EC POWER XRGI 15 Installation Manual

Hide thumbs

Also See for XRGI 15:

- Maintenance instruction (56 pages) ,

- Commissioning instruction (50 pages) ,

- User manual (36 pages)

Summary of Contents for EC POWER XRGI 15

- Page 1 I N S T A L L A T I O N G U I D E F O R P R O F E S S I O N A L S 01DOC1043 VERSION 1.0 2018...

-

Page 2: Table Of Contents

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 TA B L E O F C O N T E N T S 1. DOCUMENTATION INFORMATION 1.1 ORIGINAL OPERATING INSTRUCTION 1.2 APPLICABLE DOCUMENTS 1.3 KEEP THE DOCUMENTS 1.4 SYMBOLS USED 1.5 RATING PLATE 1.6 VALIDITY OF THE GUIDE 1.7 CE MARKING 2. - Page 3 4.6 INSTALLATION OF THE XRGI® SYSTEM 4.6.1 SOUND INSULATION 5. INSTALLATION 5.1 HYDRAULIC INSTALLATION 5.1.1 EC POWER STANDARD HYDRAULIC SYSTEM 5.1.2 INSTALLATION Q-HEAT DISTRIBUTOR – POWER UNIT 5.1.2.1 PRIMARY CIRCUIT – FLOW AND RETURN CONNECTION 5.1.3 INSTALLATION Q-HEAT DISTRIBUTOR – STORAGE TANK/CONSUMER NETWORK 5.1.3.1 SECONDARY CIRCUIT –...

-

Page 4: Documentation Information

Please read this XRGI® installation guide carefully before installation and commission. Only a correct assembling, installation and operation of the XRGI® system according to the specifications from EC POWER ensures proper functioning and a valid warranty. Please keep this XRGI® installation guide for later reference. EC POWER continuously improves its pro- ducts and reserves the right to make technical changes and to implement these changes if considered necessary. - Page 5 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 Q - H E AT D I S T R I B U T O R The rating plate is located on the inside of the Q-Heat Distributor below the electronics box. L e g e n d Q-Heat Distributor serial no.

-

Page 6: System Components

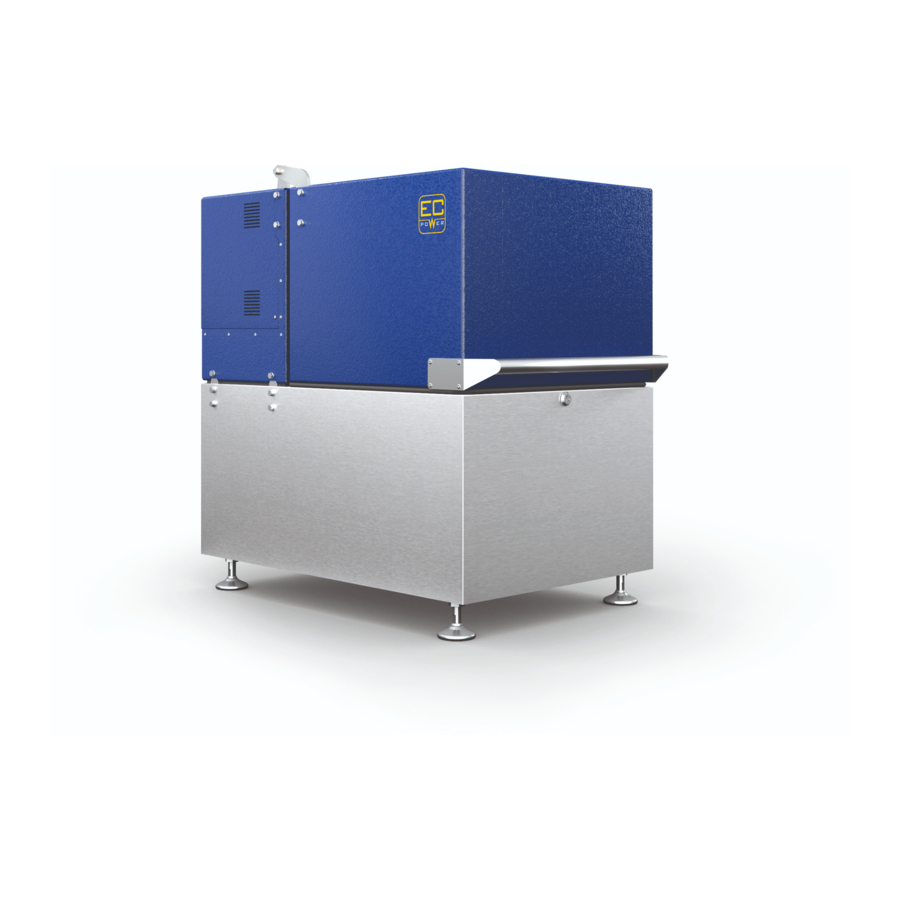

XRGI - INSTALLATION GUIDE VERSION 1.0 2018 ® S Y S T E M C O M P O N E N T S An XRGI® system consists of three main components: the Power Unit, the Q-Heat Distributor and the iQ-Control Panel. The XRGI®... -

Page 7: Power Unit

Sound- and heat-insulated engine compartment Silencer (integrated) Water-cooled generator Exhaust gas cooler (not visible) Oil sump EC POWER gas engine Oil separator Catalyst (not visible (patented)) Primary circuit flow (1“ G) Fig. 2.05 - XRGI® 6/9 Primary circuit return (1“ G) - Page 8 Air filter and mixture control Sound- and heat-insulated engine compartment Silencer (integrated) Water-cooled generator Exhaust gas cooler (not visible) Oil sump EC POWER gas engine Oil separator Fig. 2.08 - XRGI ® Fig. 2.11 - XRGI® 20 Catalyst (not visible (patented)) Primary circuit flow (1¼“...

-

Page 9: Iq-Control Panel

Unit and the Q-Heat Distributor ■ Central Control PCB with integrated modem system processor: Sends data to the EC POWER service database via mobile network C O N F I G U R AT I O N The iQ-Control Panel is operated using its front panel and turned on and off using the main switch disconnector on the left side. -

Page 10: Q-Heat Distributor

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 2.1.3 Q - H E AT D I S T R I B U T O R C O N S T R U C T I O N Legend: Expansion vessel RJ45 connector Flow and return connection to the Power Unit Flow and return connection to the storage tank/consumer network... -

Page 11: Xrgi® System Accessories

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 X R G I ® S Y S T E M A C C E S S O R I E S 2.2.1 Q-NETWORK The XRGI® control system is based on two logical networks: ■... -

Page 12: Storage Control

The Storage Control organises the management of the storage tank (filling and emptying). Each XRGI® system needs at least one Storage Control. A Storage Control is needed if no EC POWER storage tank is used. When using an EC POWER storage tank, the required storage controls are included. -

Page 13: Flow Master Control

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 2.2.1.2 F L O W M A S T E R C O N T R O L Fig. 2.21 - Flow Master Control Modules Flow Master Control unit, four PT100 sensors, one Q-Network cable S CO P E O F D EL IVERY PT100 sensor cable C A BL E D I M EN SI O N S... -

Page 14: Flow Master

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 2.2.1.3 F L O W M A S T E R Fig. 2.22 - Flow Master FM 50 FM 150 FM 250 FM 350 S CO P E O F D EL IVERY FM type (temperature controller, class II = 2 %) Flow Master, Flow Master Control Unit, four PT100 sensors, one Q-Network cable, Modules... -

Page 15: Boiler Control

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 2.2.1.4 B O I L E R C O N T R O L Fig. 2.23 - Boiler Control Modules Boiler Control unit, one green system plug, one Q-Network cable S CO P E O F D EL IVE RY Q-Network cable C A B L E D I M E NSI O N S Dimensions, W x H x D... - Page 16 The XRGI® controller guarantees the operating mode (on, off or modulating mode) on the XRGI® system. Here, the storage tank plays a key role and enables the management of the storage tank to be separated from the heat and the power production. The EC POWER control individually defines the optimum mode of operation for each property based on: ■...

- Page 17 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 2.2.1.6 E L E C T R I C H E A T E R C O N T R O L Fig. 2.28 - Electric Heater Control S CO P E O F D E L I VE RY Modules Electric Heater Control unit, one control cable Control cable...

-

Page 18: Modbus Gateway

C O N N E C T I O N T O E X T E R N A L S Y S T E M S External systems can be connected to the RS485 bus via the Modbus RTU. The data registers within the Modbus protocol are kept up to date by the EC POWER control software and/or read by the external control. - Page 19 The storage volume of 500 litres per XRGI® system should not be undercut. The EC POWER storage tank with external Storage Control ensures that heat produced in the XRGI® system is stored when the consumer uses less heat than expected or no heat. This prevents the XRGI® system from cutting in and out, and the operation of the XRGI® system becomes more efficient after start-up with longer production times.

- Page 20 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 D I M E N S I O N S A N D C O N N E C T I O N S Fig. 2.36 – Storage tank 500 litres. 1/2" 1/2"...

-

Page 21: Load Sharer S

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 2.2.1.9 L O A D S H A R E R S Fig. 2.38 - Load Sharer S Modules Load Sharer unit, one Q-Network cable S CO P E O F D E L I VE RY Q-Network cable C A B L E D IME N SI O N Dimensions, W x H x D... - Page 22 S A F E T Y I N S T R U C T I O N Please read the following chapter carefully and adhere to the safety instructions. Please contact your EC POWER dealer if you are unsure about anything or do not understand the safety instructions. The XRGI® system was developed in accordance with the rules of technology and complies with and applies recognised, conventional safety measures.

- Page 23 ■ compliance with all inspection and maintenance conditions specified in the instructions. The EC POWER XRGI® system is not intended for use in the industrial sector within the meaning of the Machinery Directive. Any improper use is prohibited!

- Page 24 G E N E R A L S A F E T Y I N S T R U C T I O N S Only a certified, skilled installer who has undergone special training for the XRGI® system through EC POWER may commission the XRGI®...

- Page 25 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 3.3.2 A C T I O N S W I T H S M E L L O F G A S I N B U I L D I N G S A malfunction can cause gas to escape and cause poisoning and explosion hazards.

- Page 26 XRGI® system without consulting your authorised EC POWER specialist. Check with your authorised EC POWER specialist to ensure that there is still a sufficient supply of combustion air to the XRGI® system before fitting moisture-tight windows.

-

Page 27: Modifications To The Xrgi® System Compounds

Use EC POWER Engine Coolant, supplied with every new XRGI® system, to fill and top up the engine circuit to avoid expensive repairs from corrosion in the pipes of XRGI® systems. Only use the heated EC POWER Engine Coolant for heating purposes in the closed circuit and do not drain it off for other purposes. -

Page 28: Modifications In The Vicinity Of The Xrgi® System

■ Structural objects that could affect the operational safety of the XRGI® system Do not undertake any modifications to XRGI® components without previous written approval from EC POWER. 3.3.13 O P E R AT I O N W I T H L I Q U I D G A S Venting the liquid gas tank when installing the XRGI®... -

Page 29: Safety Equipment On The Xrgi® System

Fig. 3.02 Make sure that the warning information labels (stickers) on the XRGI® system are always clearly visible, undamaged and complete. Replace damaged or dirty warning labels. The information labels are available from EC POWER. 3.3.16 S A F E T Y A N D W A R N I N G L A B E L S O N T H E X R G I ® S Y S T E M The XRGI®... - Page 30 R E T U R N O B L I G AT I O N S EC POWER is obliged to take back XRGI® systems after their use. XRGI® systems have to be reused or recycled following their return. Components that cannot be recycled have to be disposed of in an environmentally friendly manner.

- Page 31 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018...

-

Page 32: Iq-Control Panel

In the worst case, this can lead to a defect of the engine. Split deliveries with assembly on site are only possible after consultation with EC POWER! The dimensions of the Power Unit are described in chapter 4.4. -

Page 33: Installation Room

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 I N S TA L L AT I O N R O O M The minimum space requirement for installing an XRGI® 6/9 Power Unit is 3.5 m and an XRGI® 15/20 Power Unit is 4 m . -

Page 34: Corrosive Ambient Conditions

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 4.3.4 C O R R O S I V E A M B I E N T C O N D I T I O N S Do not expose the XRGI® system as a whole to corrosive gases, such as ammonia, chlorine, etc., which could be found in the vicinity of swimming pool systems. -

Page 35: Dimensions And Connections

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 D I M E N S I O N S A N D C O N N E C T I O N S 4.4.1 X R G I ® 6 / 9 - S Y S T E M P O W E R U N I T C O N N E C T I O N S 32A CCE plug for generator cable 4 ×... - Page 36 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 Q - H E AT D I S T R I B U T O R C O N N E C T I O N S Power Unit return (1“ G) Power Unit flow (1“...

- Page 37 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 i Q - C O N T R O L PA N E L C O N N E C T I O N S Power cable Generator cable Various external connections Network cable Fig.

-

Page 38: Xrgi® 15/20-System

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 4.4.2 X R G I ® 15 / 2 0 - S Y S T E M P O W E R U N I T C O N N E C T I O N S 63A CCE plug for generator cable 4 ×... - Page 39 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 Q - H E AT D I S T R I B U T O R C O N N E C T I O N S Power Unit return (1¼“ G) Power Unit flow (1¼“...

- Page 40 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 i Q - C O N T R O L PA N E L Abb. 4.25 – iQ15/20 C O N N E C T I O N S Power cable Generator cable Various external connections Various external connections Network cable...

-

Page 41: Q-Heat Distributor

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 REQUIRED MINIMUM CLEARANCES – ASSEMBLY & MAINTENANCE CLEARANCES Both the installation and assembly of the XRGI® system, as well as the execution of subsequent maintenance and repair work, must comply with the following minimum clearances or assembly and maintenance clearances. All dimensions exclude connections. -

Page 42: Xrgi® 15/20-System

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 min. 235 mm min. 180 mm min. 100 mm min. 100 mm min. 50 mm 1.800 mm min. 500 mm min. 500 mm min. 1.509 mm min. 500 mm min. 500 mm Fig. - Page 43 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 min. 270 mm min. 180 mm min. 100 mm min. 100 mm min. 755 mm min. 100 mm min. 50 mm Flexible hose Generator cable max. length 1.500 mm max. length 10.000 mm min.

-

Page 44: Installation Of The Xrgi® System

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 I N S T A L L AT I O N O F T H E X R G I ® S Y S T E M Use the minimum clearances from the plan above when installing the system. The installation shown above is only an example and can be modified if necessary. -

Page 45: Q-Network

Improper installation may affect the operational safety of the XRGI® system and may result in personal injury and/or property damage. Only a qualified EC POWER-certified contractor may install the XRGI® system. Residues such as weld beads, scale, hemp, putty, rust, coarse dirt and the like in the piping can be deposited in the XRGI®... - Page 46 M A I N C O M P O N E N T S F O R O P E R AT I O N O F T H E X R G I ® S Y S T E M : 2-way-valve 3-way-valve Power Unit, Q-Heat Distributor, iQ-Control Panel, Flow Master, Flow Master Control, Storage Control, storage tank Other hydraulic systems are described under EC POWER Hydraulic Solutions – the latest version of which, accessed at www.ecpower.eu , applies.

- Page 47 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 O V E R V I E W O F H Y D R A U L I C S O L U T I O N S Fig. 5.03 - Series circuit SERIES CONNECTION WITH...

- Page 48 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 H E AT I N G P I P E D I M E N S I O N S Fig. 5.05 X R G I® - S E C T I O N F M - S E C T I O N B U I L D I N G S E C T I O N Pipe diameter sized according...

-

Page 49: Installation Q-Heat Distributor – Power Unit

Connect the Power Unit‘s flow and return to the Q-Heat Distributor using flexible and insulated reinforced hoses (included within the scope of delivery). EC POWER flexible hoses have a length of 1,360 mm. When using hoses between the Power Unit and the Q-Heat Distributor other than the flexible hoses supplied by EC POWER, make sure that the hoses: ■... -

Page 50: Installation Q-Heat Distributor – Storage Tank/Consumer Network

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 5.1.3 I N S T A L L AT I O N Q - H E AT D I S T R I B U T O R – S T O R A G E T A N K / C O N S U M E R N E T W O R K H y d r a u l i c c o n n e c t i o n o n t h e Q - H e a t D i s t r i b u t o r 1"... -

Page 51: Ec Power Storage Tank

XRGI® system with two hydraulic connections, regardless of the hydraulic system selected. The EC POWER storage tank can be set up on concrete without the need for a specific foundation. Use a suitable foundation on an uneven surface to ensure that the storage tank is stable. Only set up in frost-proofed rooms unless the heating system is filled with antifreeze;... -

Page 52: Exhaust Gas Side Installation

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 E X H A U S T G A S S I D E I N S T A L L AT I O N Discharge the exhaust gases from the Power Unit through an exhaust gas pipe. Install the exhaust gas system in accordance with regulations applicable in the country of installation. -

Page 53: Gas Side Installation

The gas installation may only be carried out by a licensed installer. The local regulations of the energy suppliers, the gas safety rules and the installation guidelines of EC POWER must be observed. Make sure that the gas pipe is free of tension and torsion using the gas safety hose included in the scope of supply. -

Page 54: Electrical Installation

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 E L E C T R I C A L I N S T A L L AT I O N When working in the iQ-Control Panel, there is a risk of death from electric shock from live connections. Continuous voltage is present at the electrical terminals of the XRGI®... - Page 55 XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 E l e c t r i c a l c o n n e c t i o n o n t h e i Q - C o n t r o l P a n e l The following electrical cables and components are required and are not included in the delivery: i Q 1 0 Fuse...

-

Page 56: Storage Control

N E T W O R K I N S T A L L AT I O N Allow only authorised EC POWER specialists to connect the Q-Network modules and the Load Sharer S. Install the modules on a vibration-free foundation. Do not shorten, extend or cut-off the sensor and control cables for the Q-Network modules. -

Page 57: Flow Master Control

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 ■ The Storage Control‘s temperature sensors have to be fitted in immersion sleeves in the storage tank – sensor no. 1 has to be installed at the uppermost measuring point and sensor no. 4 at the lowest measuring point (Fig 5.22). Incorrect installation will cause operational faults! ■... -

Page 58: Boiler Control

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 Fig. 5.26 - installation in vertical pipework (upward flow) Flow Master injection pipe No obstructions Return to Storage Tank Main return Fig. 5.27 – Installation in horizontal pipework (connect to underside of main) Main return No obstructions Return to Storage Tank... -

Page 59: Vpp Gateway

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 5.5.5 V P P G AT E W AY/ E L E C T R I C H E AT E R C O N T R O L Fig. 5.29 V P P G AT E WAY ■... -

Page 60: Load Sharer S

XRGI ® - INSTALLATION GUIDE VERSION 1.0 2018 5.5.7 L O A D S H A R E R S Fig. 5.31 – Up to four XRGI® systems R E F E R E N C E M E T E R X R G I®... - Page 62 I N S T A L L A T I O N G U I D E F O R P R O F E S S I O N A L S...

Need help?

Do you have a question about the XRGI 15 and is the answer not in the manual?

Questions and answers