Subscribe to Our Youtube Channel

Summary of Contents for Dresser Masoneilan V-Max 36005 Series

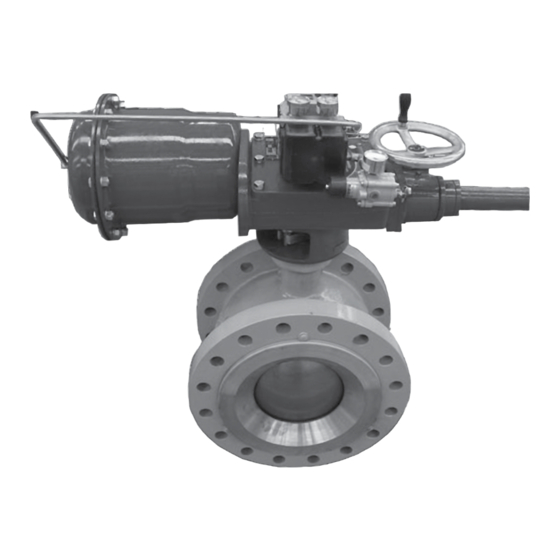

- Page 1 Instruction Manual EM36005 Putting You In Control 07/10 ® 36005 Series V-Max High Capacity Control Ball Valve...

-

Page 2: Table Of Contents

9. Work safely. Copyright Masoneilan is a registered trademark of Dresser, Inc. All information contained herein is believed to be accurate at the time of ® publication and is subject to change without notice. Copyright 2010 by Dresser, Inc. All rights reserved. -

Page 3: Important: Safety Warning

Dresser recommended usages. Dresser, Inc. reserves the right to discontinue manufacture of any product or change This is the safety alert symbol. It alerts you to potential product materials, design or specifications without notice. -

Page 4: Introduction

personnel in the operation, maintenance and application of 1.0 Introduction our control valves and instruments. Arrangements for these services can be made through your Masoneilan Representative The following instructions are designed to assist maintenance or District Office. When performing maintenance use only personnel in performing most of the maintenance required on Masoneilan replacement parts. - Page 5 3 6 X 0 5 V-Max Valves Actuator Position in Relation to Valve Body Numbering System: 1 to 8 Actuator Model 33, Size AC Actuator Model 33, Sizes B and C Instructions EM36005 – 07/10 ® 36005 Series V-Max Control Ball Valve...

-

Page 6: Installation

2.0 Installation 2.1 general Before proceeding with changing actuator position, air 2.1.1 Unpack valve carefully to avoid damage to valve, action or valve maintenance, isolate valve, vent process accessories, or tubing. pressure and shut off air supply and signal air lines or 2.1.2 Record all valve and accessory serial plate data electrical lines to unit. - Page 7 back onto shaft. Align bracket and slide back onto For each valve action (air to open/air to close) the actuator bracket mounting studs (26) and packing flange may be positioned to either side of the pipe. Actuator studs (25). Replace bracket mounting stud nuts (24) position is usually determined by adjacent piping, and washers (18).

-

Page 8: Changing Valve Action

Ensure rotation of AC actuator does not exceed washers (76). Remove actuator. 90deg. Damage to actuator rod may result. Note: Spacer rings apply only on handwheel option. K. If actuator action is air to open, rotate ball plug (2) to D. Loosen lever cap screw (33). Remove packing flange open position. -

Page 9: Maintenance

L. Set and lock indicator (35) to indicate plug position. 2.5.2 Model 33, size AC only. For sizes B & C refer to section 2.5.1 above. Do not exceed maximum air supply pressure. Keep A. If the valve is equipped with a handwheel disengage hands clear of actuator stem and linkage. - Page 10 (68), and then the second lever arm onto the shaft then slide the shaft into the bracket and bearing. A. Replace ball bearing (47) in the bracket (31). When disconnecting actuator rod end bearing from B. Place ball plug (2) in closed position. Slide bracket shaft arm, the ball is likely to rotate toward the bottom of (31) partially over shaft.

-

Page 11: Body Subassembly

3.3.2 Seal Ring – MN-7 Seal 3.3.2.1 Disassembly Note: Seal ring removal, inspection and reinstallation When stroking valve keep hands and equipment clear must be done with the valve removed from the pipeline. of ball plug and seal ring to avoid injury or damage to personnel or equipment. Do not exceed pressure A. Remove screws (9) and washers (10), retainer specified on the valve nameplate. -

Page 12: Heavy Duty Metal Seal Ring

D. Replace downstream back-up ring (32), seal 3.3.5 Ball Plug assembly, gasket (4) and retainer (3). Take care 3.3.5.1 Ball Plug Disassembly that beveled edge flexible metal seal (8) and backup rings (6 & 32) are facing the ball. A. Remove bracket (see section 3.3.2). E. -

Page 13: Actuator Subassembly

tight seal against the gasket. (Recommended A. Isolate the valve, vent process pressure and lubricant SAF-T-EZE Anti-Seize or equal.) shut off all electrical, signal air and supply air lines to the valve. E. Replace ring (29), and upper bushing (17) on the shaft (5). - Page 14 B. Ensure spring (90) and spring guide (89) are properly aligned in lower case (91) and install the diaphragm plate and stem subassembly. Replace diaphragm (85). The upper diaphragm case (84) should separate from the lower case (91) as the tension nuts are C.

-

Page 15: Handwheel Subassembly

g. Replace covers (44 & 46) and reconnect signal 3.5.2.1 Disassembly and supply lines. H. Place back in service and, if so equipped, rotate handwheel to desired position. 3.5 Handwheel Subassembly Turn handwheel to disengage position before proceeding with handwheel maintenance. 3.5.1 Model 33 sizes B &... - Page 16 g. Remove the upper diaphragm case (84) and diaphragm (85). Failure to evenly unload tension nuts may result in personal injury! F. Continue loosening tension nuts (96) until further The diaphragm plate (88) remains under spring loosening of the tension nuts (96) is no longer load.

- Page 17 SECTION A-A ALTERNATE VIEW C SCALE 2 : 1 DETAIL B ALTERNATE VIEW C SCALE 2 : 1 SCALE 2 : 1 DETAIL C SCALE 2 : 1 Figure 2 - general Assembly Instructions EM36005 – 07/10 ® 36005 Series V-Max Control Ball Valve...

- Page 18 Figure 3 - Sizes B & C Bracket and Linkage Figure 4 - Handwheel general Assembly, Actuator Sizes B & C Figure 5 - Handwheel Detail, Actuator Sizes B & C Figure 7 - Handwheel Lever Detail, Actuator Sizes B & C Figure 6 - Handwheel Bracket Detail, Actuator Sizes B &...

- Page 19 Figure 9 - Actuator general Assembly, Actuator Sizes B & C Figure 11 - Lever Position Air to Close, Figure 10 - Lever Position Air to Open, Actuator Sizes B & C Actuator Sizes B & C Instructions EM36005 – 07/10 ®...

- Page 20 Figure 12 - Position Indicator Detail, Actuator Sizes B & C Figure 13 - Size AC Actuator Instructions EM36005 – 07/10 ® 36005 Series V-Max Control Ball Valve...

- Page 21 Figure 14 - Size AC Actuator Bottom View Figure 15 - Size AC Actuator Linkage Detail Instructions EM36005 – 07/10 ® 36005 Series V-Max Control Ball Valve...

- Page 22 Figure 16 - Handwheel Assembly, Size AC Actuator Do Not Insulate Figure 17 - Insulation detail Instructions EM36005 – 07/10 ® 36005 Series V-Max Control Ball Valve...

- Page 23 Table 1 – Body Parts List Table 2 – Bracket and Linkage Parts List Ref. No. Description Ref. No. Description Body Cap Screw Ball Plug Lockwasher Retainer (ISA S75.04) Indicator Arm Retainer (ANSI B16.10) Machine Screw Gasket (Retainer/Body) Hex Nut Shaft Indicator Dot Backup Ring (Std.

- Page 24 Table 3 – Handwheel Parts List Table 4 – Actuator Parts List Ref. No. Description Ref. No. Description Lever Set Hex Nut Lockwasher Lockwasher Cap Screw Stem End Cap Clip Plate Clevis Pin Screw Clevis Handwheel S/A Button Head Cap Screw Handwheel 54-1 Upper Diaphragm Case...

- Page 25 Table 5 – Line Bolting (Inlet Side) ANSI B16.10 ISA S75.04 Size ANSI Short Pattern Face to Face Face to Face 2 1/2" 3 1/2" 3" – – 3" 5" 1-1/ 2 3 1/2" – – 3 3/4" 5 1/2" 4"...

- Page 26 Notes Instructions EM36005 – 07/10 ® 36005 Series V-Max Control Ball Valve...

- Page 27 Notes Instructions EM36005 – 07/10 ® 36005 Series V-Max Control Ball Valve...

- Page 28 About Dresser, Inc. About Dresser Masoneilan Dresser Masoneilan, headquartered in Houston, Texas, has Dresser Inc. is a global leader in providing highly- engineered infrastructure products for the global energy been the leading global partner in process control valves and solutions for more than 100 years. A business segment industry.

Need help?

Do you have a question about the Masoneilan V-Max 36005 Series and is the answer not in the manual?

Questions and answers