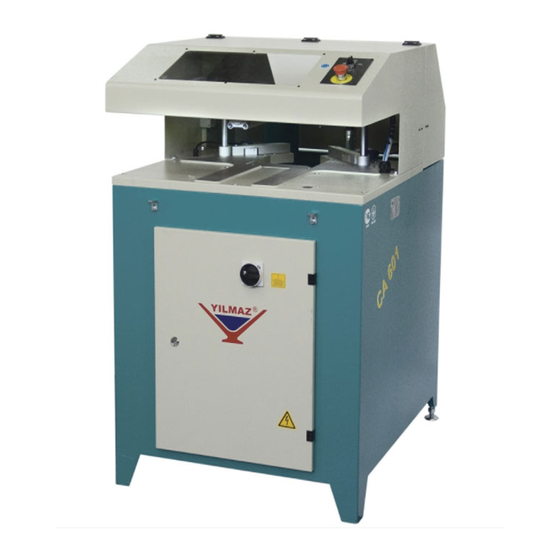

Summary of Contents for YILMAZ CA 601

- Page 1 YILMAZ ADRES TELEFON 0216.312.28.28 PBX TELEFAX 0216.484.42.88 MARKASI YILMAZ MODEL KODU CA 601 2 YIL ADRES TELEFON TELEFAX...

- Page 2 +90 0216 312 2828 fax: +90 0216 484 42 88 yilmaz@yilmazmachine.com.tr Declare on our own responsibility that ; CA 601 PVC CORNER CLEANING MACHINE Meets all the provisions of the 2006/42 EC Machinery Directive, 2006/95 EC Low Voltage Directive, and 2004/108 EC EMC Directive which apply to it...

- Page 3 TECHNICAL FEATURES - 3000 D = 215 mm W = 92 860 W 50 Hz 1200 W 50 Hz CA 601 L = 101 D/dak. max. 6/8 Bar Lt. / dak. 230 V AC P N PE 400 V AC 3P PE...

- Page 4 BOYUTLAR DIMENSIONS -FIGURE-...

- Page 5 - PART LIST - -FIGURE- -FIGURE-...

- Page 6 -FIGURE- -FIGURE-...

- Page 7 -FIGURE-...

- Page 8 STOK KODU ADET STOK KODU ADET STOCK CODE STOCK CODE 1SA010000-0053 3UA630030-0003 2TU012510-0328 87-1 3UA140030-0007 3UA060030-0014 87-3 2TU011110-0042 1SK060000-0004 87-4 2TU011110-0040 2TU011210-0474 1PN020000-0131 2TU014010-0116 1PN020000-0132 2TU012510-0332 1PN020000-0129 2TU012210-0054 1PN020000-0143 1SA050000-0185 99-1 1PN020000-0143 2TU012510-0337 2TU012510-0338 2TU011110-1101 1SC170000-0007...

- Page 9 STOK KODU / CODE PICTURE PART NO 1EL020000-0012...

-

Page 11: Table Of Contents

ENGLISH CONTENTS 1. General information 1.1. Introduction 1.2. Service Information 2. Safety 2.1. Safety Symbols and Their Meanings 2.2. Accidents Prevention 2.3. General Safety Information 4. Transport of the Machine 5. Installation of the Machine 5.1. Preparation 5.2. Connecting to Power Source 7. -

Page 12: General Information

The technical drawings and details contained in this manual constitute a guide for the operator. 1.2. Service Information In case of any technical problem please contact your nearest YILMAZ dealer, or YILMAZ head office through the above mentioned phone, fax or e-mail address. - Page 13 AUTHORIZED TECHNICAL SERVICE CENTER ADDRESS 0216 312 28 28 Pbx. 0216 484 42 88 E-mail service@yilmazmachine.com.tr www.yilmazmachine.com.tr For minimize the documantation, It is wery necessary to mention below details at the agreements signed with suppliers and dealers of the purchased machines Machine model Voltage and frequency Date of purchase...

-

Page 14: Safety

2. SAFETY 2.1. Safety Symbols and Their Meanings Ensure safe working position, always keep your Read the user guide balance. Wear ear protectors Elektrical excitation Wear safety goggles If the power cable should be damaged during operation, don't touch and unplug it. High temperature warning Never use damaged power cables. -

Page 15: Accidents Prevention

2.2. Accidents Prevention 2.2.1 Our machines are manufactured in accordance with CE safety directives, which cover national and international safety directives. 2.2.2 It is the task of the employer to warn his staff against accident risks, to train them on prevention of accidents, to provide for necessary safety equipment and devices for the 2.2.3 It is the task of the employer to warn his staff against accident risks, to train them on prevention of accidents, to 2.2.4 Machine should be operated only by staff members, who have read and understood the contents of this manual. - Page 16 2.3.4 Use correct illumination for the safety of the operator. ( ISO 8995-89 Standard The lighting of indoor work system) 2.3.5 machine. 2.3.6 Ensure that the work piece is clamped appropriately by the machine's clamp or vice 2.3.7 Ensure safe working position, always keep your balance. 2.3.8 Keep your machine always clean for safe operation.

-

Page 17: Transport Of The Machine

Adjustable to different PVC profile types Equipped with centralizing guide ensuring correct placement of profiles onto the set square. Stops automatically after the corner cleaning operation. Maximum profile processing height is 130 mm. (I165 mm profile processing height is provided as option) PLC System, with serial change of blade groups. -

Page 18: Installation Of The Machine

5. INSTALLATION OF THE MACHINE 5.1 Preparation 5.1.1 The machine size and weight measurements, given the technical specification sheet.The ground, where the machine will be placed, should be even, solid enough to bear the weight of the machine 5.1.2 The machine should be located approx. 50 cm away from the rear wall 5.1.3 You can provide the balance of the machine with adjustable counterforts (PICTURE 2 NO 72) in the bottom part. -

Page 21: Connecting To Power Source

5.2 Connecting to Power Source 5.2.1 The Electrical connection must be made by a licensed electrician 5.2.2 The power outlet socket on the machine should be available. 5.2.3 Plug the machine to a grounded socket. 5.2.4 Main voltage of the machine is optional as 230 V 50 Hz or 400 V 50 Hz. 5.2.5 Check type label 5.2.6 After electrical connection is made, machine must be operated in idle running and it must be controlled whether... -

Page 22: Operation

6.5 Never replace the milling cutters before unplugging first. parts 6.7 Do not work on the machine by removing the protective parts The safety data have been defined above. In order to prevent physical damage or damage to the equipment, please read the safety information carefully and keep the manual always in an easy accessible place. -

Page 23: Maintenance, Service And Repair

7.2.3 Put the boiled profile on the plate and justify it properly on the switches (PICTURE 4 NO.58) on set-square (PICTURE 4 NO.26). Clamp will automatically fix the profile. 7.2.4 The machine will carry out the cleaning operation and stop. NOTE: Press emergency button at the moment of potential danger The milling cutters have to be started freely, without touching the profile. -

Page 24: Changing The Cutting Tool

8.2 Changing the cutting tool 8.2.1 Use protective gloves when replacing Saw 8.2.2 Cut the electric connection of the machine. 8.2.3 Open the upper protection cover. (FIGURE 2-NO: 45) 8.2.4 WHEN REPLACING THE MILLING CUTTER GROUP, ENSURE THE CUTTERS ROTATE IN THE CORRECT DIRECTION... -

Page 25: Adjust The Air Pressure

Adjust the air pressure (pneumatic systems) 8.3.1 Pull up pressure adjustment valve. Set adjustment valve to the desired value on manometer by turning it clockwise or counter clockwise. Then lock the valve by pressing it down. 8.3.2 Set the air pressure between 6 and 8 BAR. If air pressure drops below the stated values, accessories operating with pneumatic power do not work. -

Page 26: Troubleshooting Guide

9. TROUBLESHOOTING GUIDE Here are some recommendations for solving urgent problems. If the trouble cannot be solved, or if you have a problem other than those described hereunder, please contact our technical service or your nearest dealer. Provide clamps movement Provide scratching cutters movement FIGURE-7 Provide engine movement... - Page 27 9.2. Error notices on display FIGURE-9 Motor Piston Ahead Sensor S7 Top Tearing Piston Motor Piston Sensor (-S3) at back Sensor S4 Scraping piston is not at the back (-S3) ; Scraping sensor is out of order Motor piston not at the back (-S4) ; (-S3) ;...

- Page 28 Leaning switches are out of order Leaning switches are out of order (-S5 Leaning switches are out of order (LEFT) (-S6) ; (LEFT) (-S5) ; and S6) ; Change switches Change right set square Change left set square switch Motor forward sensor is out of Emergency stop (-S1) or the cover is Motor rear sensor is out of order order (-S7);...

-

Page 29: Warranty Conditions

10. WARRANTY CONDITIONS YILMAZ Machine Industry and Trade Limited Company, guarantees that all machines have been tested and conform to the international standards. The guarantee is valid 24 months from despatch date and does not cover the electrical parts of the machine. - Page 30 ELECTRIC&PNEUMATIC...

- Page 31 3 PHASE ELECTRICAL DIAGRAM SHEET 1...

- Page 32 3 PHASE ELECTRICAL DIAGRAM SHEET 2...

- Page 33 3 PHASE ELECTRICAL DIAGRAM SHEET 3...

- Page 34 3 PHASE ELECTRICAL DIAGRAM SHEET 4...

- Page 35 PNEUMATIC DIAGRAM SHEET 1...

Need help?

Do you have a question about the CA 601 and is the answer not in the manual?

Questions and answers