Table of Contents

Summary of Contents for Terex Digger Derrick

- Page 1 DIGGER DERRICK OPERATOR’S MANUAL This Operator’s Manual MUST BE READ prior to operating your Telescoping Material Handling DIGGER DERRICK PRINTED IN THE USA Original Instructions in English Terex South Dakota, Inc. 463280 09/2014...

- Page 2 DIGGER DERRICK Terex South Dakota, Inc. 500 Oakwood Road Watertown, SD 57201 4 6 3 2 8 0 - 0 9 / 1 4 T e r e x S o u t h D ak o t a , I n c .

-

Page 3: Table Of Contents

MAIN DIGGER DERRICK CONTROL FUNCTIONS ........1... - Page 4 DIGGER DERRICK OPERATION ........

- Page 5 DIGGER DERRICK MANUAL ROTATION (WORM DRIVE ROTATION) ........1 - 68 AUXILIARY LET DOWN POWER (OPTIONAL) .

- Page 6 DIGGER DERRICK T O C - 4 46 328 0 - 9/1 4 Te re x So uth Da kota , Inc. D i gge r De rr ick...

-

Page 7: Introduction

INTRODUCTION OWNERS, USERS AND OPERATORS Thank you for choosing Terex South Dakota, Inc. equipment for your application. User safety is our number one priority and this is best achieved by our joint efforts. As equipment users and operators, you make a major contribution to safety if you: 1. -

Page 8: Bulletin Distribution And Compliance

DIGGER DERRICK BULLETIN DISTRIBUTION AND COMPLIANCE It is the owners responsibility to comply with all bulletins issued by Terex South Dakota, Inc. or the vehicle manufacturer. Safety of product users is of paramount importance to Terex South Dakota, Inc. Various bulletins are used by Terex South Dakota, Inc. -

Page 9: Safety

The operator is the single most important factor for safety when using any piece of equipment. Learn to operate your Terex South Dakota, Inc. equipment in a safe manner. NOTE: The best method to protect yourself and others from injury or death is to use common sense. - Page 10 2. Modifications to this Terex South Dakota, Inc. equipment from the original design specifications without written permission from Terex South Dakota, Inc. are strictly forbidden. A modification may compromise the safety of the Terex South Dakota, Inc. equipment, subjecting users to serious injury or death. Any such modification will void any remaining warranty.

-

Page 11: General Safety Guidelines

DIGGER DERRICK GENERAL SAFETY GUIDELINES 1. The use of this Digger Derrick is subject to certain potential dangers that cannot be protected against by mechanical means. Only the exercise of intelligence, care, and common sense can eliminate these dangers. It is essential to have competent, careful operators who are physically and mentally fit, and thoroughly trained in the safe operation of this Digger Derrick. -

Page 12: Before Operation

The Digger Derrick vehicle must have sufficient traction to prevent sliding. 9. The Digger Derrick has been stability tested per ANSI A10.31. The lift capacity shown on the load chart must be reduced if vehicle is not level. -

Page 13: During Operation

DURING OPERATION BOOM AND LIFTING OPERATIONS 1. Never operate the Digger Derrick unless you know the location, function, and operation of all the controls, including emergency and accessory operation. 2. Avoid abrupt starts, stops and reversal of direction. Operate all controls slowly for smooth motion. -

Page 14: Digging

DIGGER DERRICK DIGGING 1. Never dig until all the underground utilities (such as, electrical lines, gas lines and other lines) have been identified and marked. Call your local “Call before you Dig” hotline, the national number (888) 258- 0808 for assistance, or 811 if available in your area. -

Page 15: Operation With Personnel Platform Attached

3. When the Digger Derrick is operated from the upper controls, the pole guide and digger (if equipped) shall be rendered inoperable. -

Page 16: Electrical Dangers

ELECTRICITY OBEYS NO LAW, BUT ITS OWN. 1. Electricity is an ever-present danger when using a Digger Derrick and working from a platform. Follow all OSHA, ANSI, state, federal and company rules and regulations when working on or near energized power lines. -

Page 17: Accessories

2. All accessories must be inspected, maintained and operated with the same care and safety rules that apply to the Digger Derrick. 3. Tools selected for use with the Digger Derrick must be of the open center type and operate at 2250 PSI (15.51 MPa) and flow input shall not exceed the maximum tool rating. -

Page 18: Maintenance

4. Replace all missing or illegible decals. 5. Any changes or modifications to the Digger Derrick must be compliant by the manufacturer in writing. 6. Do not alter the insulated portion of the Digger Derrick. Alterations may reduce the insulating value. -

Page 19: Overview Of Potential Hazards

The Digger Derrick is a heavy moving machine capable of extending its reach vertically and horizontally. There are potential hazards associated with the use of this Digger Derrick. These hazards will be minimized if the machine is properly inspected, maintained and operated. The operators shall read and understand this manual and be trained to use the machine in an appropriate and safe manner. - Page 20 DIGGER DERRICK Crushing WARNING: Will Cause Serious Do not operate outriggers unless you can verify all Crushing Injury. personnel and obstructions are clear. Operator must watch the outrigger while in motion. High Pressure WARNING: Can Cause Serious Relieve pressure on hydraulic and pneumatic systems Air or Fluid Injury or Death.

-

Page 21: Safety Related Decals

DIGGER DERRICK SAFETY RELATED DECALS Safety signs are designed and fitted to the product to warn of possible dangers, and MUST be replaced immediately if they become unreadable or lost. If the product is repaired and parts have been replaced on which safety signs were fixed, be sure new safety signs are fitted before the product is put into service. - Page 22 DIGGER DERRICK TRUCK COMPUTER 495845 FALL HAZARD - MAINTENANCE 495892 HAND SIGNAL CHART 498818 OVERTURNING HAZARD 498819 SLOPE INDICATOR 486277 ESCAPING FLUID UNDER PRESSURE H23877 ELECTROCUTION HAZARD READ CAREFULLY DEATH OR SERIOUS INJURY OCCUPANTS OF THE BASKETS OF THIS AERIAL DEVICE HAVE ABSOLUTELY NO...

- Page 23 DIGGER DERRICK ELECTROCUTION HAZARD DEATH OR SERIOUS INJURY WILL RESULT FROM CONTACT WITH OR INADEQUATE CLEARANCE TO ELECTRICAL POWER LINES AND APPARATUS Maintain safe clearances from electrical power lines in accordance with applicable government regulations. Allow for boom, platform, electrical line and load line sway.

- Page 24 DIGGER DERRICK ELECTROCUTION HAZARD THIS MACHINE IS NOT INSULATED DEATH OR SERIOUS INJURY Will result from contact with or inadequate clearance to electrical power lines and apparatus Maintain safe clearance from electrical power lines in accordance with applicable government regulations. Allow for boom, platform, electrical line and load line sway.

- Page 25 DIGGER DERRICK ELECTROCUTION HAZARD FIRE HAZARD USE ONLY ORANGE, NON-CONDUCTIVE HOSE FOR TOOL, PLATFORM AREA, AND INSULATED SECTIONS. FAILURE TO DO SO MAY CAUSE DEATH OR SERIOUS INJURY. 419270A OUTRlGGER CONTACT WILL CAUSE SERIOUS CRUSHING INJURY STAND CLEAR 419269 -XIX D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c .

- Page 26 FAILURE TO OBEY THE FOLLOWING WILL RESULT IN DEATH OR SERIOUS INJURY For stationary operation, vehicle must be securely parked, driveline disengaged, and Digger Derrick properly stabilized prior to operation. To avoid tip-over, all outriggers must be properly extended on a solid level surface.

- Page 27 DIGGER DERRICK -XXI D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c . 4 63 28 0 - 9 / 1 4...

- Page 28 PROPER PROCEDURES Could Result In DEATH OR SERIOUS INJURY If YOU sell, install, offer for use, use, operate or maintain this Digger Derrick: You MUST COMPLY with the requirements of: American National Standards Institute A10.31, National Electric Safety Code, and OSHA...

- Page 29 Fasteners include turntable to rotation bearing, pedestal to rotation bearing, cylinder and boom pivot pins and retainers, subframe mounting bolts and leveling components. The Aerial Device or Digger Derrick you are operating must be maintained by a qualified person. 495892A -XXIII D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c .

- Page 30 DIGGER DERRICK STOP. With arm extended EMERGENCY STOP. With both arms extended HOIST. With upper arm RAISE BOOM. With arm horizontally to the side, horizontally to the side, palms down, arms are swung back extended to the side, extended horizontally to the palm down, arm is swung and forth.

- Page 31 DEATH OR SERIOUS INJURY May result from overturning machine For material handling, lifting operations the Digger Derrick must be level. Lift capacity is determined in a level position of the truck. If the truck is not level the capacity is reduced For lifting people, in a boom tip platform, the truck must be at less than a 5 degree slope.

- Page 32 DIGGER DERRICK Escaping fluid under pressure penetrate skin causing serious injury. Relieve pressure before disconnecting hydraulic lines. Keep away from leaks and pin holes. Use a piece of cardboard or paper to search for leaks. Do not use your hand.

-

Page 33: What Is Insulated And Not Insulated

DIGGER DERRICK WHAT IS INSULATED AND NOT INSULATED The following will apply to insulated units only. If the unit is not equipped with an insulating boom the unit does not provide any electrical protection. Refer to the ID plate on the unit to determine if it is considered an insulating unit. -

Page 34: Upper Boom Rating

UPPER BOOM RATING The ID plate on your digger derrick will indicate if the unit is insulated and the voltage the insulation has been designed and tested to withstand. The manuals also indicate what areas of the machine will provide insulation. - Page 35 Death or serious injury to the operator or ground personnel can occur if any part of the Digger Derrick contacts an energized conductor, ground line, grounded line, or other OBJECTS. Proper clearance must be maintained. Working around electrical power lines is covered by ANSI and OSHA Regulations.

- Page 36 DIGGER DERRICK The fiberglass boom and platform liners must be dielectrically tested periodically to verify the insulating properties are being maintained. Do not assume it is providing any protection. Ground personnel must stay away from vehicle and any items or components connected to the vehicle, in case of accidental boom contact between conductor and metallic portion of boom, which will cause serious injury or death.

-

Page 37: Section 1

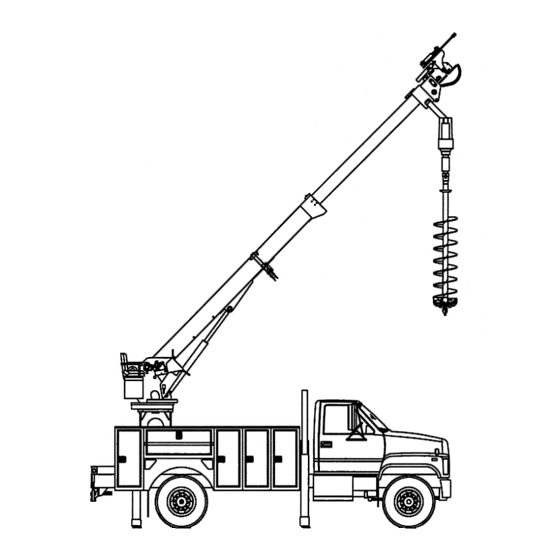

DIGGER DERRICK SECTION 1 OPERATION GUIDELINES NOMENCLATURE D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c . 4 63 28 0 - 9 / 1 4... -

Page 38: Cab Control Operation

The power take-off (PTO) is a gearbox used to transmit power from the vehicle transmission to the hydraulic pump, which provides hydraulic oil for the Digger Derrick functions. The power take-off control can be a switch on the dash, for electric control systems, or a “push-pull” knob, (usually mounted on the cab floor). An indicator light will show that the PTO is engaged. -

Page 39: Operator Controls And Descriptions

DIGGER DERRICK OPERATOR CONTROLS AND DESCRIPTIONS Please contact your Terex South Dakota, Inc. Dealer for the proper page to insert for your machine. This page is to show the Lower control station layout. D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c . - Page 40 DIGGER DERRICK Please contact your Terex South Dakota, Inc. Dealer for the proper page to insert for your machine. This page is to show the Lower control station layout. 1 - 4 46 328 0 - 9/1 4 Te re x So uth Da kota , Inc.

-

Page 41: Main Digger Derrick Control Functions

MAIN DIGGER DERRICK CONTROL FUNCTIONS Control location and function varies depending on purchaser's requirements and options. Some of the following control functions may not be included in the controls for this Digger Derrick. Refer to the control decals on unit for proper operation. - Page 42 DIGGER DERRICK Digger Push lever to dig and also to store auger. Pull lever to reverse auger and also to unstore auger. Winch Push lever to lower “DOWN” load. Pull lever to raise “UP” load. Pole Guide Push lever to close “HOLD” arms and guide pole.

- Page 43 DIGGER DERRICK Upper/Lower Selector Push lever to divert control to the boom tip. CNTRLS When in top controls, lower controls are inoperative. Pull lever to return to lower control operation. The Control Selector will function as an emergency Emergency Stop stop by taking oil flow away from the active control.

- Page 44 Push and hold to engage auxiliary lowering system. (Optional) Used when vehicle engine is not operable. PUSH Do no use to operate Digger Derrick continuously. Foot Throttle Depress with foot to increase engine RPM. Release to decrease engine RPM. Tachometer Used to monitor the engine RPM.

-

Page 45: Single Stick Functions (If Equipped)

DIGGER DERRICK SINGLE STICK FUNCTIONS (IF EQUIPPED) DOWN BO OM ROTATE CONTROL ILLUSTRATION DESCRIPTION Rotation Twist control counterclockwise to rotate boom “LEFT“. Twist control clockwise to rotate boom “RIGHT”. ROTATE Lift Push control to lower “DOWN” the boom. Pull control to raise “UP” the boom. -

Page 46: Controls Below Rotation

CONTROLS BELOW ROTATION Control locations and function varies depending on purchaser’s requirements and options. Some of the following control functions may not be included in the controls for this Digger Derrick. Refer to the control decals on unit for proper operation. -

Page 47: Controls Below Rotation Functions

Used when vehicle engine is not operable. PUSH (Optional) Do not use to operate Digger Derrick continuously. NOTE: *Can be included with two-speed throttle circuit. When vehicle engine is disabled, the auxiliary let down power can be activated by the two-speed throttle switch. -

Page 48: Personnel And Training

• The purpose and use of manuals. • Operating manuals are an integral part of the Digger Derrick and must be properly stored on the vehicle when not in use. • A pre-start inspection. - Page 49 If a deficiency is found, have maintenance performed immediately. Malfunction of one component can cause serious injury to the operator or to others if not corrected immediately. The ground crew must be trained to operate the Digger Derrick in case of emergency. A WELL TRAINED CREW IS A PRODUCTIVE CREW!

-

Page 50: Pre-Operation

DIGGER DERRICK PRE-OPERATION DAILY PRE-OPERATION CHECKS Before operating the Digger Derrick perform the daily checks and also check the following: 1. Perform the frequent and periodic inspections and lubrications as outlined in the maintenance section of this manual. 2. Store loose objects properly. - Page 51 DIGGER DERRICK ITEM DESCRIPTION ITEM DESCRIPTION Fuel Reservoir Outrigger Pads Tires and Wheels Outrigger and Tool Controls Engine, Radiator and Cooling System Body Grab Handles Battery Body Access Steps Steering Mechanism Fire Extinguisher Brakes Grounding or Barricade Kit Transmission Hydraulic Reservoir...

- Page 52 DIGGER DERRICK 21 5 9,10 DIGGER DERRICK CHECKS ITEM DESCRIPTION ITEM DESCRIPTION Hydraulic Pump Transferable Pole Guide Mechanism Auger Storage Bracket and Mechanism Platform Auger Roll Up Cable Harness Auger to Hex Shaft Retention Bolt Non-Skid and Platform Step Digger to Hex Shaft Coupling...

- Page 53 Load Line Sheaves Boom Angle Indicator NOTE: Some items listed above are optional and may not be installed on your Digger Derrick. NOTE: The lower controls shown are above rotation. The lower controls on your Digger Derrick may be mounted elsewhere. Refer to the controls section.

-

Page 54: Job Site Survey

• Lift capacity is reduced if not level for material handling. 3. Determine if the ground is firm enough to support the Digger Derrick. If the ground is not firm enough, use pads under the outriggers and crib as needed to distribute the load. -

Page 55: Operating Temperature Range

Do not exceed an oil temperature of 150 degrees F (66 degrees C). WIND SPEED Do not operate the Aerial device or Digger Derrick at any wind speed that would create a potential hazard or does not allow safe operation for the work to be performed. -

Page 56: Job Site Setup

DEATH OR SERIOUS INJURY May result from overturning machine For material handling, lifting operations the Digger Derrick must be level. Lift capacity is determined in a level position of the truck. If the truck is not level the capacity is reduced For lifting people, in a boom tip platform, the truck must be at less than a 5 degree slope. - Page 57 Digger Derrick. If one tire and axle spring is not loaded the same as the other, on that axle, it will not be able to provide the stability needed.

-

Page 58: Setting Up On A Slope

DIGGER DERRICK SETTING UP ON A SLOPE If the chassis is set-up across the slope as shown below, the surface can be up to 5 degrees from level but must be firm and flat where tires are located. If one side of the chassis is low, extend the low side outrigger first and make sure that firm contact is made. -

Page 59: Setting Up On A Soft Surface

DIGGER DERRICK SETTING UP ON A SOFT SURFACE If the ground is too soft to support the outrigger load or wheel load, mats or pads must be used. If the ground will not support the load the unit cannot be used at that location. Make certain the tires and outriggers are centered on the pads and the cribbing provides stable support as the booms are moved. -

Page 60: Outrigger Interlock

STABILITY The stability of a vehicle equipped with a Digger Derrick depends on the gross weight of the vehicle and platform capacity, the slope of the work area, and whether the ground is firm enough to support the force on the outrigger pads. -

Page 61: Digger Derrick Operation

DIGGER DERRICK OPERATION Operation of a Digger Derrick as a lifting device must follow the appropriate OSHA rules, 1926 subpart CC or Subpart V. The operator may be required to be certified as a digger Derrick operator. Signal persons and riggers are required to be competent and qualified. - Page 62 Make certain that all personnel are clear of the workzone and that there is sufficient overhead clearance before operating the Digger Derrick. CLEAR ALL BODY OBSTRUCTIONS BEFORE ROTATING Inspect all slings, hooks, rigging, and lifting attachments daily before use. All items must have sufficient safe working load capacity for loads being lifted.

-

Page 63: Load Chart

LOAD CHART The load chart at the operator station provides the load capacities of the Digger Derrick when lifting a freely suspended load. The load chart gives allowable loads when the vehicle is level. If not level, the capacity is reduced. -

Page 64: Installed Options

DIGGER DERRICK INSTALLED OPTIONS CONTROLS. REF: E04G-1196 OPTIONS: FBG HYD 3RD, ESK, AUG 20, TRANS TPP LOWER RIGHT SECTION OF LOAD CHART This section of the load chart gives the options that are installed at the time of test to determine the capacity. -

Page 65: Reading The Load Capacity Chart

DIGGER DERRICK READING THE LOAD CAPACITY CHART The chart is divided into areas depending on the extension of the boom. A section is considered extended unless fully retracted. The areas of the chart are labeled: • FULLY RETRACTED •All sections are fully retracted. - Page 66 DIGGER DERRICK UPPER CONTROL UPPER CONTROL WINCH CAPACITIES WINCH CAPACITIES WINCH CAPACITIES IN LBS BOOM WINCH CAPACITIES BOOM JIB EXT JIB EXT JIB EXT ANGLE IN LBS ANGLE 0 FT 2 FT 4 FT 80º 2700 80º 2700 2700 1850 70º...

-

Page 67: Lifting And Boom Sections

LIFT CYLINDER CAPACITY When you consult your Digger Derrick load capacity chart, note that the Digger Derrick lift capacity increases at high boom angles and at shorter distances from the centerline of rotation to the centerline of the load (radius). -

Page 68: Intermediate Section (Second Section)

DIGGER DERRICK POSITION THE DIGGER DERRICK TO AVOID DRAGGING THE LOAD Lifting speeds can be controlled with the engine throttle and by metering the control valve. Slow speeds should be used on all heavy loads or when working in close quarters. For smooth operation, start and stop with low engine speed. -

Page 69: Transferable Pole Guide (Optional)

When used with the boom tip winch, the winch line has to be routed as shown below. Route the winch line on any Digger Derrick with a transferable pole guide and pole grabbing winch as shown in following graphic. At all times, the winch line must be routed from the winch drum over the sheave in the third section. -

Page 70: Winches

DIGGER DERRICK WINCHES TURNTABLE WINCH The turntable winch is located in the turntable behind the rear of the boom. Boom movement, articulation or extension will cause load line to move relative to the boom tip sheave. Be aware you must payout or pull in on the winch line to prevent contact of the hook or load being pulled into the sheave end. -

Page 71: Winch Line

3. Do not allow ground personnel to ride the winch line or load. 4. If your Digger Derrick is supplied with a jib, do not exceed the jib capacity load chart. 5. Maintain proper clearance between energized conductors and boom tip, winch line, hook, and load. -

Page 72: Electrocution Hazard

DIGGER DERRICK ELECTROCUTION HAZARD Electrocution Hazard exists when any winch line contacts energized source. Serious injury or death can result if electrical contact is made with a contaminated synthetic rope or a wire rope. This type of contact can electrically charge the rope, the load, and the vehicle. -

Page 73: Operating The Winch

DIGGER DERRICK OPERATING THE WINCH The following instructions outline the proper method of hydraulic winch operation to give safe efficient trouble-free service. Winch line speed should be controlled by metering the control valve with the winch control lever. Move the winch control lever in the desired direction using a slow smooth movement of the control lever. -

Page 74: Digging Operations

DIGGER DERRICK DIGGING OPERATIONS Observe the following five rules to unstow or stow the digger/auger. 1. Before lowering or storing auger, make certain that all ground personnel are clear and the boom is raised high enough (approximately 45 to 50 degrees) and so the auger clears the vehicle body. -

Page 75: Changing Augers

DIGGER DERRICK CHANGING AUGERS 1. DO NOT change or remove an auger directly underneath a power line. 2. Lower the outriggers. Make sure the vehicle is stable for boom movements. 3. If the changeover auger is stored on the bed of the vehicle, it must be removed to ground level. Use a sling and the winch for removing auger. -

Page 76: Digging Pole Holes

DIGGER DERRICK DIGGING POLE HOLES Remember to “Call before you dig” or 811 if available in your area or the number for your location. Before digging locate all overhead lines and all underground utilities. Call 811 if available in your area, or your state or province “Call before you dig”... -

Page 77: Digging In Rocky Conditions

DIGGER DERRICK Push the digger control to “DIG” position and lower the auger into the ground by slowly lowering the boom. Control the rate of lowering the boom to get maximum penetration but do not stall the digger. When using carbide teeth, always remove down pressure before reversing the auger to avoid damage to the carbide teeth. -

Page 78: Digging In Frost Or Hard Pan

DIGGER DERRICK DIGGING IN FROST OR HARD PAN When digging in frost or hard pan, use carbide auger teeth and point. For digging in these conditions, recommend using a slow speed and maximum down pressure. If auger head is allowed to slide, a tough ice slick may form, which could prevent penetration. -

Page 79: Digging Anchor Holes

If it is necessary to dig at any angle to the Digger Derrick, use the lift cylinder, second section, and rotation. DIGGING ANCHOR HOLES AT AN ANGLE DIG AS NEARLY IN LINE WITH THE DERRICK AS POSSIBLE Attach the anchor auger to the end of the hexagon extension shaft of the digger. -

Page 80: Setting Screw Anchors

Set the screw anchors as nearly in line with the Digger Derrick as possible. This permits controlling the proper angle of screw anchor by using only the lift cylinder and the second section cylinder. -

Page 81: Handling And Setting Poles

1. Ground the vehicle while following your companies policies. 2. Always maintain proper clearance from energized power lines. The Digger Derrick cannot protect you from phase-to-phase or phase-to-ground contact. Allow for sag, sway, or rocking. Boom tip contains conductive materials. - Page 82 8. Never allow ground personnel to come in contact with the Digger Derrick, vehicle, or vehicle attachments while in operation near energized power lines. 9. While operating the digger derrick, the operator must not create a connection between the vehicle and ground.

- Page 83 DIGGER DERRICK Once the pole hole is dug to the required depth, it is ready to accept the pole. Make sure soil is packed tight at bottom of hole, using a tamper (see Recommended Tamp section). Before hooking the pole, two things must be determined: •...

- Page 84 DIGGER DERRICK When the pole has been raised to the vertical position, take up on the winch line until the pole is firmly held between the boom tip flanges. If the unit is equipped with a pole guide, bring the arms around the pole so they can be used as a guide when lowering the pole into the hole.

-

Page 85: Hydraulic Tilt Pole Plummer (Optional)

DIGGER DERRICK HYDRAULIC TILT POLE PLUMMER (OPTIONAL) Open the tilt pole plummer circular arms to allow the pole, retained by the winch line, to be nested into the winch flanges. Then tilt the pole plummer either forward or backward to align the circular arms perpendicular to the pole. -

Page 86: Hydraulic Tilt Pole Guide Transferable (Optional)

DIGGER DERRICK HYDRAULIC TILT POLE GUIDE TRANSFERABLE (OPTIONAL) The same method of operation as the hydraulic tilt pole plummer applies; except it can be transferred from the second boom section to the end of the third section. TRANSFERABLE TILT POLE GUIDE WITH TURNTABLE WINCH... -

Page 87: Recommended Use Of Hydraulic Tamp

DIGGER DERRICK RECOMMENDED USE OF HYDRAULIC TAMP After the pole is inserted and plumbed, recommend one crew member shovels dirt in around the pole and another begins tamping from the bottom of the hole. For even compaction, make sure the dirt is tamped as the hole is filled. -

Page 88: Recommended Procedure For Removing Poles

RECOMMENDED PROCEDURE FOR REMOVING POLES (ZONE A ONLY) The winch and boom on the Digger Derrick must never be used to pull poles or other objects embedded in the ground. The load imposed is an undetermined force that can damage the equipment and endanger operators and ground personnel, causing serious injury or death. -

Page 89: Hydraulic Pole Puller

RECOMMENDED PLACEMENT OF POLE PULLER 2. Place the pole puller on the side of the pole either toward or away from the boom, so the force exerted does not result in a side pull on the Digger Derrick. 1-53 D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c . - Page 90 8. To prevent damage to the pole puller cylinder rod when retracting, maintain the pole puller in an upright position. 9. Use the Digger Derrick to keep the pole vertical until the pole is freely suspended and the pole puller is removed.

-

Page 91: Aerial Operation

Controls to operate the equipment from the platform are required when working on structures with energized components. For use in aerial operations, the Digger Derrick must be manufactured and tested for use with a platform as an aerial. This must be indicated on the ID Placard in the areas shown below. -

Page 92: Aerial Platform Operation

DIGGER DERRICK AERIAL PLATFORM OPERATION Perform all daily pre-operational procedures before using the Digger Derrick for aerial platform operations. Operators must know and understand the aerial operations contained in this manual before using the Digger Derrick for aerial platform operations. - Page 93 Platform insulation must never be depended upon when operating in an electrical environment. A tested liner is the only component offering insulation. If the Digger Derrick has a section that is manually extended, the pin that locks the manual section in the extended position must be installed. If not pinned, the manual section will retract and can result in serious injury or death.

- Page 94 10. Ground and/or barricade the vehicle per OSHA, ANSI and your company policies. 11. Electricity is an ever-present danger when using a Digger Derrick. Follow all OSHA, ANSI, state, federal and company rules and regulations when working on or near energized power lines.

-

Page 95: Aerial Platforms (Optional)

Do not move the Digger Derrick until the problem has been diagnosed and resolved with your safety in mind. No matter how long it may take to get help, waiting is better than a serious or fatal accident. -

Page 96: Aerial Platform And Bracket Installation

DIGGER DERRICK AERIAL PLATFORM AND BRACKET INSTALLATION 1. To install platform on the boom tip, use the following procedures: a.Install sleeve (4) on platform mounting shaft (7). Insert bolt (2) through sleeve (4) and platform mounting shaft (7). Secure with nut and lock washer. - Page 97 (1) in the platform bracket for storage. NOTE: Terex Utilities does not recommend traveling with the platform installed on the boom tip. To travel with the platform at the boom tip, a permanent platform rest must be installed.

-

Page 98: Full Pressure Hydraulic Top Controls

DIGGER DERRICK FULL PRESSURE HYDRAULIC TOP CONTROLS EXTENDING AND STORING FULL PRESSURE TOP CONTROLS To extend and store the top controls, use the following procedure: 1. Retract the second section and third section. 2. Remove Klik pin (1) from storage bracket (2) on main boom. Pull top controls (6) forward and store Klik pin (1) on storage bracket (2). -

Page 99: Upper Control Selector At Lower Controls (Option Valve)

Use high speed only when traveling to and from the job site in open areas with no obstacles. Use slower, controlled speeds when moving in the job site or around obstacles. Look in the direction the Digger Derrick is traveling to be certain there is clearance for the boom(s), platform, and operator. -

Page 100: Top Controls Functions

DIGGER DERRICK TOP CONTROLS FUNCTIONS The controls shown are generic. The actual location varies depending on purchasers requirements and options. Some of the following control functions may not be included in the controls. ITEM CONTROL LABEL DESCRIPTION Engine Stop/ Push the air cylinder once to start the vehicle engine. - Page 101 DIGGER DERRICK Outer Boom Push lever to extend “OUT”. “3rd” (Non-Insulated Units) Pull lever to retract “IN”. 7. * Sequenced Push lever to extend “OUT”. Third section always extends first Second and and then the second section. Third Sections (Insulated Units) Pull lever to retract “IN”.

-

Page 102: Auxiliary Platform

It is always important to remember to follow the standard work practices and the safety regulations that apply. If the Digger Derrick is operable, move the platform away from the danger and into the shortest, clear path of descent to get the operator on the ground. - Page 103 APPROACHING A VEHICLE THAT MAY BE ENERGIZED In an emergency situation, it may be necessary for ground personnel to operate the Digger Derrick. The entire vehicle and any attachments must be considered energized any time the booms are in the vicinity of power lines.

-

Page 104: Control Selector (Equipped With Upper Controls)

If the Digger Derrick will not operate due to the damage incurred, consider one of the other auxiliary operating procedures presented in this section to solve the problem. -

Page 105: Hydraulic Line Failure

DIGGER DERRICK HYDRAULIC LINE FAILURE Hydraulic line failure during Aerial Device operation presents numerous hazards. Be aware that a hydraulic oil mist caused by a leak or hydraulic line failure is conductive even though nonconducting oil is used. A spray or mist produced by a hydraulic leak under pressure is very hazardous to personnel. -

Page 106: Engine Failure

DIGGER DERRICK WHAT TO DO IF HYDRAULIC LINES FAIL? A quick response to stop oil flow caused by a hydraulic line failure is important to prevent further damage and prevent injury. The following sequence can be used to stop the flow. -

Page 107: Control Valve Failure

FALL PROTECTION Fall protection is required whenever in an aerial or digger derrick platform. An OSHA compliant fall arrest system with the lanyard attached to the provided anchor at the boom tip must be used. The issue is not falling from the platform;... -

Page 108: Jib Installation And Removal

DIGGER DERRICK JIB INSTALLATION AND REMOVAL When using jibs on this Digger Derrick, use the chart that is applicable to the jib operation. Do not use the Digger Derrick load capacity chart or handle poles with the jib. The jib assembly, which consists of the jib mounting bracket and the jib, may be installed or removed as a complete assembly or as separate parts. - Page 109 DIGGER DERRICK TURNTABLE MOUNT WINCH TRANSFERABLE (UNDER SLUNG) TURNTABLE MOUNT WINCH TRANSFERABLE (TWO STAGE UNDER SLUNG) END OF 3RD TURNTABLE MOUNT WINCH TRANSFERABLE (OVER SLUNG) POLE GRABBING (BOOM TIP) WINCH TRANSFERABLE (UNDER SLUNG) 1-73 D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c .

- Page 110 DIGGER DERRICK POLE GRABBING (BOOM TIP) WINCH TRANSFERABLE (UNDER SLUNG TWO STAGE) POLE GRABBING (BOOM TIP) WINCH TRANSFERABLE (OVER SLUNG) POLE GRABBING (BOOM TIP) WINCH NON-TRANSFERABLE (UNDER SLUNG) POLE GRABBING (BOOM TIP) WINCH NON-TRANSFERABLE (TWO STAGE UNDER SLUNG) 1 - 7 4 46 328 0 - 9/1 4 Te re x So uth Da kota , Inc.

- Page 111 DIGGER DERRICK POLE GRABBING (BOOM TIP) WINCH NON-TRANSFERABLE (OVER SLUNG) TURNTABLE MOUNT WINCH NON-TRANSFERABLE (UNDER SLUNG) TURNTABLE MOUNT WINCH NON-TRANSFERABLE (TWO STAGE UNDER SLUNG) TURNTABLE MOUNT WINCH NON-TRANSFERABLE (OVER SLUNG) 1-75 D ig g e r D er ri c k Te re x S o u t h D a k o t a , I n c .

-

Page 112: Tilting And Extending Jib

DIGGER DERRICK TILTING AND EXTENDING JIB The following procedures are for tilting and extending the jib boom. To tilt the jib boom (4), use the following procedures: 1. Support the jib boom (4) and remove pins (2). 2. Tilt jib boom (4) to desired angle. -

Page 113: Leaving The Job Site

LEAVING THE JOB SITE When leaving the job site, do the following: 1. If the Digger Derrick was used with the aerial platform, remove the platform and store the control package on the lower boom bracket. 2. Fully retract all boom sections. If equipped with manual fiberglass extension, pull retaining pin and return to the stored position. - Page 114 DIGGER DERRICK 1 - 7 8 46 328 0 - 9/1 4 Te re x So uth Da kota , Inc. D i gge r De rr ick...

-

Page 115: Section 2

• Relieve hydraulic oil pressure from all hydraulic circuits before loosening or removing hydraulic components. After adjustments and repairs have been made the digger derrick shall not be operated until all guards have been reinstalled, trapped air removed from hydraulic system, safety devices reactivated and maintenance equipment removed. -

Page 116: Lubrication

DIGGER DERRICK LUBRICATION All moving parts of the digger derrick and vehicle, for which lubrication is specified, shall be regularly lubricated. Lubricating systems shall be checked for proper delivery of lubricant. Particular care should be taken to follow manufacturer’s recommendations as to points and frequency of lubrication, maintenance of lubricant levels and types of lubricant to be used. -

Page 117: Frequent And Periodic Inspection Intervals

DIGGER DERRICK FREQUENT AND PERIODIC INSPECTION INTERVALS DAILY 1. Check controls at platform and lower controls for proper operation. 2. Inspect fall protection equipment and attachments. 3. Inspect visual and audible devices. 4. Check condition, cleanliness, and dryness of fiberglass components. -

Page 118: Lubrication Chart

DIGGER DERRICK LUBRICATION CHART DIGGER DERRICK 21 20 OIL FILTER OIL TANK ROTATION GEAR BOX DIGGER GEAR BOX PLANETARY ROTATION COMMAND POST CONSOLE DUAL CONTROLS TYPE OF SERVICE ITEM LUBRICATION POINT LUBRICATION INTERVAL METHOD 2ND BOOM WEAR PADS DIGGER BRACKET... -

Page 119: Wire Rope Inspection

DIGGER DERRICK WIRE ROPE INSPECTION The wire rope must be inspected daily for any deterioration, which results in appreciable loss of strength, described as follows. Refer to the maintenance manual for complete instructions on proper inspection of the wire rope and criteria for replacement. -

Page 120: Hook Inspection

DIGGER DERRICK HOOK INSPECTION The load line hook and safety latch must be inspected prior to any lifting operation. Any hooks showing defects shall be discarded. Field repairs by welding or re-shaping shall not be permitted. • Any damaged hook safety latch shall be replaced immediately. -

Page 121: Standards And Regulations

The information provided herein is accurate as of the date your Terex South Dakota, Inc. unit was manufactured. You must comply with the codes, standards and regulations as they are updated over time. It is your employer's responsibility to obtain copies and comply with all standards and regulations. -

Page 122: Osha Excerpts: (Clearance Distance)

APPENDIX A OSHA EXCERPTS: (CLEARANCE DISTANCE) The following are excerpts from OSHA Standards. They are not complete and do not cover all safety work rules. PARTIAL EXCERPT FROM SUBPART S - ELECTRICAL: (02-01-1998 EDITION) 1910.333 Selection and use of work practices. (c), (i) Unqualified person. - Page 123 APPENDIX A ALTERNATING CURRENT MINIMUM DISTANCES VOLTAGE RANGE MINIMUM WORKING AND (PHASE-TO-PHASE) KILOVOLT CLEAR HOT STICK DISTANCES 2.1 to 15 2 ft. 0 in. (0.61 m) 15.1 to 35 2 ft. 4 in. (0.71 m) 35.1 to 46 2 ft. 6 in. (0.76 m) 46.1 to 72.5 3 ft.

-

Page 124: Standard Hand Signals

APPENDIX A STANDARD HAND SIGNALS STOP. With arm extended EMERGENCY STOP. With both arms extended HOIST. With upper arm RAISE BOOM. With arm horizontally to the side, horizontally to the side, palms down, arms are swung back extended to the side, extended horizontally to the palm down, arm is swung and forth. -

Page 125: Responsibilities

7.6 Quality Assurance. The installer shall have a documented quality assurance program that will ensure compliance with this standard. 7.7 Welding. All welds made by the installer, whose failure could result in motion of the digger derrick, shall meet the Structural Welding Code ANSI/AWS D1.1/D1.1M and ANSI/AWS D1.2/D1.2M. The installer shall establish applicable welding quality assurance procedures for all welded joints and assemblies. - Page 126 This training or training materials shall be offered initially and subsequently on request. 7.9 Dealer or Installer as User. Whenever a dealer or installer directs personnel to operate a digger derrick (inspecting, sales demonstrations or any form of use), the dealer or installer shall assume the responsibilities of users as specified in Section 9.

- Page 127 (17) If the digger derrick is rated as insulating, it shall be tested for compliance with the rating of the digger derrick in accordance with one of the applicable methods and procedures as outlined in Section 5.4.3.

- Page 128 60 days. If the owner uses other entities as agents (e.g., brokers) for the sale or the arrangement of a sale of a digger derrick(s), the owners or agents responsibilities under this section continue.

- Page 129 (1) The purpose and use of manuals. (2) That operating manuals are an integral part of the digger derrick and must be properly stored on the vehicle when not in use.

- Page 130 9.3.2 Retraining. The operator shall be retrained, when so directed by the user, based on the user’s observation and evaluation of the operator. 9.3.3 Familiarization. When an operator is directed to operate a digger derrick with which they are not familiar, they shall receive prior instruction regarding the following items: (1) The location of the manuals.

- Page 131 Combined platform and material handling load shall not exceed 3,000 pounds. When operating a digger derrick with a platform but no top controls, the operator shall not leave the lower controls unattended when personnel are aloft in the platform.

- Page 132 (1) The purpose and use of manuals. (2) That operating manuals are an integral part of the digger derrick and must be properly stored on the vehicle when not in use.

- Page 133 11.1.2 Lessor or Lessee as Owner. When a lessor or lessee uses the digger derrick as an owner, they shall have the same responsibilities as specified under Section 8. 11.1.3 Lessor or Lessee as User. When a lessor or lessee uses the digger derrick as a user, they shall have the same responsibilities as specified under Section 9.

- Page 134 11.5 Communications. In the event the manufacturer or installer provides the lessor manuals, bulletins or other materials for the information of the user of a digger derrick, the lessor shall pass them on to the user without delay.

-

Page 135: Survey Of Job Site

Construction and electrical workers are subject to certain hazards that cannot be eliminated by mechanical means and must be controlled by care, common sense and intelligence. Terex South Dakota, Inc. realizes the importance of safety and strongly recommends that prior to commencing any operation, the employer make a survey of the conditions of the site to determine the hazards and the kind and number of safeguards that the employer will install. - Page 136 APPENDIX B (7) Workers and foremen (a) Job assignment (b) Training and supervision (c) Number of workers (d) Plans for maintaining interest in safety: (1) Safety bulletins, record charts and posters (2) Recognition for groups or individuals (3) Investigation and reporting on reportable accidents (4) Knowledge of safety orders (5) Safety meetings (6) Specific safety instructions for new employees...

Need help?

Do you have a question about the Digger Derrick and is the answer not in the manual?

Questions and answers