Summary of Contents for Eaton AirFlex TLC 5004

- Page 1 TLC 5004 - Installation, Operation and Maintenance Manual Airflex Torque Limiting Coupling ®...

-

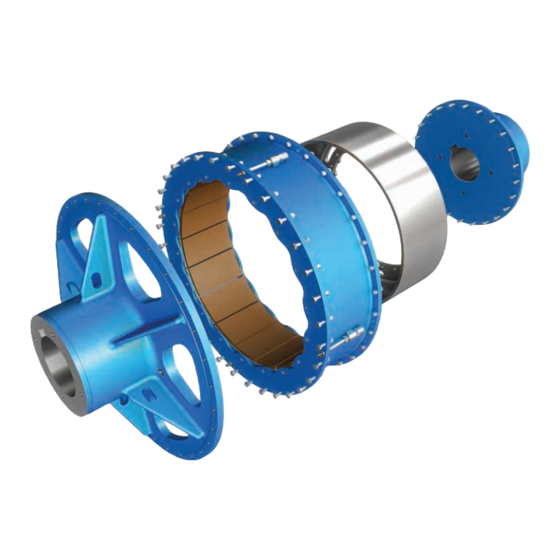

Page 2: Parts Breakdown Of Tlc Hub, Spider, Drum, Axial Locking Assy. And Rotorseal Figure

Eaton warranty. For optimum performance, contact Airflex: In the U.S.A. and Canada: (800) 233-5890 Outside the U.S.A. and Canada: (216) 281-2211 EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 3: Table Of Contents

Parts breakdown of TLC hub, spider, drum, axial locking assy. and rotorseal figure 2 (Standard) Torque bar kit (Standard) Friction shoe assembly, torque bar and release spring kit 10.1 Description axial locking assembly EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... - Page 4 Item Description Item Description Rubber washer Tube Friction shoe assembly Spider Snap rings Side plate (2 required) Drum Torque bar Axial locking assembly Air tube Release spring Rotorseal EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015...

- Page 5 Friction shoe assembly Figure 3 Friction Material in contact with the drum Rubber backed washer Torque bar Drum surface Release spring (Compressed) Contact with drum Drum surface Figure 4 EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015...

-

Page 6: Introduction

At a predetermined level of slippage based on rpm, the TLC controls disengage the TLC element(s) instantaneously by releasing the applied air pressure. EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 7: Tlc Adjustment

(service factor) for mill start up and operation. All TLC’s are supplied with axial locking devices. Single-Wide Mounting Element Spider Drum Rotorseal Drum Hub Axial Locking Assembly Figure 5 EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 8: Mounting Spider And Drum Hub

HUB to LCKG Assy. Size 1-8NC-2 1-8NC-2 1-8NC-2 1-8NC-2 1-8NC-2 Quantity Torque, Lubed 190 (258) "LO" 190 (258) "LO" 190 (258) "LO" 190 (258) "LO" 190 (258) "LO" EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 9: Shaft Alignment

90 degrees. Continue in this manner until four sets of readings have been taken For misalignment correction, use the average of the four readings at each position. Figure 7 EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 10: Axial Locking Device Adjustment

(10) inner race, and must never be allowed to be in shaft (3) groove at bearing lockwasher (14) location after final tightening of bearing locknut (13) EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 11: Installation Of Single Wide Element And Drum

TLC for slippage during operation and disengages the TLC if slippage beyond the allowable user set limits should occur. Refer to the CP3130 TLC Slip control IOM for details. EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 12: Operation

Use normally closed contacts and wire into the motor starter interlock circuit. The purpose of this pressure switch is to prevent starting the motor with the TLC disengaged. EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... - Page 13 If two or more adjacent shoes shoe retraction. are worn on one end only, the air actuating tube has most likely developed a ply separation at that location. EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015...

-

Page 14: Removal Of Element Assembly And Drum

275°F (135°C). 4.5.1 Make sure the torque bars and release springs have been removed from the backing plates. EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... -

Page 15: Assembly Of The Element

4.6.8 Attach the side plate to the rim with cap screws and lockwashers, making sure all of the torque bars are seated in their side plate holes. EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... - Page 16 515147 515147 Spider 513886 510807 514849 515152 515152 Drum 409711 411501 413727 515149 515382 Axial locking 145839DD 145839DU 145839DW 145839EJ 145839EL assembly Rotorseal 105519AA 105519AA 105519AA 105519AA 105519AA EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015...

-

Page 17: 9.1 (Standard) Torque Bar Kit

000073X0051 2 000073X0051 2 000073X0051 2 000073X0051 2 Spacer 000153X0951 16 000153X0951 16 000153X0951 16 000153X0951 16 000153X0951 16 Spacer (Wired to 306987 306987 306987 spider adaptor plate) EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015... - Page 18 Revisions EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015...

- Page 19 Notes EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015...

- Page 20 Eaton Eaton Hydraulics Group USA Eaton Hydraulics Group China Airflex Products Airflex Products 9919 Clinton Road 281 Fa Sai Road Cleveland, Ohio 44144 WaiGaoQiao Free Trade Zone Shanghai 200131 Tel: 216-281-2211 China Fax: 216-281-3890 Tel: (+86 21) 5048 4811 www.eaton.com/airflex Fax: (+86 21) 5048 4911 ©...

Need help?

Do you have a question about the AirFlex TLC 5004 and is the answer not in the manual?

Questions and answers