Table of Contents

Advertisement

RETURN TO MAIN MENU

IM772-A

Power Feed 10 Robotic

October, 2006

K1780-2

For use with machines having code numbers: 10944, 11301

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

OPERATOR'S MANUAL

Copyright © 2006 Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric Power Feed 10 Robotic K1780-2

- Page 1 RETURN TO MAIN MENU IM772-A Power Feed 10 Robotic October, 2006 K1780-2 For use with machines having code numbers: 10944, 11301 Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ...

- Page 2 351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

- Page 3 SAFETY ARC RAYS can burn. ELECTRIC SHOCK can 4.a. Use a shield with the proper filter and cover kill. plates to protect your eyes from sparks and 3.a. The electrode and work (or ground) circuits the rays of the arc when welding or observing are electrically “hot”...

- Page 4 SAFETY WELDING SPARKS can CYLINDER may explode cause fire or explosion. if damaged. 6.a. Remove fire hazards from the welding area. 7.a. Use only compressed gas cylinders If this is not possible, cover them to prevent containing the correct shielding gas for the the welding sparks from starting a fire.

- Page 5 SAFETY PRÉCAUTIONS DE SÛRETÉ 6. Eloigner les matériaux inflammables ou les recouvrir afin de prévenir tout risque d’incendie dû aux étincelles. Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce 7.

- Page 6 The code number is especially important when identifying the correct replacement parts. On-Line Product Registration - Register your machine with Lincoln Electric either via fax or over the Internet. • For faxing: Complete the form on the back of the warranty statement included in the literature packet accompanying this machine and fax the form per the instructions printed on it.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page Installation .......................Section A Technical Specifications .......................A-1 Safety Precautions .......................A-2 Mounting the Wire Drive Unit ..................A-2 Electrode Routing......................A-2 Electrode and Work Cable Connections ...............A-2 Negative Electrode Polarity ...................A-3 Shielding Gas Connection.....................A-3 Control Cable ........................A-3 Control Cable Connections ...................A-3 Control Cable Specifications ..................A-4 Wire Drive Gear Ratio (High or Low Speed) ..............A-4 Selecting the Proper Gear Ratio ...................A-4... -

Page 8: Installation

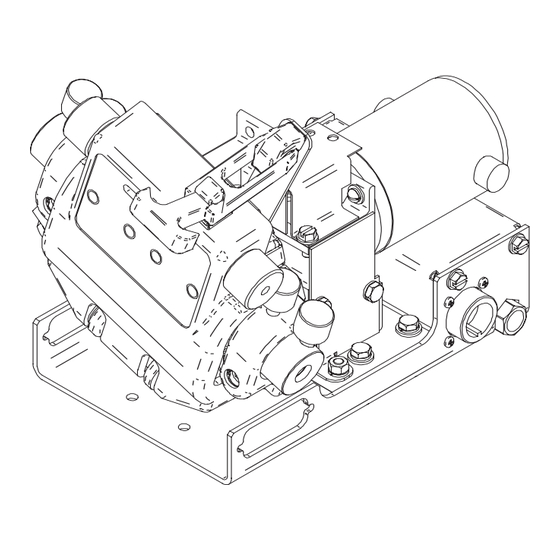

INSTALLATION TECHNICAL SPECIFICATIONS – Power Feed 10 Robotic-K1780-2 WIRE DRIVE OR WIRE DRIVE SECTION OF FEEDER SPEC.# TYPE LOW SPEED RATIO HIGH SPEED RATIO Wire Size Wire Size Speed Solid Cored Speed Solid Cored K1780-2 Power Feed 10 50-800 IPM .025 - 3/32 in. -

Page 9: Safety Precautions

INSTALLATION SAFETY PRECAUTIONS ELECTRODE ROUTING WARNING The electrode supply may be either from reels, Readi- Reels, spools, or bulk packaged drums or reels. Observe the following precautions: can kill. ELECTRIC SHOCK • Do not bend the conduit more than 45°, and to use the minimum amount of conduit necessary for the •... -

Page 10: Negative Electrode Polarity

INSTALLATION SHIELDING GAS CONNECTION When using an inverter type power source, Use the largest welding (electrode and work) cables that are WARNING practical. At least 2/0 copper wire - even if the aver- age output current would not normally require it. When pulsing, the pulse current can reach very high CYLINDER may explode if damaged. -

Page 11: Control Cable Specifications

INSTALLATION SELECTING THE PROPER GEAR RATIO CONTROL CABLE SPECIFICATIONS See Specification Section A-1 for feed speed and wire It is recommended that genuine Lincoln control cables size capabilities with high and low speed gear ratios. be used at all times. Lincoln cables are specifically To determine whether you should be using the high or designed for the communication and power needs of low speed ratio use the following guidelines:... -

Page 12: Changing The Wire Drive Ratio

INSTALLATION CHANGING THE WIRE DRIVE RATIO CHANGING THE ANGLE OF THE FEED PLATE WARNING WARNING • Turn off power to the power source at the dis- connect switch. Turn off power to the power source at the discon- ------------------------------------------------------------------------ nect switch. ------------------------------------------------------------------------ Changing the ratio requires a gear change and a PC board switch change. -

Page 13: Wire Feed Drive Roll Kits

INSTALLATION WIRE FEED DRIVE ROLL KITS 6. Install each drive roll by pushing over shaft until it butts up against locating shoulder on the drive roll shaft. (Do Not exceed maximum wire size rating of NOTE: The maximum rated solid and cored wire the wire drive). -

Page 14: Gun Receiver Bushings And Adapters

INSTALLATION GUN RECEIVER BUSHINGS AND The K1546-1 and K1546-2 Adapter for use with ADAPTERS Lincoln Magnum conduit (K515 or 565) and E-Beam conduit. The K1546-1 is to be used for wire sizes The Power Feed wire feeders are equipped with facto- (.023 - 1/16), K1546-2 is to be used for wire sizes ry installed K1500-1 gun connection kits, as described (1/16 - .120) -

Page 15: Feeding Electrode And Brake Adjustment

INSTALLATION Feeding Electrode and Brake Adjustment 3. If the only result is drive roll slippage, disengage the gun, pull the gun cable forward about 6" (150 mm). 1. Turn the Reel or spool until the free end of the elec- There should be a slight waviness in the exposed trode is accessible. -

Page 16: Operation

OPERATION SAFETY INSTRUCTIONS GENERAL DESCRIPTION Read and understand this entire section of operat- The Power Feed 10 Robotic is a high performance, ing instructions before operating the machine. digitally controlled, modular wire feeder. Properly equipped, it can support the GMAW, GMAW-P and WARNING FCAW processes. -

Page 17: Accessories

ACCESSORIES PLATFORM COMMONALITIES OPTIONAL EQUIPMENT • Power Feed 10 series Feed head. • CGA gas connections. • KP1505 Drive Roll and Wire Guide Kits • Works with all PowerWave ArcLink systems. “It is • KP1507 Drive Roll and Wire Guide Kits not compatible with the PowerWave 350, 450 or 500 or Linc-net PowerWave 455’s”... -

Page 18: Maintenance

MAINTENANCE SAFETY PRECAUTIONS AVOIDING WIRE FEEDING PROBLEMS Wire feeding problems can be avoided by observing the following gun handling and feeder set up proce- dures: WARNING a) Do not bend the conduit more than 45°. ELECTRIC SHOCK can kill. b) Keep the minimum amount of conduit necessary •... - Page 19 HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

-

Page 20: Troubleshooting

TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS RECOMMENDED POSSIBLE CAUSE (SYMPTOMS) COURSE OF ACTION Rough wire feeding or wire not 1. Gun cable kinked and / or twist- feeding but drive rolls are turning. 2. Wire jammed in gun and cable. Check for mechanical restric- tions in feeding path. - Page 21 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS RECOMMENDED POSSIBLE CAUSE (SYMPTOMS) COURSE OF ACTION Variable or “hunting arc. 1. Wrong size, worn and/or melted contact tip. 2. Worn work cable or poor work connection. 3. Loose electrode or work cable connections.

- Page 22 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS RECOMMENDED POSSIBLE CAUSE (SYMPTOMS) COURSE OF ACTION Tip seizes in diffuser. 1. Tip overheating due to pro- longed or excessive high current and/or duty cycle welding. Note: A light application of high temperature antiseize lubri- cant (such as Lincoln E2067 Graphite Grease) may be...

-

Page 23: Diagrams

DIAGRAMS POWER FEED 10 ROBOTIC... - Page 24 DIAGRAMS POWER FEED 10 ROBOTIC...

- Page 25 NOTES POWER FEED 10 ROBOTIC...

- Page 26 Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. Insulate yourself from work and ground. Spanish No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE bajo carga con la piel o ropa moja-...

- Page 27 Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. WARNING remove fumes from breathing zone. Spanish Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o AVISO DE...

- Page 28 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the Power Feed 10 Robotic K1780-2 and is the answer not in the manual?

Questions and answers