Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for EASYPRINT Compact 32D

- Page 1 Easyprint Product Manual Compact 32d Compact 32C Compact 53c Communicator II...

-

Page 2: Issue 8 March

THIS PAGE INTENTIONALLY LEFT BLANK 25364 Issue 8 March 2018... -

Page 3: Part

V-SERIES THERMAL TRANSFER PRINTER PRODUCT MANUAL This manual, Easyprint Part No. 25364, is for use in the operation and maintenance of Compact and Communicator Thermal Transfer Printers. Users of these printers are warned that it is essential to read, understand and act according to the information given in Part 1: Health and Safety. -

Page 4: Part

End User License Agreement You have acquired a device (“DEVICE”) that includes software licensed by Easyprint A/S from Microsoft Licensing Inc. or its affiliates (“MS”). Those installed software products of MS origin, as well as associated media, printed materials, and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual property laws and... - Page 5 • EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is of US-origin. You agree to comply with all applicable international and national laws that apply to the SOFTWARE, including the U.S. Export Administration Regulations, as well as end- user, end-use and country destination restrictions issued by U.S. and other governments.

- Page 6 This declaration of conformity is issued under the sole responsibility of the manufacturer. Objects of the declaration: EASYPRINT Compact 32D, 32C, 53C (labelled as EASYPRINT 53 MK2) Printers from serial number VP944527and EASYPRINT Touch Screen (Labelled as Compact TS) from serial number...

- Page 7 EC DECLARATION OF CONFORMITY 25364 Issue 8 March 2018...

- Page 8 Manufacturers name: Domino UK Limited Manufacturers address: Bar Hill, Cambridge CB23 8TU. This declaration of conformity is issued under the sole responsibility of the manufacturer. Object of the declaration: Easyprint Communicator II Printer, Type (2"/53mm) from serial numbers 320L02M17G111881 &...

- Page 9 EC DECLARATION OF CONFORMITY 25364 Issue 8 March 2018...

-

Page 10: Part

FCC NOTICE This equipment has been tested and found to comply with the limits for Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. -

Page 11: Table Of Contents

CONTENTS PART 1 HEALTH AND SAFETY PART 2 DESCRIPTION AND INSTALLATION PART 3 OPERATION PART 4 MAINTENANCE, SERVICE AND FAULT FINDING PART 5 TECHNICAL REFERENCE PART 6 GLOSSARY OF TERMS 25364 Issue 8 March 2018 (11) - Page 12 AMENDMENT RECORD Amendment Date All Parts at Issue 1 November 2010 All Parts at Issue 2 April 2011 All Parts at Issue 3 January 2013 All Parts at Issue 4 April 2013 All Parts at Issue 5 September 2013 All Parts at Issue 6 March 2015 All Parts at Issue 7 November 2015...

- Page 13 PART 1 : HEALTH AND SAFETY CONTENTS Page GENERAL SAFETY ................HAZARD INFORMATION............... Warning Notices................Lethal Voltages ..............Handling the Compact 32c, 53c / Communicator II Cassette Printer ..............Replacing the Ribbon ............Heating Element..............Organic Solvents..............Battery Replacement ............Fuses Fire Hazard ..............

- Page 14 HEALTH AND SAFETY THIS PAGE INTENTIONALLY LEFT BLANK 25364 Issue 8 March 2018...

-

Page 15: General Safety

- 230/115V – 50/60Hz for the printer and a 4 amp T 5x20 UL fuse - 230/ 115V - 50/60Hz for the printer power supply unit V200006). Installation must only be performed by qualified Easyprint personnel. For customer installations, authorisation must be obtained from Easyprint A/S. - Page 16 Read the Safety Data Sheet (SDS) for Cleaning Fluid (P/N WJ-111) before using it with any Easyprint product. There is a danger of electrical shocks from the electrical outlet. All electronic checks must be performed by qualified personnel.

-

Page 17: Hazard Information

HEALTH AND SAFETY HAZARD INFORMATION This document uses the following warning signs that give warning of a hazard or danger: Denotes Danger: Electricity Denotes General Danger Read the following important notices before using the printer. The hazard information is prioritised into warning and caution notices. Warning Notices Warning notices denote a potential hazard to the health and safety of users. -

Page 18: Replacing The Ribbon

HEALTH AND SAFETY Replacing the Ribbon Care must be taken when replacing ribbons to avoid cutting hands or fingers. Heating Element The heating element and surrounding area become very hot during use. To avoid the risk of burns, never touch the heating element area of the print head. -

Page 19: Caution Notices

HEALTH AND SAFETY Caution Notices Caution notices denote a potential hazard to the physical integrity of equipment / software but not a danger to personnel. These notices clearly state the nature of the hazard and the means by which it can be avoided. Damage to Print Head Changing the print head without setting the new resistance value may cause severe damage to the print head. -

Page 20: Spare Parts And Consumables

HEALTH AND SAFETY Spare Parts and Consumables To avoid the risk of damage to the print head use only Easyprint spares, parts and consumables. Contact supplier for details. For Sales and Service contact: Easyprint A/S www.easy-print.com sales@easy-print.com 25364 Issue 8 March 2018... -

Page 21: Issue 8 March

Output Voltage..............2-22 Example Connections............2-23 Using a 24V Product Detector or Proximity Sensor ..... 2-25 Output Connections - Compact 32d, 32c and 53c ....2-26 Output Connections - Communicator II ....... 2-27 Remote Pause (Not available on Communicator II in CM mode)....2-29 Connecting Encoder to I/O Connector (Instead of Encoder Connector).......... - Page 22 Compact 32c / 53c Ribbon Threading Procedure ....2-48 Communicator II Ribbon Threading Procedure ....2-50 Ribbon Path ..................2-50 Set Up Printer - Final Steps (Compact 32d, 32c and 53c)....2-51 Calibrating the Printer ............2-51 Optimising the Print Head ............... 2-52 Test Print, Align and Calibrate - (Compact 32d, 32c and 53c)..........

- Page 23 Adding More Connections ............... 2-62 Compact Touchscreen ............2-62 Touchscreen ................. 2-63 USB Connection Setup (Compact 32d, 32c, 53c and Compact Touchscreen only) .. 2-64 Reconnecting the Compact Touchscreen via USB (Compact 32d, 32c and 53c) ..........2-64 ADVANCED SETTINGS ................. 2-65 System Variable ................

- Page 24 DESCRIPTION AND INSTALLATION THIS PAGE INTENTIONALLY LEFT BLANK 25364 Issue 8 March 2018...

-

Page 25: Unpacking

Before installation, it is important to check that the printer has not been damaged during shipment, and that all parts needed for the installation and operation of the printer are present. Ensure that the following items are present: Compact 32d Unit Inventory Contents Part No. Compact 32d Printer Unit... -

Page 26: Communicator Ii Unit Inventory

DESCRIPTION AND INSTALLATION Communicator II Unit Inventory Contents Part No. Communicator II 53mm Printer Unit Communicator II 128mm Printer Unit Power Supply Unit (PSU) V200006 I/O Box V200005 Fix Shim Pack (0.2, 0.4 and 0.8mm) V200042 Wall Bracket - PSU Box VEY9984 Wall Bracket - I/O Box VEY9985... -

Page 27: Compact 32D, 32C And 53C Printer Main Parts

DESCRIPTION AND INSTALLATION Compact 32d, 32c and 53c Printer Main Parts Printer Unit (Front View) Quarter-turn Latch Port Compact 32d Power/Reset Status Button Compact 32c / 53c Printer Connections (Rear View) Rear USB Small* Rear USB Ethernet cable port Large*... -

Page 28: Communicator Ii Printer Main Parts

DESCRIPTION AND INSTALLATION Communicator II Printer Main Parts Printer Unit (Front View) Cassette Handle Status Printer Connections (Rear View) USB Mini Connector Secure Digital Flash Card Slot USB Standard Sliding Connector Shutter Air Pressure Air Inlet Gauge Air Pressure Regulator Air Outlet Power Supply Connector Communication Connector... -

Page 29: Compact 32D, 32C And 53C Peripherals

DESCRIPTION AND INSTALLATION Compact 32d, 32c and 53c Peripherals Power Supply Unit Encoder 25364 Issue 8 March 2018... -

Page 30: Communicator Ii Peripherals

DESCRIPTION AND INSTALLATION Communicator II Peripherals Power Supply Unit Mains Switch Mains Connector Power Connector Mains Fuse I/O Box Encoder Communication I/O Connector Ethernet Connector Connector Connector Shims Shim used with the bracket assembly (0.2, 0.4 and 0.8 thicknesses available in pack) 2-10 25364 Issue 8 March 2018... -

Page 31: Mechanical Installation

Installation Requirements Ensure that the following services and control signals are available: Notes: (1) Compact 32d, 32c and 53c Power: 120/240 VAC, 50/60Hz, 1.5A (2) Communicator II Power: 115/230 VAC, 50/60Hz (1) For Communicator II: Compressed Air: 2-5 Bar, dry, uncontaminated. - Page 32 DESCRIPTION AND INSTALLATION Window Bracket - (IM Version), 0.9m - Part No. EAS002706 Note: Three guide rollers are shown for illustration purposes - only two are supplied in the kit. Window Bracket - (CM Version), 0.9m - Part No. EAS002717 2-12 25364 Issue 8 March 2018...

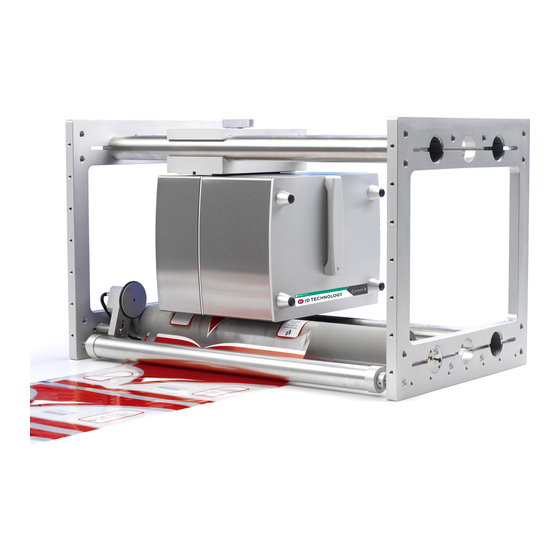

- Page 33 DESCRIPTION AND INSTALLATION Web Positioning Module (0.9m) - Part No. 5-0460281 Labeller Bracket Assembly - Part No. EAS001626 Notes: (1) The Labeller Bracket can be assembled in either a left-hand or a right-hand version. (2) Installation drawing EAS002727 is included with the bracket kit. 25364 Issue 8 March 2018 2-13...

-

Page 34: Mounting The Printer In The Bracket System

The precise height of the print head will need to be adjusted electronically via the software once the services are connected. See “Set Up Printer - Final Steps (Compact 32d, 32c and 53c)” on page 2-51. (4) When the correct distance is obtained, tighten the screws. -

Page 35: Communicator Ii

DESCRIPTION AND INSTALLATION Communicator II (1) Mount the printer in the bracket system, using four screws (M6 x 35mm). Note: When mounting the printer in the CM bracket, ensure the print head is mounted on the top point of the rubber roller. This may be adjusted to obtain the best print quality. -

Page 36: Connect Cables

DESCRIPTION AND INSTALLATION Connect Cables Compact 32d, 32c and 53c Note: Refer to page 2-33 for Connection Diagram when connecting the printer to the mains, peripherals and network. • Connect the cable from the PSU to the printer’s power input port •... -

Page 37: Communicator Ii

DESCRIPTION AND INSTALLATION Communicator II Note: Refer to page 2-34 for Connection Diagram when connecting the printer to the mains, peripherals and network. • Connect the cable from the power supply to the printer • Connect the printer cable between the printer and the I/O Box •... -

Page 38: Set Up Communicator Ii Printer

DESCRIPTION AND INSTALLATION Set Up Communicator II Printer • Load the cassette with ribbon. Follow the instruction on the cassette unit for the ribbon path when fitting or replacing the ribbon. “Threading the Ribbon” on page 2-45. • Check the height of the print head to the print base. Note: Use the shims to ensure the correct distance between print head and substrate (0.2 to 2.0mm) for both CM and IM. -

Page 39: I/O Connection Details

DESCRIPTION AND INSTALLATION I/O Connection Details Inputs and outputs are made on the 15-pin D-type connector on the rear of the printer. The pin allocations follow. Notes: (1) Output Volt-free contacts: These contacts are operated and driven by a relay on the printer circuit board. They are normally open or normally closed depending on the assigned function. -

Page 40: Compact 32D, 32C And 53C Pin Allocations

DESCRIPTION AND INSTALLATION Compact 32d, 32c and 53c Pin Allocations Name Type Default Function J3 Pins Colours Volt-free Orange - Light Output 1 Ready / Returning 4, 12 contacts Green Volt-free Output 2 Error 3, 11 Red - Pink contacts... -

Page 41: Communicator Ii Pin Allocations

DESCRIPTION AND INSTALLATION Communicator II Pin Allocations Name Type Default Function J3 Pins Colours Volt-free Orange - Light Output 1 Ready / Returning 4, 12 contacts Green Volt-free Output 2 Error 3, 11 Red - Pink contacts Encoder Purple - Red / Input 1 (duplicated on 8, 15... -

Page 42: Output Voltage

DESCRIPTION AND INSTALLATION Output Voltage Compact 32d, 32c and 53c Pin 9 can be used to provide 5V or 24V with ground on pins 13, 14 or 15. Note: Default output voltage is 24V. Output voltage of the powered contacts is set by JP1 and JP2 on the... -

Page 43: Example Connections

DESCRIPTION AND INSTALLATION Example Connections Start Signal Using volt-free contacts - The start signal is the trigger for the printer to start the printing process. The signal must be a minimum of 50ms duration. The connection is made using pins 5 and 13 of the I/O connector, as shown in the following diagram: Pin 5 (Yellow) Printer... - Page 44 DESCRIPTION AND INSTALLATION Front Multi-Function Button (Compact 32d, 32c and 53c only) Using volt-free contacts - The front multi-function button can be triggered with a 1 second pulse which will either tension the ribbon, initialise the printer or clear error (depending on printer status). An 8 to 10 second pulse will switch off the printer.

-

Page 45: Using A 24V Product Detector Or Proximity Sensor

DESCRIPTION AND INSTALLATION Using a 24V Product Detector or Proximity Sensor Compact 32d, 32c and 53c (1) Ensure JP1 and JP2 on the connector board are set to the default position 2-3 for 24V. See “Output Voltage” page 2-22. (2) Connect the NPN sensor as follows:... -

Page 46: Output Connections - Compact 32D, 32C And 53C

DESCRIPTION AND INSTALLATION Output Connections - Compact 32d, 32c and 53c Outputs 1, 2 and 3 are volt-free contacts with a maximum loading of 30V 100mA. Output 4 is a powered contact, Pin 9 is supplied with 24V by default. See the pin allocation table on page 2-20. -

Page 47: Output Connections - Communicator Ii

DESCRIPTION AND INSTALLATION Output Connections - Communicator II Outputs 1 and 2 are volt-free contacts with a maximum loading of 30V 100mA. See the pin allocation table on page 2-21. I/O Connector Printer 15-pin D-Type Pin 4 (Orange) Output 1 Pin 12 (Light Green) Pin 3 (Red) Output 2... - Page 48 /returning in IM mode Error Contacts open when an error is active Error (inverted) Contacts close when an error is active (Compact 32d, 32c and 53c) Warning Contacts open when a warning is active Warning (inverted) Contacts close when a warning is active...

-

Page 49: Remote Pause

(2) When the switch is closed the printer is paused, when the switch is open the printer will resume. (1) Select 2 available pins from one of the tables bellow and connect the switch. Compact 32d, 32c, 53c and Communicator Pins Colours 5-13... -

Page 50: Connecting Encoder To I/O Connector (Instead Of Encoder Connector)

DESCRIPTION AND INSTALLATION Connecting Encoder to I/O Connector (Instead of Encoder Connector) The encoder can be connected to Input 1 of the I/O Connector which duplicates the encoder connector. (1) Ensure printer supplies +5VDC on pin 9 see “Output Voltage” on page 2-22 (2) Connect:... -

Page 51: I/O Wiring Diagrams

I/O Wiring Diagrams Compact 32d, 32c and 53c... -

Page 52: Communicator Ii

Communicator II VCC_ISO VCC_ISO GND_ISO IO_OUT1 I/O_IN1 VCC_ISO I/O_OUT2 I/O_OUT1 I/O_OUT1 IO_OUT1_RET I/O_IN2 I/O_IN1 IO_OUT2 T 3359 900 EPP001684 53014-0610 IO_OUT2_RET I/O_OUT2 GND_ISO LH1250AAC VCC_ISO 1-1634585-2 DEFAULT LINK POSITION GND LINKAGE SELECTION: IO_OUTn_RET = GND_ISO: DEFAULT = SEPARATE GND and GND_ISO LINK PINS 1 and 2 LINK PINS 1 and 2 IO_OUT1... -

Page 53: Connectivity - Compact 32D, 32C And 53C

(2) To connect the printer to a network, see “Compact Touchscreen to One Printer - Compact 32d, 32c and 53c” on page 2-35. connect the printer to a PC or laptop, see “PC or Touchscreen to One Printer”... -

Page 54: Connectivity - Communicator Ii

DESCRIPTION AND INSTALLATION CONNECTIVITY - COMMUNICATOR II Mains Power Supply - Clean Air Supply V20006 Air Tube Cable VEY0786 VEY1414 Euro Cable VEY1415 US VEY0190 Euro VEY190-1 US Rear View Touchscreen Cable Cable VEY1402 VEY1404 Crossover Cable VEY1420 Laptop* Crossover Cable EPT007719 Net-... -

Page 55: Compact Touchscreen To One Printer - Compact 32D, 32C And 53C

DESCRIPTION AND INSTALLATION Compact Touchscreen to One Printer - Compact 32d, 32c and 53c The Compact Touchscreen can be connected to the printer via direct USB connection (no network.) - One Compact Touchscreen connects to one printer at a time... -

Page 56: Network Set-Up

DESCRIPTION AND INSTALLATION - One Compact Touchscreen connects to many printers at a time - Extra PSU for Compact Touchscreen is required - Network hub and Ethernet cables are not supplied Compact Touchscreen Connection - Networked Printers CAUTION: If using an Ethernet cable to connect the printer to the Compact Touchscreen, use STP (Shielded Twisted Pair) type - rather than UTP (Unshielded Twisted Pair) type - to comply with EMC regulations. -

Page 57: Pc Or Touchscreen To One Printer

DESCRIPTION AND INSTALLATION PC or Touchscreen to One Printer Compact 32d, 32c and 53c Crossover Ethernet Cable Note: Initially, ensure both printer and PC are DHCP enabled. Then, if required, set the IP settings for the printer and PC/Touchscreen. Communicator II To connect a Touchscreen, see “Connectivity - Communicator II”... -

Page 58: Pc To Networked Printers

DESCRIPTION AND INSTALLATION PC to Networked Printers Refer to the example network diagram on page 2-35. Printer Network Settings All printers and controllers are set up to connect to each other out of box. Ethernet Set the Ethernet setting as required for the connected printer. DHCP will automatically assign IP addresses on a dynamic network. -

Page 59: Advanced

Port: Enter the port location at which the ODBC resides (normally 701). ODBC Active: Tick or untick the box as appropriate. Note: Requires ODBC server software, this is available from Easyprint. 25364 Issue 8 March 2018 2-39... -

Page 60: Webserver

DESCRIPTION AND INSTALLATION Webserver The printer can be controlled from a desktop PC or laptop using a standard web browser. Note: The Message Editor function is not available. The following web browsers are supported: • Microsoft Internet Explorer from version 9.0 •... -

Page 61: Encoder Connection

DESCRIPTION AND INSTALLATION Encoder Connection The Shaft Encoder connection, when the printer is used in CM, is shown. ENCODER 1. RED +5V CONNECTION 2. WHITE SIGNAL 3. BLUE 0V Shaft Encoder Connections to the Printer 25364 Issue 8 March 2018 2-41... -

Page 62: Compact Touchscreen

DESCRIPTION AND INSTALLATION Compact Touchscreen Notes: (1) The Compact Touchscreen is optional and may not be supplied with the printer. (2) USB connection is not suitable for the Communicator II. Stylus Rear View Compact USB A Mini-USB Ethernet Touchscreen Port Port Port LCD Panel... -

Page 63: Touchscreen

Touchscreen Notes: (1) The Touchscreen is optional and may not be supplied with the printer. (2) Compact 32d, 32c and 53c printers have a powered Ethernet port. This can be used to power the Touchscreen without additional power cables. Contents Part No. -

Page 64: Touchscreen Rear View

DESCRIPTION AND INSTALLATION Touchscreen Rear View Communication Mains Mains Mains Port Fuse Ports Switch Socket • Plug the crossover cable into the I/O box • Connect the mains cable to the Touchscreen • Connect the crossover cable to the Touchscreen •... -

Page 65: Printer Set-Up

DESCRIPTION AND INSTALLATION Printer SET-UP Setting the Ribbon Type The ribbon type setting is used to set the optimum print parameters for each ribbon type. This allows for faster set up, better print quality and sets the correct ribbon length. Note: The default ribbon type is Custom, this allows the ribbon diameter and length to be set manually. -

Page 66: Compact 32D Ribbon Threading Procedure

Ribbon Guide Cover Roller Ribbon Threading - Compact 32d Right-hand Printer (1) Rotate the quarter-turn latch anti-clockwise. Gently pull the printer’s front cover straight out towards you to remove it. (2) Fit the new ribbon roll on the unwind spindle and the empty core to the rewind spindle. - Page 67 Compact 32d Ribbon Path - Left Hand Compact 32d Ribbon Path - Right Hand Note: To change the printer from left hand to right hand - or vice versa see “Changing Printer Configuration”...

-

Page 68: Compact 32C / 53C Ribbon Threading Procedure

DESCRIPTION AND INSTALLATION Compact 32c / 53c Ribbon Threading Procedure (1) To remove the cassette, pull the latch down and gently pull the cassette straight out towards you. Place it on a clean flat surface. Unwind Rewind Spindle Spindle Dancing Dancing Capstan Compact 32c / 53c Cassette... - Page 69 DESCRIPTION AND INSTALLATION (5) Ensure that the print head is in the fully retracted position by manually adjusting if necessary. Normally this is achieved automatically when the cassette is removed with the power on and the printer has the status ‘Printer open’. (6) Fit the cassette to the printer.

-

Page 70: Communicator Ii Ribbon Threading Procedure

DESCRIPTION AND INSTALLATION Communicator II Ribbon Threading Procedure Dancing Dancing Rewind Unwind Spindle Spindle Capstan Ribbon Guide Ribbon Guide Roller Roller Ribbon Path label Cassette Unit showing Ribbon Path Label (Right-Hand Cassette Shown) (1) If fitting a replacement ribbon, remove the used roll and discard, re-use the inner core if needed. -

Page 71: Set Up Printer - Final Steps (Compact 32D, 32C And 53C)

Ensure the ribbon is tensioned and under the bottom guide rollers as shown. Set Up Printer - Final Steps (Compact 32d, 32c and 53c) CAUTIONS: The printer must be calibrated before installing it on the production line. See below. In dusty environments, it may be beneficial to fit a V-Series Positive Air Kit (P/N EAS002970). -

Page 72: Optimising The Print Head

(a) For CM applications, set the Encoder Divide to 0. The current read-only Line Speed is updated every few seconds. (2) For Compact 32d, 32c and 53c printers: Go to Settings > Production Line Setup > Head Functions and use the Align button to automatically set the head position to the roller. - Page 73 DESCRIPTION AND INSTALLATION Peel-off Print head Roller Ribbon Guide Roller Platen Bracket Mounting - Intermittent Mode (IM) (4) Set the Print Trigger as required at Settings > Production Line Setup > Print Trigger. For more information, see “Print Trigger” on page 3-49. (5) Go to Settings >...

-

Page 74: Test Print, Align And Calibrate - (Compact 32D, 32C And 53C)

DESCRIPTION AND INSTALLATION Test Print, Align and Calibrate - (Compact 32d, 32c and 53c) Go to Settings > Production Line Setup > Head Functions and select the desired function. For further information, see “Head Functions” on page 3-51. Speed Profile The Speed Profile function allows instantaneous display of the print trigger signal alongside the substrate speed and the ribbon speed. -

Page 75: Cm Speed Profile Graph

DESCRIPTION AND INSTALLATION CM Speed Profile Graph Substrate speed Ribbon Speed Printing Print Go It may be necessary to scroll up/down and left/right to see the full graph. Press Refresh to repeat the capture. 25364 Issue 8 March 2018 2-55... -

Page 76: Im Speed Profile Graph

DESCRIPTION AND INSTALLATION IM Speed Profile Graph Printhead speed Ribbon Speed Printing Print Go It may be necessary to scroll up/down and left/right to see the full graph. Press Refresh to repeat the capture. 2-56 25364 Issue 8 March 2018... -

Page 77: User Interface Settings

DESCRIPTION AND INSTALLATION User Interface Settings User Interface Settings are used to define the Compact Touchscreen / Touchscreen settings and connectivity to printers. Unlock User Interface Settings User interface settings are password protected to prevent accidental changes. To unlock the user interface settings whilst the user interface is connected to the printer follow the procedure from step (1). -

Page 78: Network

DESCRIPTION AND INSTALLATION Network Set up the network settings for the Compact Touchscreen / Touchscreen. The IP address of the device can be changed manually or automatically. When connected to a network, always manually assign one IP address to the printer and another IP address to the Compact Touchscreen. While automatic assignment of IP addresses may seem simpler, some complications are associated with this approach. -

Page 79: Locating The Printer's Ip Address When Not Known

• Ensure that the standard USB connector at the rear of the printer is not being used. Use the mini USB cable to connect the PC to the printer’s mini USB connector, as shown in the following images: Mini USB port Communicator II Compact 32d, 32c and 53c 25364 Issue 8 March 2018 2-59... -

Page 80: Use Of Usb To Find Out Which Ip The Printer Is Using

DESCRIPTION AND INSTALLATION • ActiveSync should now activate, as shown in the following image: • To explore the device using Explorer in ActiveSync, select Explore. If ActiveSync does not start, remove the mini USB cable and reinsert it. Use of USB to Find Out which IP the Printer is Using (1) Navigate to the root folder of the device. -

Page 81: Changing The Ip Address For The Compact Touchscreen / Touchscreen

(4) Change the IP Address, which changes immediately. Note: For Compact 32d, 32c and 53c only: If the default server IP address of the Compact Touchscreen is changed, the user will be unable to reconnect to the printer via USB using the Compact Touchscreen. -

Page 82: Adding More Connections

DESCRIPTION AND INSTALLATION Adding More Connections To add a new printer to the network or if an existing printer has been assigned a new IP address follow the procedure bellow. Note: User interface settings must be unlocked before starting this procedure see “Unlock User Interface Settings”... -

Page 83: Touchscreen

DESCRIPTION AND INSTALLATION Touchscreen (1) Ensure that the printer is turned on and attached to the network. (2) Ensure that the Touchscreen is not connected to any printers. (3) Select Settings > Printer Connection > Connection Method and choose one of the following options. Broadcast: Select Broadcast to display a list of detected devices on the network. -

Page 84: Usb Connection Setup (Compact 32D, 32C, 53C And Compact Touchscreen Only)

DESCRIPTION AND INSTALLATION USB Connection Setup (Compact 32d, 32c, 53c and Compact Touchscreen only) Note: User interface settings must be unlocked before starting this procedure see “Unlock User Interface Settings” on page 2-57. To connect to a printer with a Compact Touchscreen via USB follow the procedure bellow. -

Page 85: Advanced Settings

DESCRIPTION AND INSTALLATION ADVANCED SETTINGS System Variable • Machine ID - Use this setting to assign a name to the printer. It is this name that defines the machine ID (identity), which can be used as a variable in a message Note: Do not confuse the machine ID with the host name. -

Page 86: Install Options

• Abort print at low speed - The user can select to abort the print at the speed below the set value by ticking the box • Ignore Cover Sensor - This variable is available on Compact 32d only. See “Ignore Cover Sensor” on page 4-3. - Page 87 DESCRIPTION AND INSTALLATION 25364 Issue 8 March 2018 2-67...

- Page 88 DESCRIPTION AND INSTALLATION THIS PAGE INTENTIONALLY LEFT BLANK 2-68 25364 Issue 8 March 2018...

- Page 89 PART 3 : OPERATION CONTENTS Page START-UP ..................... HOME SCREEN MENUS............... SCREEN FUNCTIONS................General..................... Editor Screen ................... SHUT DOWN ..................Disconnect Compact Touchscreen / Touchscreen from Printer ..Printer Shut Down................STATUS BAR..................MESSAGES ................... 3-10 NEW MESSAGE ..................3-11 Add....................

- Page 90 Print Head ..................3-50 Heater State ................. 3-50 Print Head Set Temp............3-50 Print Head Resistance............3-50 Print Head Height (Compact 32d, 32c and 53c) ....3-50 Head Position............... 3-50 Head Position Offset ............3-51 Head Functions ................3-51 INPUTS/OUTPUTS ................3-52 Assignment..................

- Page 91 OPERATION SD EMULATOR ..................3-57 Unsupported Functions ............3-57 Enable the SD Emulator............3-58 Connect to the Printer Using CoLOS Create......3-58 Use Messages Designed for SD 5, X40 or X60 ....3-59 Download a File to the Printer ..........3-59 Request a Message at the Printer ........

- Page 92 OPERATION THIS PAGE INTENTIONALLY LEFT BLANK 25364 Issue 8 March 2018...

-

Page 93: Start-Up

OPERATION START-UP For Compact 32d, 32c and 53c: With the printer connected to the power supply and the mains, see page 2-33, select the Power / Reset button on the front of the printer. For Communicator II: With the printer connected to the power supply and... -

Page 94: Home Screen Menus

OPERATION HOME SCREEN MENUS The default Home Screen Menus are Messages, Printer Status, Global Print Settings and Settings, as shown below: Home Screen Menus Long-press to Access Security Management It is possible to configure the third button (‘Global Print Settings’ in the example above): •... -

Page 95: Screen Functions

OPERATION SCREEN FUNCTIONS General Status Icons Screen Play / Stop Title Button (when activated*) Tabs Alert / Status Bar Scroll By: Line Page Lock Screen / Breadcrumb Main Log Off / Trail Screen Area Disconnect (Navigation) from Printer * For more information, see “STATUS BAR”... -

Page 96: Shut Down

Communicator II USB port. Printer Shut Down To shut down the Compact 32d, 32c or 53c printer, select and hold the Reset button until the LED changes colour, then release the Reset button. To shut down the Communicator II printer, turn off the switch on the power supply. - Page 97 OPERATION • When selecting Pause Print, the Status Bar turns blue and displays Paused. Select the Play / Stop button to select a new state • If no message is selected, the message field displays No message selected. The Status Bar is blue and displays ‘Idle’, and the Play / Stop button is not visible.

-

Page 98: Messages

OPERATION Messages Selecting the Messages button will open the messages screen: Message Store In the screen above, the message store called Internal and a list of messages it contains are displayed. Select any saved message from within a message store or from the list of messages. You can then edit, preview, cancel or send the message to print. -

Page 99: New Message

OPERATION NEW MESSAGE Select Messages > New Message to open the Message Editor - note that for new messages, the default menu will be Add: Undo/Redo Add Menu Notes: (1) The Undo/Redo buttons can be used at any stage of the message creation or editing process to undo or redo the previous action. -

Page 100: Text

OPERATION Text To enter text into the message, select the Add Text icon. Enter the required text using the keyboard. Move Cursor within Text Area Clear the Text Field Text Area Delete Previous Shift, Character Unicode and IME Buttons Select to Display Available Alternative... - Page 101 OPERATION Unicode characters can be entered by selecting the Unicode button (the button will change to amber). Enter the Unicode value - the responding character (and value) will be displayed in the top right of the screen: Unicode Value Unicode Character Text Area Select...

-

Page 102: Variable

OPERATION Variable Variables such as clocks, counters, prompts, links, etc. can be included in the message. Select the button and select +Create New... to display a list of new variables that can be created. Clock Create a new clock variable - enter any offsets required. The following properties are available for editing: Format: Click the format field to display a list of possible clock formats. -

Page 103: November

OPERATION Supported Time Formats Value Description Hours with no leading zero for single-digit hours; 12-hour clock Hours with leading zero for single-digit hours; 12-hour clock Hours with no leading zero for single-digit hours; 24-hour clock Hours with leading zero for single-digit hours; 24-hour clock Minutes with no leading zero for single-digit minutes Minutes with leading zero for single-digit minutes Seconds with no leading zero for single-digit seconds... -

Page 104: March

OPERATION Offset Policy: If a clock is required showing a later (or earlier) date than the current one, an offset may be applied. The time which will be printed is then the current time plus (or minus) the offset. The value of the offset can be set in three ways: Fixed offset A defined offset is applied. -

Page 105: March

OPERATION Truncate Date is only active for offsets with months and years. The different types of offset are applied in the following order: Year Month Week, Day, Hours and Minutes. Example: Current day = 31.01.2013, plus 1 month = 31.02.2013 Truncate Day active: Since 31.02.2013 is an invalid date, it is truncated to Date: 28.02.2013... -

Page 106: Counter

OPERATION Counter Create a new counter variable. This will increment/decrement according to the parameters set. The following properties are available for editing: Fixed Start Check this box for the counter to start at the value set in the Value property. If this box is not checked, the user will be prompted to enter a start value. -

Page 107: Prompted Field

OPERATION Resume Check this box and the counter will resume from the last printed number. Roll Over Check this box to set a minimum and maximum range for the counter. Example: If the minimum value is 0 and the maximum value is 5 the sequence would be: “0,1,2,3,4,5,0,1,2,3,4,5,0,1,2,3,4,5..”... -

Page 108: External Data

OPERATION External Data This menu is used to set up data transmission of variables from an external PC to the printer. The following properties are available for editing: Default Text: Once the Use Default check box has been ticked, the user can then enter any value. - Page 109 OPERATION If the software libraries are used, the transfer is UNICODE as opposed to the example (which is ANSI). To make the input definition UNICODE enter \x00 after each character (Result: \x01\x00F\x00i\x00l\x00l\x00S\x00e\x00r\x00i\x00a\x00l\x00V\x00a\x 00r\x00=\x0 0\x02\x00S\x00e\x00r\x00i\x00a\x00l\x00\x03\x00,\x00\x02\x00\v01\ x00\v01\x00\ v01\x00\v01\x00\x03\x00\x17\x00) Note: If the input definition fails, it is ignored - if the preceding libraries were used, the user would not be able to tell if the input definition was typed incorrectly.

-

Page 110: Database Content

OPERATION Database Content It is possible to include data from a database on a remote server within the message. Database Select which database to connect to. Connection Field Select a specific field from the database. Fixed Length Select the check box to set a fixed data length. Length Set the length of data if the Fixed Length check box has been selected. -

Page 111: Edit Variable

OPERATION Edit Variable Edit variables contained within the selected item. A list of the variables contained is displayed, select from the list to edit, or select to delete from the list. Properties To view a message item’s properties, select the item within the message and long-press it. -

Page 112: Barcode

OPERATION Barcode Select the Add Barcode button, type the name of the message and select button. Select the More button. On the barcode’s list of Properties, enter the barcode data as appropriate, then select the button to insert the code into the message. To display / edit properties, either: •... - Page 113 OPERATION The following barcode properties are available for editing: Height (mm): This allows the height of the barcode to be indicated. Note: This is not applicable for all types of barcodes. Numerical values can be entered. Bold: The barcode can be formatted in bold. Invert: Selecting Invert will convert the black lines of the barcode to spaces, and the gaps between the original black lines of the barcode will be...

- Page 114 OPERATION Show Human Readable Code: To show the values contained in the barcodes, this box should be active. The human readable interpretation will be printed under the actual barcode. Human readable interpretation for the 2D composite component will be printed above the code (one application identifier per line). Invert: Select the checkbox to invert the barcode.

-

Page 115: Shape

OPERATION Shape To insert a shape into the message, select the Shape button from the Add menu, select the required shape from the list. A properties box will open, define the properties of the shape and select the button to insert into the message. Using the Move/Size and Rotate/Flip functions, arrange the item as... -

Page 116: Move/Size

OPERATION Move/Size Once an item has been added to the message, select the Move /Size Menu to move or resize the item within the message field. To move an item in the message: • Select the desired item within the message, then, using the directional Move arrows, move the item as required, or, •... -

Page 117: Zoom

OPERATION Zoom Select the Zoom Menu to change the magnification of the message area. Use the Zoom Toolbar: To view the item(s) in the Message field or the whole Message field in a different size, select the item(s) and then select the appropriate button from the above toolbar: (1) Incrementally zoom in on the message area (2) Incrementally zoom out of the message area... -

Page 118: File

OPERATION File At the File Menu screen, the user can select from the following Message Options: (1) Create new message (2) Save message (3) Save as a new message (4) Add or edit a connection to a database (5) Add new Shift Code table (6) View/edit variable properties (7) View/edit the message properties (8) Delete item from message... -

Page 119: Selecting An Existing Message

OPERATION SELECTING AN EXISTING MESSAGE Where no message is selected, no message will be displayed in the Home screen: Selecting the Messages button will open the Message Store or stores. Select the required store and then the required message from the list. The following screen will display: Choose to Edit, Preview, Send to Print or Cancel. - Page 120 OPERATION (3) Select Edit. (4) The message will then open in the Message Editor, note that the Edit toolbar is open. Note: Long-press an item within the message to open its properties menu. (5) The message can now be edited, using any of the following edit functions: (10) (11)

- Page 121 OPERATION To edit the content within an item, select the item and select the More button. The following screen will display: Note: The above screen will differ slightly for Barcode items. The Properties area will be open as default. Dimensions and location details can be changed, as well as rotation, font and italicisation.

-

Page 122: Adjusting Printing Parameters

OPERATION ADJUSTING PRINTING PARAMETERS Global Print Settings This sets the print settings for new messages and any parameters that are not saved with the messages. To adjust the print settings, go to Settings > Global Print Settings: Quality The Quality menu allows the alteration of those parameters that will normally affect print quality. -

Page 123: Economy

Print Speed (IM only) Use this setting to adjust the Print Speed. The Print Speed is in the range of 50-400mm/s. Print Head Pressure (Compact 32d, 32c and 53c) Print head pressure controls the pressure that is applied to the print head during printing. - Page 124 OPERATION where the FADING technology cannot be used. It is recommended to experiment with this feature when installing the printer. The printer and the print head cannot be overloaded in any way by entering high values in this menu, but if increasing the Ribbon Economy, reduce the contrast and head pressure settings accordingly, thus increasing the lifetime of the print head.

- Page 125 OPERATION Stop Mid Print (CM only) It might be that the design contains text lines spaced widely apart. The resulting space between the lines is a waste of ribbon, as in the following example: BAKED BEANS The bracket relates to the size of the print and it is obvious that there is a waste of ribbon between the upper part (BAKED BEANS) and...

- Page 126 OPERATION If it has been set to Manual, the number of millimetres the printer should pull back the ribbon must be defined. Measure the desired pull back before entering a value to avoid entering an overly high value causing prints to overlap on the ribbon.

- Page 127 • The appropriate length of ribbon cannot be retracted. This is determined by the operating movement of the dancing arm and cannot be adjusted. On Compact 32d, 32c and 53c printers, print lengths of 10-20mm can usually be retracted successfully. On Communicator II printers, print lengths of 40-50mm can usually be retracted successfully.

-

Page 128: Position

OPERATION • The retraction function is compromised by a dirty capstan roller. The drive roller must be kept clean with Head Cleaning Wipes (P/N MT25215) Column Mode is set up by varying the Number of Columns and Column Width parameters, as follows: •... - Page 129 OPERATION Start Pulse Offset There may be reasons to displace the print in the Y direction, but such a displacement is prevented by printing starting in the middle of the packaging machine signal. If this occurs, an error or warning will be displayed on the screen and the machine will only print every other print.

-

Page 130: Technical

Head down For Compact 32d, 32c and 53c printers: When the print head needs be lowered, i.e. at the start of a print, the printer's software sends a signal to the twin-shafted motor, thus lowering the print head. - Page 131 The default setting is sufficient in most applications. At extremely high speeds (600mm per second on the Compact 32d, 32c and 53c printers and 1000mm per second on the Communicator II printer) or printing on rough material like paper, it may be advantageous to increase this value.

-

Page 132: Print Counter

OPERATION Print Counter During message selection, the Print Counter prompts the user to enter a number of prints to be printed. For example, if you have selected that 100 labels are printed, once printing is complete you will be prompted to select the next action. -

Page 133: Alert Configuration

OPERATION ALERT CONFIGURATION Configure Alerts Go to Settings > Alert Configuration to configure errors / warnings: Note: The screen above shows configurable alerts in IM. CM has more alert configuration options. It is possible to change the alert level for some alerts. In the above example, the Ribbon Error is currently a Warning. -

Page 134: Ranged Alerts

The user can change this limit by selecting it and entering a new limit in meters between a range of 20 to 200. Error and Ready Signals See “Connectivity - Compact 32d, 32c and 53c” on page 2-33. 3-46 25364 Issue 8 March 2018... -

Page 135: Printer Setup

OPERATION PRINTER SETUP Production Line Setup To add a printer to a production line or change the setup, select Production Line Setup. If the Home screen buttons are not set to default, the Production Line Setup can be found at: Settings > Production Line Setup. Line Movement Set details of the Production Line, whether the substrate / printer are operating in Continuous Mode (CM) or Intermittent Mode (IM):... - Page 136 OPERATION Line Movement - IM (Static) 3-48 25364 Issue 8 March 2018...

-

Page 137: Print Trigger

OPERATION Print Trigger This menu changes, depending upon whether the printer is in CM or IM. Set details of how printing is triggered: (1) Trigger By: (a) In CM, from the pull-down menu, select the source for the print trigger - External Input, Internal (Distance) (which prints continuously while the print trigger is closed) or Internal Continuous (which prints continuously while a valid message is selected and there are no errors or warnings active). -

Page 138: Print Head

OPERATION Print Head CAUTION: The Compact 32d, 32c and 53c printers must be calibrated before installing them on the production line. Go to Settings > Production Line Setup > Head Functions and select Calibrate. When calibrating, the print head must be able to extend fully, please ensure enough space is allowed to perform this function. -

Page 139: Head Position Offset

If the printer is in CM, the encoder must be turning in order to make a print. • Align (Compact 32d, 32c and 53c): Automatically set the print head position to the roller • Calibrate (Compact 32d, 32c and 53c): Calibrate the printer. -

Page 140: Inputs/Outputs

OPERATION Inputs/Outputs Assignment This tab shows the pin, input and output assignments. Pull-down menus accompany each assignment. For a detailed pin allocation table, see page 2-20 page 2-21. For a table of functions / behaviours for each output, see page 2-28. -

Page 141: Regional Settings

OPERATION Regional Settings To change the UI Language or Keyboard layout, go to the following: Settings > Regional: Language and Keyboard From this tab, the user can access pull-down menus to select the printer’s defaults for the following: Language, Keyboard Layout, IME Scheme and Primary Currency. -

Page 142: File Manager

OPERATION FILE MANAGER This menu allows the user to add new stores and manage existing Local and Printer directories and files. To access the File Manager, go to Settings > File Manager. Printer From this directory, the user can access files and directories that reside on the printer. -

Page 143: Security Management

OPERATION SECURITY MANAGEMENT Security management allows users and groups to be setup and access levels set accordingly. To access the Security Management menu, from the Home Screen long-press the user / printer ID area or go to Settings > Security: Setup This screen configures the printer’s Auto Log in feature. -

Page 144: Groups

OPERATION Groups Create and manage groups - this will allow the access level to be set for each group. For example, Operators can be set such that they can only select and send messages to print, whereas the Operator Supervisor could be created and set such that they can create and manage messages. -

Page 145: Sd Emulator

OPERATION SD EMULATOR The SD Emulator is a special feature which allows an Easyprint Communicator or Compact printer to print messages that have been created using CoLOS. It also allows messages to be saved on the printer converting them into EasyDesign format. -

Page 146: Enable The Sd Emulator

(1) From the V-Series home screen Select Settings > Advanced > Special Features. Make a note of the System ID number. (2) Contact the Easyprint and request a feature code for the SD emulator. Note: Contact details for Easyprint can be found at www.easy-print.com. -

Page 147: Use Messages Designed For Sd 5, X40 Or X60

OPERATION Use Messages Designed for SD 5, X40 or X60 Messages designed for SD 5, X40 or X60 machines have some different functionality, but when being used with CoLOS Create they can be loaded and sent to an SD 3 printer and CoLOS will convert the features as needed. Alternatively the message can be permanently converted in CoLOS Create by loading the message and selecting File >... -

Page 148: Allocating A Job Source To A Printer

OPERATION Allocating a Job Source to a Printer (1) In CoLOS Control right click the printer to be changed and select Properties. (2) Select Job Sources > Configuration > Browse, this will display a list of available job sources. (3) Select Default Job Source (or as applicable), then select OK. (4) The device properties will now show the selected job source. - Page 149 OPERATION 25364 Issue 8 March 2018 3-61...

- Page 150 OPERATION THIS PAGE INTENTIONALLY LEFT BLANK 3-62 25364 Issue 8 March 2018...

- Page 151 Adjusting the Print Head Angle............4-18 REPLACING THE CAPSTAN ROLLER ..........4-20 Compact 32d, 32c and 53c ............. 4-20 CHANGING THE DRIVE BELT - COMPACT 32D, 32C AND 53C ..4-22 CHANGING PRINTER CONFIGURATION ..........4-24 Compact 32d, 32c and 53c ............. 4-24 Compact 32d Printer ............

- Page 152 MAINTENANCE, SERVICE AND FAULT FINDING Sensor Test - Communicator II ............4-33 Sensor Descriptions ............. 4-33 User Interface Menu............. 4-34 Procedure................4-35 IO Test ..................... 4-37 Printer LED Status................4-38 ERRORS / WARNINGS................. 4-39 LIST OF ERRORS ................. 4-39 TROUBLESHOOTING GUIDE............... 4-61 Print Problems.................

-

Page 153: Preventative Maintenance

Compact 32d, 32c and 53c Front Cover Sensor The Compact 32d printer is fitted with a front cover to protect the internal mechanism of the printer from dust. During normal use, the cover should be fitted at all times to ensure that the mechanism is protected. -

Page 154: Maintenance Schedule

MAINTENANCE, SERVICE AND FAULT FINDING Maintenance Schedule The Compact 32d, 32c, 53c and Communicator II do not require component replacement as part of a preventative maintenance routine. We recommend regular checks to ensure optimum performance is maintained and to allow any parts requiring future replacement to be identified early. - Page 155 MAINTENANCE, SERVICE AND FAULT FINDING Frequency Recommended Actions Every 2 years CAUTION: The following actions should be performed with the printer switched off. Check the motion of the print head for horizontal and vertical movement. Check that movement is smooth and free from resistance. There should be no lateral movement from the bearings.

-

Page 156: Cleaning The Print Head

MAINTENANCE, SERVICE AND FAULT FINDING Cleaning The Print Head Note: Always clean the print head after replacing it or a ribbon. Some of the dots on the print head can get damaged during use. Overheated dots can result in disintegration of the ceramic material as shown in the picture on the left. -

Page 157: Replacing The Print Head

MAINTENANCE, SERVICE AND FAULT FINDING REPLACING THE PRINT HEAD Compact 32d, 32c and 53c Notes: (1) This procedure is applicable for all printer variants, although the 32mm print head appears in the following photographs. (2) Tool required: 2.5mm Allen key. -

Page 158: Head Resistance

MAINTENANCE, SERVICE AND FAULT FINDING Move the retaining clip upwards. Slide the old print head out. Record print head resistance value. Slide in the new print head assembly and fit a new retaining clip. Fit the head cable back into the connector and gently close the connector. -

Page 159: Communicator Ii

MAINTENANCE, SERVICE AND FAULT FINDING Communicator II WARNING: Ensure printer is switched off and disconnected from the power supply before following this procedure. Remove the ribbon cassette from the printer by pulling the handle to release the cassette. Remove the unit and set aside. - Page 160 MAINTENANCE, SERVICE AND FAULT FINDING Disconnect the print head cable from the IDC by gently pulling it off squarely to avoid damaging or bending the connector pins. Using a 2mm Allen key, loosen the grub screws sufficiently to remove the print head assembly. CAUTION: If the printer was in use, the print head will...

- Page 161 MAINTENANCE, SERVICE AND FAULT FINDING This new resistance value must be entered into the software before using the printer. This will be done at the final stage. Record this resistance value: R=1342 Fit the new print head to the printer and ensure the head is pushed up flush against the mounting plate.

- Page 162 MAINTENANCE, SERVICE AND FAULT FINDING Replace the print head housing cover. Refit the cassette unit to the printer. Switch on and let the printer initialise. Go to Settings > Production Line Setup > Print Head and enter the ‘Print Head Resistance’ figure recorded earlier.

-

Page 163: Replacing The Print Head Actuator

MAINTENANCE, SERVICE AND FAULT FINDING REPLACING THE PRINT HEAD ACTUATOR Compact 32d, 32c and 53c Notes: (1) The print head actuator is supplied without the print head and print head adaptor board. (2) Tools required: Flat-head screwdriver, Threadlocker (medium strength), 2.5mm and 3mm Allen keys, TX20 Torx driver, 5.5mm nut spinner, long-nosed pliers. -

Page 164: Align Small Stepper Motor Gears

MAINTENANCE, SERVICE AND FAULT FINDING Align Small Stepper Motor Gears Fitting the small stepper motor gears onto the plastic side arm teeth is crucial to proper printer operation. Perform this procedure after changing either: • Any parts of the print head actuator mechanism OR •... - Page 165 MAINTENANCE, SERVICE AND FAULT FINDING (3) Lift the stepper motor and position the gears so that the plastic side arm teeth are even on both sides of the stepper motor, as shown in the following photo: (4) Hold the stepper motor in place and retighten the four screws. (5) Refit the printer back cover and print head.

- Page 166 MAINTENANCE, SERVICE AND FAULT FINDING (3) Disconnect the print head heater. Print Head Heater and Pipes Print Head Heater and Pipes (Shown Disconnected from (Shown Connected to Printer) Printer) (4) Remove the air pipes to the print head and move the print head connector board so that it is out of the way.

- Page 167 MAINTENANCE, SERVICE AND FAULT FINDING (6) Loosen and remove the distance screw that the actuator rotates around. Note: Remove ONLY the distance screw that holds the actuator. This distance screw is on the right side for a right-hand printer and left side for a left-hand printer.

-

Page 168: Adjusting The Print Head Angle

Conversely, for slow applications reducing the angle may increase print quality. For Compact 32d, 32c and 53c: The print head angle is embossed on the side of the print head angle block, the default is 27°. - Page 169 MAINTENANCE, SERVICE AND FAULT FINDING Rotating the Adjustment Default Position of Head Screw (5) Retighten the lock screw. (6) Re-latch the actuator. (7) Replace the cover. (8) Test for good print quality. 25364 Issue 8 March 2018 4-19...

-

Page 170: Replacing The Capstan Roller

REPLACING THE CAPSTAN ROLLER Compact 32d, 32c and 53c Notes: (1) Tools required for Compact 32d: 2mm Allen key (2) Tools required for Compact 32c / 53c: 5mm Allen key To replace the capstan roller on the Compact 32d printer: (1) Turn the grub screw behind the capstan anti-clockwise. - Page 171 MAINTENANCE, SERVICE AND FAULT FINDING To replace the capstan roller on the Compact 32c / 53c cassette: (1) Undo the bolt contained in the capstan roller, using a 5mm Allen key. Capstan Dancing Arms Compact 32c / 53c Cassette (2) Put the new roller into the base plate. (3) Tighten the bolt with the Allen key.

-

Page 172: Changing The Drive Belt - Compact 32D, 32C And 53C

MAINTENANCE, SERVICE AND FAULT FINDING CHANGING THE DRIVE BELT - COMPACT 32d, 32c AND 53c Notes: (1) Photographs show a Compact 32d. (2) Tools required: 2.5mm Allen key. (1) Remove the bridge cover. Bridge Cover (2) Remove the actuator assembly, as described in “Replacing the Print... - Page 173 MAINTENANCE, SERVICE AND FAULT FINDING (3) Lift the print head mounting arm to expose the two screws. Belt Clamp Screws (4) Loosen the two belt clamp screws. (5) Remove the belt. (6) Fit the new belt. (7) Tighten the belt clamp screws. (8) Refit the actuator assembly onto the printer.

-

Page 174: Changing Printer Configuration

MAINTENANCE, SERVICE AND FAULT FINDING CHANGING PRINTER CONFIGURATION Compact 32d, 32c and 53c This procedure details how to change a right-handed printer set-up to a left-handed printer set-up or vice versa. Notes: (1) Parts required for non-cassette printer: EDP003942 Rehanding... - Page 175 MAINTENANCE, SERVICE AND FAULT FINDING Note: The rewind spindle has the smaller gap. (10) Remove the back cover. (11) At the back of the printer, disconnect the IM stepper motor and the capstan stepper motor. CAUTION: When unplugging the stepper motor connectors from the PCB set, fully press the clip on the inner part of the connector before pulling it out (see the following photograph).

- Page 176 MAINTENANCE, SERVICE AND FAULT FINDING (13) Adjust the ribbon tension. Ribbon tension is controlled by springs fitted to each of the two dancing arms. Dancing arm springs can be fitted in a number of defined positions, allowing the spring force and ribbon tension to be varied if required - see the next photograph.

-

Page 177: Compact 32C / 53C Printer

MAINTENANCE, SERVICE AND FAULT FINDING Changing from Default Dancing Arm Spring Positions Dancing arm spring positions may need to be changed from the default positions in the following conditions only: • If using 22mm wide R1 Grade ribbon, the ribbon tension must be reduced by changing the rewind dancing arm spring to position 6 and the unwind dancing arm spring to position 4. - Page 178 MAINTENANCE, SERVICE AND FAULT FINDING (7) Remove the IM stepper motor and the capstan stepper motor. CAUTION: When unplugging the stepper motor connectors from the PCB set, fully press the clip on the inner part of the connector before pulling it out. Failing to do so may damage the PCB’s connector, and replacement of the PCB set will be necessary.

-

Page 179: Back-Up & Restore

MAINTENANCE, SERVICE AND FAULT FINDING BACK-UP & RESTORE Go to Settings > Backup & Restore: Backup On the Backup tab screen: (1) Review and note the list of back-up types that are required. (2) Go to Settings > Security > Electronic Signature and view / edit / add Electronic Signatures so that the list matches that of the desired back-up types. -

Page 180: Restore

MAINTENANCE, SERVICE AND FAULT FINDING Restore The Restore tab screen follows: From the Restore tab: • Select the Source • Select an available Restore Type and select the Restore button. Update From the Update tab, if updates are found on this screen, you can manually restart the update. -

Page 181: Fault Finding

Front Cover Sensor “Front Cover Sensor” on page 4-3. Sensor Test - Compact 32d, 32c and 53c Note: To test the sensors, the printer needs to be connected to the Power Supply Unit (PSU) and the unit switched on. When you are ready to perform the test, see “Procedure”... -

Page 182: Procedure

MAINTENANCE, SERVICE AND FAULT FINDING Procedure To access the menu that assists in testing the printer, select Settings > IO Port > Monitor. The following screen will display: Scroll down to Sensor and observe the display readings obtained. Note: All sensors are Hall Effect devices. The values obtained are as follows: 0 = No value read 1-99 = Background noise... - Page 183 MAINTENANCE, SERVICE AND FAULT FINDING Home ‘Sensors’ - To test the home sensor, move the print head carrier (sledge) ‘horizontally’ slowly and gently from one side to the other while observing the sensor readings on the screen. Print Head assembly (Sledge) “Home Sensor (Left, Middle and Right)”...

-

Page 184: User Interface Menu

MAINTENANCE, SERVICE AND FAULT FINDING Ribbon Alarm Left and Right - The ribbon alarm is activated if the dancing arm reaches the magnetic sensor. To manually activate the sensor, place a magnet in front of the sensor and verify that the sensor is activated. Home Sensor (Left, Middle and Right) - This detects the position of the print head carrier. -

Page 185: Procedure

MAINTENANCE, SERVICE AND FAULT FINDING Procedure Activate the appropriate sensor and observe the display readings obtained. Note: Except for the ‘Printer Open’ sensor, all sensors are Hall Effect devices. The values obtained are as follows: 0 = No value read 1-99 = Background noise 100-1000 = Working range 1024 = Saturated reading... - Page 186 MAINTENANCE, SERVICE AND FAULT FINDING Printer Open ‘Sensor’ - Open and close the cassette to activate the sensor (photocell) and observe indication. Cassette Handle Status Home ‘Sensors’ - To test the home sensor, remove the cassette. Move the print head carrier (sledge) slowly and gently from one side to the other while observing the sensor readings on the screen.

-

Page 187: Io Test

MAINTENANCE, SERVICE AND FAULT FINDING IO Test Select Settings > IO Port > Test. The following screen appears: Select Test Mode to check the input / output settings to ensure that they are wired correctly. 25364 Issue 8 March 2018 4-37... -

Page 188: Printer Led Status

MAINTENANCE, SERVICE AND FAULT FINDING Printer LED Status The LED indicator on the printer is used to indicate the various states of the printer. The indicator is either on the front of the printer or in the cassette handle. Printer Status LED Colour Idle Blue... -

Page 189: Errors / Warnings

MAINTENANCE, SERVICE AND FAULT FINDING ERRORS / WARNINGS “Alert Configuration” on page 3-45. LIST OF ERRORS Use this list for quick troubleshooting problems with the printer. Note: All error codes in the following list can trigger an error signal EXCEPT for the ones in Error/Warning settings that have been set to Warning or Ignore. - Page 190 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action Event buffer overflow To reduce ribbon consumption, the printer stops the ribbon motor if there is a section of white space in the print out. Too many sections of white space can cause this error.

- Page 191 The voltage supplied by the external supply power supply is tested during start. If the voltage is out of specification (24V±6V for Compact 32d, 32c and 53c or 48V for Communicator II), this error is shown. Check the power connection.

- Page 192 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action Stepper motor One of the stepper motors has drawn voltage overload too much current. This could be caused by faulty motor or print head card error. Print head voltage Print head has drawn too much overload current.

- Page 193 Manually cancel print job and try reloading it. 1018 Head Position error Set the correct distance of 0.2-2.0mm (Compact 32d, 32c between the print head and substrate and 53c) for both CM and IM. Adjust the print head by selecting Settings >...

- Page 194 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1024 Transfer failed Retry operation. If problem persists, contact service technician. 1025 Not ready to transfer Contact service technician. 1026 Ribbon Warning The remaining ribbon has reached the limit specified in the Error/Warning screen.

- Page 195 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1052 Error incompatible Only on 21CFR - Part 11 compliant version controllers: The design being loaded is too new (and hence the controller does not know how to handle it) or too old (created without CRC checksum).

- Page 196 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1065 Not Enough Space on Reserved System Disk 1066 Not Enough Space Reserved 1070 Unable to open log The log file could not be opened. file If the log is located on the LAN check access rights.

- Page 197 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1083 Only BMP and PCX The controller only supports BMP and supported PCX images. Use a paint program to convert any other formats to either BMP or PCX. 1084 Error Reading Image Check if the file exists.

- Page 198 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1106 Error writing The sequence variable can be set to continuous sequence resume count. Check for access rights. file 1107 Error loading The sequence variable can be set to continuous sequence resume count.

- Page 199 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1118 “}” Expected A “}” was expected during the syntax check of the macro. 1119 “>” Expected A “>” was expected during the syntax check of the macro. 1120 Constant number or A constant or a variable was expected.

- Page 200 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1128 Max Loop Count If any of the statements in the macro is executed more than 1000 times and a result is not yet achieved, the macro has entered a deadlock. The error comes up to prevent a faulty macro stopping the entire unit.

- Page 201 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1140 Unreferenced Macro A macro output variable is inserted into Output variable a field (Text field), but is never calculated by any macro. Check the macro and the macro output variable for any inconsistency.

- Page 202 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1174 No columns in file No columns are found in the database file. Check filename and integrity of database. 1175 Database Row Not A search in the database for a Found particular row failed.

- Page 203 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1220 Error Creating Design The item could not be created. Item 1221 Error Creating The variable could not be created. Variable 1222 Unknown Barcode The barcode item contains info about a Type type currently unknown.

- Page 204 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1243 Block Did Not Fit The rectangle around the field does not Label fit the label. Check the size of the field and the data. 1244 Text Did Not Fit Label Too much text is typed into the label. Check the field.

- Page 205 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1274 Shortcut is no longer The network is no longer available. available. Check the cable. 1275 CRITICAL: More General network error. entries are available. 1276 CRITICAL: The handle General network error. is not valid.

- Page 206 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1406 Init Serial port Could not open serial port. Try to reopen the port by switching baud rate. 1407 Read Timeout The start of a command was read, but the remainder of the command was not received within a period of time.

- Page 207 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1419 Error Parsing Block Check transmission. Buffer 1420 Invalid Socket Data Check transmission. Block 1421 Failed To Send Check communications cable. Command 1422 Handshake failed Check communications cable. closing connection 1423 Socket ident is not The internal handle used for the...

- Page 208 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1438 Command is not An attempt to send data not supported supported by actual by the actual version used. Check version capabilities of used version. Upgrade if required or modify the transmission. 1439 Id not supported for An attempt to send data not supported...

- Page 209 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1608 Could not initiate Check for valid upgrade file. upgrade 1609 Upgrade path invalid If upgrading, make sure the upgrade file can be located. If backing up, make sure the destination folder is valid. 1611 Archive invalid Check for valid upgrade file.

- Page 210 MAINTENANCE, SERVICE AND FAULT FINDING Error No. Error Text Action 1625 Upgrade script failed Retry operation. If problem persists, contact service technician. 1626 Could not read Verify that the upgrade file is not upgrade info damaged and that it is created for this device.

-

Page 211: Troubleshooting Guide

MAINTENANCE, SERVICE AND FAULT FINDING TROUBLESHOOTING GUIDE Print Problems When poor print quality occurs, check the following list to ensure that settings/conditions are correct: Setting/Condition to Check Setting/ Setting/ Condition Condition Applicable Applicable to IM to CM Is the printer in ‘Ready’ mode and able to print? ... - Page 212 MAINTENANCE, SERVICE AND FAULT FINDING Setting/Condition to Check Setting/ Setting/ Condition Condition Applicable Applicable to IM to CM Is the substrate surface clean and suitable for Thermal Transfer printing? Is the dwell time sufficient for the amount of print required? ...

- Page 213 MAINTENANCE, SERVICE AND FAULT FINDING Setting/Condition to Check Setting/ Setting/ Condition Condition Applicable Applicable to IM to CM Is the print head heater being used and set appropriately (that is, 30° for cold environments)? Is the peel-off roller in the correct position, parallel to head and clean? ...

-

Page 214: Print Quality And Print Head

MAINTENANCE, SERVICE AND FAULT FINDING Print Quality and Print Head Problem Action No Information is Printed If the printer appears to be operating correctly but no data is printed, check the following: Is a valid message selected? Check the print speed and contrast values are at appropriate levels for the thermal ribbon and substrate. - Page 215 The matching of the ribbon and the substrate is very important. An incorrect match will not give good print quality. Contact your local Easyprint distributor for further details. If lines of dots are not printing and cleaning the print head and platen / roller does not resolve the problem, replace the print head.

- Page 216 MAINTENANCE, SERVICE AND FAULT FINDING Problem Action Set the print head to substrate gap between 0.2 and 2.0mm. The air pressure should then be increased until a good quality print is apparent. As a rough guide, during printing this should be 2.5-3.5 bar on the printer’s rear air pressure gauge.

- Page 217 If this is the case, use another ribbon grade. Ask your local Easyprint distributor for ribbon advice. Print smudges Reduce the Contrast value setting to compensate for extra friction forces that are applied on the ribbon during printing.

- Page 218 MAINTENANCE, SERVICE AND FAULT FINDING Problem Action Ribbon Creasing Ribbon creasing is generally due to the ribbon attempting to 'track' across the print head. The most common causes are: Bent ribbon guide pins. This may occur if the printer is dropped. It is not usually possible to bend a pin back into position.

- Page 219 MAINTENANCE, SERVICE AND FAULT FINDING Problem Action Missing front edge of the print Head down time is too short. Increase the head down time step by step in 'run settings' until the front edge is included. Should the controller report that the Y-offset is too short, increase its value.

- Page 220 There is a mismatch between the ribbon and packaging material. This is a common error when using a ribbon other than a Easyprint ribbon. After changing a print head, an incorrect print head resistance value was input. When changing the print...

- Page 221 The contrast is too high. The ribbon is not fitting correctly over the top of the print head guide roller(s). For Compact 32d, 32c and 53c only: If using 22mm wide R1 Grade ribbon, the ribbon tension must be reduced by...

- Page 222 MAINTENANCE, SERVICE AND FAULT FINDING Problem Action Ribbon sticks to the substrate When increasing the level of ribbon economy, reduce the Print Head Pressure setting to compensate for extra friction forces that are applied on the ribbon during printing. Reducing the Print Head Pressure reduces the friction forces that can cause the ribbon to crease, stick to the substrate...

-

Page 223: Printer

MAINTENANCE, SERVICE AND FAULT FINDING Problem Action After a fault condition has The print head is in the extended been rectified, Compact 32d position and needs to be manually ribbon cannot be fitted retracted. After a fault condition has The print head is in the extended... - Page 224 MAINTENANCE, SERVICE AND FAULT FINDING Problem Action For Communicator II only: The print head up / down motion is driven by a small pneumatic solenoid. Check the following: Check the air supply pressure and the tubes between the components. Check that the head is free to rotate in its mounting.

-

Page 225: Ribbon Breaks

MAINTENANCE, SERVICE AND FAULT FINDING Ribbon Breaks Problem Action Ribbon breaks may be Check that the encoder matches the caused by one of the substrate speed correctly, otherwise the following issues: ribbon may be dragged out of the printer and eventually break. IM only: Check that the printer is printing whilst the substrate is stationary. - Page 226 MAINTENANCE, SERVICE AND FAULT FINDING THIS PAGE INTENTIONALLY LEFT BLANK 4-76 25364 Issue 8 March 2018...

- Page 227 PART 5 : TECHNICAL REFERENCE CONTENTS Page COMPACT 32D, 32C AND 53C SYSTEM SPECIFICATION....Compact Touchscreen ..............Printer Specification................. Power Supply Unit ................COMMUNICATOR II SYSTEM SPECIFICATION ........Touchscreen ..................Printer Specification................. PRINTING DATA..................25364 Issue 8 March 2018...

- Page 228 TECHNICAL REFERENCE THIS PAGE INTENTIONALLY LEFT BLANK 25364 Issue 8 March 2018...

-

Page 229: Compact 32D, 32C And 53C System Specification

TECHNICAL REFERENCE COMPACT 32d, 32c AND 53c SYSTEM SPECIFICATION Compact Touchscreen Type 5.7 inch, full colour Compact Touchscreen (640x480 resolution), handheld, with docking station. Compact Touchscreen 170(W) x 127.9(H) x 33.7(D) Dimensions (mm) Weight (kg) 0.385kg Connectivity USB, Ethernet, (Mini USB for power / data... - Page 230 Fonts Most TrueType fonts Controller / hardware No dedicated controller required. Hardware interface options interface options: Easyprint Compact Touchscreen (via USB cable- hot swappable), Shared Compact Touchscreen (via Ethernet cable or network), PC-based interface (via Ethernet cable or network) Connectivity...

-

Page 231: Power Supply Unit

TECHNICAL REFERENCE Power Supply Unit Dimensions: 135mm x 58mm x 35mm Weight: 0.5kg Rated Input Voltage 90-264V; 1.5A Range: Output Voltage: +24V d.c. Rated Output Power: 120W subject to de-rating Working Temperature: 0 to +50°C subject to de-rating Storage Temperature: -20°C to +85°C 25364 Issue 8 March 2018... -

Page 232: Communicator Ii System Specification

TECHNICAL REFERENCE COMMUNICATOR II SYSTEM SPECIFICATION Touchscreen Display 10.4 inch SVGA Full Colour Touchscreen Operating System Windows CE 7 Dimensions (mm) 307(W) x 232(H) x 75(D) IP Rating Designed to IP55 Mounting Accessories Full range of brackets Temperature 5 - 45°C Humidity 10 - 90% non-condensing Electrical supply voltage... -

Page 233: Printer Specification

Connectivity Ethernet, USB (for USB Stick), Secure Digital (On printer only), Digital I/O for host machine integration. Ribbon Compatible with the full range of Easyprint ribbons. Ribbon Width Standard Widths: 30mm, 55mm and 130mm. Other widths available on Request Beacon Alarm Outputs General fault and Printer Ready conditions. - Page 234 Economy mode) Approvals IP Rating Designed to IP44 (when print head opening is covered) Note: For purity of supplied compressed air, Easyprint requires compliance with Compressed air purity classes ISO 8573-1 6 3 2 : 2001. 25364 Issue 8 March 2018...

-

Page 235: Printing Data

TECHNICAL REFERENCE PRINTING DATA Material PE - PP - PA - PET - paper, Tyvek™, cellophane, etc. Print resolution Normal mode: 12 x 12 dots / mm = 300 x 300 DPI Fast Mode: 6 x 12 dots / mm = 150 x 300 dpi TrueType Fonts Arial, Arial black, Arial Narrow, Comic Sans MS, Courier New, Gautami, Georgia, HYGothic Extra,... - Page 236 TECHNICAL REFERENCE THIS PAGE INTENTIONALLY LEFT BLANK 5-10 25364 Issue 8 March 2018...

- Page 237 PART 6 : GLOSSARY OF TERMS CONTENTS Page GLOSSARY OF TERMS ................ 25364 Issue 8 March 2018...

- Page 238 GLOSSARY OF TERMS THIS PAGE INTENTIONALLY LEFT BLANK 25364 Issue 8 March 2018...

- Page 239 GLOSSARY OF TERMS GLOSSARY OF TERMS Alphanumeric Letter or number characters. Attribute A characteristic or distinctive feature. Breadcrumb Trail A sequential set of icons that allows the user to view where they are, where they’ve been and how to return to previously visited areas. Column Mode Printer feature which retracts the ribbon after each Ribbon Economy...

- Page 240 ODBC Open Database Connectivity. A standard for accessing different database systems. EasyView Common user interface that will be used across Easyprint’s technologies. Range Information presented by the printer - the range between which the value should appear. Ribbon Economy Patented feature that enables user to select how much ribbon will be used for each print.

- Page 241 GLOSSARY OF TERMS Start Pulse Offset Function that displaces the print like an ordinary Y-Offset, but also allows the printer to receive a start signal from the packaging machine “sending signals” in the middle of printing. Status Information presented by the printer - the current value, setting or adjustment in the printer.

- Page 242 GLOSSARY OF TERMS THIS PAGE INTENTIONALLY LEFT BLANK 25364 Issue 8 March 2018...

- Page 243 Easyprint Compact 32c, 32d, 53c & Communicator II Product Manual Easyprint A/S has a policy of continuous product improvement, the Company therefore reserves the right to modify the specification contained within this document without notice. © Easyprint A/S 2018. All rights reserved.