pipes conditions. Using kerosene, they have to be replaced at least every 2 years. A metal bowl filter with replaceable micronic filter must be fitted in the oil supply pipe. The pump is designed to allow working with one pipe. In order to obtain two pipes working it is necessary to unscrew the return plug (2), screw the by-pass screw (3) and then screw again the plug (2). -

Page 7: Electrical Wiring

ELECTRICAL WIRING NOTES WARNING – Wires of min. 1 mm section. Do not exchange the neutral with the phase. (Unless requested otherwise by local stand- ards and legislation). – The electrical wiring carried out by the 230V 50Hz installer must be in compliance with the rules in force in the Country. -

Page 8: Working

WORKING COMBUSTION ADJUSTMENT In conformity with Efficiency Directive 92/42/EEC the application of the burner on the boiler, adjustment and testing must be carried out observing the instruction manual of the boiler, including verification of the CO and concentration in the flue gases, their temperatures and the average temperature of the water in the boiler. To suit the required appliance output, fit the proper nozzle, then adjust the pump pressure and the air damper opening in accordance with the following schedule. -

Page 9: Air Damper Adjustment

AIR DAMPER ADJUSTMENT, (see fig. 11) Fig. 11 The mobile air damper (1) operated by the jack (2) assures the complete opening of the air intake. The regulation of the air-rate is made by adjusting the fixed air damper (3), after loosing the screws (4). When the optimal regulation is reached, screw tight the screws (4) to assure a free movement of the mobile air damper (1). -

Page 10: Maintenance

MAINTENANCE The burner requires periodic maintenance carried out by a qualified and authorised technician in conform- ity with legislation and local standards. Maintenance is essential for the reliability of the burner, avoiding the excessive consumption of fuel and consequent pollution. Before carrying out any cleaning or control always first switch off the electrical supply to the burner acting on the main switch of the system. -

Page 11: Faults / Solutions

FAULTS / SOLUTIONS Here below you can find some causes and the possible solutions for some problems that could cause a fail- ure to start or a bad working of the burner. A fault usually makes the lock-out lamp gas which is situated inside the reset button of the control box (8, fig. - Page 12 RIELLO S.p.A. I-37045 Legnago (VR) Tel.: +39.0442.630111 http:// www.rielloburners.com Subject to modifications...

Need help?

Do you have a question about the G3B FIREBIRD 70K and is the answer not in the manual?

Questions and answers