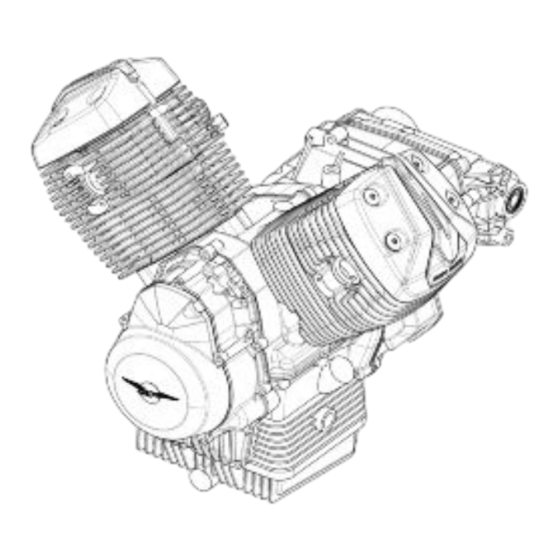

MOTO GUZZI V750 IE Service Station Manual

Hide thumbs

Also See for V750 IE:

- Manual (480 pages) ,

- Workshop manual (153 pages) ,

- Use and maintenance manual (121 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for MOTO GUZZI V750 IE

- Page 1 SERVICE STATION MANUAL B043109 Engine V750 IE...

- Page 2 The reliability of the vehicle also depends on its mechanical conditions. Checking the vehicle before riding it, its regular maintenance and the use of original Moto Guzzi spare parts only are essential factors! For information on the nearest Official Dealer and/or Service Centre consult our website: www.motoguzzi.com...

- Page 3 In order to optimise customer satisfaction when using our vehicles, Moto Guzzi s.p.a. commits itself to continually improve its products and the relative documentation. The main technical modifications and changes in repair procedures are communicated to all Moto Guzzi Sales Outlets and its International Subsidiaries.

-

Page 5: Index Of Topics

INDEX OF TOPICS CHAR HARACTERISTICS S-TOOLS PECIAL TOOLS NGINE... - Page 6 INDEX OF TOPICS CHAR HARACTERISTICS...

-

Page 7: Tightening Torques

Engine V750 IE Characteristics Tightening Torques Engine RANKCASE pos. Description Type Quantity Torque Notes Column nuts 42 Nm (30.98 lbf ft) M8x1.25 22 Nm (16.22 lbf ft) TCEI screw M6x25 10 Nm (7.37 lbf ft) Oil drainage plug M10x1 40 Nm (29.5 lbf ft) Spark plugs 30 Nm (22.13 lbf ft) - Page 8 Engine V750 IE Characteristics IMING SYSTEM COVER pos. Description Type Quantity Torque Notes TCEI screw M6x25 10 Nm (7.37 lbf ft) TCEI screw M6x30 10 Nm (7.37 lbf ft) Alternator cover screws M6x35 10 Nm (7.37 lbf ft) Loctite 243...

- Page 9 Engine V750 IE Characteristics CYLINDER pos. Description Type Quantity Torque Notes Central stud bolt M8x143 20 Nm (14.75 lb ft) Loctite 542 Short stud bolt M10x182 42 Nm (30.98 lb ft) Long stud bolt M10x214 42 Nm (30.98 lb ft) Nuts - pre-tightening M10x1.5...

- Page 10 Engine V750 IE Characteristics IMING SYSTEM pos. Description Type Quantity Torque Notes Tone wheel screw M8x22 25 Nm (18.44 lb ft) Timing system gear screws 25 Nm (18.44 lb ft) Loctite 243 Chain tensioner screw M6x16 10 Nm (7.38 lb ft)

- Page 11 Engine V750 IE Characteristics IL PUMP pos. Description Type Quantity Torque Notes Transmitter joint 25 Nm (18.44 lbf ft) Oil pressure sensor 30 Nm (22.13 lbf ft) Oil pump screws M6x35 10 Nm (7.38 lbf ft) Loctite 648 Oil filter screw 6 Nm (4.43 lbf ft)

- Page 12 Engine V750 IE Characteristics LUTCH pos. Description Type Quantity Torque Notes Clutch shaft nut 100 Nm (73.76 lbf ft) Loctite 243 EARBOX pos. Description Type Quantity Torque Notes Neutral sensor 8 Nm (5.90 lbf ft) Screws M6x14 10 Nm (7.38 lbf ft)

- Page 13 Engine V750 IE Characteristics pos. Description Type Quantity Torque Notes Gearbox cover screws M6x30 10 Nm (7.38 lbf ft) Gearbox cover screws M6x35 10 Nm (7.38 lbf ft) Gearbox cover screws M8x35 22 Nm (16.23 lbf ft) Oil breather plug 20 Nm (14.75 lbf ft)

- Page 14 Engine V750 IE Characteristics EAR SELECTOR pos. Description Type Quantity Torque Notes Index lever screw M6x12 10 Nm (7.38 lbf ft) Loctite 243 Screws M6x16 10 Nm (7.38 lbf ft) LTERNATOR EGULATOR pos. Description Type Quantity Torque Notes Alternator nut 90 Nm (66.38 lbf ft)

- Page 15 Engine V750 IE Characteristics TARTER MOTOR pos. Description Type Quantity Torque Notes Starter motor fixing screws M8x35 25 Nm (18.44 lbf ft) HROTTLE BODY pos. Description Type Quantity Torque Notes Pipe fixing screw M6x22 10 Nm (7.38 lbf ft) CHAR - 15...

- Page 16 INDEX OF TOPICS S-TOOLS PECIAL TOOLS...

- Page 17 Engine V750 IE Special tools ATTREZZI SPECIALI Stores code Description 19.92.73.00 Bushing for fitting seal ring on secondary shaft 19.92.72.20 Tool for fitting seal ring on timing system cover 10.90.72.00 Tool for valve removal and refitting 19.92.61.00 Punch for seal ring of bevel gear set pin- 19.92.88.00...

- Page 18 Engine V750 IE Special tools Stores code Description 19.92.60.00 Punch for gearcase sealing ring 19.90.59.00 Punch for seal ring on clutch shaft 19.92.72.00 Punch for fitting seal ring on gearbox cov- er (secondary shaft) 19.90.65.00 Tool for clutch plate fitting/centring 19.91.18.00...

- Page 19 Engine V750 IE Special tools Stores code Description 19.92.75.00 Extractor for external ring of gearcase bearing 19.92.62.00 Punch for bearing on bevel gear set pin- 19.92.77.00 Transmission gear locking tool for gear- box removal 19.92.63.00 Punch for primary shaft bearing on gear- 19.92.64.00...

- Page 20 Engine V750 IE Special tools Stores code Description 19.92.78.00 Adapter bushing for valve removing tool 19.92.79.00 Punch for pressing bearing inner ring on- to drilled pin 12.91.20.00 Tool to fit the flywheel-side flange togeth- er with sealing ring on the crankshaft 19.92.71.00...

- Page 21 Engine V750 IE Special tools Stores code Description 19.92.60.20 Punch for cap installation on valve guide. 19.92.73.20 Tool for fitting seal ring on camshaft tim- ing system cover 19.92.64.60 Inserting tool for outer ring of secondary shaft bearing S-TOOLS - 21...

- Page 22 INDEX OF TOPICS NGINE...

- Page 23 Engine V750 IE Engine Gearbox Diagram EARBOX pos. Description Type Quantity Torque Notes Main shaft nuts 60 Nm (44.25 lbf ft) ENG - 23...

- Page 24 Engine V750 IE Engine EAR SELECTOR pos. Description Type Quantity Torque Notes Index lever screw M6x12 10 Nm (7.38 lbf ft) Loctite 243 Screws M6x16 10 Nm (7.38 lbf ft) LUTCH pos. Description Type Quantity Torque Notes Crown screws M6x16 10 Nm (7.38 lbf ft)

- Page 25 Engine V750 IE Engine LUTCH pos. Description Type Quantity Torque Notes Clutch shaft nut 100 Nm (73.76 lbf ft) Loctite 243 Gearbox ENG - 25...

-

Page 26: Removing The Gearbox

Engine V750 IE Engine EARBOX pos. Description Type Quantity Torque Notes Neutral sensor 8 Nm (5.90 lbf ft) Screws M6x14 10 Nm (7.38 lbf ft) Gearbox cover screws M6x30 10 Nm (7.38 lbf ft) Gearbox cover screws M6x35 10 Nm (7.38 lbf ft) - Page 27 Engine V750 IE Engine Disassembling the gearbox • Remove the gearbox • Fit the clutch shaft onto the gearbox so that the gear becomes engaged with the primary shaft gear. • Install the specified locking tool onto the clutch shaft splines.

- Page 28 Engine V750 IE Engine • Remove the gear and the clutch shaft. • Unscrew the breather cap with its pawl. • Unscrew and remove the neutral indi- cator. ENG - 28...

- Page 29 Engine V750 IE Engine • Unscrew the gearbox cover bolts and remove the cover tapping it with a mal- let. • Slacken the lock nut and unscrew the pre-selector positioning eccentric screw. ENG - 29...

- Page 30 Engine V750 IE Engine • Slide off the pre-selector and remove the pre-selector seal ring. • After unscrewing the retaining plate fixing screws, remove the complete set of gears, shafts and forks. See also Removing the gearbox ENG - 30...

-

Page 31: Disassembling The Clutch Shaft

Engine V750 IE Engine Disassembling the clutch shaft • Remove the clutch bell. • Undo the three screws with washers and remove the bearing retaining plate. • Undo the clutch shaft fixing nut. • Slide off the clutch shaft and remove the seal ring. - Page 32 Engine V750 IE Engine See also Clutch bell removal Assembling the clutch shaft • Fit the clutch shaft using a plastic mal- let and refit circlip and seal ring. ENG - 32...

-

Page 33: Gear Selector

Engine V750 IE Engine • Position the retaining plate and tighten the screws with their washers with threadlocker. Gear selector Reassembling the gear selector • After refitting the complete shaft as- sembly to the gearbox cover, insert the spring and insert the two tangs onto the... - Page 34 Engine V750 IE Engine • Refit the eccentric screw to the cover together with its lock nut and make sure that the eccentric end of the screw is facing the selector nut. • Refit the selector spacer. ENG - 34...

- Page 35 Engine V750 IE Engine • Fit the selector onto the cover making sure that the two tangs of the spring lo- cate into the adjuster screw groove, then turn the screw by 90° and tighten the lock nut. • Refit the gasket and tighten the gear- box cover fixing screws to the prescri- bed torque.

- Page 36 Engine V750 IE Engine • Insert the gear with its washer onto the gearbox primary shaft, tighten the re- taining nut to the prescribed torque and squash with a punch. ENG - 36...

-

Page 37: Removing The Flywheel

Engine V750 IE Engine Flywheel RANKSHAFT pos. Description Type Quantity Torque Notes Oil plug 15 Nm (11.06 lbf ft) Loctite 601 Connecting rod screws 33 Nm (24.34 lbf ft) Flywheel screws 42 Nm (30.98 lbf ft) Loctite 243 Removing the flywheel •... - Page 38 Engine V750 IE Engine • Unscrew the screws securing the pres- sure plate flywheel to the crankshaft and then remove it. Checking • Check that the flywheel surface that contacts the plate is not scratched. • Check that the contact faces on the crankshaft are not distorted;...

-

Page 39: Installing The Flywheel

Engine V750 IE Engine Installing the flywheel • When refitting the pressure plate fly- wheel onto the crankshaft, make sure the "yellow mark" on the shaft is per- fectly aligned with the slot on the en- gine flywheel. • Tighten the screws and fit the specified flywheel locking tool. - Page 40 Engine V750 IE Engine Generator IMING SYSTEM COVER pos. Description Type Quantity Torque Notes TCEI screw M6x25 10 Nm (7.37 lbf ft) TCEI screw M6x30 10 Nm (7.37 lbf ft) Alternator cover screws M6x35 10 Nm (7.37 lbf ft) Loctite 243...

-

Page 41: Removing The Generator

Engine V750 IE Engine LTERNATOR EGULATOR pos. Description Type Quantity Torque Notes Alternator nut 90 Nm (66.38 lbf ft) Loctite 243 Front cover fixing screws M5x65 6 Nm (4.43 lbf ft) Removing the generator • Unscrew the fixing screws and remove the alternator unit protection covers. - Page 42 Engine V750 IE Engine • Unscrew the screws fixing the stator to the timing system cover and slide off the stator. • Unscrew the nut fixing the rotor to the crankshaft, slide off the rotor, remove the key and collect the washer.

-

Page 43: Installing The Generator

Engine V750 IE Engine Installing the generator • Insert supporting washer, key and ro- tor, and tighten the nut to the prescri- bed torque with a torque wrench. • Fit stator and cover and tighten the three screws. ENG - 43... -

Page 44: Revolution Sensor

Engine V750 IE Engine • Fit stator cover. • Tighten the five cover fixing screws to the prescribed torque. Revolution sensor • Undo and remove the two screws and remove the sensor. ENG - 44... -

Page 45: Starter Motor

Engine V750 IE Engine • Position the engine speed sensor on the timing system cover and tighten the two fastening screws to the prescribed torque. Starter motor TARTER MOTOR pos. Description Type Quantity Torque Notes Starter motor fixing screws M8x35 25 Nm (18.44 lbf ft) -

Page 46: Removing The Starter Motor

Engine V750 IE Engine Removing the starter motor • Remove the starter motor fixing screws. • Slide off the starter motor. Clutch side ENG - 46... - Page 47 Engine V750 IE Engine EARBOX pos. Description Type Quantity Torque Notes Neutral sensor 8 Nm (5.90 lbf ft) Screws M6x14 10 Nm (7.38 lbf ft) Gearbox cover screws M6x30 10 Nm (7.38 lbf ft) Gearbox cover screws M6x35 10 Nm (7.38 lbf ft)

- Page 48 Engine V750 IE Engine • Loosen the Allen screws that secure the clutch bell to the gearbox. • Detach and remove the clutch bell to- gether with the clutch shaft tapping lightly around clutch bell edge. ENG - 48...

-

Page 49: Disassembling The Clutch

Engine V750 IE Engine • Remove the gasket. Disassembling the clutch • Remove the clutch cover. • Fit the specified flywheel locking tool on the crankcase. Specific tooling 19.91.18.00 Flywheel locking tool • Unscrew the clutch plate fixing screws and remove clutch plate together with starting sprocket. -

Page 50: Checking The Clutch Plates

Engine V750 IE Engine • Remove the clutch plate. Checking the clutch plates Clutch plates Make sure that the clutch plate is not scratched or badly worn. Check the flexible coupling springs and make sure that clutch plate thickness is not lower than the specified value: if so, replace the clutch plate. -

Page 51: Assembling The Clutch

Engine V750 IE Engine Assembling the clutch • Install the flywheel locking tool. Specific tooling 19.91.18.00 Flywheel locking tool • Insert the cap with its seal ring. • Position the specified clutch plate cen- tring tool on the plate and fit the plate into place. - Page 52 Engine V750 IE Engine • Fit the assembly on the pressure plate flywheel and tighten the screws to the prescribed torque. Clutch bell fitting • Fit the clutch shaft. • Position the clutch bell gasket and fit the clutch bell into place.

- Page 53 Engine V750 IE Engine • Snug the Allen nuts and the external screws and tighten them to the prescri- bed torque. • Tighten the clutch shaft nut using the suitable tool and squash. Specific tooling 19.90.71.60 Clutch shaft locking equipment •...

- Page 54 Engine V750 IE Engine • Tighten the neutral switch. • Insert the clutch control rod into the shaft with the larger diameter facing the control lever. Head and timing CYLINDER pos. Description Type Quantity Torque Notes Central stud bolt M8x143 20 Nm (14.75 lb ft)

-

Page 55: Removing The Head Cover

Engine V750 IE Engine pos. Description Type Quantity Torque Notes Long stud bolt M10x214 42 Nm (30.98 lb ft) Nuts - pre-tightening M10x1.5 25 Nm (18.44 lb ft) Nuts - tightening M10x1.5 42 Nm (30.98 lb ft) Column nut 25 Nm (18.44 lb ft) 28 Nm (20.65 lb ft) - Page 56 Engine V750 IE Engine • Loosen the central fastening screws • Remove the head cover • Remove the gasket • Check that the mating faces that contact the heads are not damaged or blistered. Removing the cylinder head • The following instructions refer to one head, but apply to both.

- Page 57 Engine V750 IE Engine • Loosen the fastening nuts of the rocker cam tower. See also Removing the head cover • Remove the rocker cam tower and col- lect the plates • Remove the rocker rods • Remove the outer nuts that fix the head...

-

Page 58: Cylinder Head

Engine V750 IE Engine • Remove the internal screws fixing the head to the cylinder • Remove the complete head from the cylinder • Remove the cylinder head gasket Cylinder head Removing the rocker arms NOTE THE FOLLOWING OPERATIONS REFER TO REMOVING ONLY ONE HEAD BUT APPLY TO BOTH HEADS. - Page 59 Engine V750 IE Engine • Remove the circlips, slide off the two rockers and the oil delivery fitting. See also Removing the head cover ENG - 59...

-

Page 60: Removing The Valves

Engine V750 IE Engine Removing the valves • Place the special tool on the upper cap of the valve to be removed and at the centre of the head of the valve. Specific tooling 10.90.72.00 Tool for valve removal and refitting 19.92.78.00 Adapter bushing for valve remov-... - Page 61 Engine V750 IE Engine • Remove the valve guide seals and ex- tract the lower cap of the springs. VALVE GUIDES MUST BE REPLACED WHEN THEY ARE WORN TO THE POINT THAT REPLACING THE VALVE ALONE IS NOT ENOUGH TO ELIMINATE CLEARANCE BE- TWEEN VALVE STEM AND VALVE GUIDE BORE.

-

Page 62: Checking The Rocker Arms

Engine V750 IE Engine • Valve guides need to be knocked out tapping from the inside with punch and mallet; heat the head up to approxi- mately 50-60 °C to aid removal. Specific tooling 19.92.60.20 Punch for cap installation on valve guide. - Page 63 Engine V750 IE Engine Unloaded length PRING SPECIFICATIONS Specification Desc./Quantity Inside diameter 17.8 ± 0.2 mm (0.7007 ± 0.0079 in) Wire diameter 3.4 ± 0.03 mm (0.1338 ± 0.0012 in) Unloaded length 43.6 mm (1.7165 in) Compressed length 27.5 mm (1.0827 in) Test length L1 36 mm (1.4173 in)

-

Page 64: Checking The Cylinder Head

Engine V750 IE Engine Specification Desc./Quantity Detected test load P1 17.6 ± 5% Kg (38.8013 ± 5% lb) Detected test load P2 44 ± 3% Kg (97.0033 ± 3% lb) Hand right Spring class according to UNI 7900/4 Checking the cylinder head CAUTION VALVE SEAT GRINDING AFTER VALVE GUIDE REPLACEMENT OR WHEN THE VALVES LEAK. - Page 65 Engine V750 IE Engine • Insert the T handle into the cutter and turn clockwise while pressing lightly achieving an even valve contact sur- face. • Repeat the procedure using the suita- ble cutter to achieve the correct valve seat sealing surface.

-

Page 66: Installing The Valves

Engine V750 IE Engine • Remove any tools you have used to complete the procedure. • Insert the lower spring seats and fit the seal rings onto the valve guide using the specified tool. Installing the valves • Press the valve guides into the heads from the outside towards the inside us- ing punch and mallet;... - Page 67 Engine V750 IE Engine INTAKE A Ø mm (in) B (nominal) Ø mm (in) C (nominal) Ø mm (in) D mm (in) 32.0-32.25 (1.2598-1.2697) 34 (1.3386) 1.42 (0.0559) 1 (0.0394) EXHAUST A Ø mm (in) B (nominal) Ø mm (in) C (nominal) Ø mm (in) D mm (in) 27.72-27.97 (1.0913-1.1012)

- Page 68 Engine V750 IE Engine Installing the rocker arms • Make sure that the longitudinal slot is pointing to the oil delivery passage. WHEN REFITTING, PAY SPECIAL ATTENTION TO THE MOUNTING POSITION OF THE WASHERS. • Insert the oil delivery fitting and the rockers on the shaft and lock them in place with the circlips.

-

Page 69: Adjusting Valve Clearance

Engine V750 IE Engine • Check that the rocker rods are straight and that the contact surfaces at the ends show no signs of seizing; other- wise, replace it. • To check the pressed ends on the rods (pads) for looseness, simply drop the rods from a small height on a flat sur- face;... - Page 70 Engine V750 IE Engine • Use a feeler gauge to check that the clearance between the valve and the set screw corresponds with the indica- ted values. When the valve clearance values, intake and exhaust respective- ly, are different from the ones indicated...

- Page 71 Engine V750 IE Engine Timing IMING SYSTEM COVER pos. Description Type Quantity Torque Notes TCEI screw M6x25 10 Nm (7.37 lbf ft) TCEI screw M6x30 10 Nm (7.37 lbf ft) Alternator cover screws M6x35 10 Nm (7.37 lbf ft) Loctite 243...

- Page 72 Engine V750 IE Engine IMING SYSTEM pos. Description Type Quantity Torque Notes Tone wheel screw M8x22 25 Nm (18.44 lb ft) Timing system gear screws 25 Nm (18.44 lb ft) Loctite 243 Chain tensioner screw M6x16 10 Nm (7.38 lb ft)

-

Page 73: Removing The Chain Tensioner

Engine V750 IE Engine Removing the chain tensioner • Remove the timing system cover. • Remove the chain tensioner. • Collect the washer. See also Timing Chain removal • Remove the tone wheel. • Remove the two screws, slide the tim- ing gear off the shaft, remove chain and oil pump gear. - Page 74 Engine V750 IE Engine See also Removing the phonic wheel Removing the phonic wheel • Remove the engine unit from the chas- sis. • Remove the timing system cover. • Remove the chain tensioner. • Unscrew and remove the tone wheel fixing screw and collect the washer.

-

Page 75: Cam Timing

Engine V750 IE Engine Installing the phonic wheel • Tone wheel position is dictated by the pin on the camshaft. • Position the tone wheel making sure it locates correctly on the camshaft (see slot) and tighten to the prescribed tor- que using a torque wrench. - Page 76 Engine V750 IE Engine • Place the camshaft with the reference pin of the gear pointing downwards. • Insert the oil pump shaft (pin) key. • Fit the two gears with the timing chain; after installation, check the position of...

- Page 77 Engine V750 IE Engine • Tighten the oil pump nut while holding the oil pump shaft steady. • Fit the chain tensioner and tighten to the prescribed torque using a torque wrench. ENG - 77...

- Page 78 Engine V750 IE Engine Cylinder-piston assembly CYLINDER pos. Description Type Quantity Torque Notes Central stud bolt M8x143 20 Nm (14.75 lb ft) Loctite 542 Short stud bolt M10x182 42 Nm (30.98 lb ft) Long stud bolt M10x214 42 Nm (30.98 lb ft) Nuts - pre-tightening M10x1.5...

-

Page 79: Removing The Cylinder

Engine V750 IE Engine Removing the cylinder • Remove the head. • Slide off the cylinder from the stud bolts. • Remove the gasket from the stud bolts See also Removing the cylinder head • Remove the O-ring of the lubrication... -

Page 80: Disassembling The Piston

Engine V750 IE Engine Disassembling the piston • After protecting the cylinder seat, re- move the two snap rings that retain the piston pin • Slide off the pin using the specified tool (turn the tool screw) and remove the piston. -

Page 81: Checking The Piston

Engine V750 IE Engine 2. 2nd measurement 3. 3rd measurement 4. measurement for classification Checking the piston • After checking for scoring, check cylin- der surface wear using a dial gauge graduated in hundredths of a millime- tre. • Measure the inner diameter of the cyl-... -

Page 82: Inspecting The Piston Rings

Engine V750 IE Engine Inspecting the piston rings PISTON RINGS AND OIL SCRAPER REMOVAL • Remove piston rings and oil scraper. CAUTION PUSH THE PISTON RING END GAPS APART JUST ENOUGH TO EASE THE PISTON RINGS OFF THE PISTON TO AVOID BREAKING THEM •... -

Page 83: Fitting The Piston

Engine V750 IE Engine Fitting the piston • To refit the piston into the connecting rod small end, heat up the piston in an oil bath up to approximately 60°C (140° F); this will cause the piston to expand slightly and facilitate pin insertion. -

Page 84: Installing The Cylinder

Engine V750 IE Engine Installing the cylinder • Check that the piston ring end gaps are approximately 120 degrees from each other. • Position the O-ring on the lubrication duct of the thermal unit • Fit a new gasket •... - Page 85 Engine V750 IE Engine • As soon as past the piston ring area, remove the piston ring compressor clamp from the piston and insert the cylinder into its seat. • Install the head. See also Installing the cylinder head Selecting the cylinder YLINDER SELECTION Ø...

-

Page 86: Installing The Cylinder Head

Engine V750 IE Engine • Check that the piston bears the selec- tion mark and the arrow that denotes mounting position. ISTON Ø SELECTION GRADE "D" mm (in) GRADE "E" mm (in) GRADE "F" mm (in) 79.940 - 79.950 (3.1472 - 3.1476) 79.950 - 79.960 (3.1476 - 3.1480) - Page 87 Engine V750 IE Engine • Fit the rocker lower spacers, the rocker control rods, the rockers and the upper spacers with their nuts. ENG - 87...

- Page 88 Engine V750 IE Engine • Tighten the nuts to the prescribed tor- que following a crisscross pattern. Installing the head cover • Replace the head cover gaskets and refit the covers to the heads. ENG - 88...

- Page 89 Engine V750 IE Engine • Tighten the screws following a criss- cross pattern with a torque wrench set to the prescribed torque. ENG - 89...

-

Page 90: Crankcase - Crankshaft

Engine V750 IE Engine Crankcase - crankshaft RANKCASE pos. Description Type Quantity Torque Notes Column nuts 42 Nm (30.98 lbf ft) M8x1.25 22 Nm (16.22 lbf ft) TCEI screw M6x25 10 Nm (7.37 lbf ft) Oil drainage plug M10x1 40 Nm (29.5 lbf ft) Spark plugs 30 Nm (22.13 lbf ft) -

Page 91: Splitting The Crankcase Halves

Engine V750 IE Engine RANKSHAFT pos. Description Type Quantity Torque Notes Oil plug 15 Nm (11.06 lbf ft) Loctite 601 Connecting rod screws 33 Nm (24.34 lbf ft) Flywheel screws 42 Nm (30.98 lbf ft) Loctite 243 Splitting the crankcase halves •... - Page 92 Engine V750 IE Engine • Remove the upper crankcase being careful not to damage its mating face. • Remove the crankshaft together with connecting rods and half-bearings. Unscrew the oil pressure sensor from the upper crankcase and remove the retaining bushing of the camshaft;...

-

Page 93: Removing The Crankshaft

Engine V750 IE Engine Removing the crankshaft • Remove the crankshaft connecting rods. • Unscrew the oil plug and thoroughly clean the oilway and oil passages de- livering oil to connecting rods and main journals. ENG - 93... - Page 94 Engine V750 IE Engine See also Disassembling the connecting rod Disassembling the connecting rod After removing the crankshaft together with the connecting rods from the upper crankcase, loosen the screws and separate connecting rod from small end noting the reference marks and mount- ing direction.

-

Page 95: Inspecting The Crankcase Halves

Engine V750 IE Engine Inspecting the crankcase halves • Check that the mating faces are not damaged, dented or scored. Remove any liquid gasket residues with thry- chlorethylene. • Check that the threads of the stud bolts are not dented or stripped; if they are, replace the stud bolt or stud bolts. -

Page 96: Inspecting The Crankshaft Components

Engine V750 IE Engine Inspecting the crankshaft components • Smear the thread of the cap with threa- dlocker and tighten the cap firmly. • Blow with compressed air to clean the lubrication passage seats. CAUTION THE CRANKSHAFT IS NITRIDED AND CANNOT BE GROUND;... -

Page 97: Checking The Connecting Rod

Engine V750 IE Engine Checking the connecting rod • Measure connecting rod pin diameter across the pin and again at 90° degrees away. Meas- ure bearing seats on both timing system and flywheel side at the half-bearing locations. • Assemble the connecting rod without half-bearings and tighten the connecting rod screws to the prescribed torque. -

Page 98: Refitting The Crankcase Halves

Engine V750 IE Engine Assembling the connecting rod • Before installation, pay attention to ref- erence marks and mounting direction. • Reassemble the connecting rods on the connecting rod pin in the crankshaft seat and tighten the screws to the pre- scribed torque. - Page 99 Engine V750 IE Engine • Insert the camshaft into the seat in the upper crankcase, lubricate and insert locking the camshaft locking fitting. • Insert the timing system side and fly- wheel side half-bearings with their thrust washers into the seats in the up- per crankcase.

- Page 100 Engine V750 IE Engine • Insert the seal ring (after lubricating it) on the crankshaft and the assembly onto the engine crankcase making sure that the connecting rods locate correctly into their seats. ENG - 100...

- Page 101 Engine V750 IE Engine • Fit the half-bearings (lubricate them first) into the lower crankcase; apply the specified liquid gasket to the crank- case mating faces • Join the two crankcase halves and tap lightly with a mallet to ensure that the two mating faces adhere together firm- ly;...

- Page 102 Engine V750 IE Engine Lubrication RANKCASE pos. Description Type Quantity Torque Notes Column nuts 42 Nm (30.98 lbf ft) M8x1.25 22 Nm (16.22 lbf ft) TCEI screw M6x25 10 Nm (7.37 lbf ft) Oil drainage plug M10x1 40 Nm (29.5 lbf ft) Spark plugs 30 Nm (22.13 lbf ft)

-

Page 103: Oil Pump

Engine V750 IE Engine Oil pump IL PUMP pos. Description Type Quantity Torque Notes Transmitter joint 25 Nm (18.44 lbf ft) Oil pressure sensor 30 Nm (22.13 lbf ft) Oil pump screws M6x35 10 Nm (7.38 lbf ft) Loctite 648 Oil filter screw 6 Nm (4.43 lbf ft) - Page 104 Engine V750 IE Engine • Remove the retaining key. • Slide off the pump drive shaft with the internal rotor attached. • Slide off the external rotor. • Slide off the bearings and their inner housing from pump body. ENG - 104...

- Page 105 Engine V750 IE Engine Inspection OIL PUMP BODY Check that the faces and inner seats of the oil pump body are not scored, damaged or dented. Pump body specifications • External rotor seat Ø 40.650 - 40.675 mm (1.6004 - 1.6014 in);...

- Page 106 Engine V750 IE Engine • External rotor seat thickness 15.030 - 15.070 mm (0.5917 - 0.5933 in). EXTERNAL ROTOR Check that the inner and outer surfaces and the flat faces are not scored, damaged or dented; if they are, replace both rotors.

- Page 107 Engine V750 IE Engine OIL PUMP DRIVE SHAFT Check shaft and thread for damage; check the keyway for burrs and make sure the head the runs in the rotor is not damaged; replace the shaft if needed. Shaft specifications: •...

- Page 108 Engine V750 IE Engine Removing the oil sump • Remove the engine oil filter. • Unscrew the screws fixing the oil sump to the engine crankcase, remove the oil sump and the gasket. ENG - 108...

- Page 109 Engine V750 IE Engine • Remove the oil level indicator. • Straighten the safety plate, remove the mesh filter retaining screw from the oil sump and remove the mesh filter. • Check that the mesh filter is not dirty, wash and blow with compressed air if needed.

- Page 110 Engine V750 IE Engine Refitting the oil sump • Insert filter, safety plate and fixing screw, then tighten the screw. • Bend the safety plate. • Position the gasket between the sump and crankcase (always change the gasket). Pay attention during the pro- cedure;...

- Page 111 Engine V750 IE Engine • Tighten the sump screws following a crisscross pattern to the prescribed tor- que using a torque wrench. • Insert the filter cartridge and tighten the screw to the prescribed torque. Pressure reducer valve REMOVAL •...

- Page 112 Engine V750 IE Engine FITTING • Insert the valve first and then the spring, apply threadlocker to the screw and tighten to the prescribed torque. ENG - 112...

- Page 113 Alternator: Chain: 73, 74 Chain tensioner: 73, 74 Clutch: 31, 32, 46, 47, 49–52 Crankcase: 90, 91, 95, 98 Crankshaft: 90, 93, 96 Cylinder: 56, 58, 64, 79, 80, 84–86 Exhaust: Head cover: 55, 57, 59, 88 Oil sump: 108, 110 Starter motor: 45, 46 Throttle body:...

Need help?

Do you have a question about the V750 IE and is the answer not in the manual?

Questions and answers